today's work

Collapse

X

-

-

-

Got mine in today. Nice Winter project. I finally got a place where I can get models together. It’s nice to be empty-nesters with three bedrooms to spare. One for my man cave/model room.

Correct.

Cyanoacrylate is best suited for this task -- it is fast setting; easily broken away (fails readily in shear) for re-alignment/replacement; and is adequate for the job of bonding dissimilar materials which are not chemically able to fuse together at room temperature.Of the approximately 40,000 men who served on U-boats in WWII, it is estimated that around 28,000 to 30,000 lost their lives.Comment

-

OK Casey! With all the chatting you enjoy doing on this forum! How about a build blog on your new Kilo class submarine?!

Rob

"Firemen can stand the heat."Comment

-

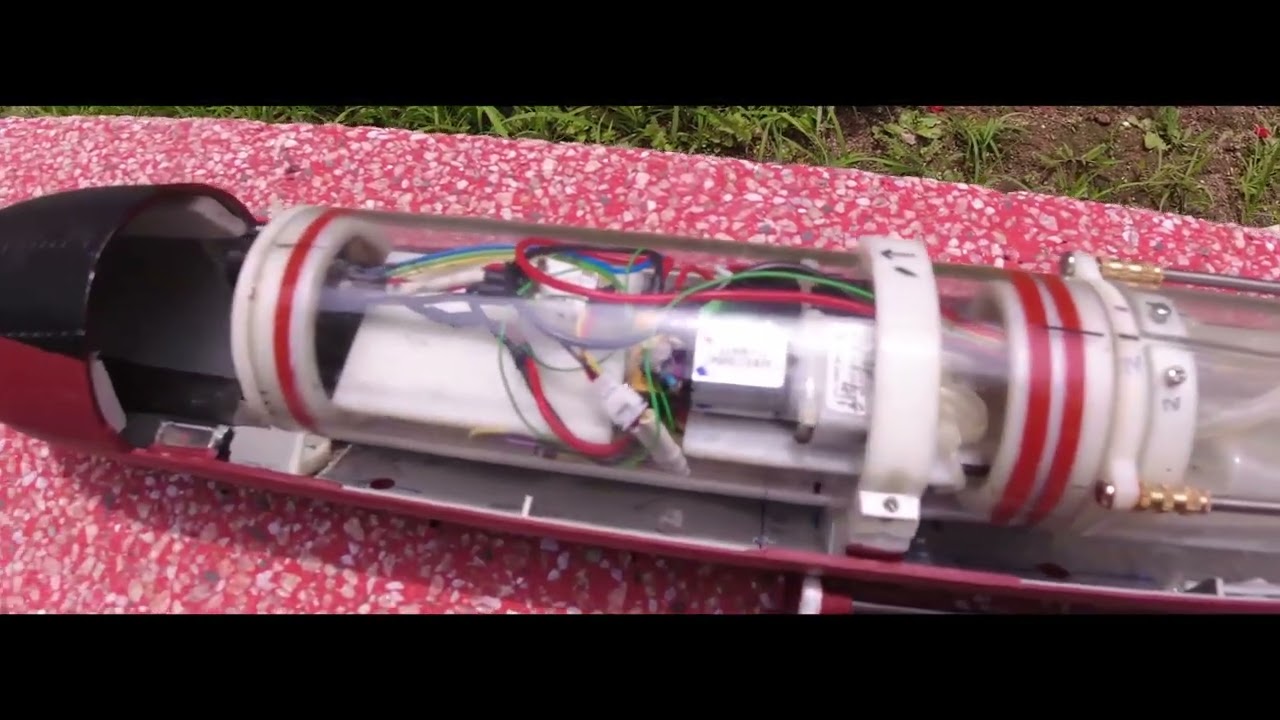

I’m no good with blogs, but I’ll try to take a bunch of pictures and then do some narrative after a bit. It’s gonna take a 2 inch WTC.Of the approximately 40,000 men who served on U-boats in WWII, it is estimated that around 28,000 to 30,000 lost their lives.Comment

-

Make it simple, make strong, make it work!Comment

-

OK! Couldn't see the writing on the box that well without my magnifier. (sorry, I wasn't even close, but it is a submarine) Got to laugh! We better get off Davids build blog, or we will be in for it...;-))

Rob

"Firemen can stand the heat."

Comment

-

-

When you install the plastic ring (polycarbonate?), do you add pressure against the o-ring or just snuggle up to it? In other words are you compressing the o-ring any to add its friction fit against the pipe?

Love your documentation....lots to learn from you.

If you can cut, drill, saw, hit things and swear a lot, you're well on the way to building a working model sub.Comment

-

The sealing is affected at the outer and inner surfaces of the O-ring, so compressing it is only required if the fit between bulkhead body and conduit tube is loose. So, I select an O-ring diameter that is a bit smaller than the conduit, and a bit larger than the bore of the bulkhead it fits within. The 'compression' ring is not that at all -- its only purpose is to retain the O-ring within the bore as I install/remove the conduit tube.

I went through all this voodoo bull**** because I wanted a larger diameter conduit than my stock bulkheads were designed for. Here's the standard O-ring, encapsulated during the bulkhead casting operation:

Who is John Galt?👍 1Comment

-

-

is that a 1/72 scale Alfa? I’d swear if looks like my old boat from the spray and fittings inside the hull.Comment

-

Comment