today's work

Collapse

X

-

Tags: None👍 2

-

-

-

-

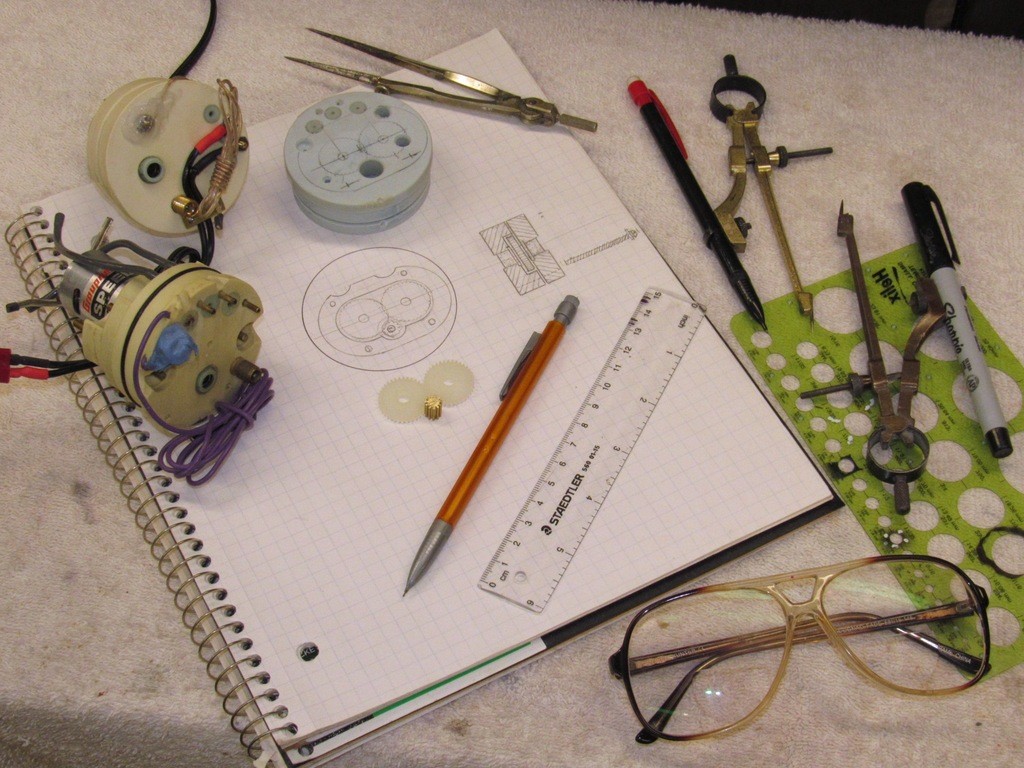

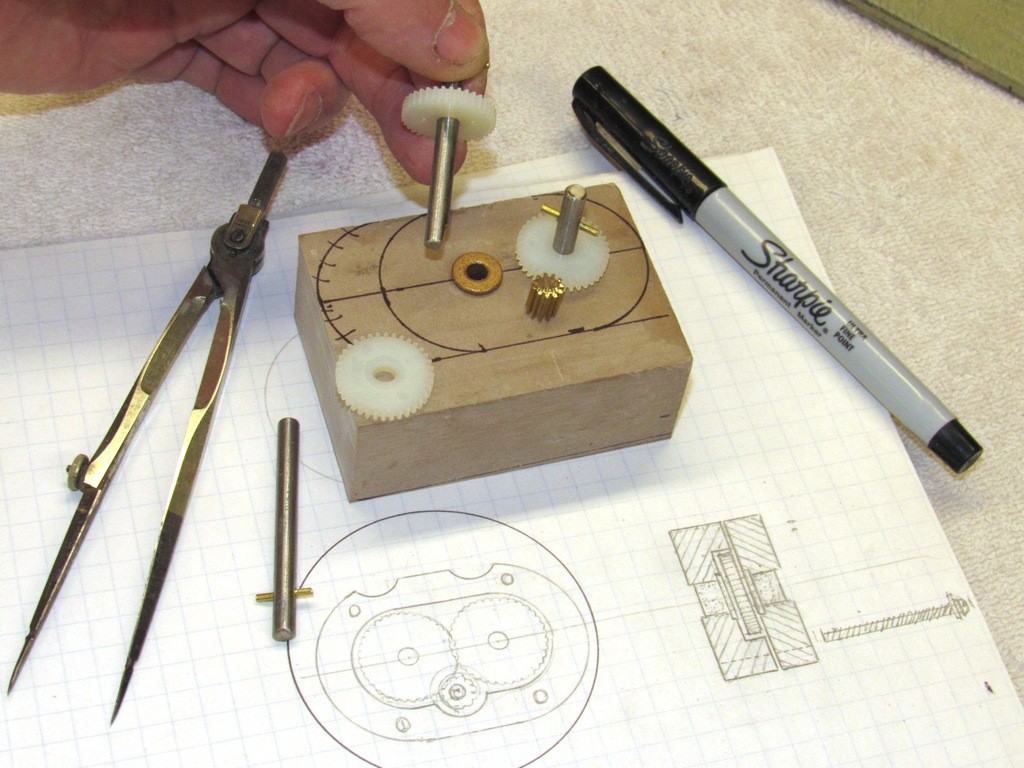

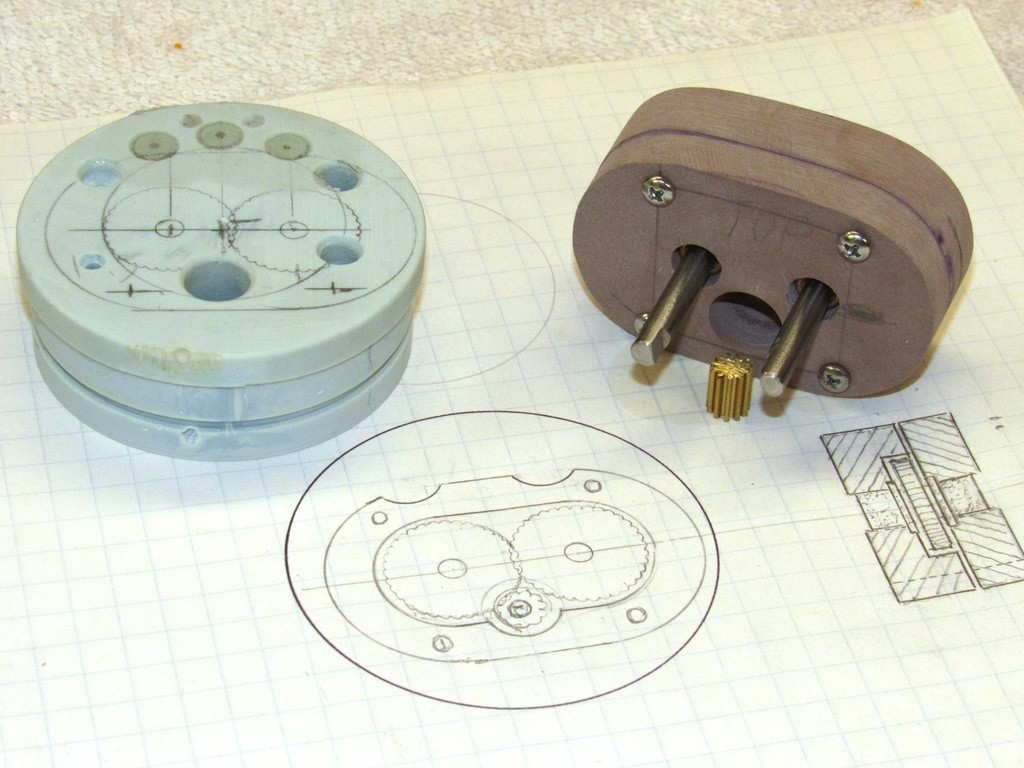

Sir, can I ask you a mechanical question about your picture 5 from the bottom up?

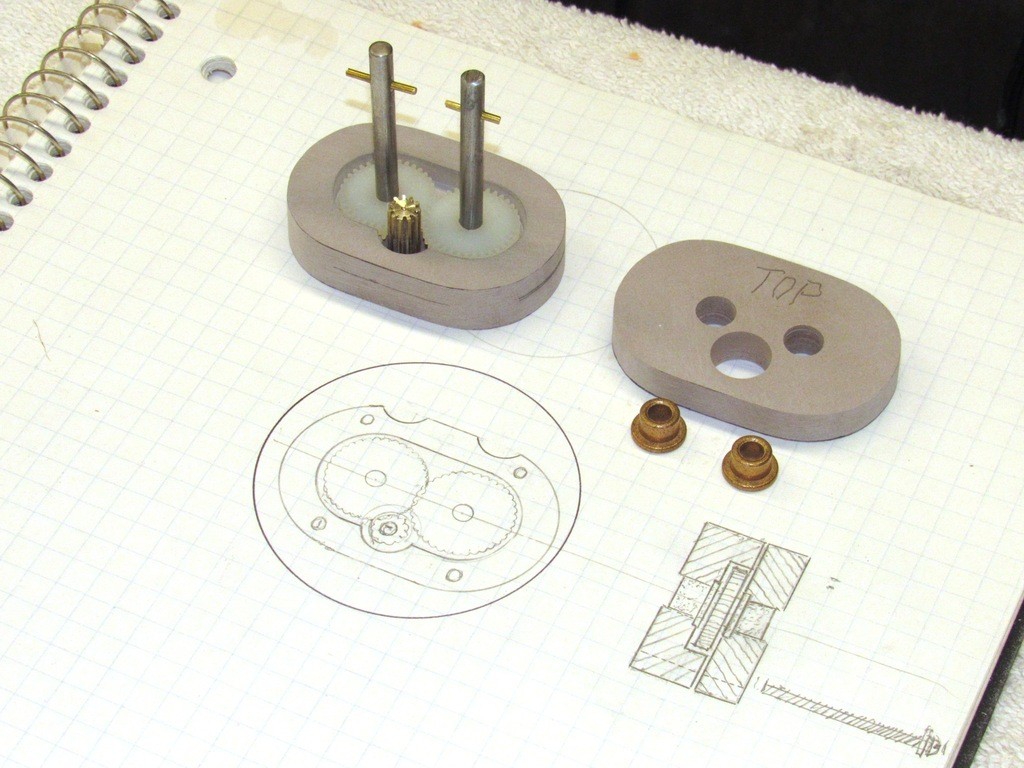

I think I see it clearly BUT I am NOT sure. It looks like for the dual drive mech. the two larger gears are making contact with each other and the small brass gear is only contacting the left gear. Is that right?

Can you tell me what size the gears are and their number of teeth?

Thank You Sir.

Comment

-

-

-

-

-

From you, an accomplished model-builder, that is high praise. Thank you, sir.

And my childhood interests paralleled your:

My dad was Comptroller at the McCord Radiator Company -- a big developer-manufacturer in Detroit that supplied parts to the automotive companies there. Sometimes he would take me, a snot-nosed, ten-year old 'rich kit' with him (from Ann Arbor to downtown Detroit) to work. At the plant he would go 'upstairs' to the Executive offices and leave me downstairs in the prototype pattern-foundry area. I spent all my time marveling at the process of turning wooden patterns into iron castings. Amazing! Pure eye-candy. It formed me. The dirty, rough men who worked there tolerated my questions and interest in the magic they were doing with their hands and flesh-eating machines and terrible white-hot crucibles of molten metal. There was no OSHA back then and I could stand right next to a flask as two guys ladled the magic metal into a green-sand mold. I could never get enough of this magic, magnificent, hellish environment.

As that Cooper's shop formed you, Bob, those Carpenters and foundry workers formed me.

DavidWho is John Galt?Comment

-

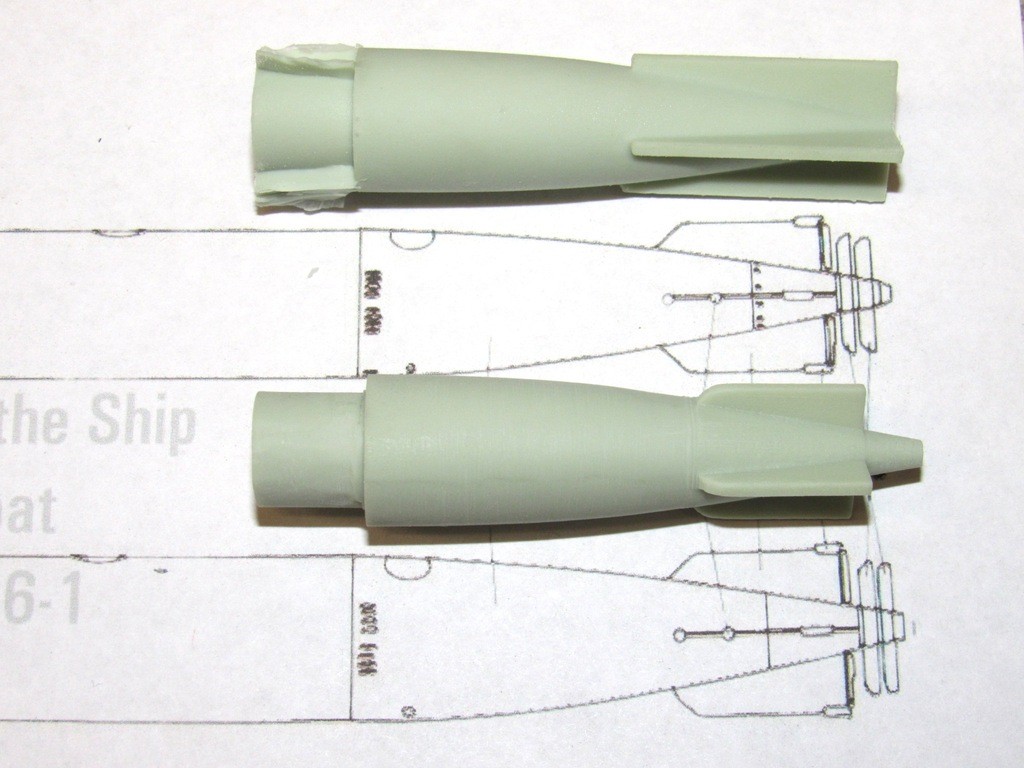

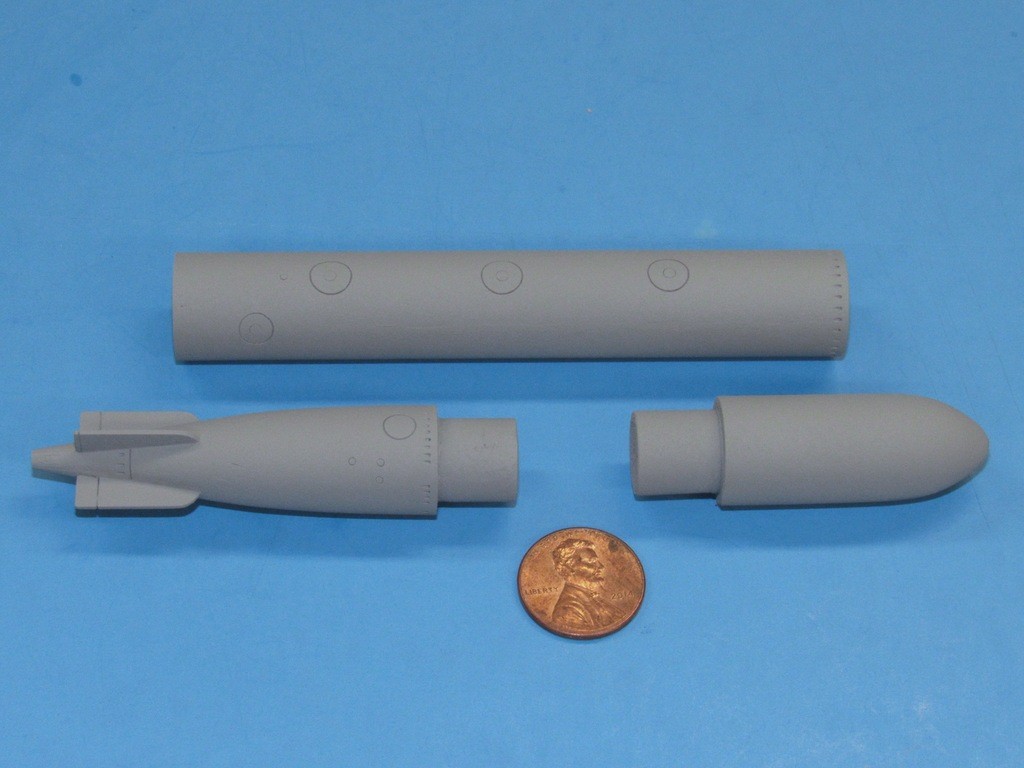

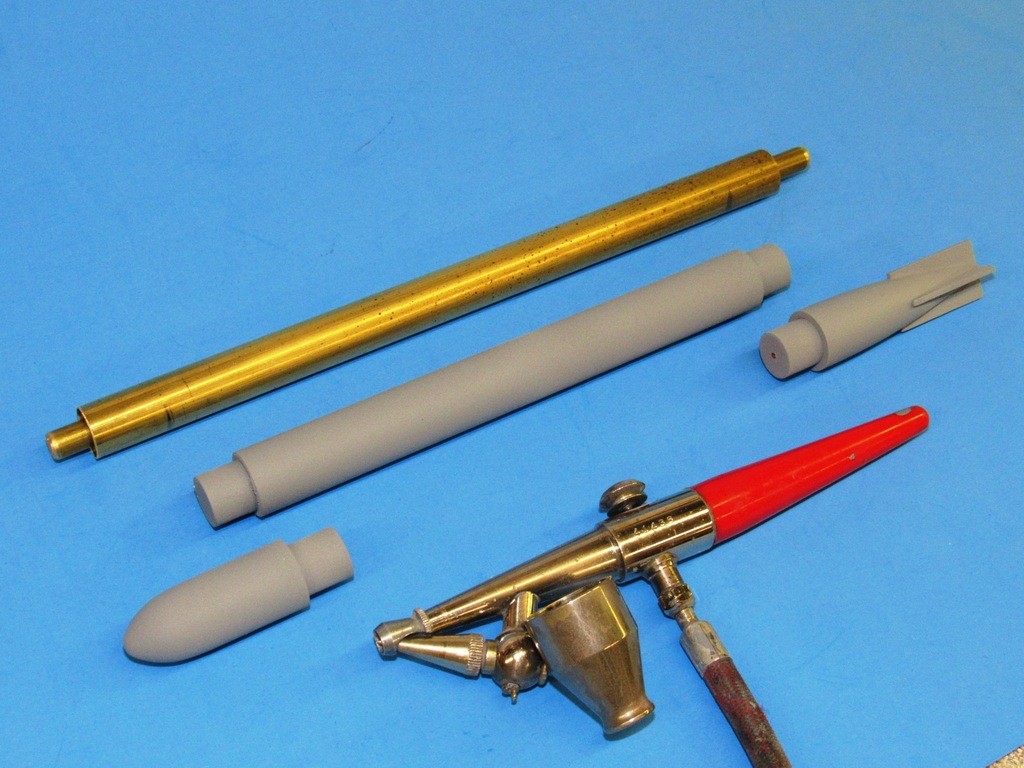

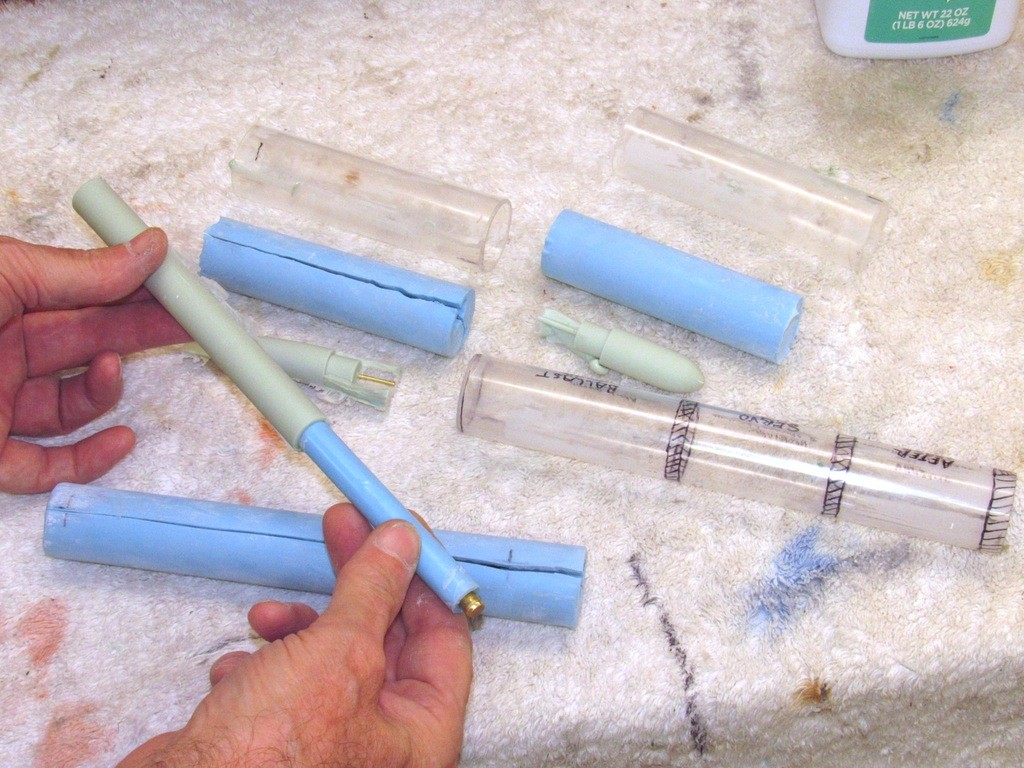

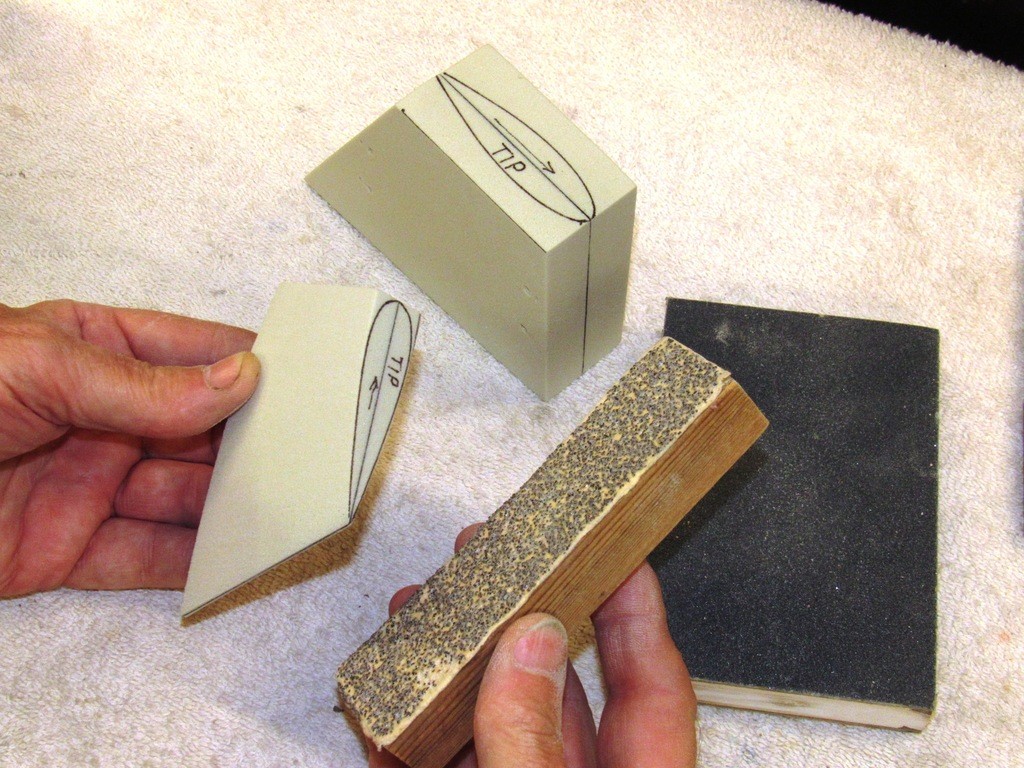

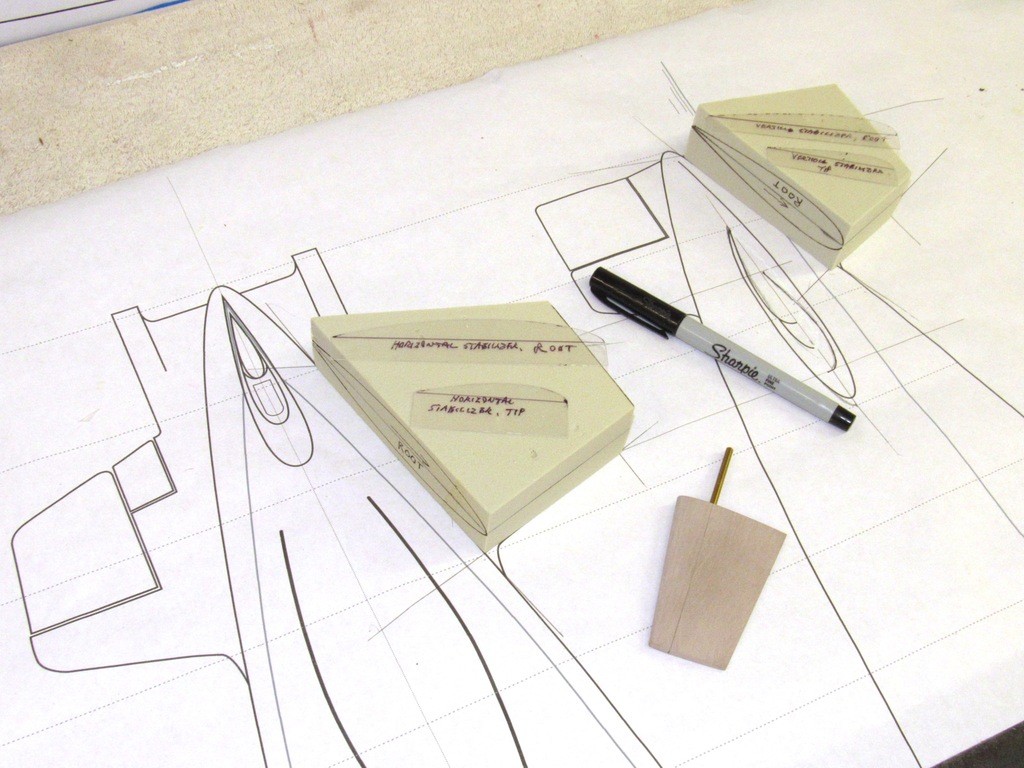

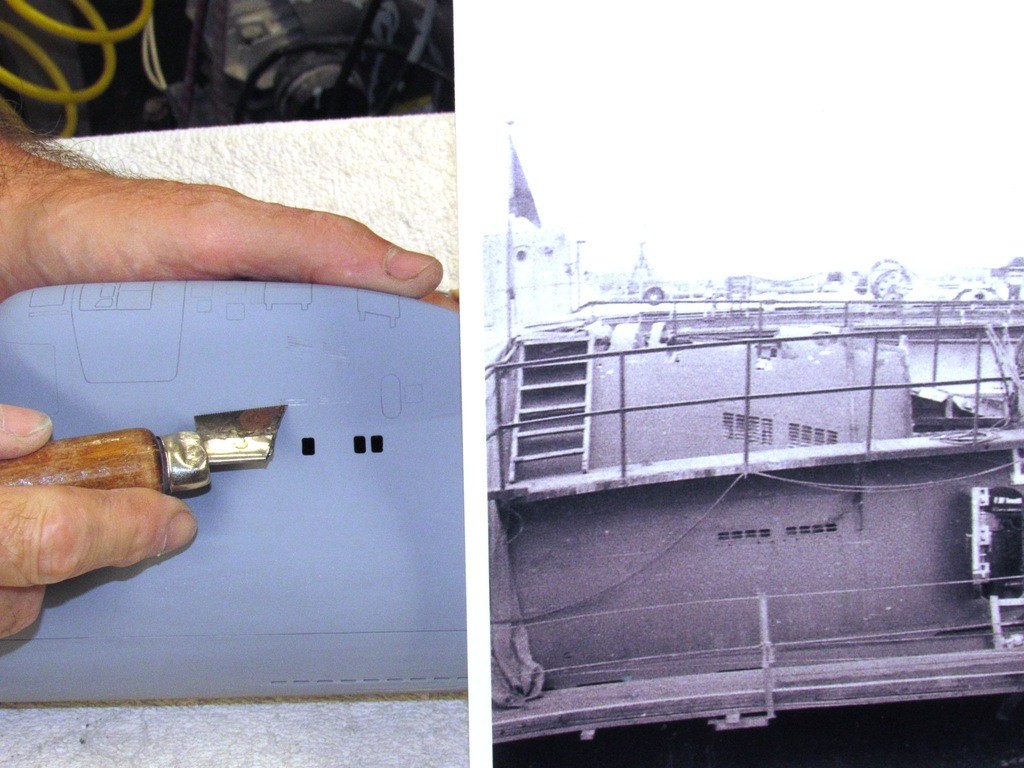

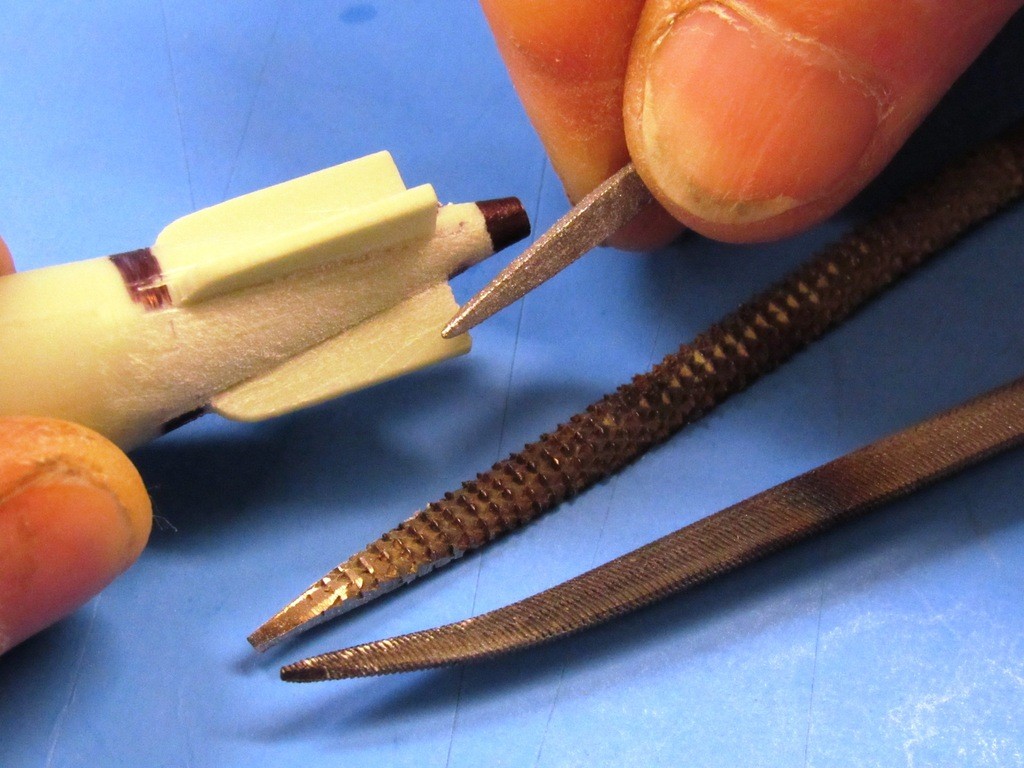

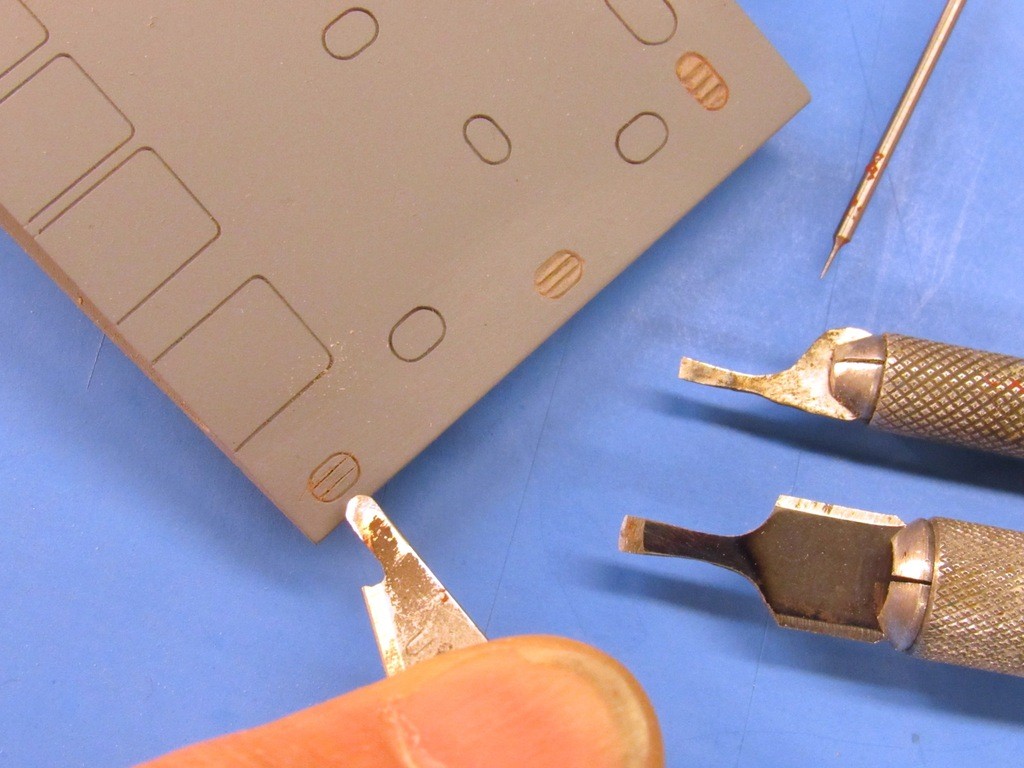

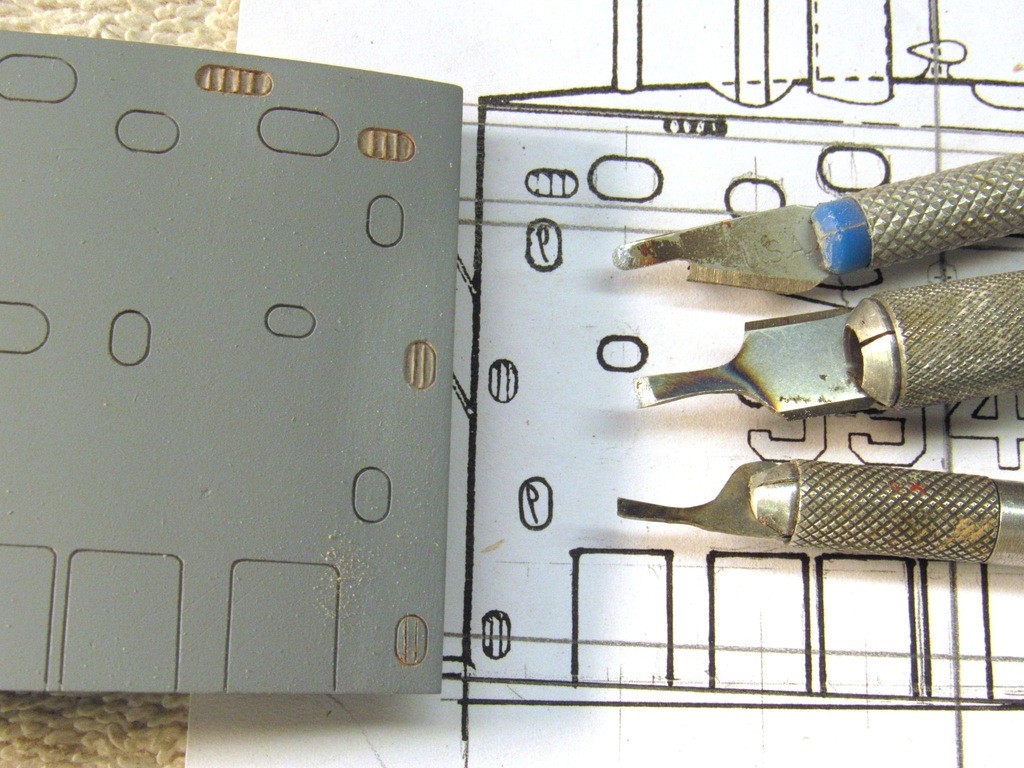

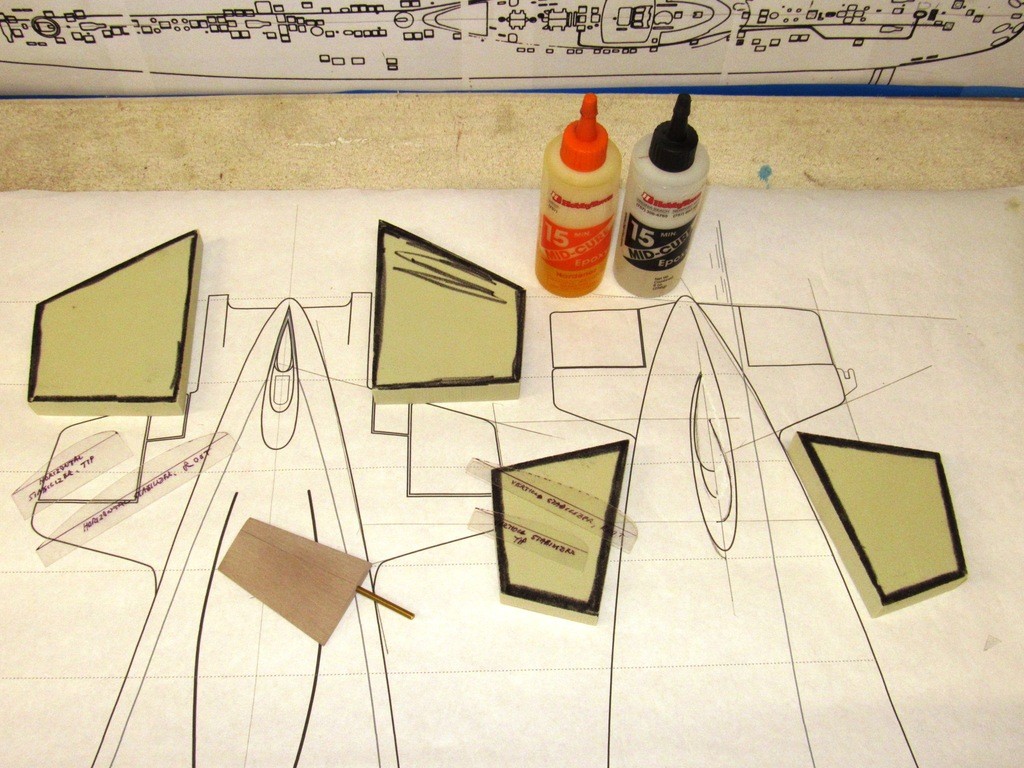

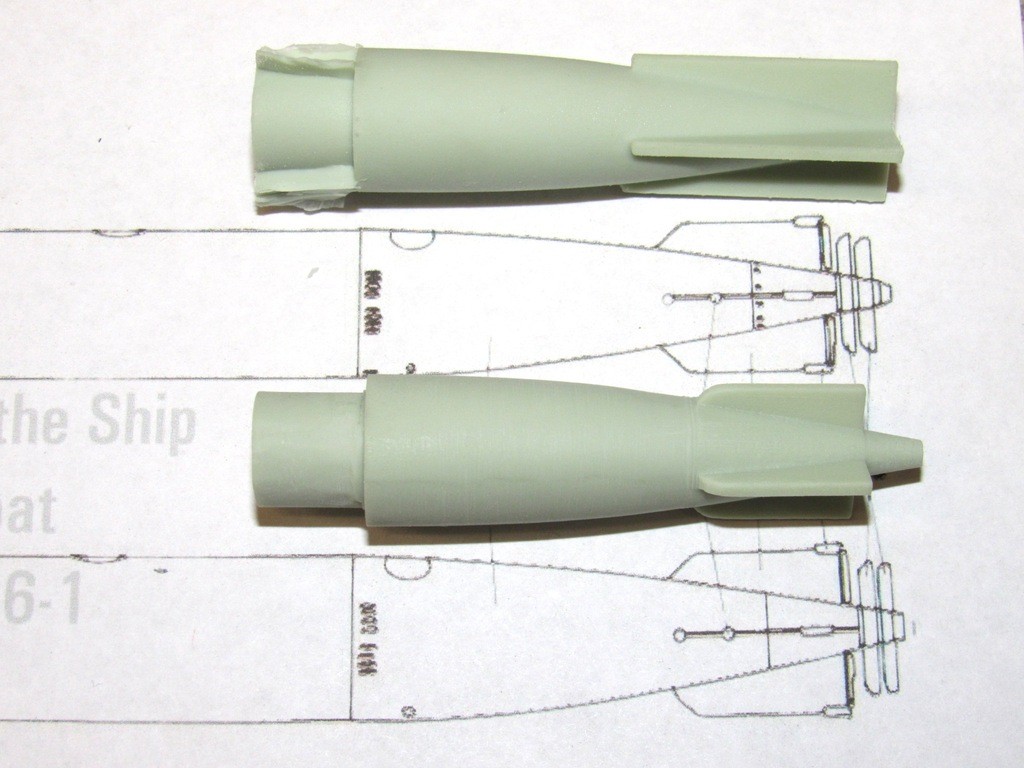

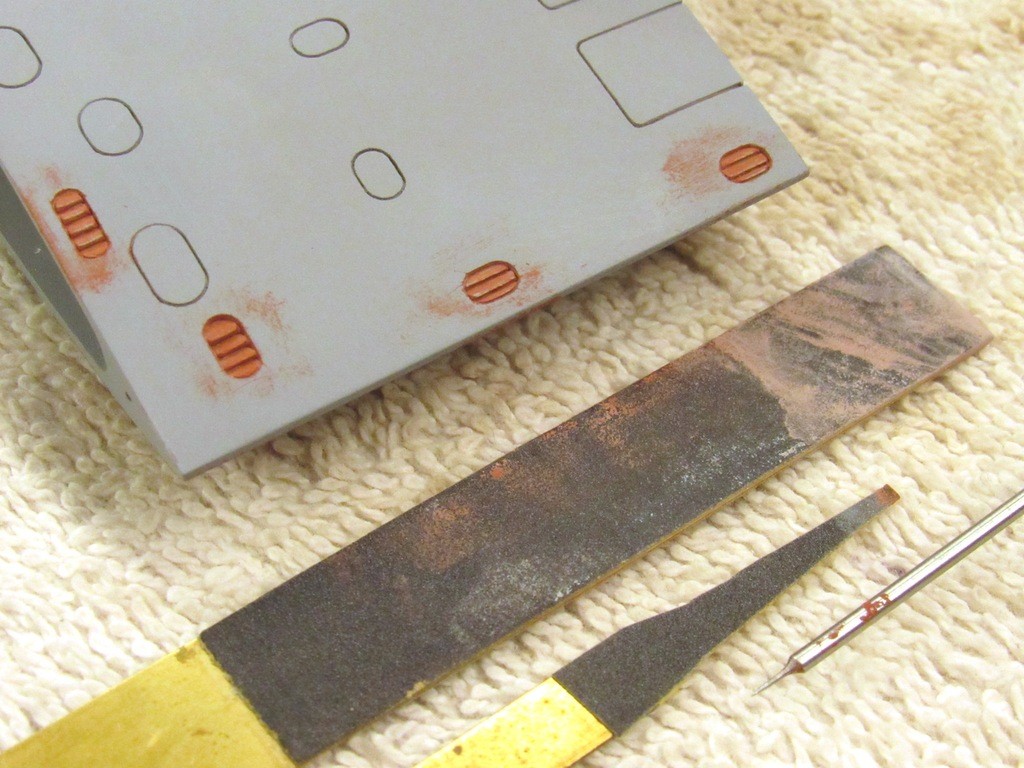

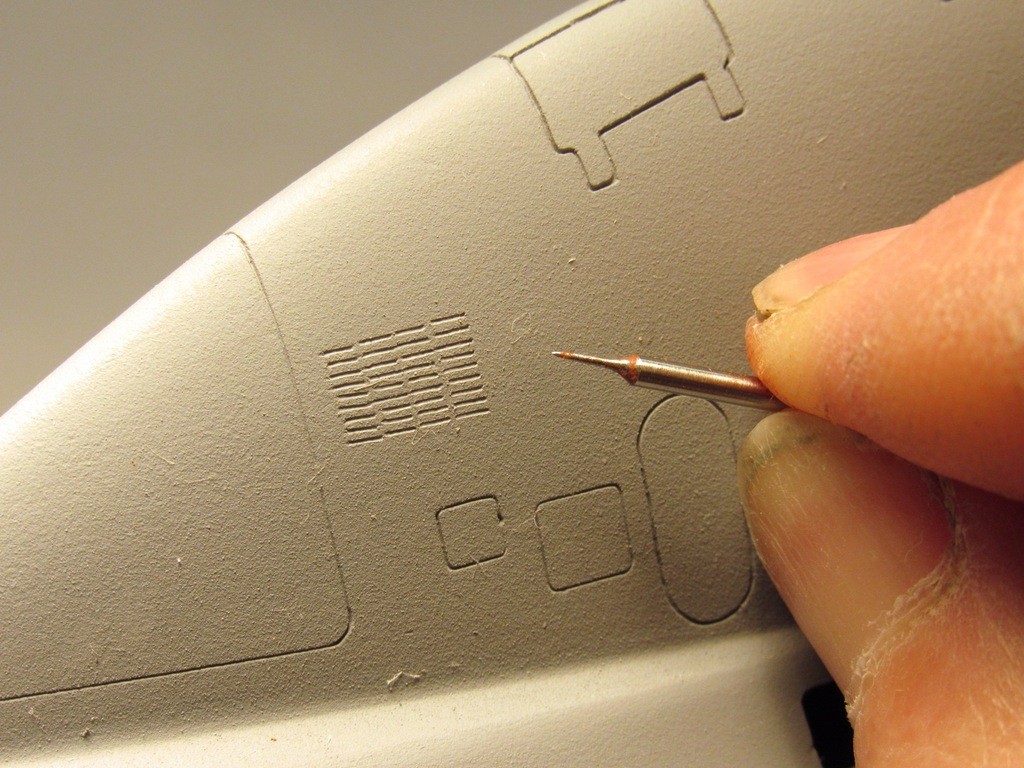

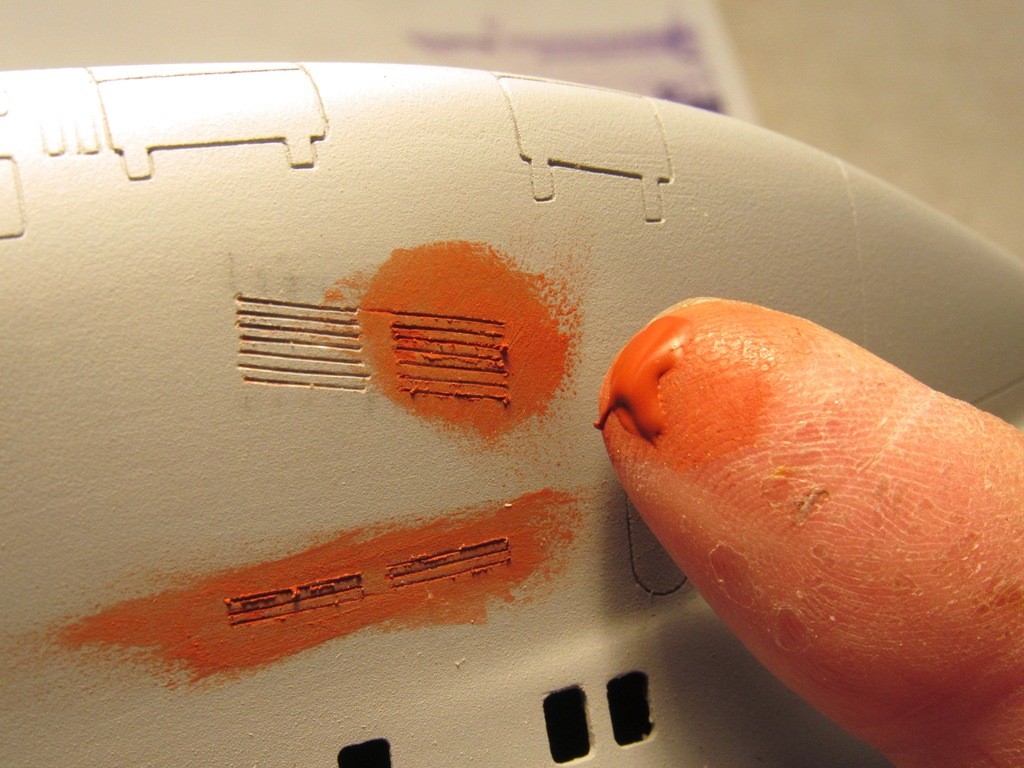

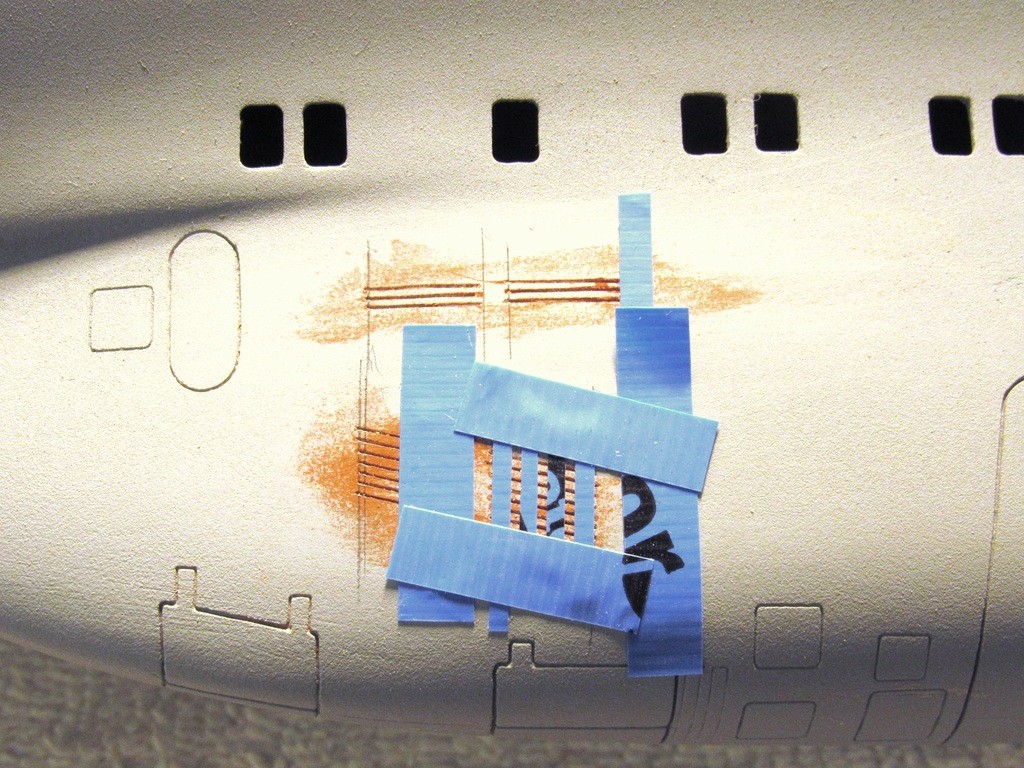

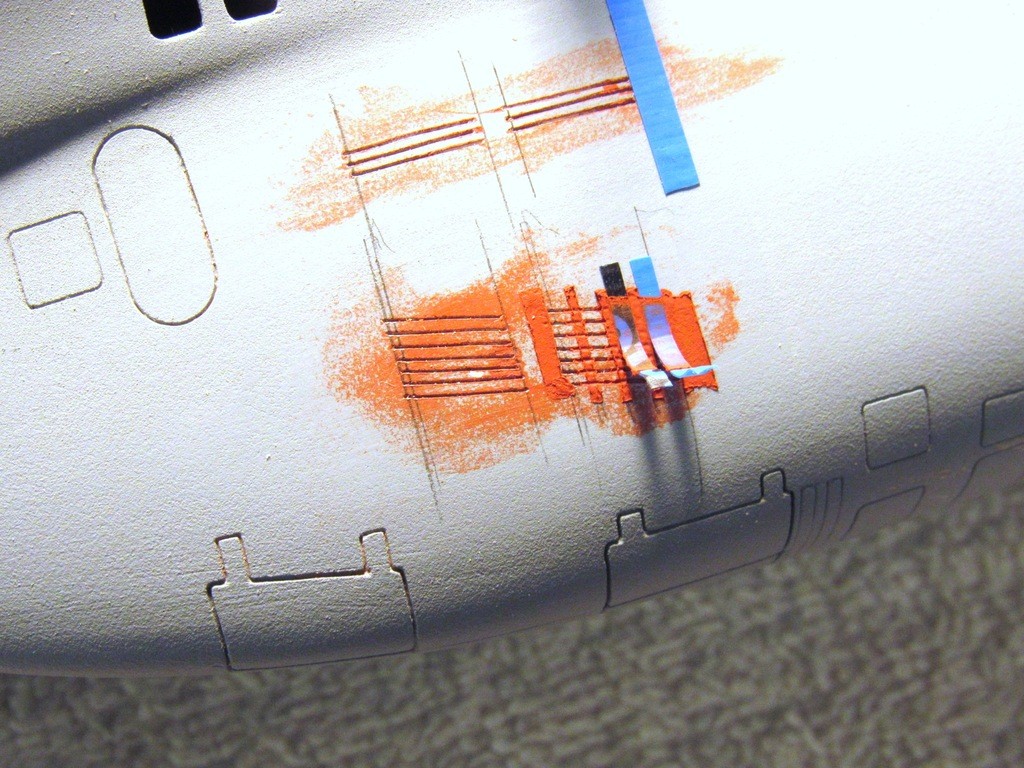

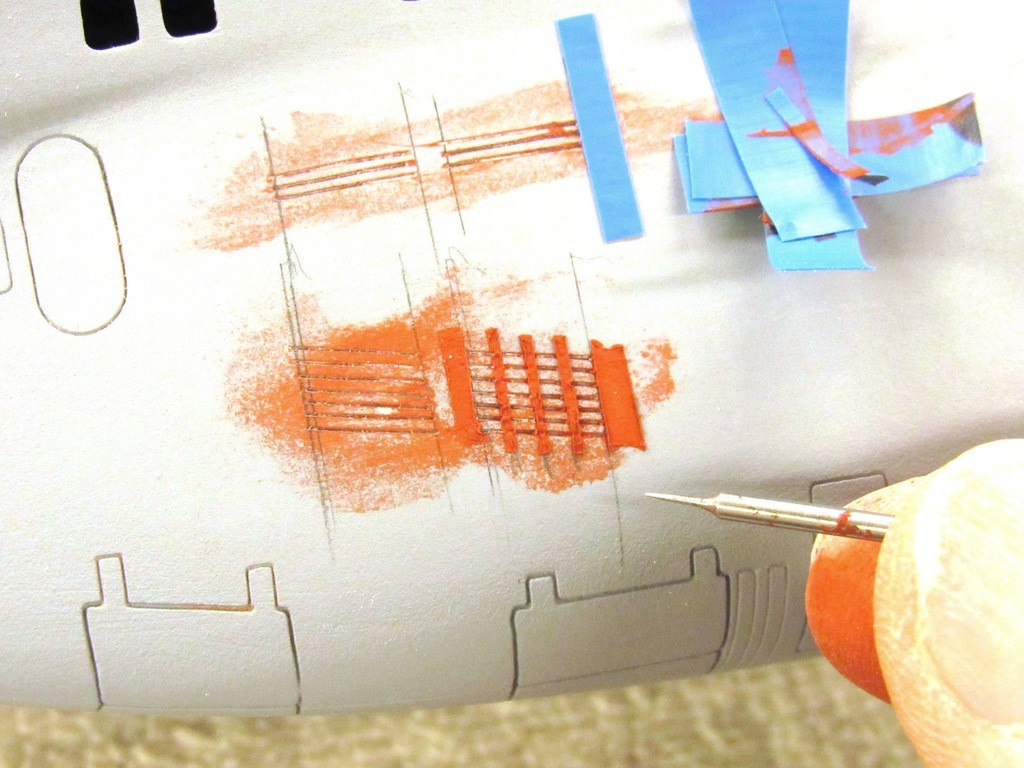

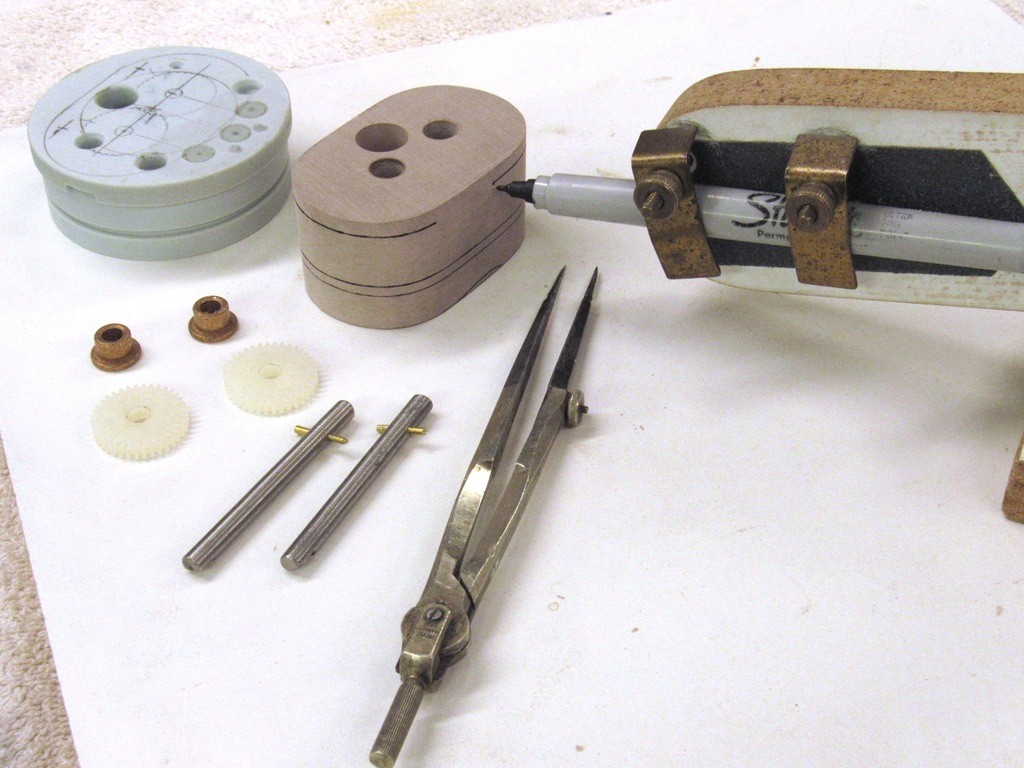

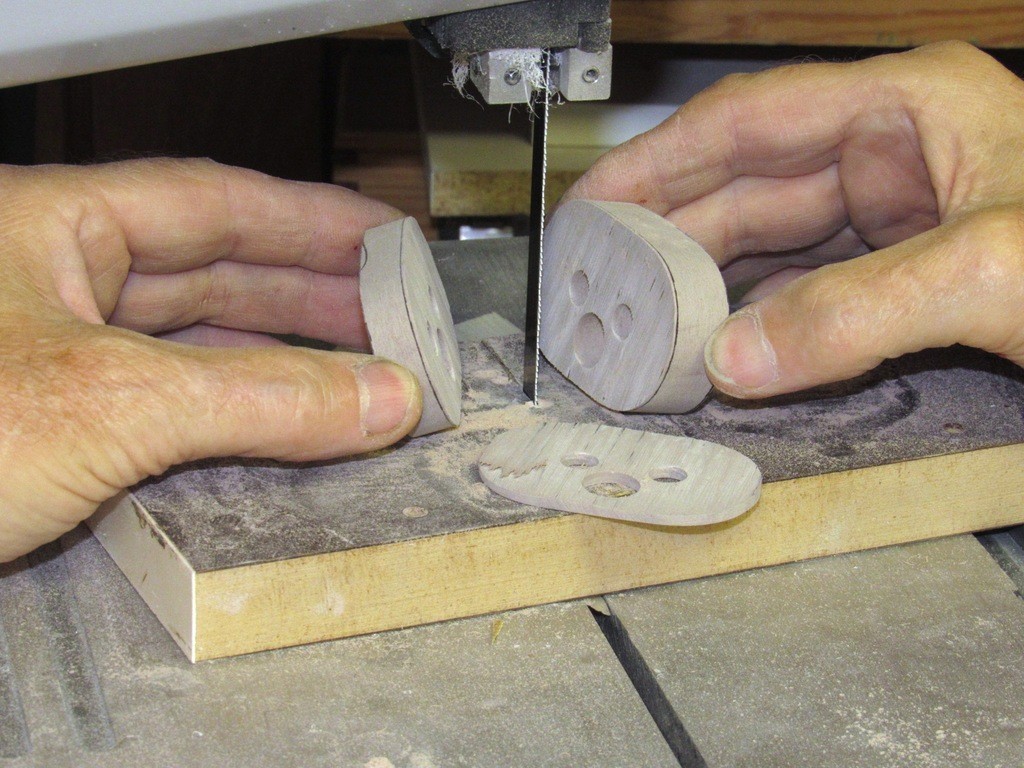

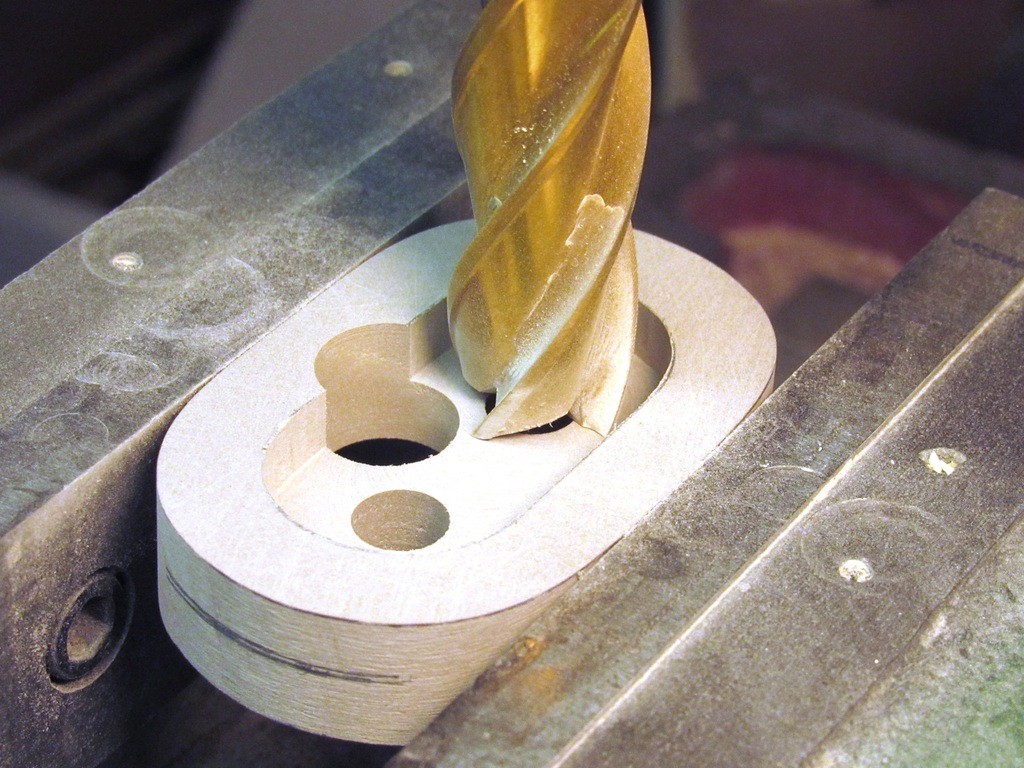

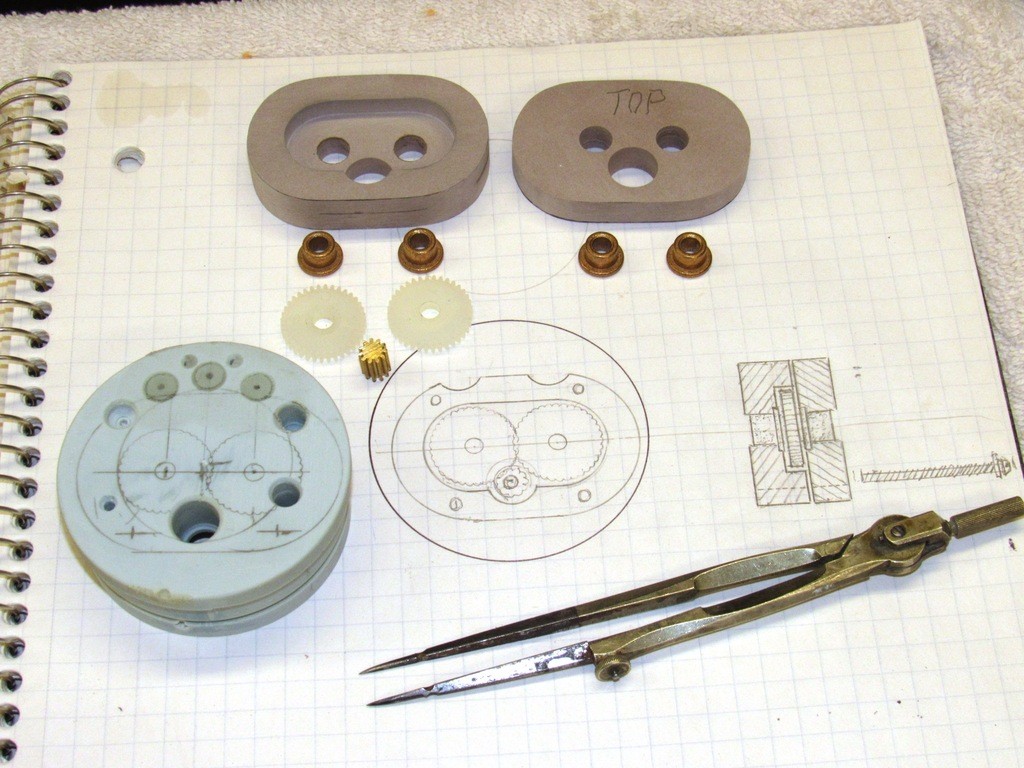

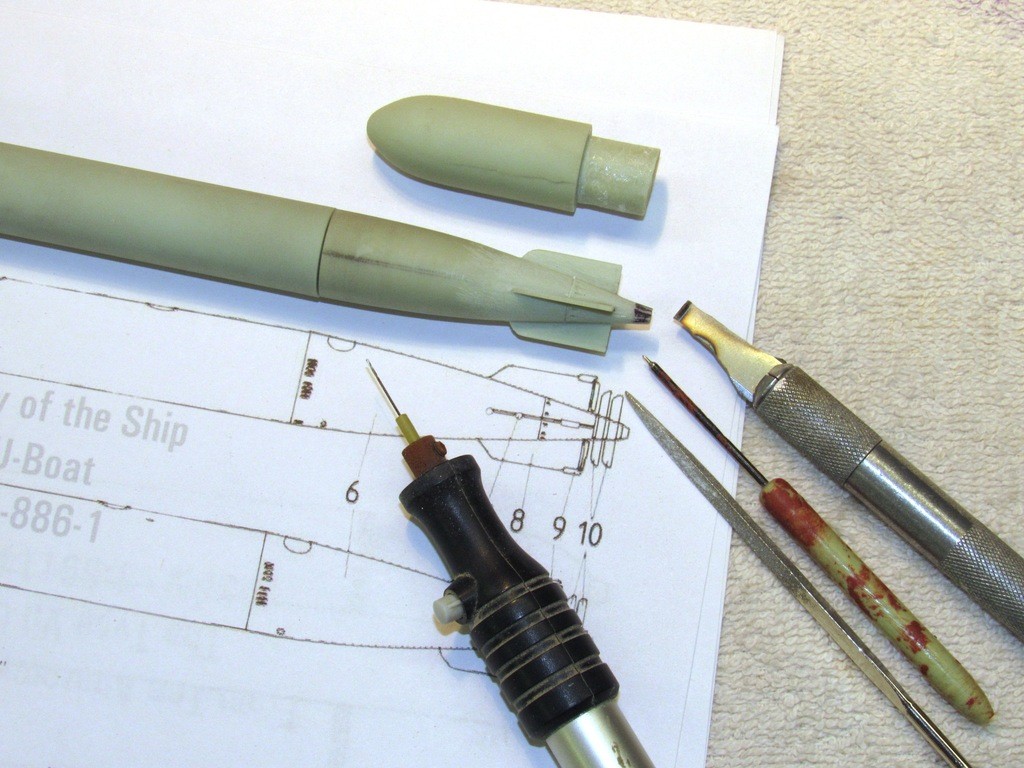

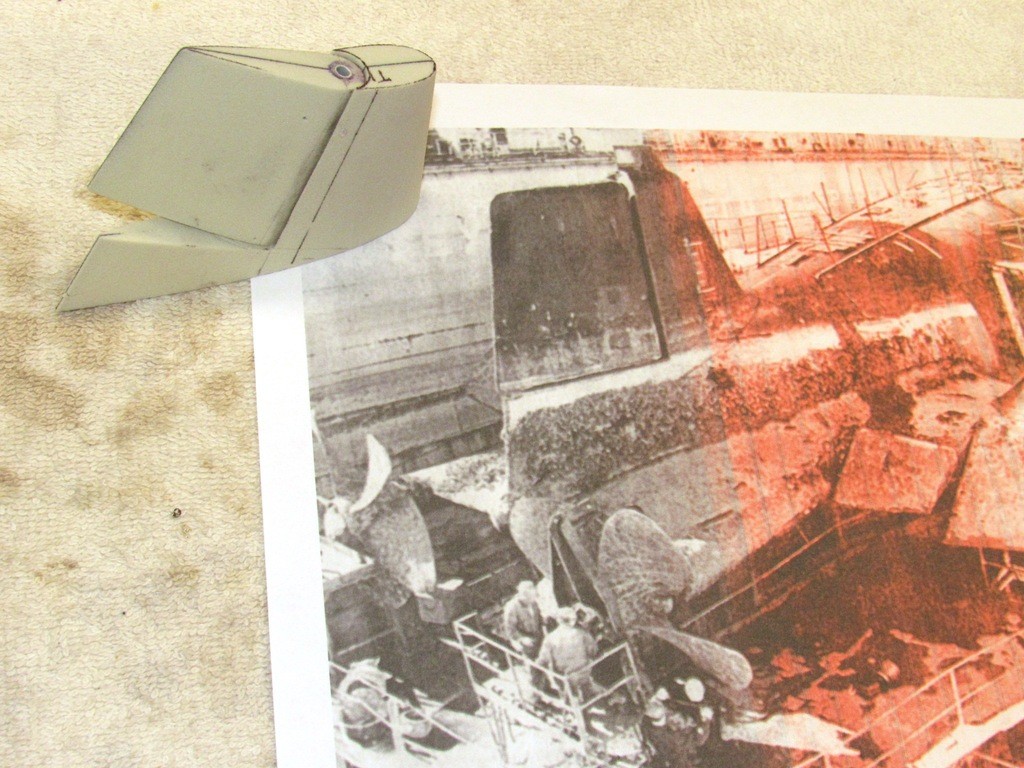

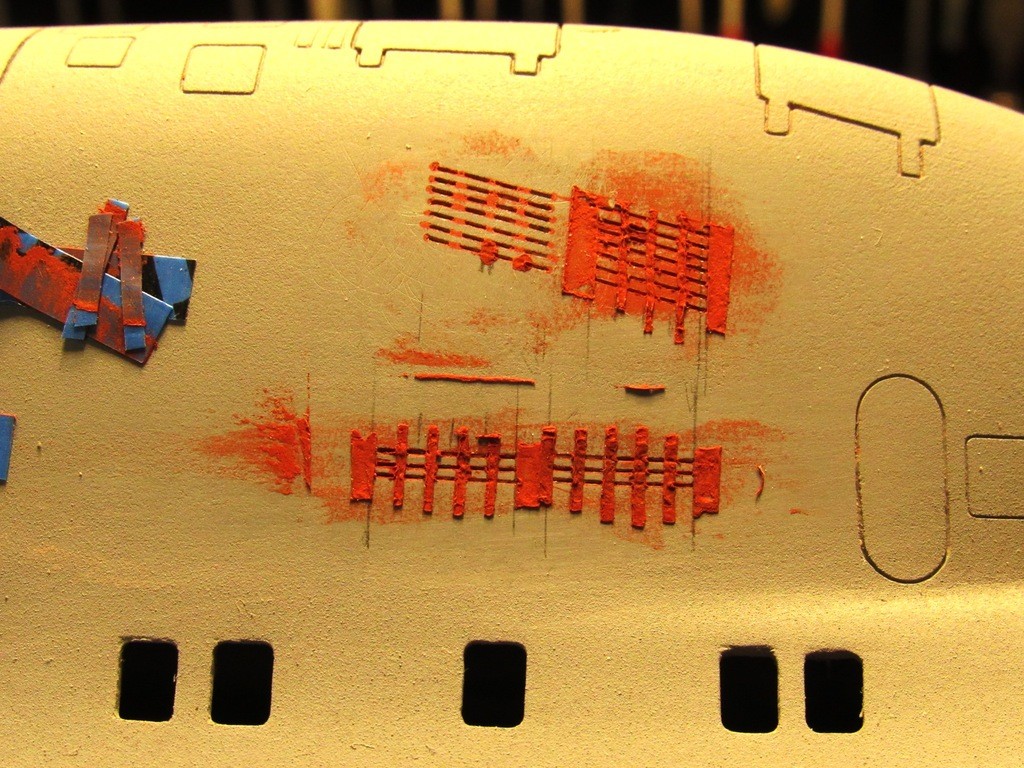

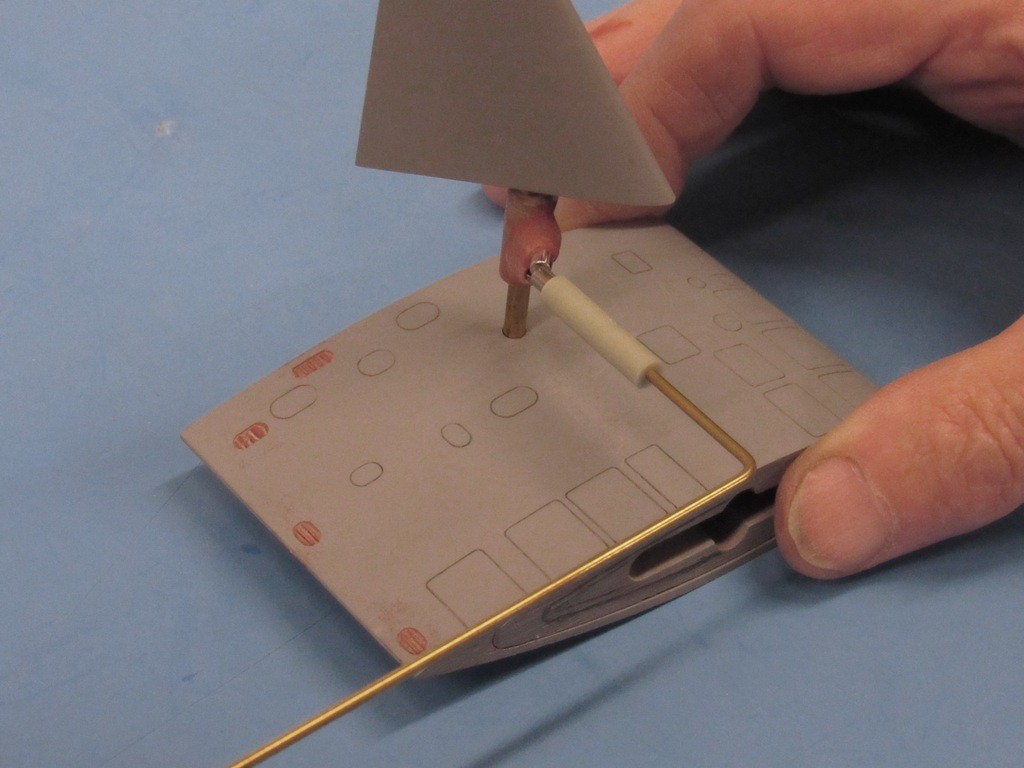

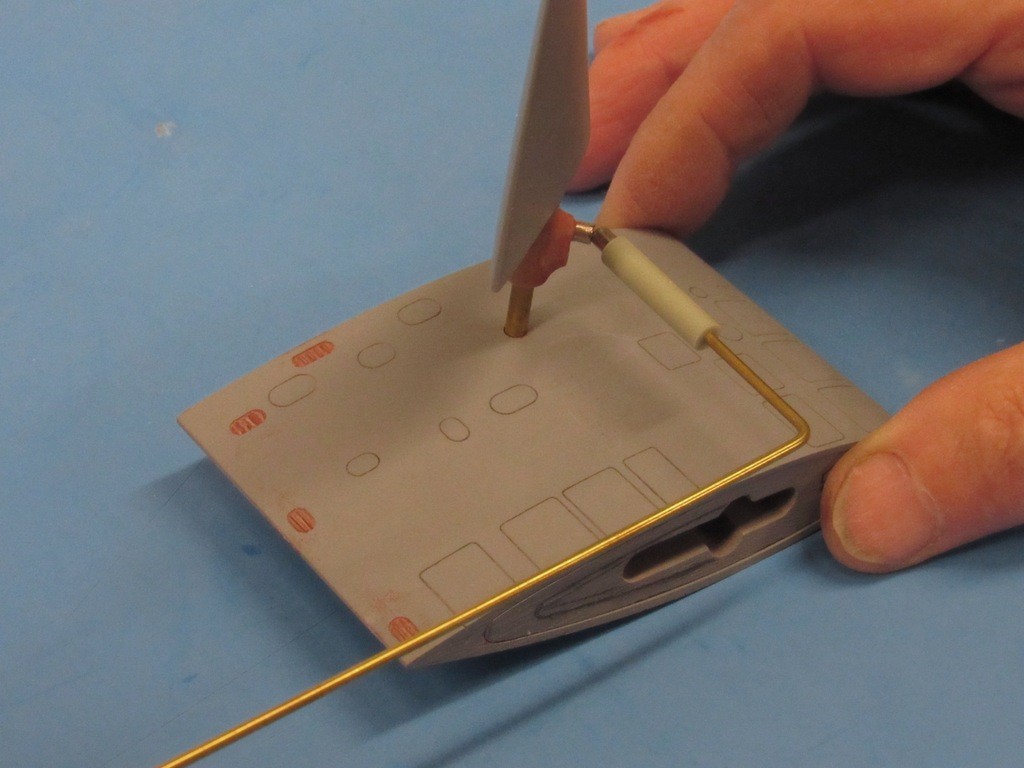

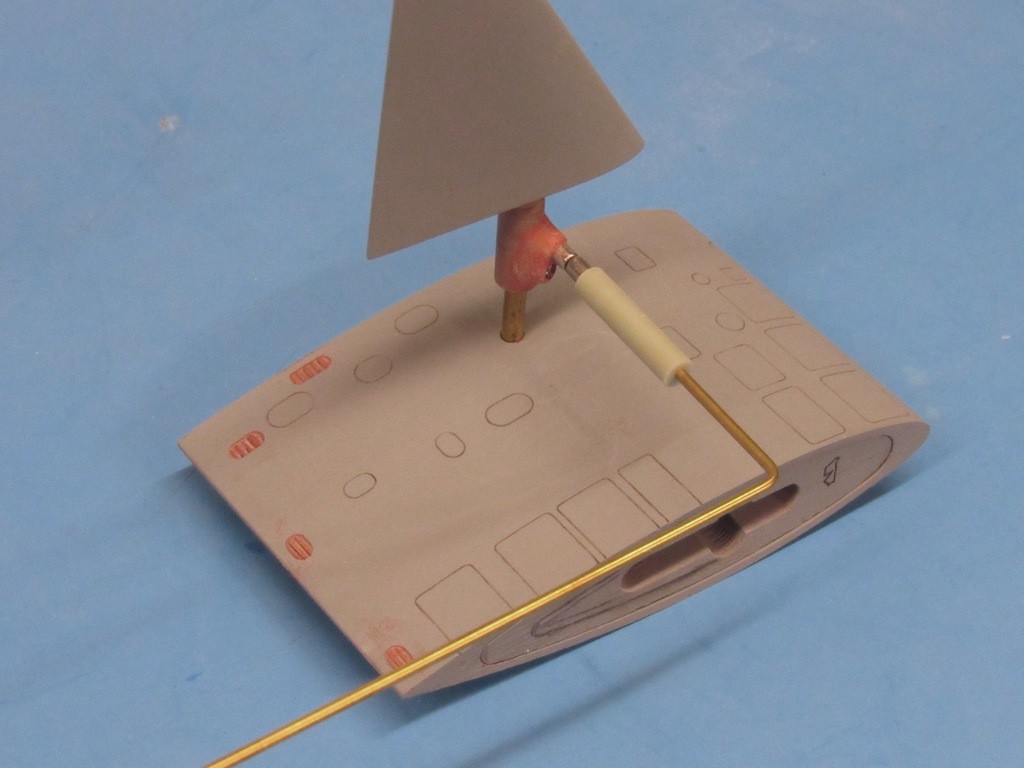

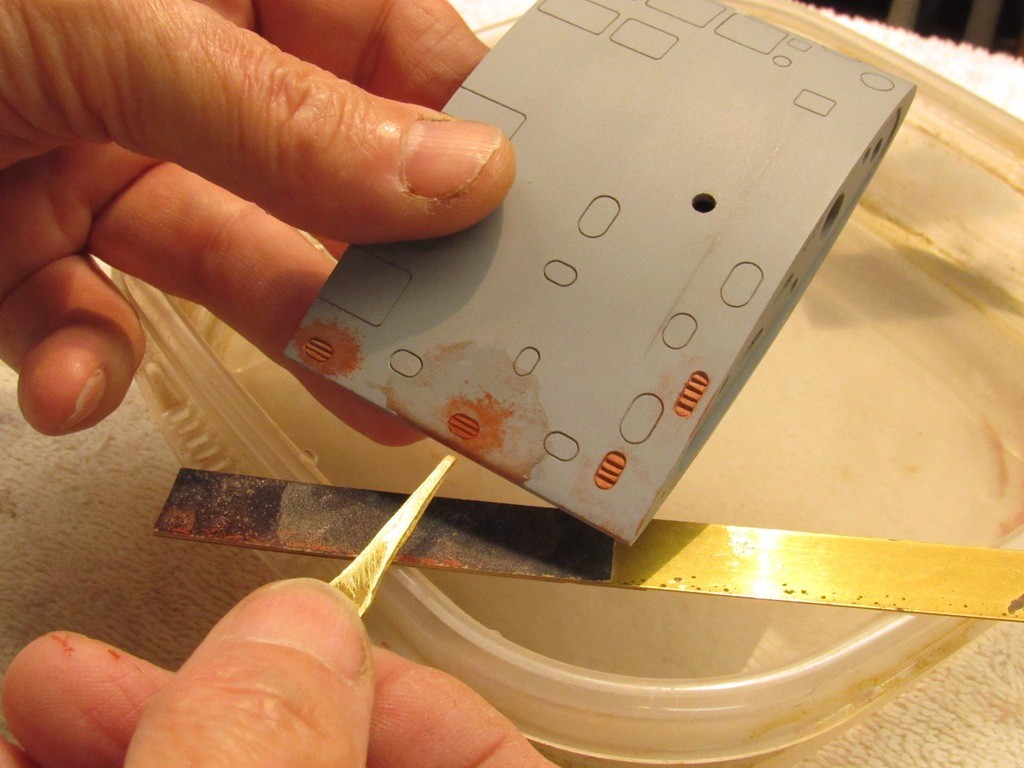

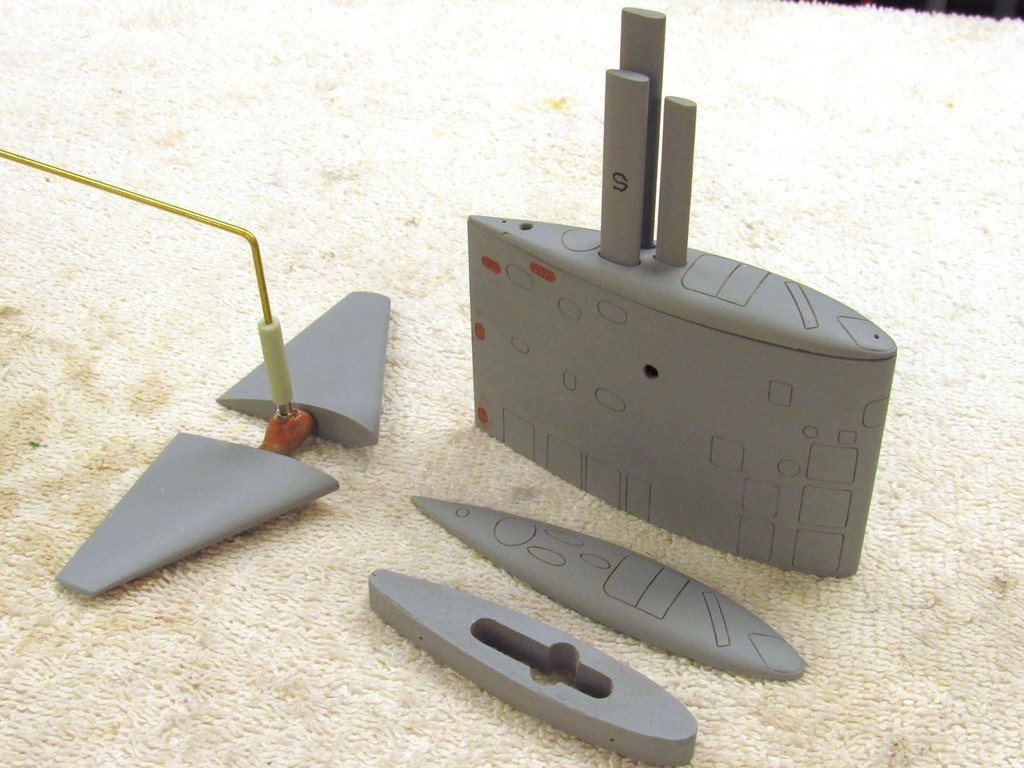

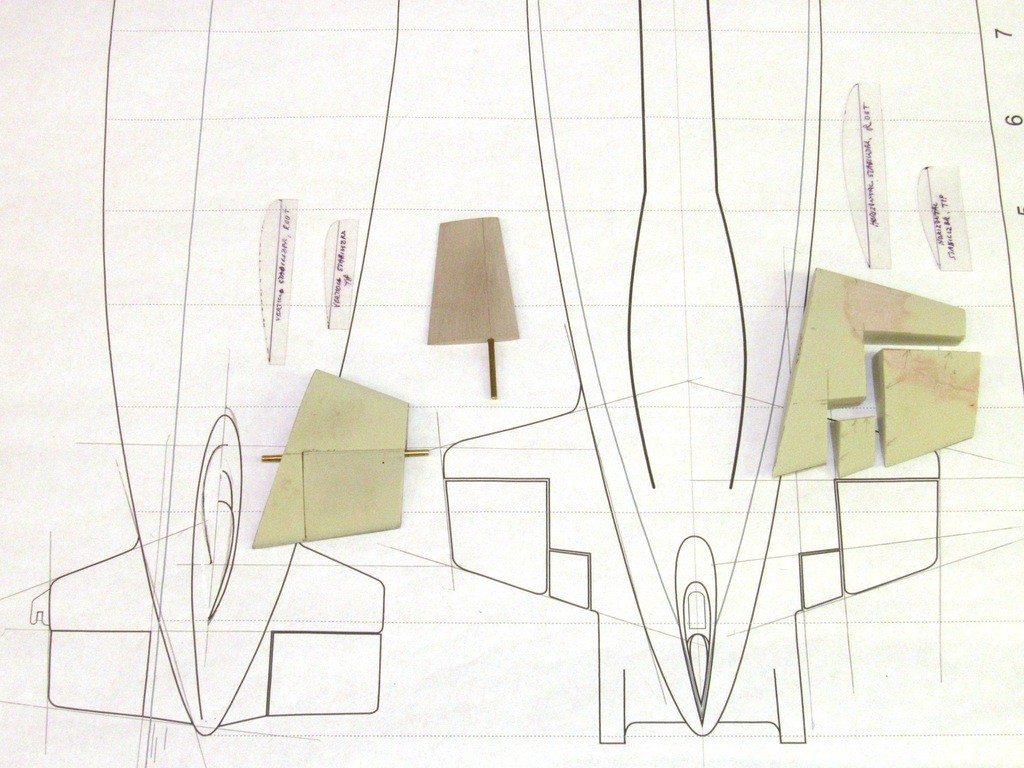

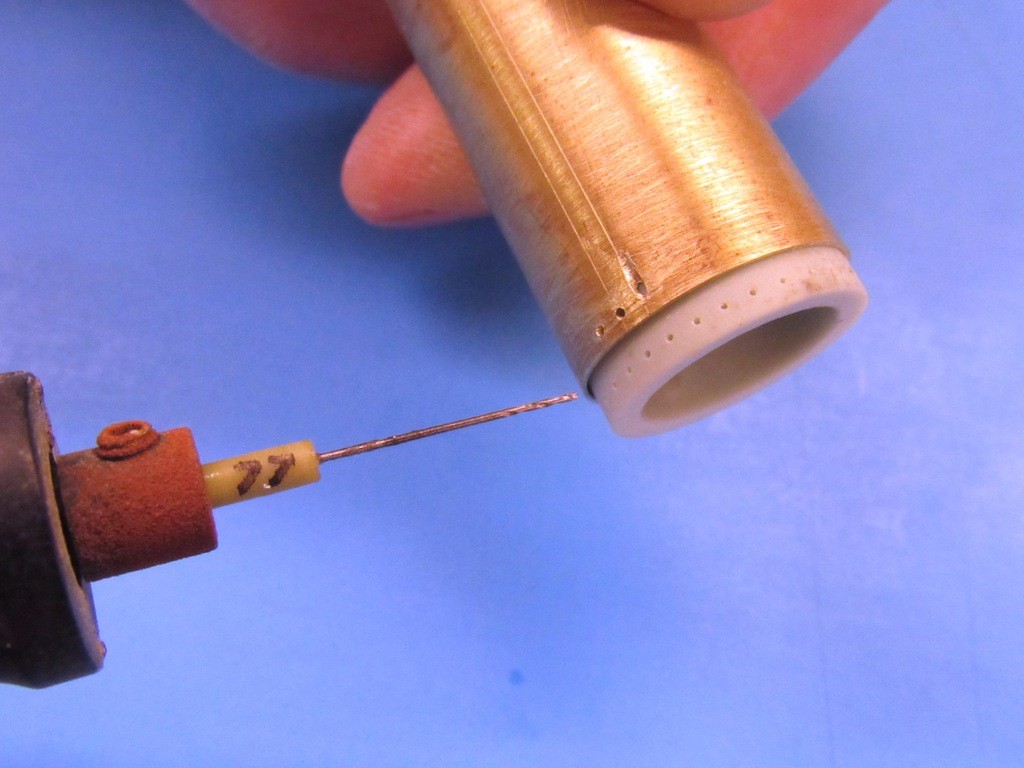

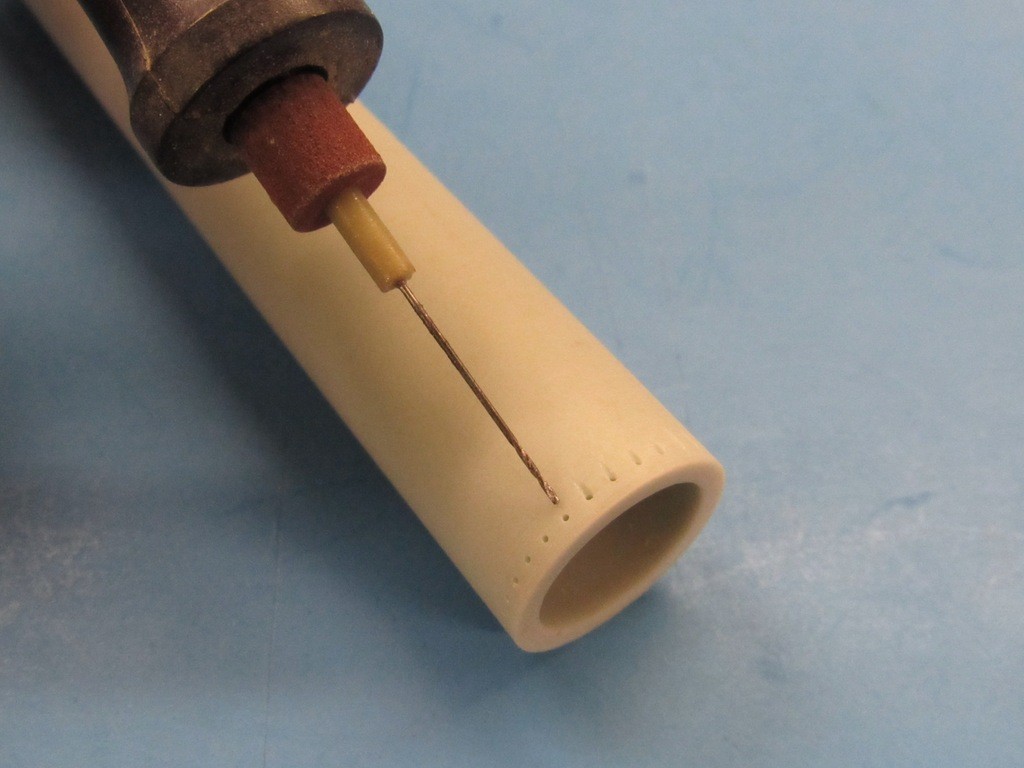

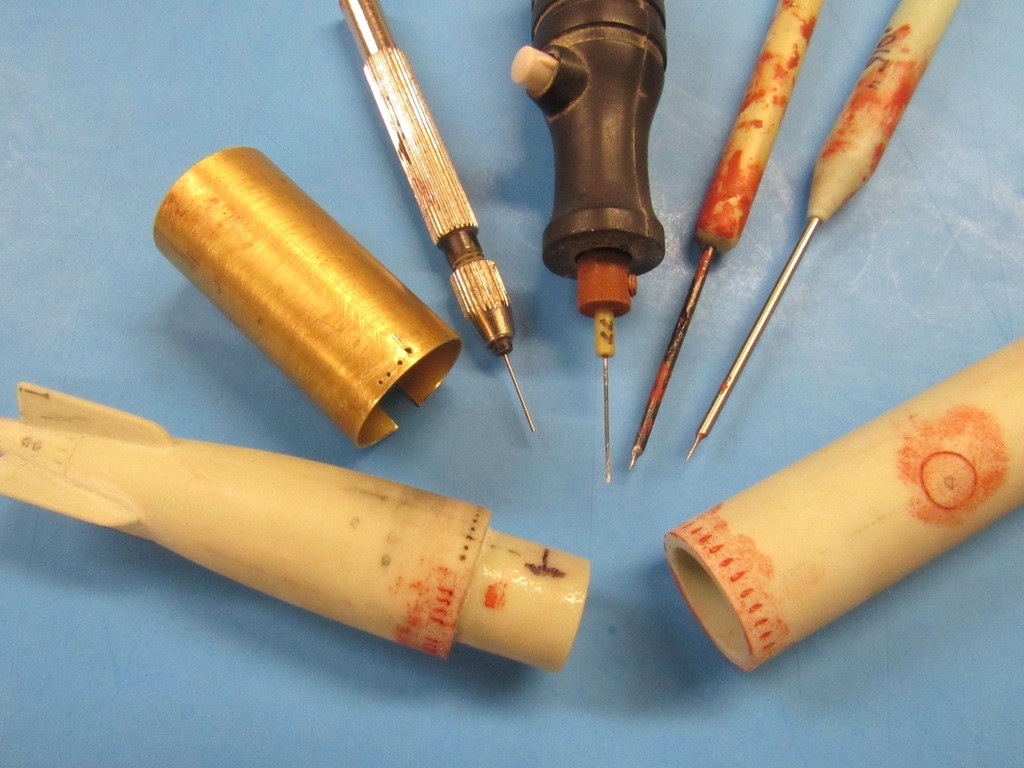

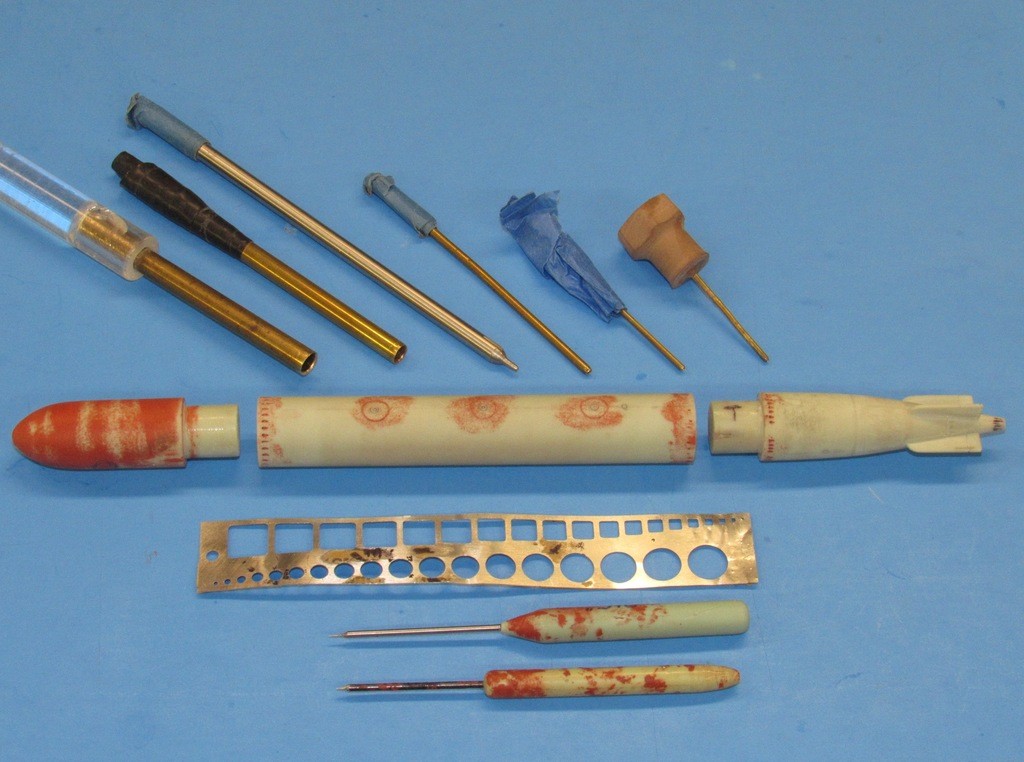

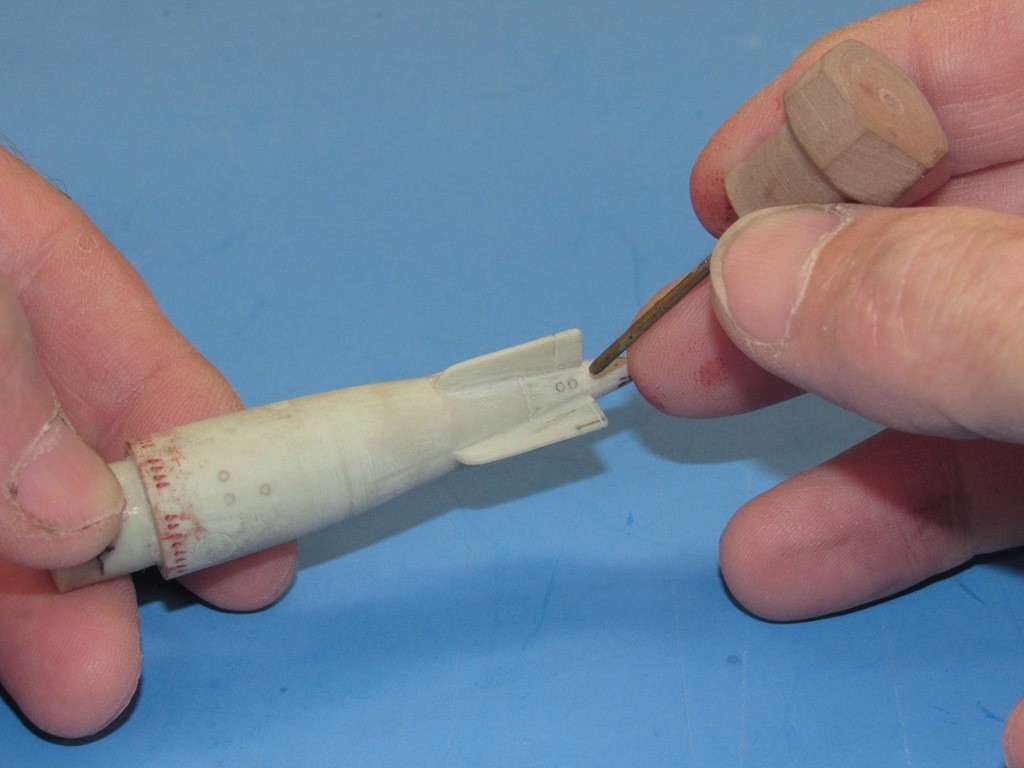

That's right, Andy. The initial work was forming resin castings of a 'generic' 21" diameter, 1/32 torpedo. I took a set of those cast resin 'blanks' and detailed them into a German G7E weapon. An abbreviated look at the process below. From blanks to finished masters.

Later, other sets of torpedo blanks will be used as the foundation for any type torpedo of 21" diameter, used by any navy.

DavidLast edited by He Who Shall Not Be Named; 12-10-2019, 10:25 AM.Who is John Galt?Comment

-

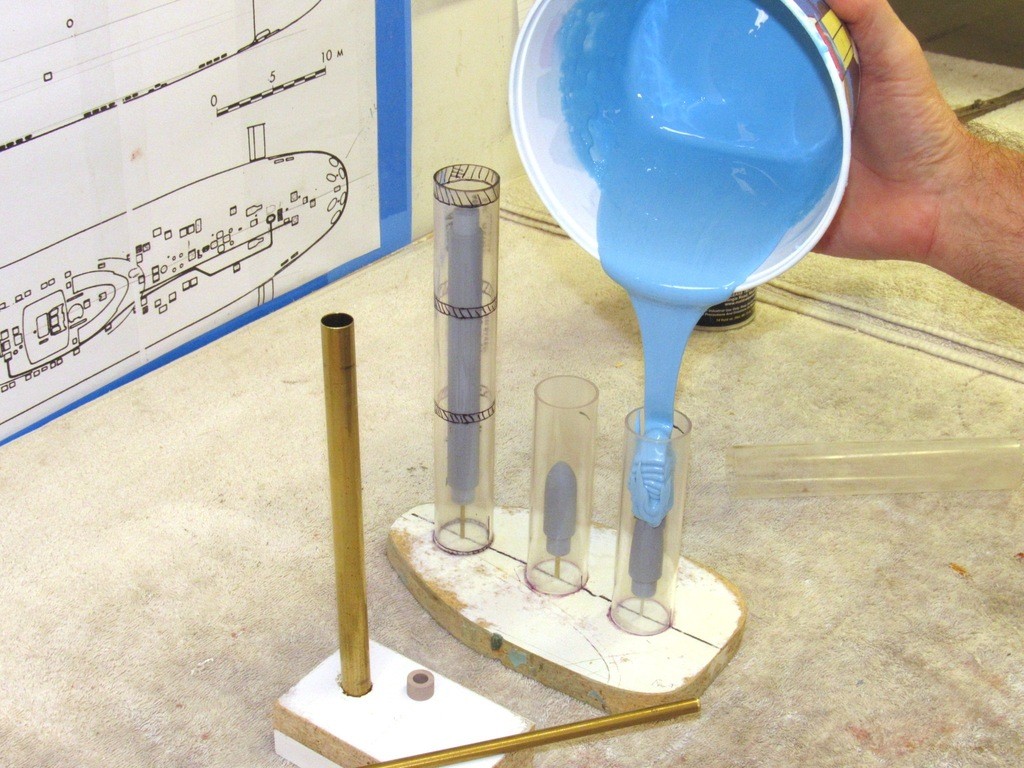

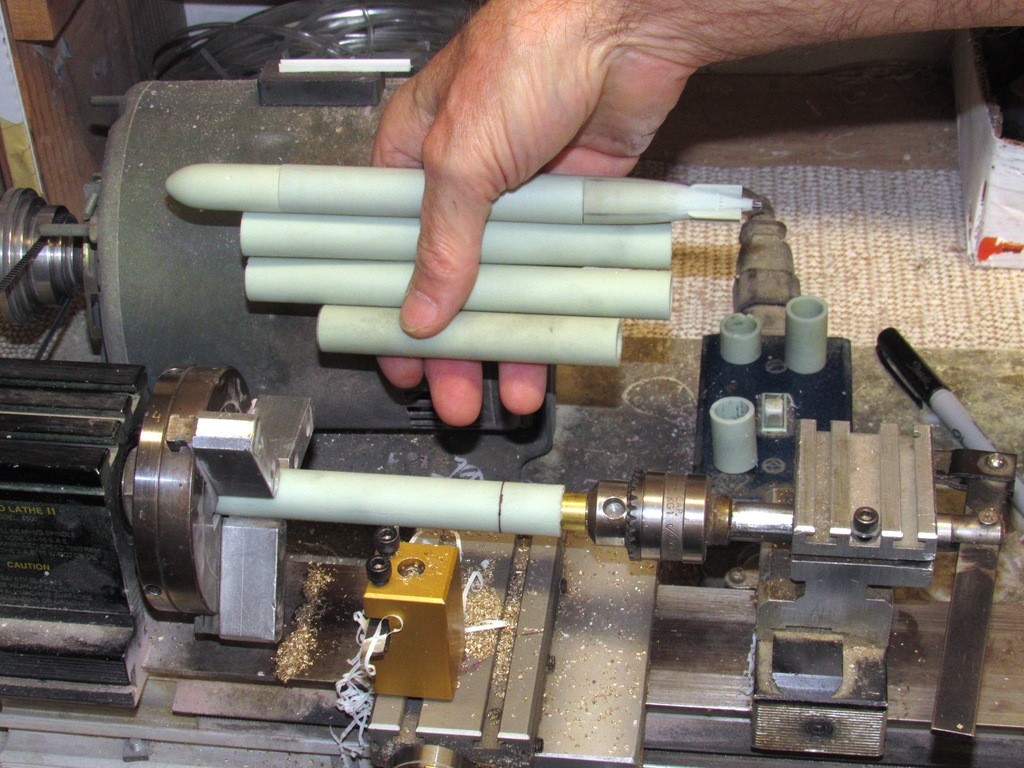

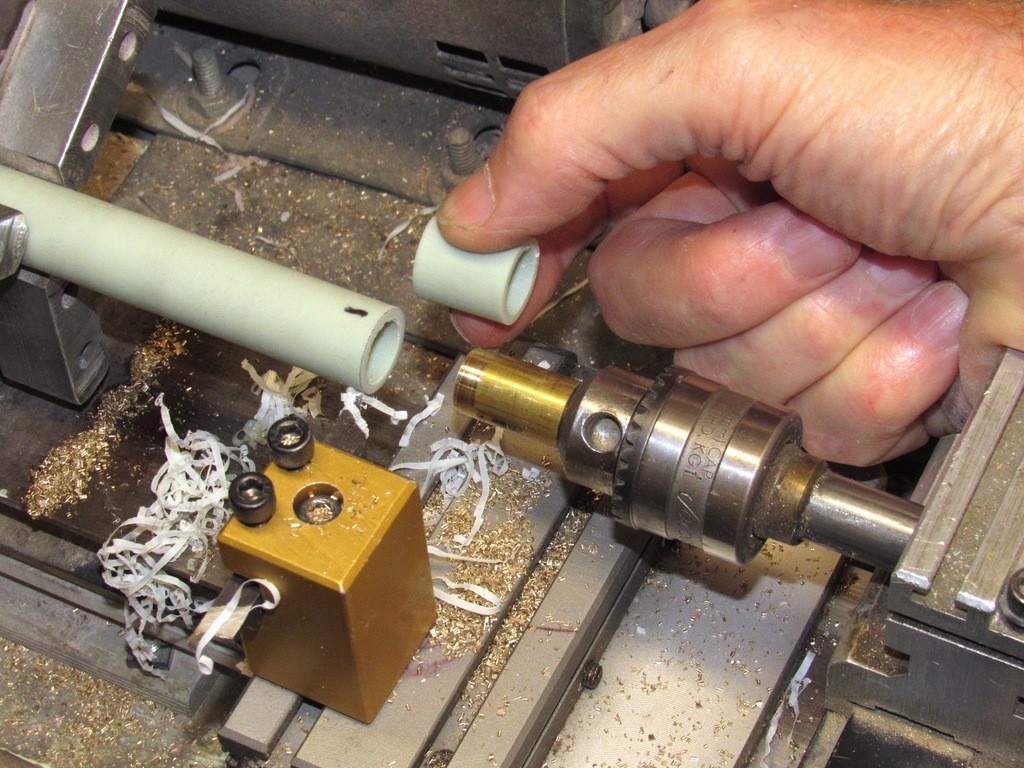

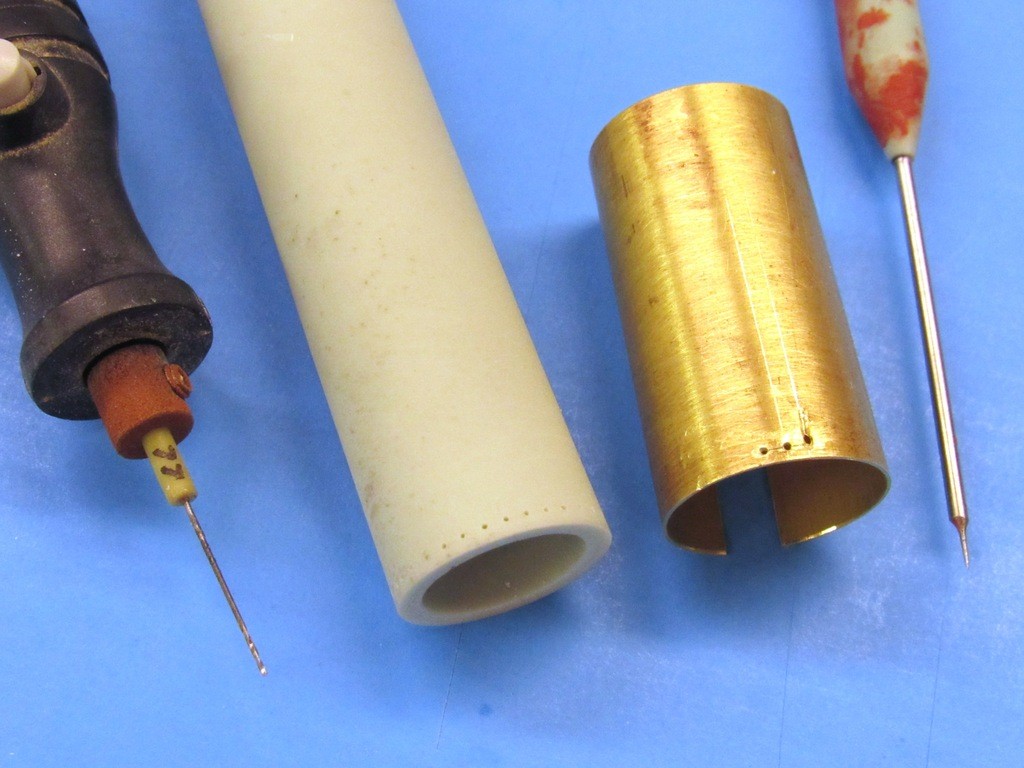

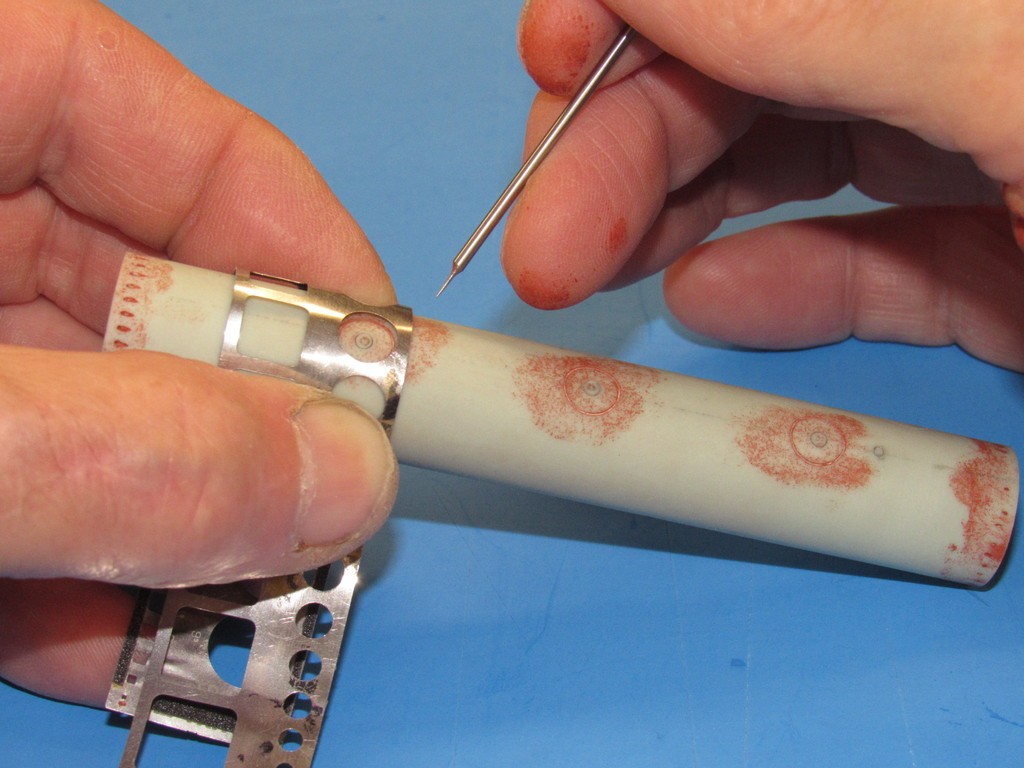

I initially used a brass rod as a core, but found it way to hard to extract from the cast resin mid-body, no matter what kind of part-release I used before the pour. Bob came up with the idea of making the core from rubber, with a metal rod within that core to make it ridged. Did that and it works like a charm: no more problem extracting the core from the weapons mid-body now.

DavidWho is John Galt?👍 1Comment

Comment