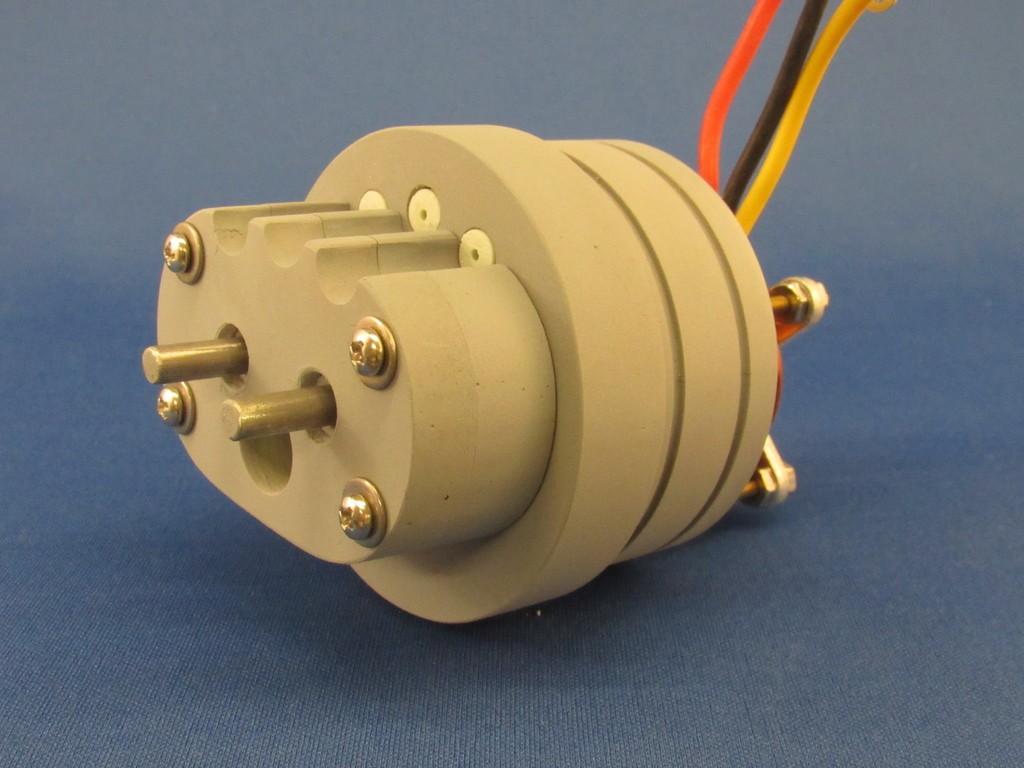

Can the motor bracket be mounted on the shaft end to make those long mounting rods go away? Never mind I think the answer is the outer shell spins on this type of motor so it has to be mounted at the one end.

today's work

Collapse

X

-

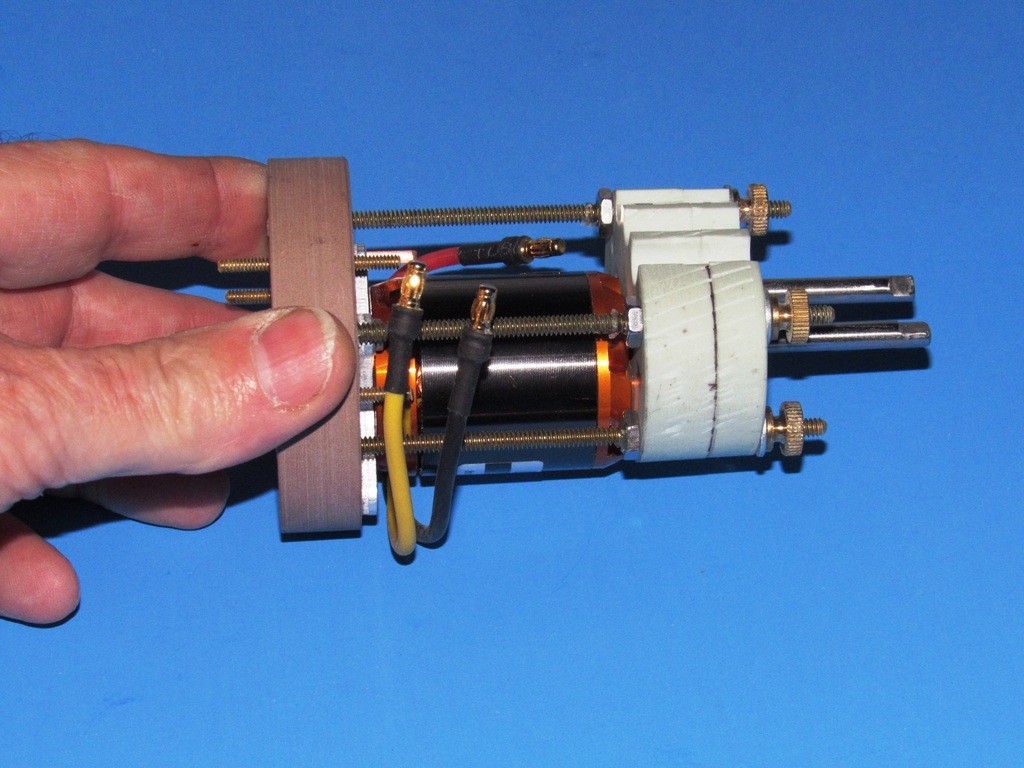

You got it, Scott. the only stationary portion of the motor case is the 'base' where the three power cables enter the stator. That's the portion that has to be physically attached to the MB. I'm now working on a motor on the wet side of the MB -- much easier to mount as there are no stand-off studs involved. That work to be chronicled in tonight's picture-show.

DavidWho is John Galt?Comment

-

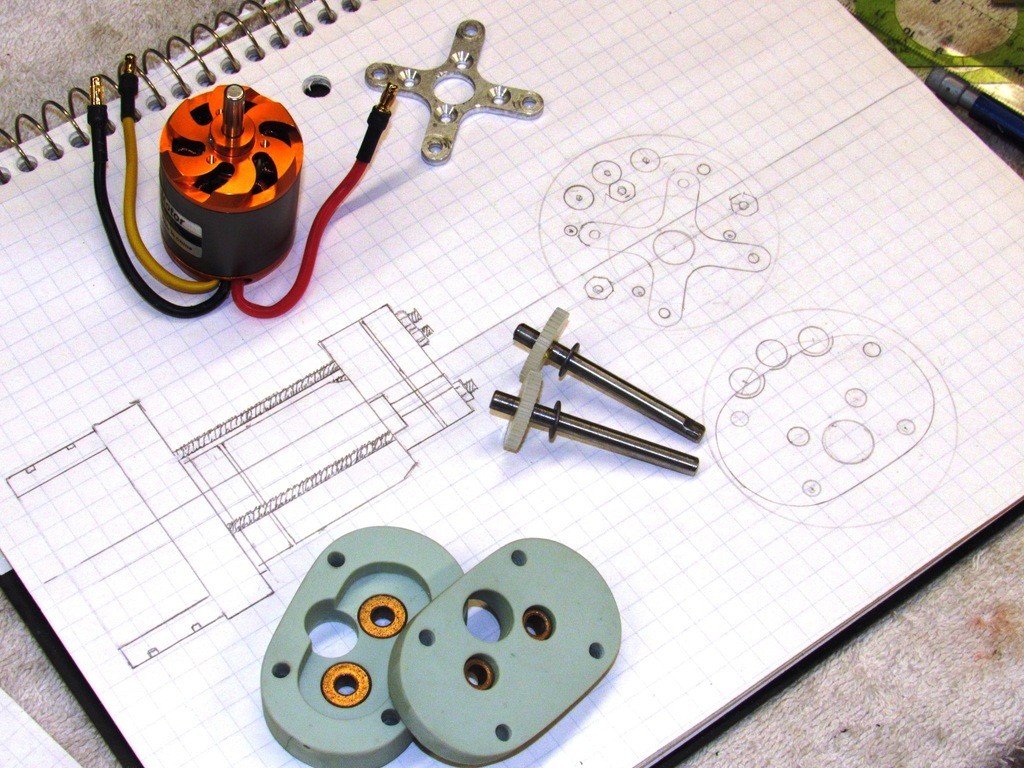

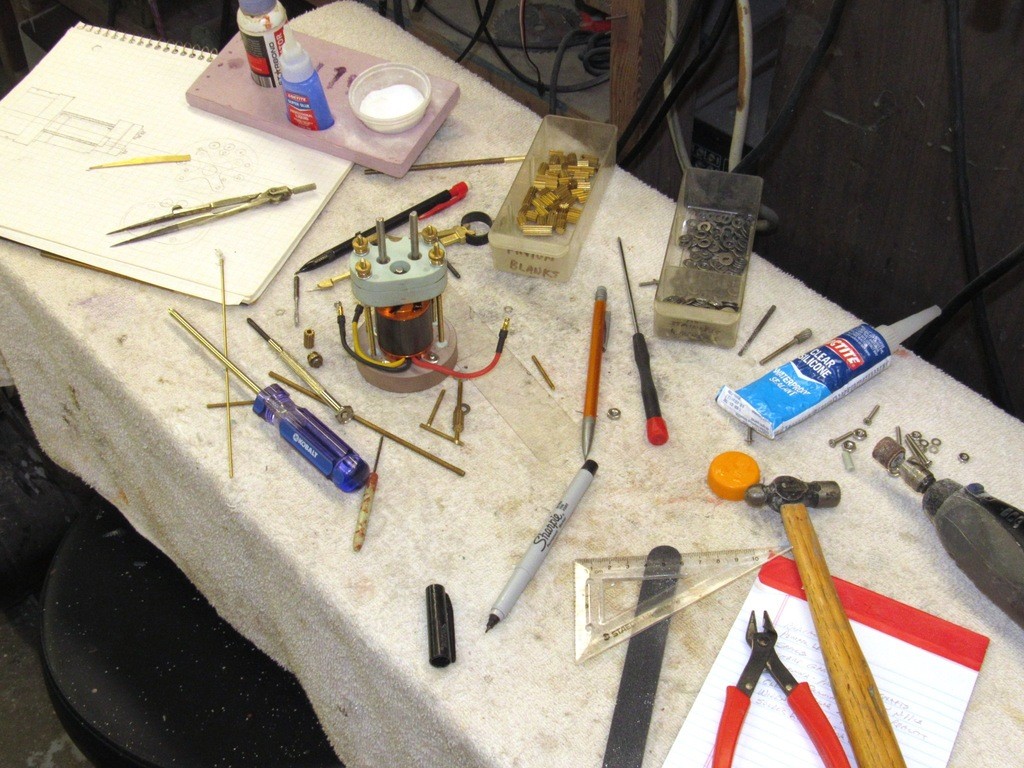

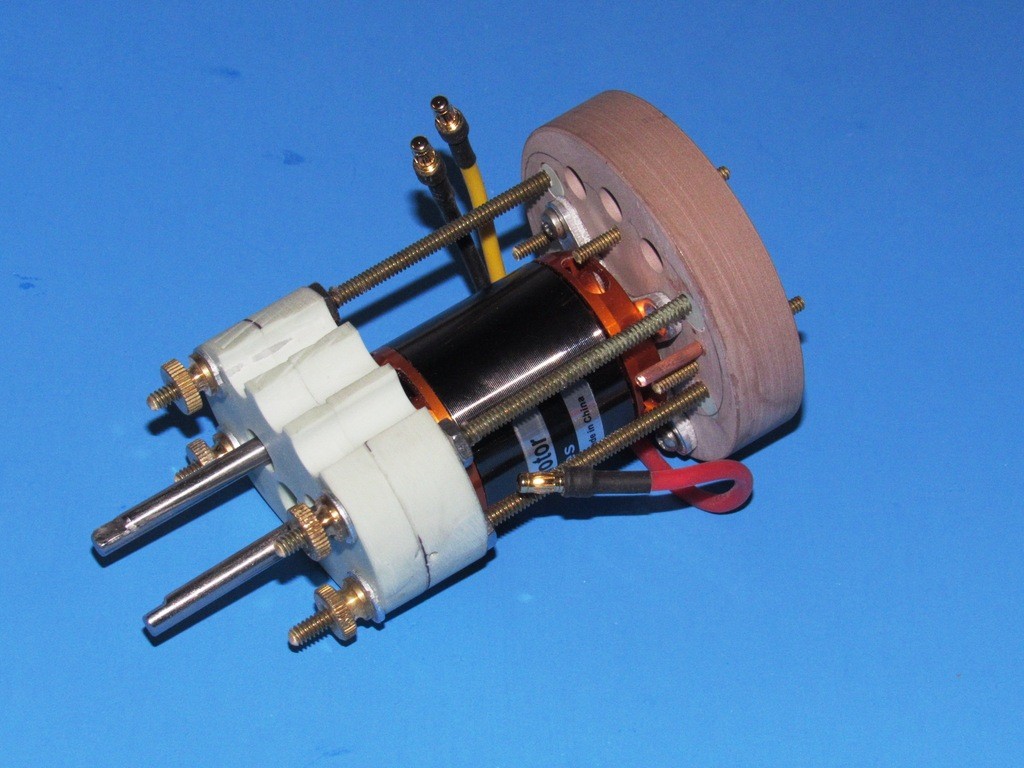

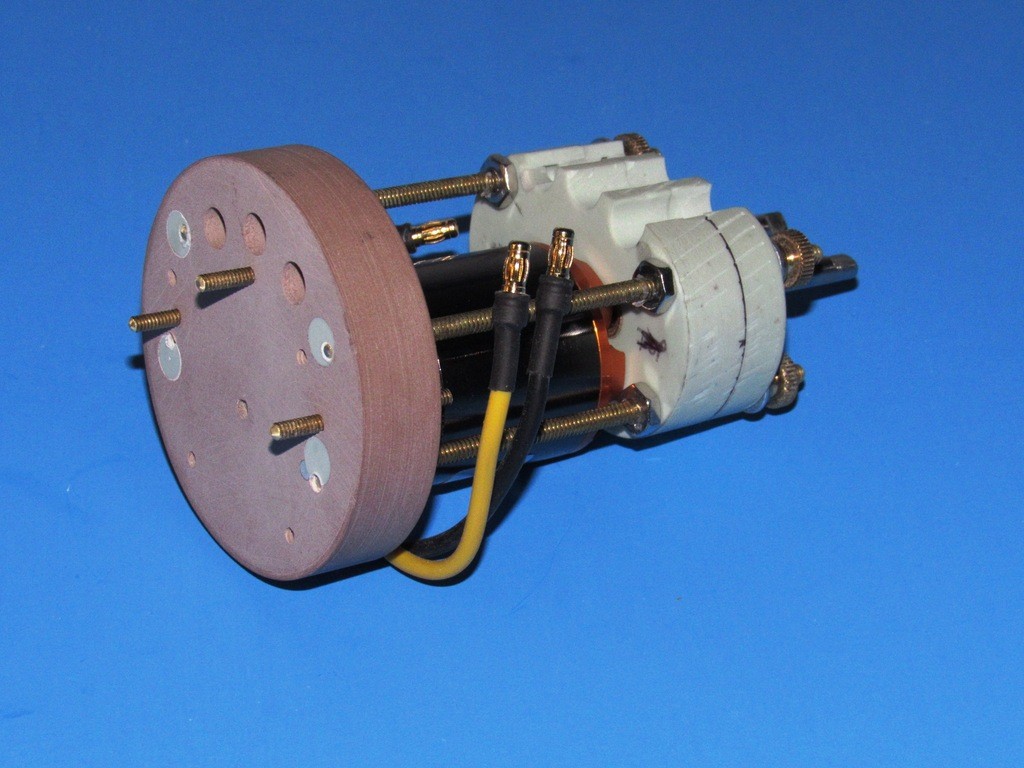

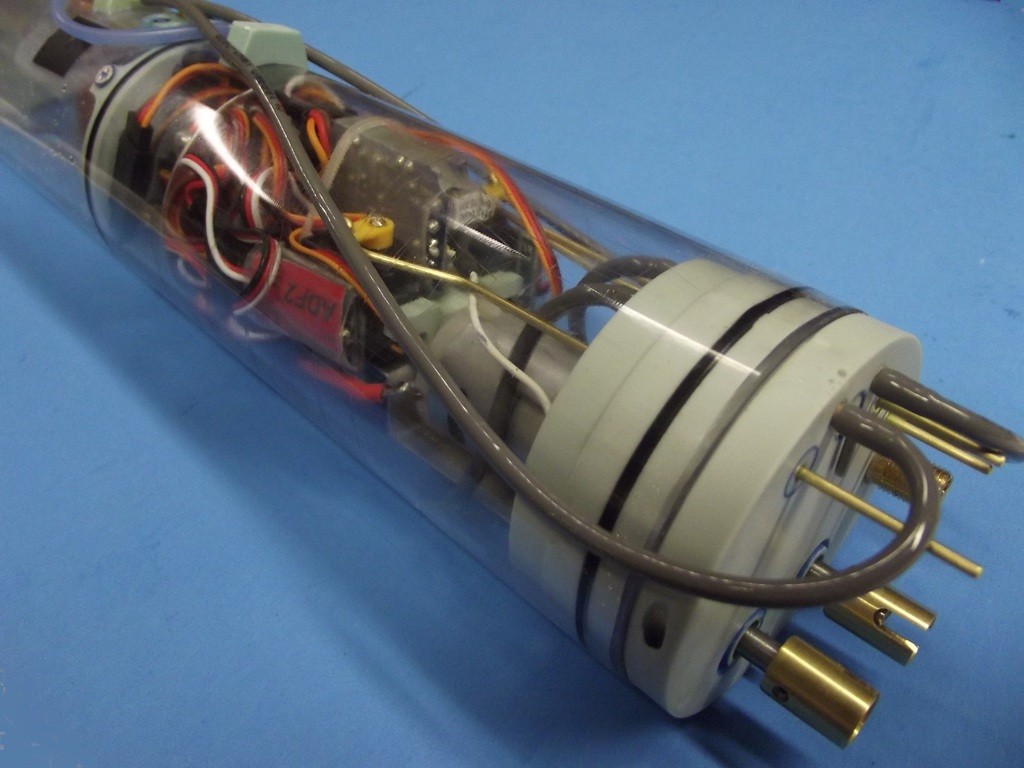

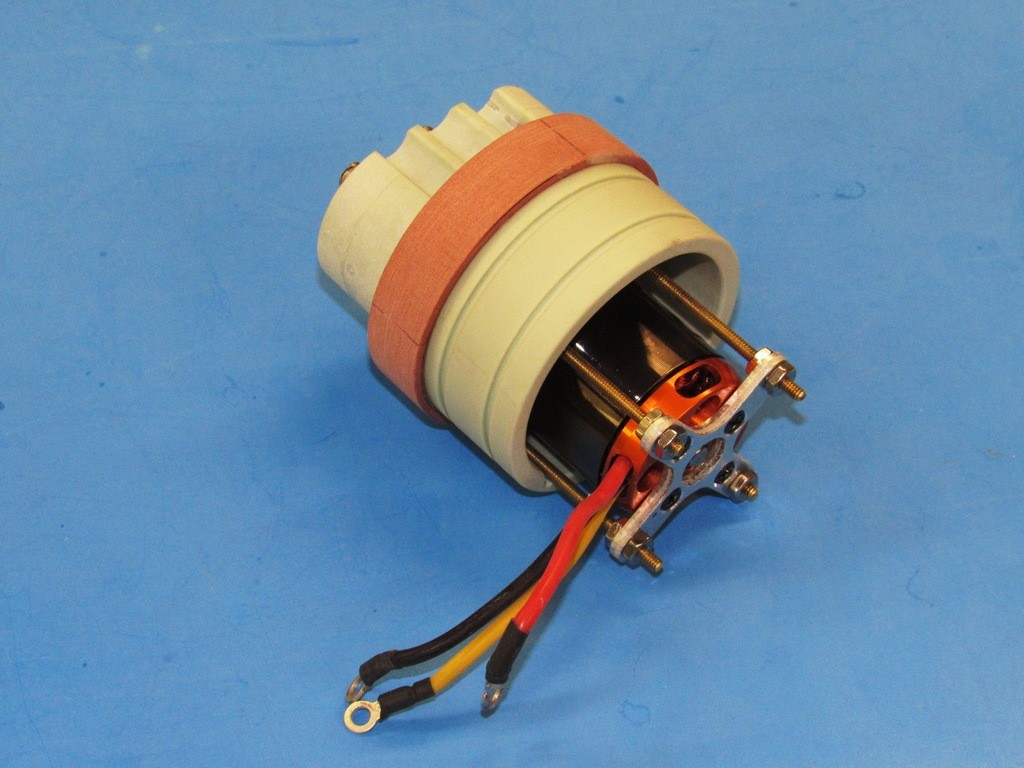

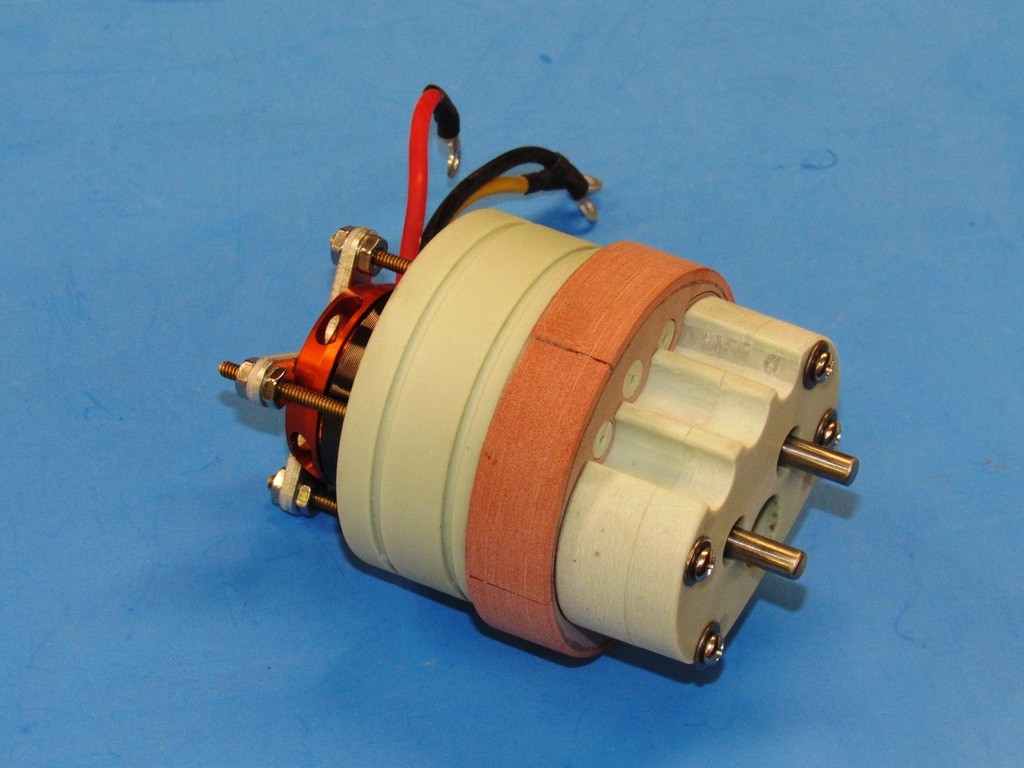

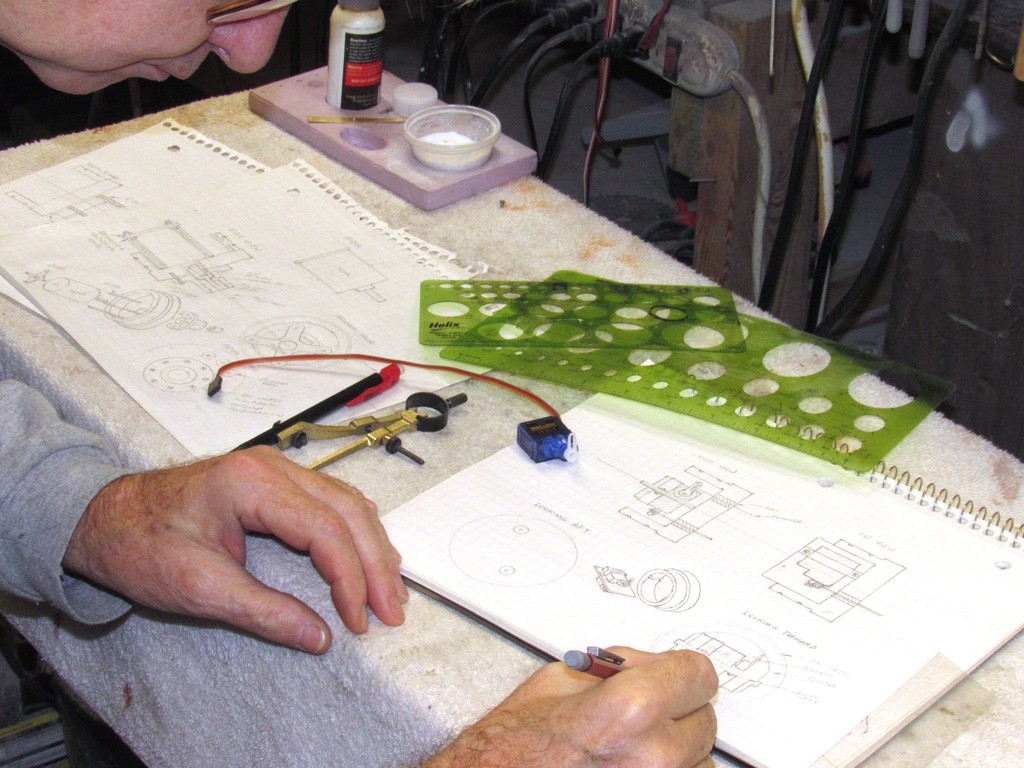

This version of the motor-bulkhead puts the motor in the water. Suspended aft of the motor is a gear splitter which outputs two counter-rotation shafts from the single motor input. This is still in the mock-up stage where I check fit and non-interference of the parts. I have yet to add the radial flange.

Who is John Galt?Comment

-

Hello David,

Thanks for your prompt response.

I should have put two and two together earlier, I had seen your silicon mould with all the pushrod inserts before Duh!....

I do have another question. I have always found it information overload with websites when looking up the "Cup seal". I have heard them called "lip seals" and even "Y' seals and the German name "Simmering" I know what I am looking for but find there are so many seals that look the same, some for Hydraulic and other applications I have been lost on websites trying to find stuff only to find that maybe the name I have been assuming they were called was wrong.

Anyway, to cut to the chase. Do you get your Cup seals from Mc- Master Carr as well?. I looked over their web page and couldn't find anything. IF i may ask what are the spec for yours?

Sorry,

Pain in the ass from Oz.

David HComment

-

I go into seals in detail in this video, including the source for cup seals along with part numbers.

Comment

-

You are not a pain in the ass! You are my student. You are my attentive and participating student. I very much enjoy passing on to guys like you what others have taught me.Hello David,

Thanks for your prompt response.

I should have put two and two together earlier, I had seen your silicon mould with all the pushrod inserts before Duh!....

I do have another question. I have always found it information overload with websites when looking up the "Cup seal". I have heard them called "lip seals" and even "Y' seals and the German name "Simmering" I know what I am looking for but find there are so many seals that look the same, some for Hydraulic and other applications I have been lost on websites trying to find stuff only to find that maybe the name I have been assuming they were called was wrong.

Anyway, to cut to the chase. Do you get your Cup seals from Mc- Master Carr as well?. I looked over their web page and couldn't find anything. IF i may ask what are the spec for yours?

Sorry,

Pain in the ass from Oz.

David H

Lip/cup/wiper seals are all unsupported rubber units. Simmering type seals feature an imbedded tensioner that forces the lip of the seal up tight against the rotating shaft -- ideal with WTC's that see great pressure differentials between their interior and the water around them, which is the case with ballast sub-systems of the 'piston' type.

Here's where I get mine, David: Precision Associates, Inc.; 3800 Washington Avenue North; Minneapolis, MN 55412 https://www.precisionassoc.com/ https://catalog.precisionassoc.com/c...tes-inc-u-cups

And for Christ's Sake!!! Improve your scribing techniques, will ya!????.... Still looks like crap!

David

The HorribleWho is John Galt?Comment

-

-

Comment

-

-

Good point, Manfred. You're alluding to the 'water-hammer' effect; the rapid squeezing of an incompressible fluid (water) between the teeth of the water immersed gears and the great lateral force it presents to the bearings that support the gears through their shafts. That hazard is real and is mitigated by a less than optimal meshing of the gears. In other words, I space the gears far enough apart to permit the water to squish out from the teeth without too much water-hammer occurring, but not so fare as to risk slippage and damaged gear teeth.

DavidWho is John Galt?Comment

-

OK, that can be a solution, but if you get lipseals at both ends of your gear-enclosure, you can leave the gearbox as it is, much less work to alter the gearsetting, and keeping the stuff more standard for production.

Manfred.I went undergroundComment

-

That certainly is the preferred option, and I've already done just as you described with the 2.5" cylinder developed to run the 1/72 Type-9

I could do that with the smaller brushed motor, but not possible with the larger brushless motor Bob and I have selected to be our basic install on the majority of our future MSD's.

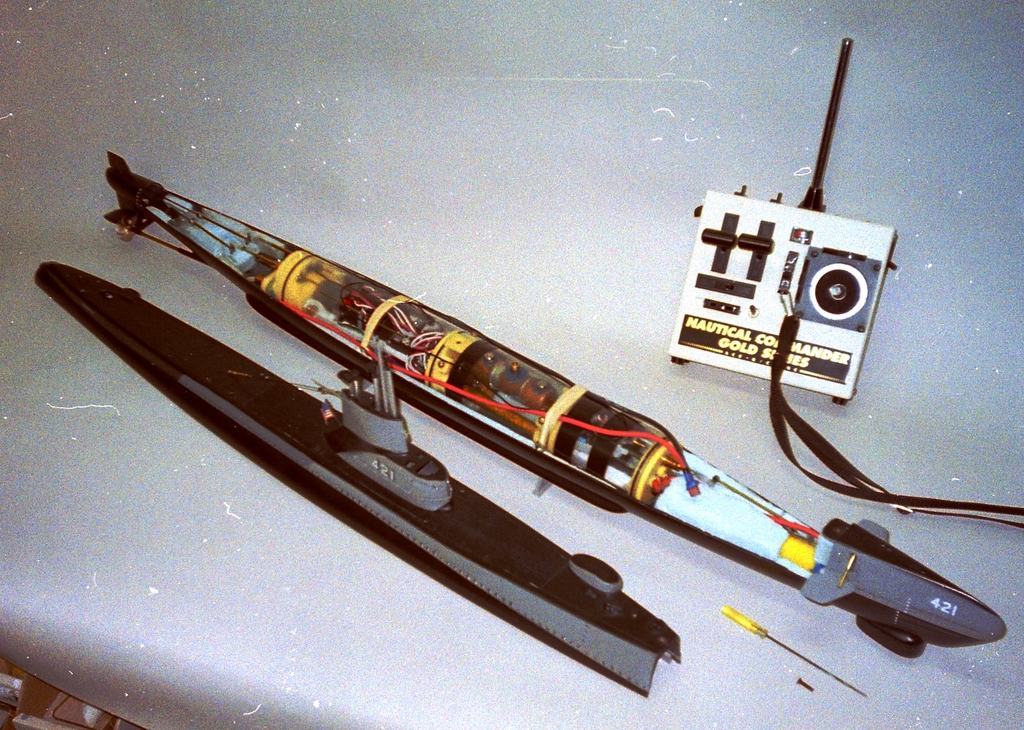

This is my first in-water gear splitter, done over 30 years ago:

DavidWho is John Galt?Comment

-

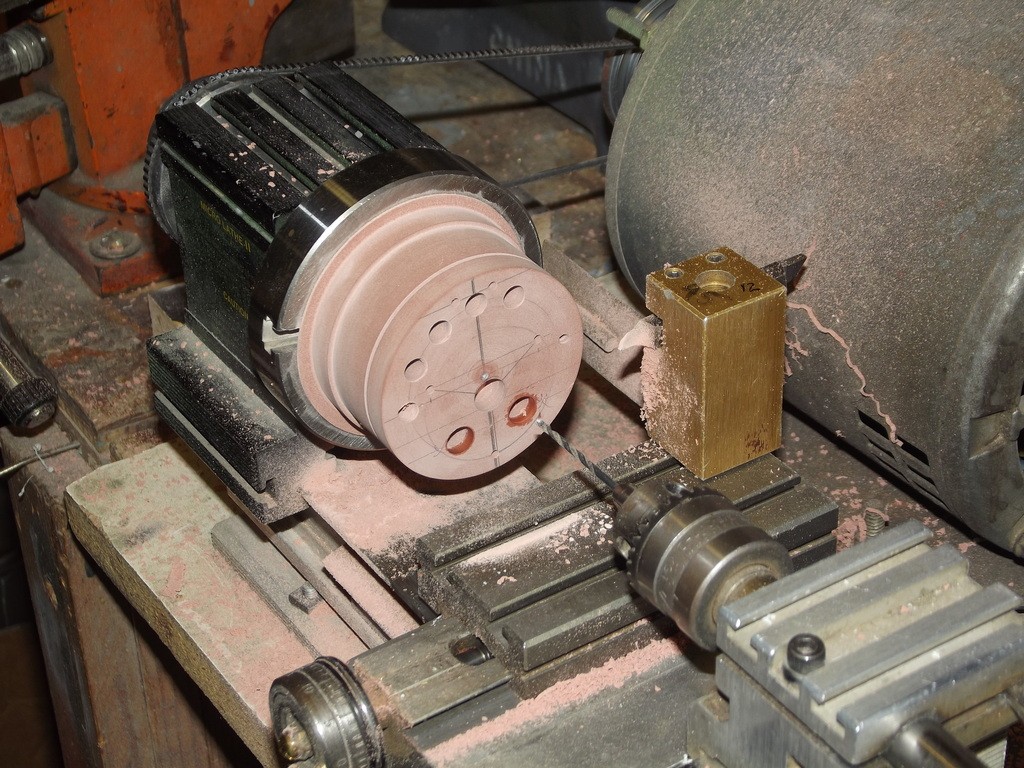

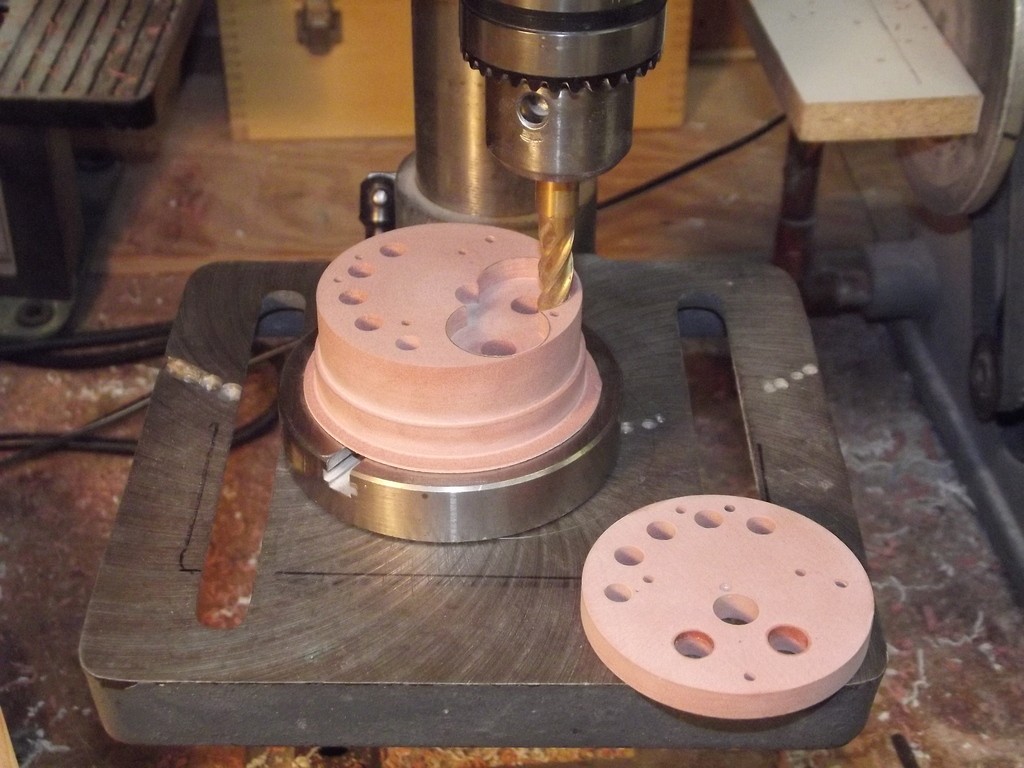

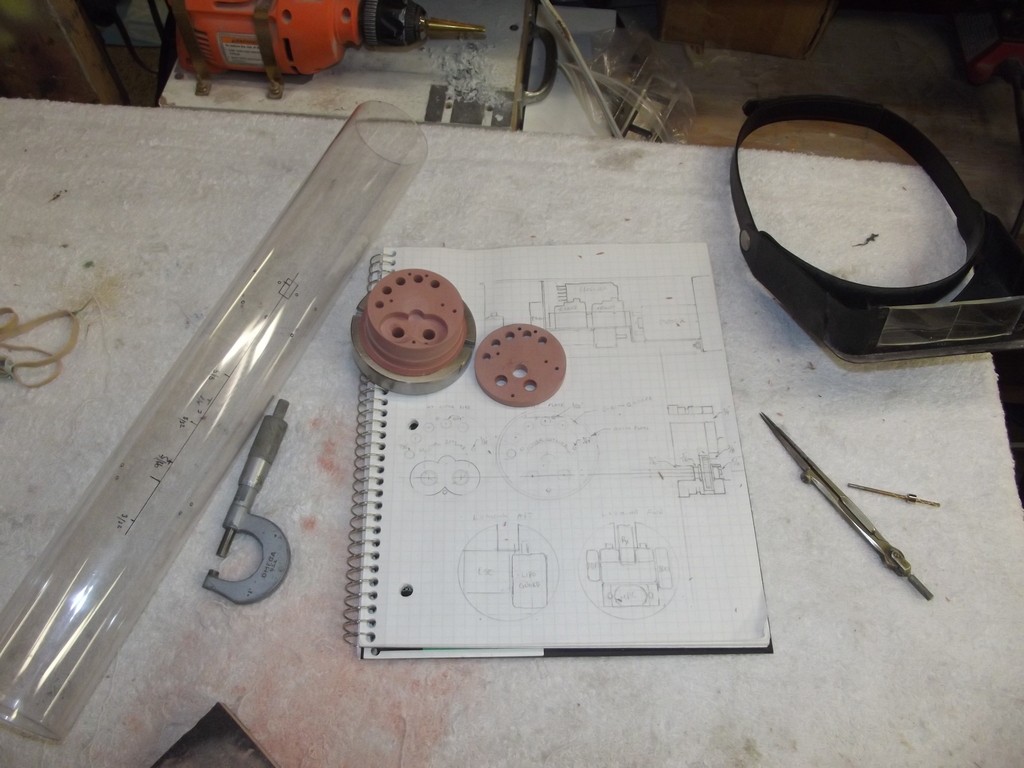

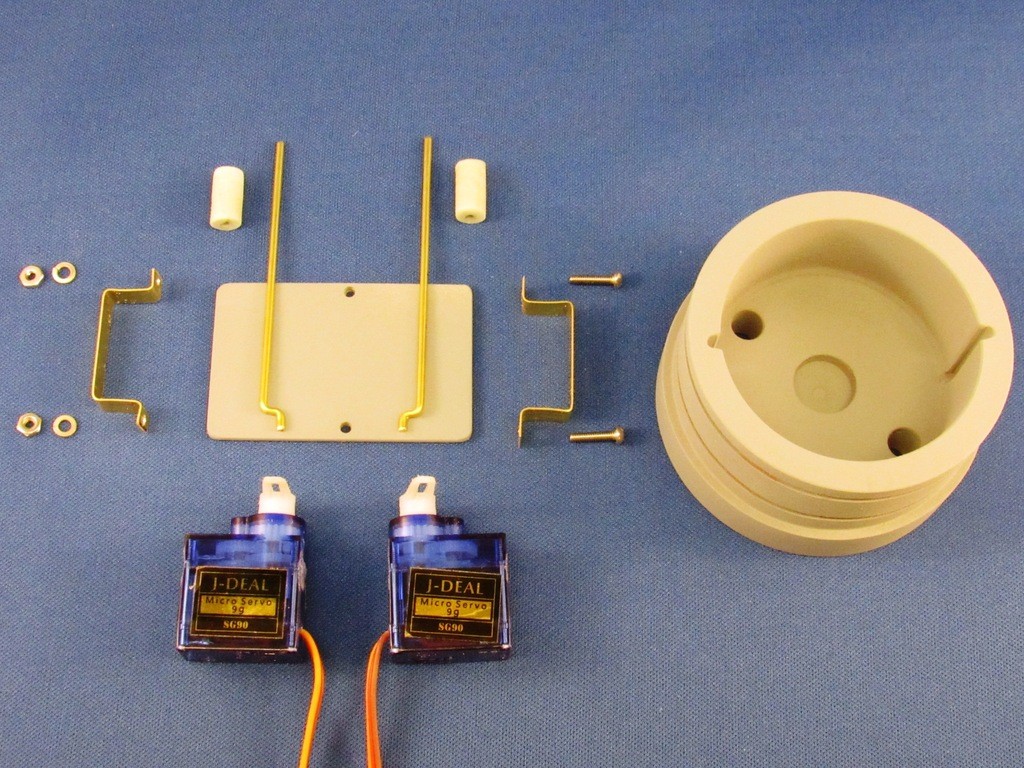

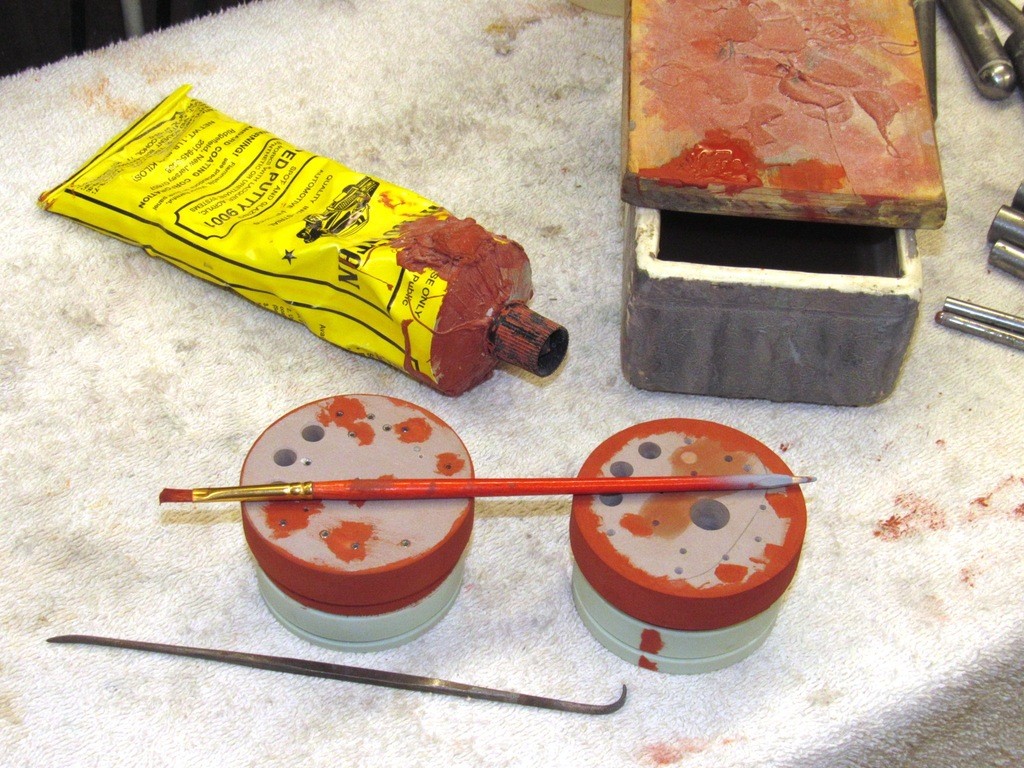

I'm just about ready to use these Modular SubDriver bulkhead masters to give form to the rubber tools from which cast resin production parts will be produced. Some last-minute machining, putty work, wet-sanding, primer, and things are now good to go. Fine with me, I'm sick of this grunt work, I want to get back to proper model-building, damnit! I use them to mock-up a practical demonstrator -- this is the stage where you want to find faults, not after you've committed to production tooling!

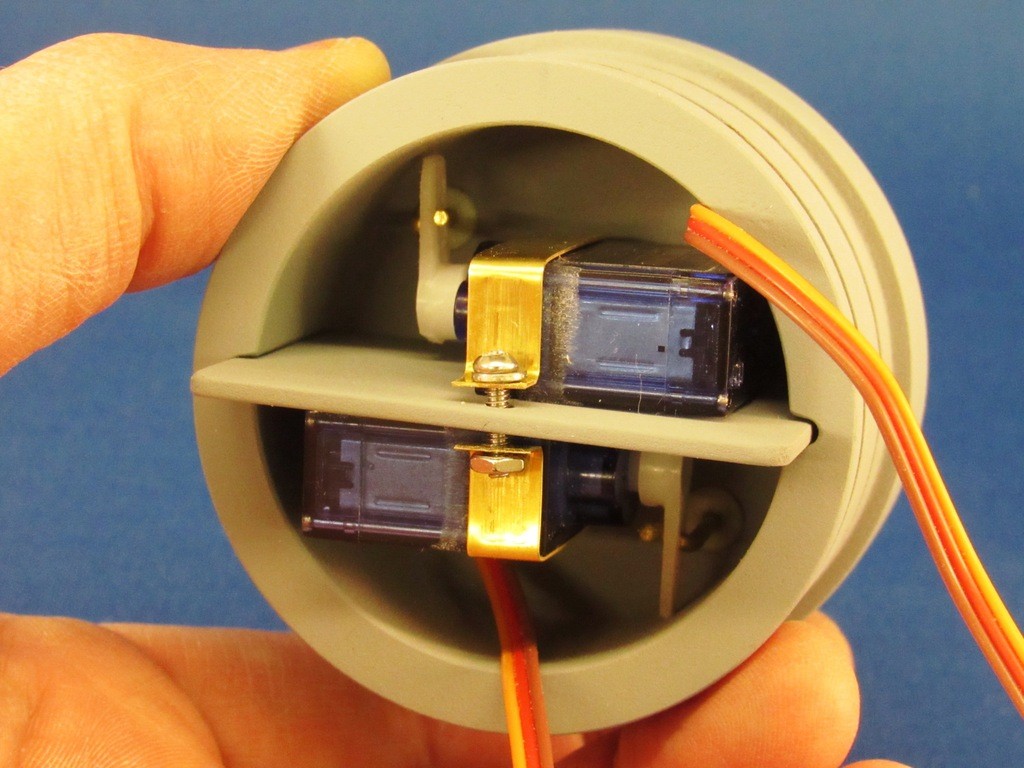

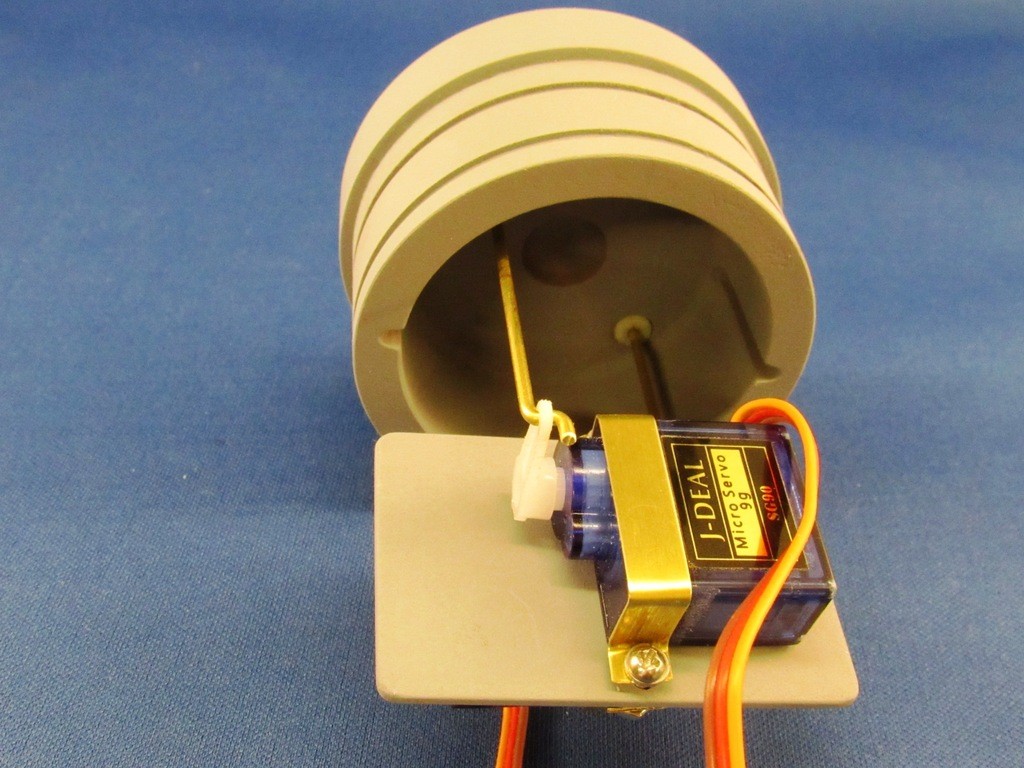

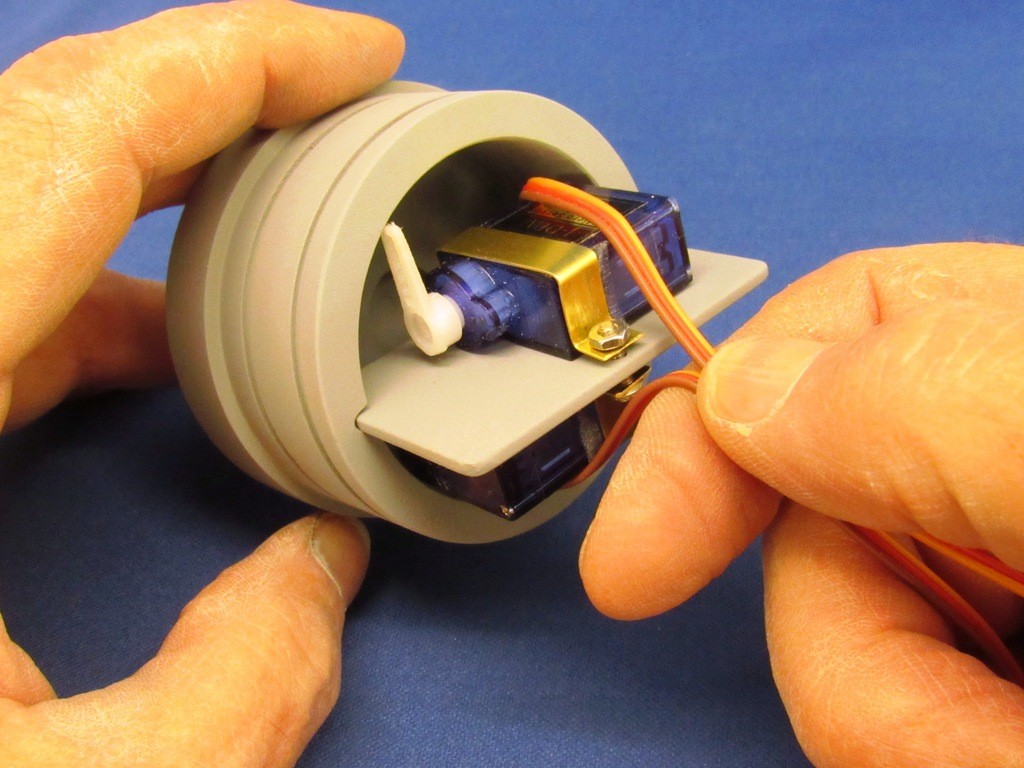

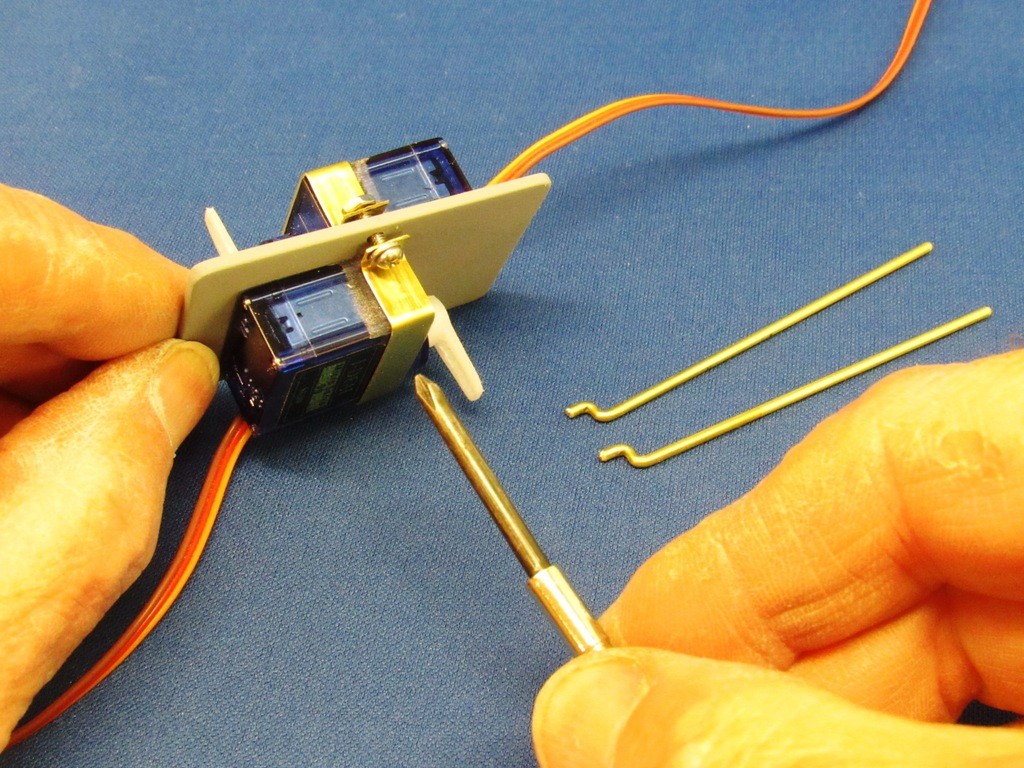

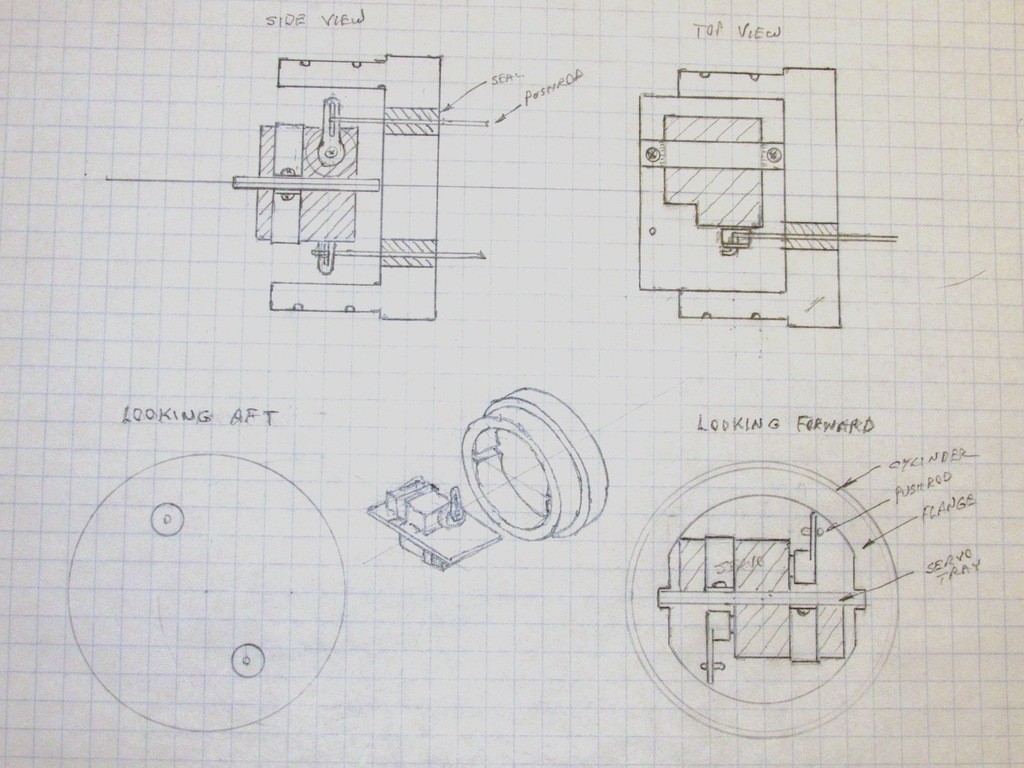

Last item on the MSD work list is this forward bulkhead used to give access to the forward dry space where the battery is stored. We wanted to provide the option of outfitting this bulkhead with two servos -- some customers would rather take the direct route with their linkages rather than run a long pushrod forward from the motor bulkhead mounted servos. Typical items needing r/c activation at the bow include bow plane, bow plane retract/deploy, anchor, and torpedo launching.

Who is John Galt?Comment

Comment