today's work

Collapse

X

-

-

Hello Sir

Please excuse some OLD questions. In your 1/72 torpedo you mentioned long before that the brass core you used was 7/32" solid but it`s finished O.D would be 0.279" and your 1/96 brass core 3/16" so it`s O.D would be 0.210". Is that a strong enough wall thickness to handle to run gas torpedoes safely?

Comment

-

It worked for me. The launcher is designed so that the weapon is charged and maintained within the tube before launching. The tube itself is insurance against fragmentation should a weapon explode under pressure.Hello Sir

Please excuse some OLD questions. In your 1/72 torpedo you mentioned long before that the brass core you used was 7/32" solid but it`s finished O.D would be 0.279" and your 1/96 brass core 3/16" so it`s O.D would be 0.210". Is that a strong enough wall thickness to handle to run gas torpedoes safely?

DavidWho is John Galt?Comment

-

That's good news, Tim. Lots of boat sailors out there who served on those cramped pencils. Should be a market out there to exploit. Other than an abundance of fresh water and no diesel stench the LA's had worse habitability than the GUPPY's. Glad I never served on them.

DavidWho is John Galt?Comment

-

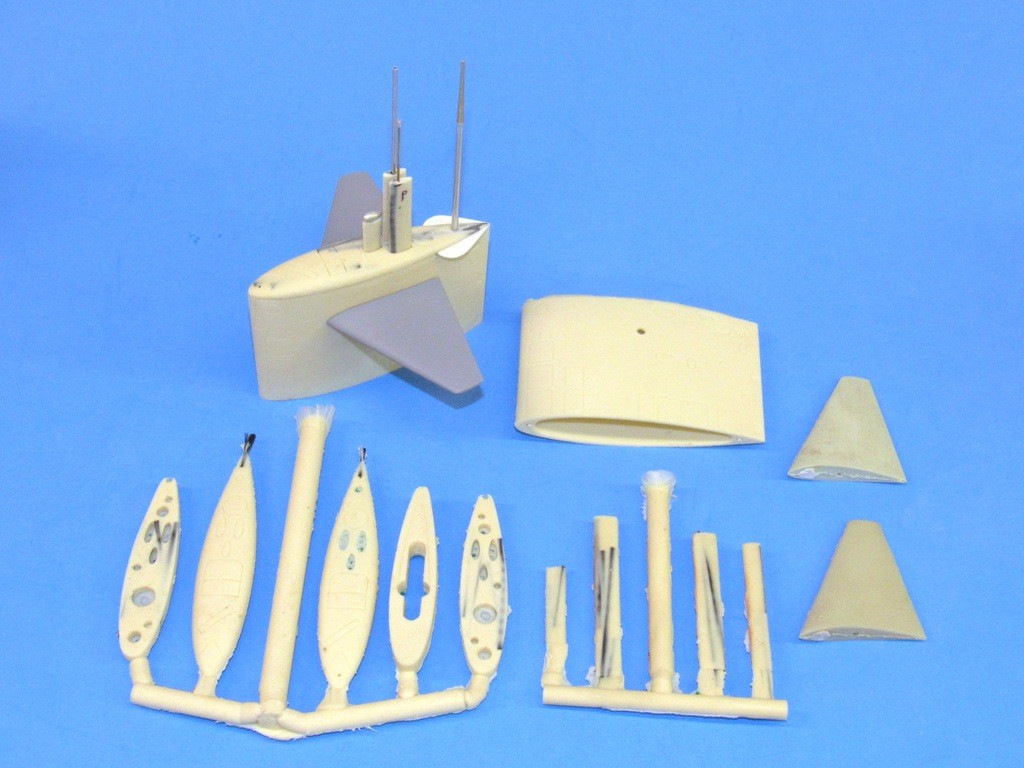

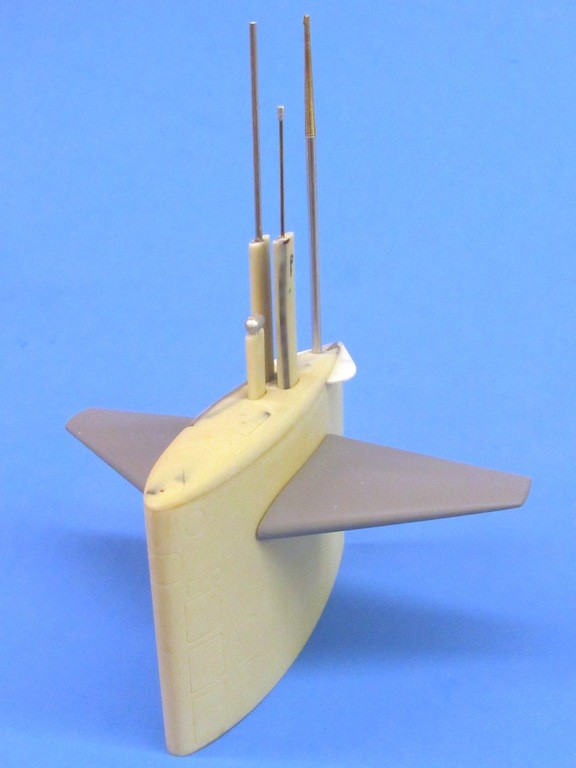

I took the cast resin sail parts and stuck them together. Assembly was straight forward: the three internal platforms were glued within the sail, the sail top piece (the one with the openings through which the raised mast fairings project) glued atop the main structure, and two holes drilled and tapped at the bottom platform to accept the screws that would pass up through the upper hull to secure the sail in place.

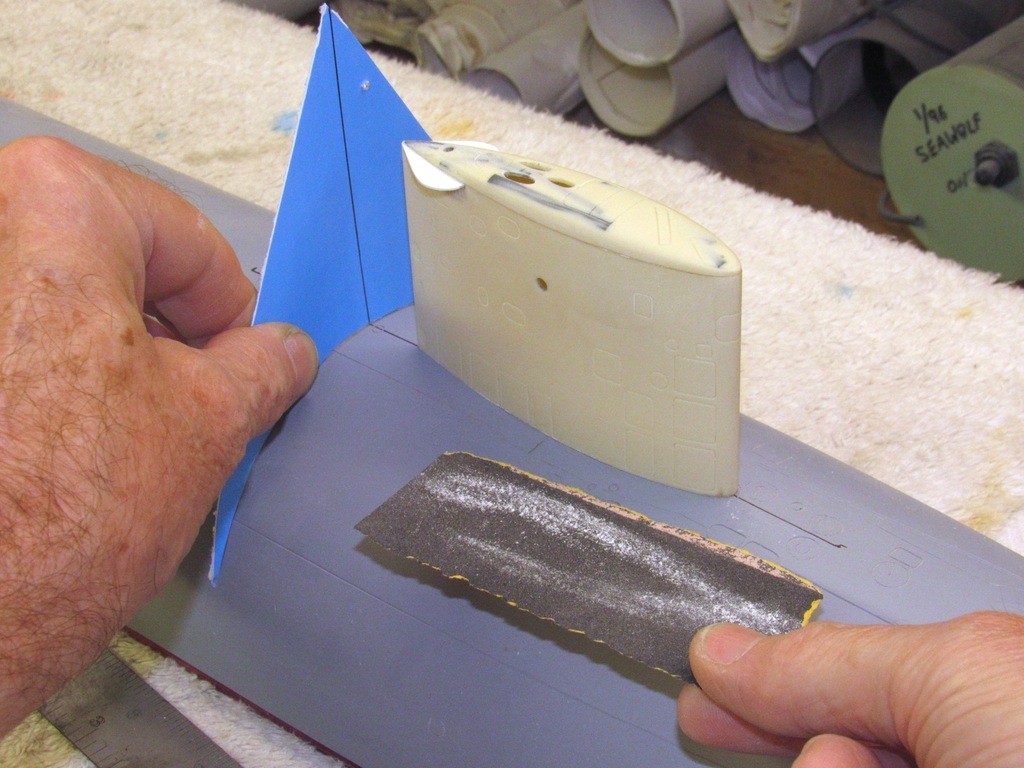

A simple poster-board alignment jig insured I sanded the base of the sail so it would sit level atop the upper hull. Any significant gaps between sail top and sail proper were filled with CA and flashed to hardness with either a sprinkling of baking soda or a good wetting with 'accelerator', followed by careful file work.

The engraved lines on the kits upper hull were not up to my standard: though an appreciated attempt the hull featured both non-skid and waterline cheat-lines -- these were way too deep and had to be filled to the point were once the model is painted, those cheat-lines will be barely perceptible. I spent the entire day using circular cutters and scratch awls to dress up the original work. Lots of putty to fill dings errors and overly aggressive cheat-lines. Once dry the excess putty was knocked down through some spot wet-sanding, followed by careful re-scribing.

Who is John Galt?Comment

-

I missed this post, David. Thanks for reminding me.Hello David,

Thanks for your latest write up. You may remember months ago, how I asked you about Vacuum pumps and critical specs for pulling enough vacuum to de-gas silicon. You mention in your last write up how you quickly purchased from Harbour Freight a new ‘ cheaply low CFM vacuum pump’. I thought these pumps had to pull a relatively high CFM to do the job? I am confused. Could you give me the crucial specs for this pump? I have a chamber but Am still trying to get my head around the right pump.

thanks

David h

The big issue with the vacuum pump, in our applications anyway, is not how quickly it can evacuate the work, but how pure a vacuum it can produce. So, the machine is chosen based on how close it can get to a perfect vacuum. Our minimum, for the work we do -- most of it will be de-airing either mold making rubber or pulling air from a resin filled tool -- is 38-inches of Mercury. That's the magic number. Inches of vacuum, not air evacuation rate.

If the pump is too slow you buy a cheapy air-volume tank, some none-collapsible hose, a three-way valve. You hook it all up to the vacuum table. In operation you evacuate the tank before hand. It's then a simple matter to slam a vacuum to the work in seconds, not minutes. I have yet to encounter a job, even with this low CFM pump I'm currently using, that needs a volume tank buffer between pump and work.

DavidWho is John Galt?Comment

-

3 January 2020

David,

Thanks for information about the 1:72 scale US boats. I would like to ask Kevin a couple of questions about what he has in the que. Can you give me Kevin’s member id or email address.

Thanks

Ernie

Comment

-

Nope. When he wants to go public he will. He monitors this forum and others. His call, Ernie.

DavidWho is John Galt?Comment

-

Hello Again Sir:

AS I know NOTHING about Vacuum chamber workings and JUST A LITTLE of pressure pot uses. I have to ask, how easy is it to work with Vacuum pressure system and what is the actual connections that are needed between the pump and the chamber?

Maybe I`m wrong BUT it seems to me that the vacuum system is faster to work with than pressure pots.

Where do you get the vacuum chamber? Does it have to be a glass object?

Comment

-

Why are Diver's more bad-ass than astronauts? Because an astronaut will only see a maximum differential pressure of one atmosphere, but won't live long. A Diver will experience many multiples of that and (if he follows the tables) he'll be just fine.Hello Again Sir:

AS I know NOTHING about Vacuum chamber workings and JUST A LITTLE of pressure pot uses. I have to ask, how easy is it to work with Vacuum pressure system and what is the actual connections that are needed between the pump and the chamber?

Maybe I`m wrong BUT it seems to me that the vacuum system is faster to work with than pressure pots.

Where do you get the vacuum chamber? Does it have to be a glass object?

vacuum system plumbing is the same as pressurized systems, only less robust. In my world one-atmosphere is a fart in the wind. The only unique consideration with vacuum plumbing is to use flexible hoses that are of the non-collapsible type. Other than that, off the shelf fittings work fine in a vacuum system.

pressurized pots are quicker to cycle through than vacuum assisted pours for cast resin production runs.

No glass. Acrylic or Lexan bell-jar is what you want. Or a pressure pot pressed into vacuum service. Keep in mind: the larger the surface area, the more force applied (14.something per square inch!). Check Jewelry supply houses for the bell-jar (have oxygen at hand when you see the price). eBay is your friend. Vigor is one source for bell-jars.

David

Who is John Galt?Comment

-

Comment

-

Great, Thank You.

Was wondering if I could ask you for your information help?

I as well as.others have asked in the past where you got this where you got that for supplies you use in the building process.

Would you be willing to create a Master Source List of parts and their suppliers and Part numbers?

This way we can have one place to refer to to find things we need instead of always bugging you for the same thing.

For instance

O rings

1/8"I.D -- Part # Source

1/16" I.D

3/16"

Oil lite Bearings, Flange Bearings

1/8

3/16

Cup Seals

1/8

3/16

Grey Air pressure plastic hose

Hose clamps

Scribe tools

Scribe templates

Silver Solder Specs/type

Plastic Gears

Brushed Motors

For sure there are More questions out there. Could this Supply Source list be a separate Post that can be updated by you to questions from us? Oh WISE and Patient One.

Please give us your thoughts on this request.Comment

Comment