Any advice on using "industrial grade" paint on styrene models, some model builders claim the solvent used in these are too "hot" than those used in hobby grade stuffs that the plastic becomes brittle and eventually crack.

today's work

Collapse

X

-

-

Of the approximately 40,000 men who served on U-boats in WWII, it is estimated that around 28,000 to 30,000 lost their lives.Comment

-

Make it simple, make strong, make it work!Comment

-

Automotive primers work great on the styrene hulls! Been using them for years on various plastics with no problems encountered. Since Rustoleum bought out everybody else (why no Antri-Trust action by US gov't????), everything has been reformulated to be less harmful to the environment, and less nasty for styrene. Shame too, as the primer colors have been changed and are no longer correct for our boats, close, but not quite!!!Comment

-

Nice to know. Thanks.Automotive primers work great on the styrene hulls! Been using them for years on various plastics with no problems encountered. Since Rustoleum bought out everybody else (why no Antri-Trust action by US gov't????), everything has been reformulated to be less harmful to the environment, and less nasty for styrene. Shame too, as the primer colors have been changed and are no longer correct for our boats, close, but not quite!!!Make it simple, make strong, make it work!Comment

-

-

-

Hi David,

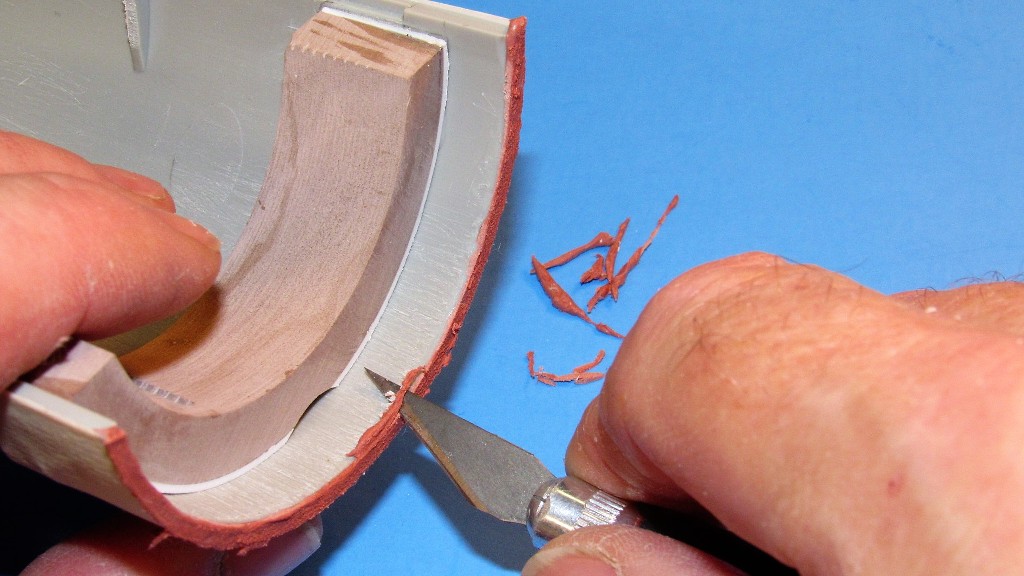

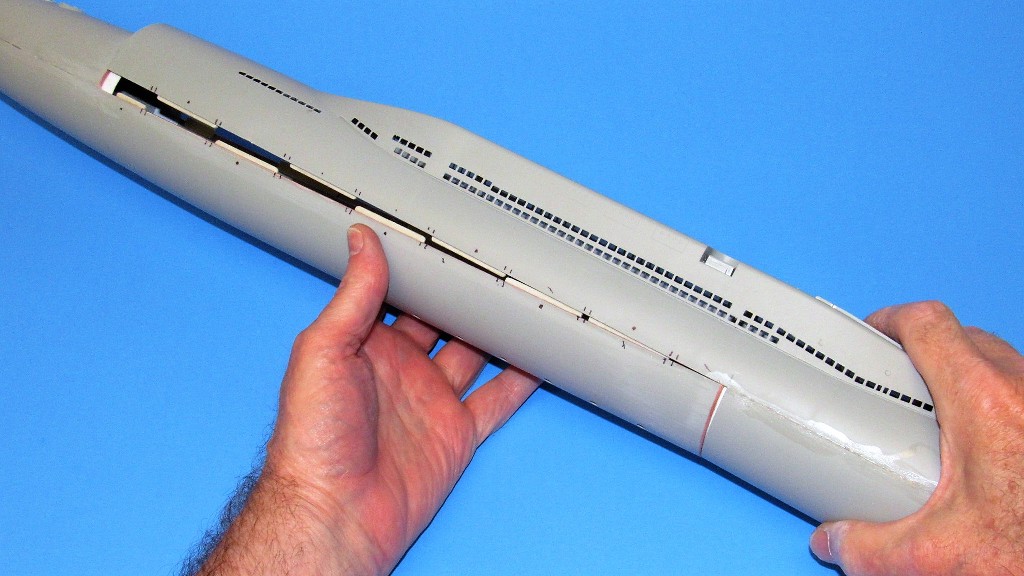

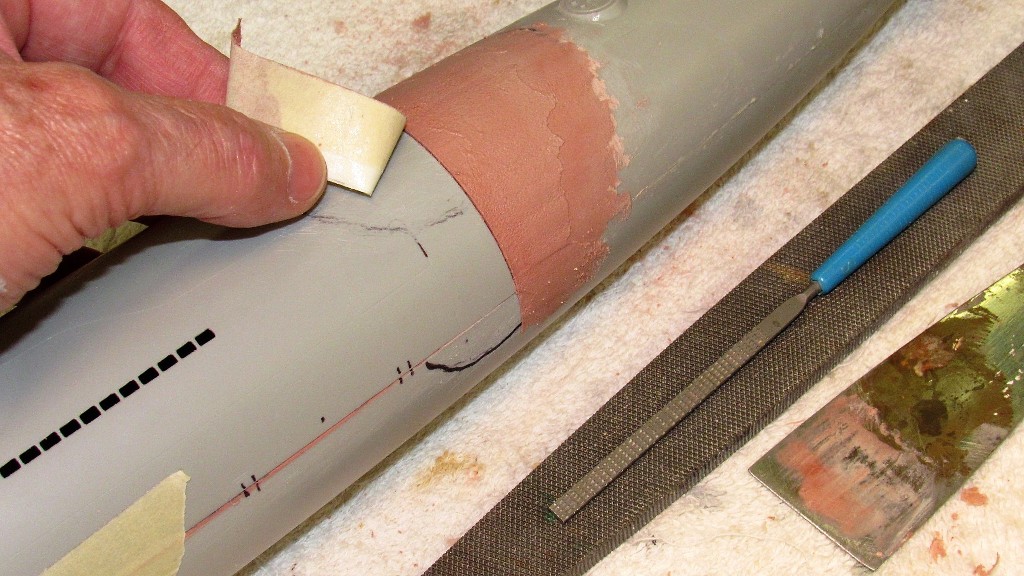

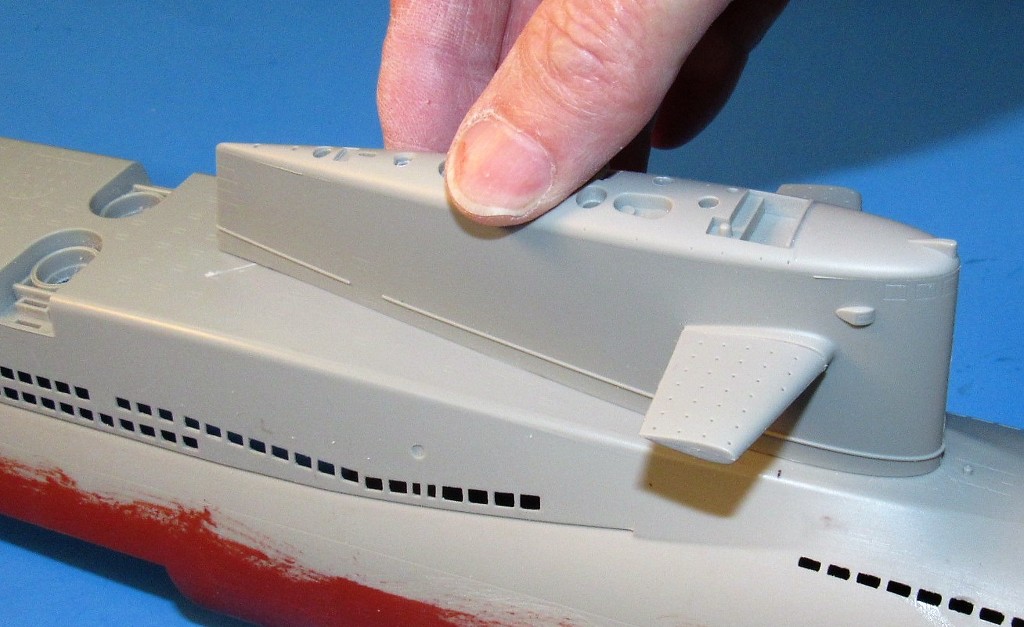

Looking at your gap filling process, you are applying masking tape as a means to dam up the Bondo to form the gap filler. After the Bondo has cured you pull away the tape and shape the Bondo, and then apply thin CA to the cured Bondo? I assume this adds more strength to the Bondo joint?

David! Now that I sort of have my feet wet in this hobby, I am going to spend some real learning time by going through all 77 pages of your "Todays Work" blog and read all your information and study every photo you have put up. I truly want to get into the real nuts and bolts of this hobby! I do have a somewhat firm foundation (2.5 years) of building submarines and some primitive scratch built WTC, but now I would like to really learn more about it.

Again, I want to thank you for all the help and information that you provide to all of us in this hobby!

Rob

"Firemen can stand the heat"

Last edited by rwtdiver; 04-01-2022, 12:32 PM.Comment

-

-

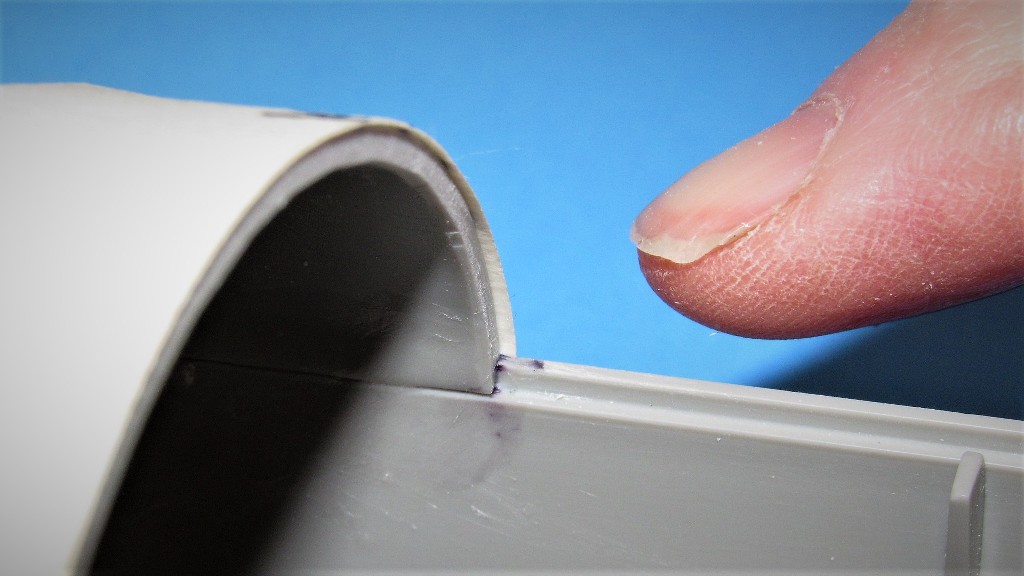

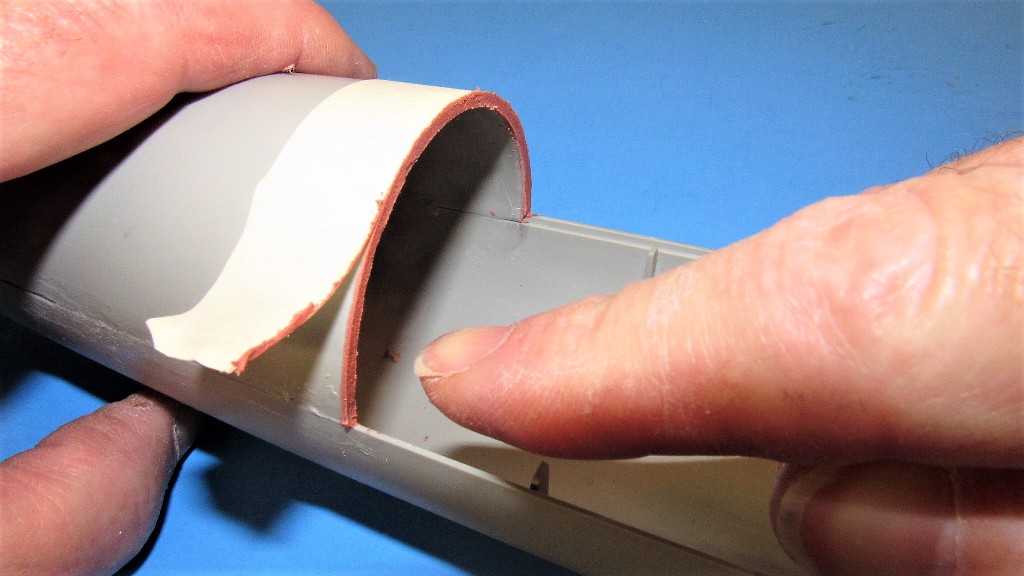

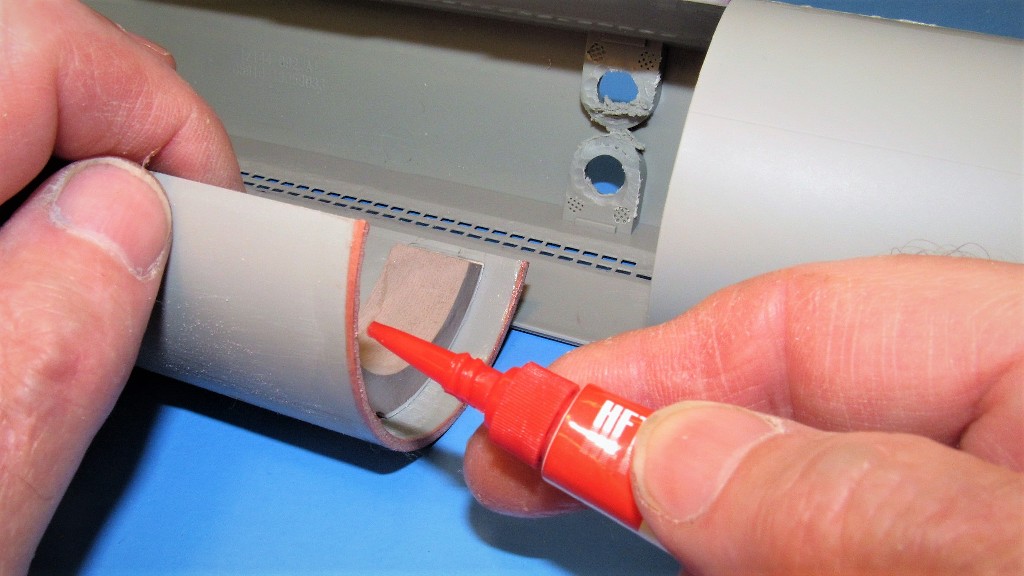

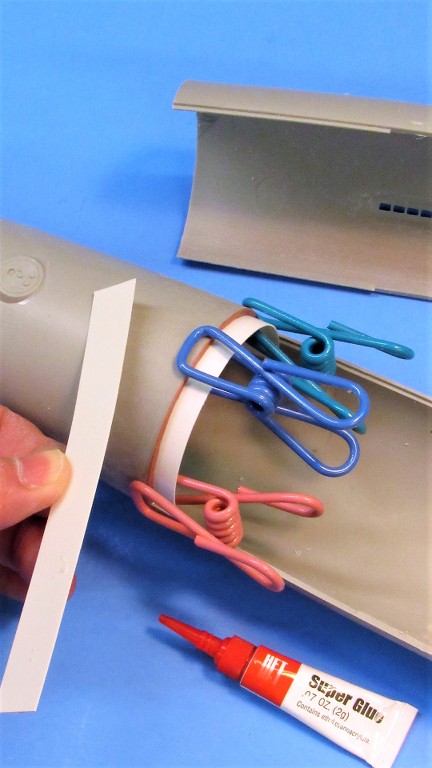

Good observation. The indexing tabs/lips are cast polyurethane, which necessitates the use of an adhesive bond over the preferred welding a cohesive provides.

Who is John Galt?Comment

-

Correct.

Cyanoacrylate is best suited for this task -- it is fast setting; easily broken away (fails readily in shear) for re-alignment/replacement; and is adequate for the job of bonding dissimilar materials which are not chemically able to fuse together at room temperature.Who is John Galt?Comment

-

-

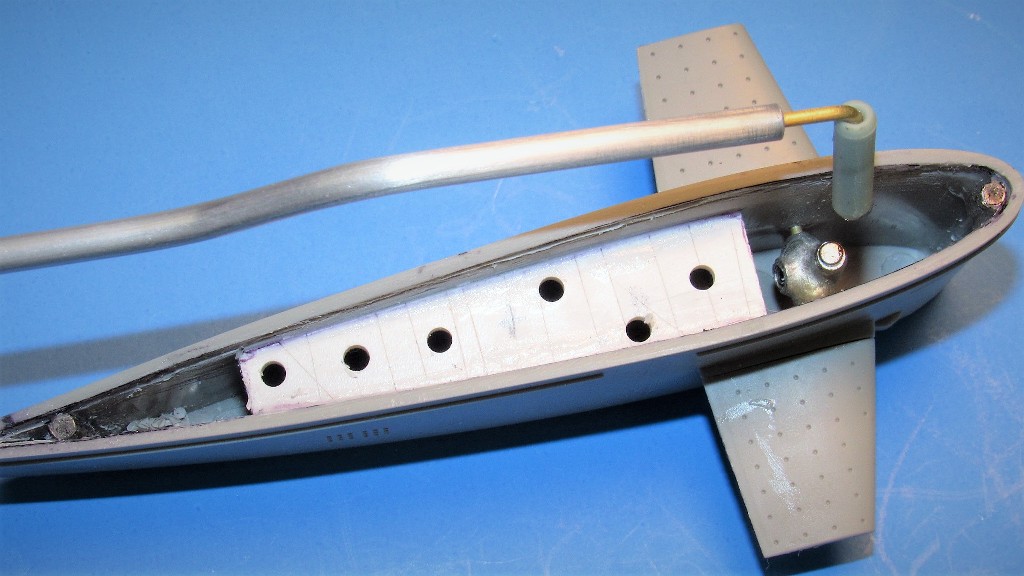

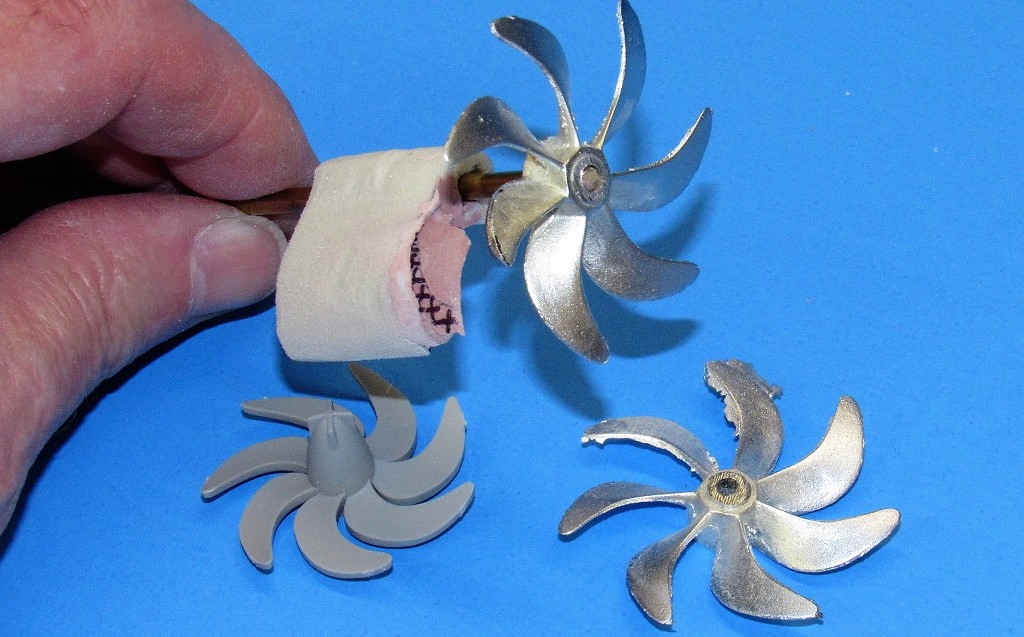

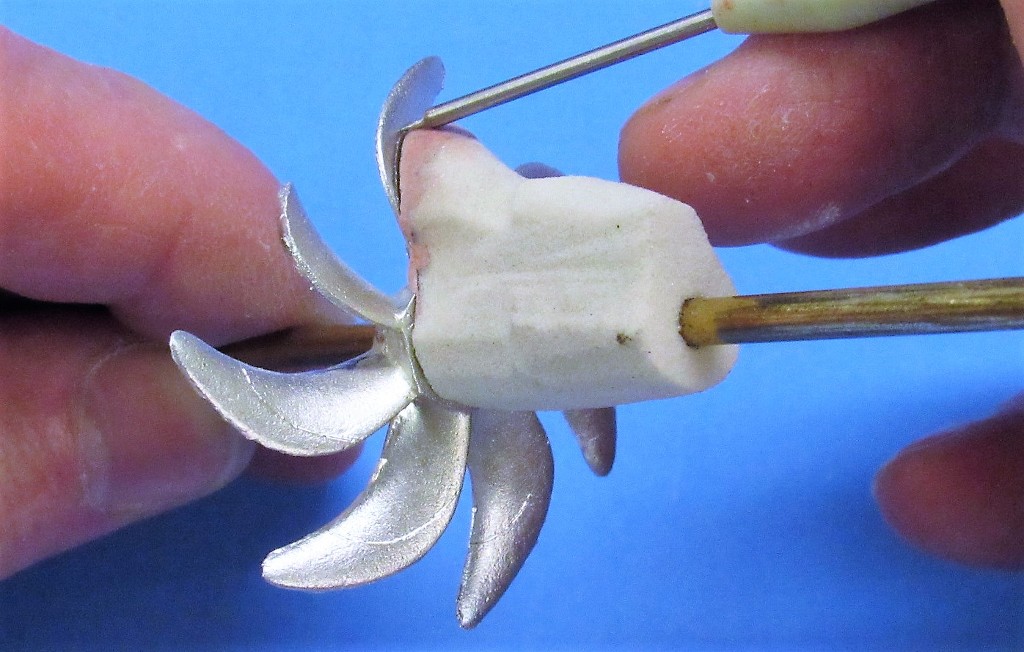

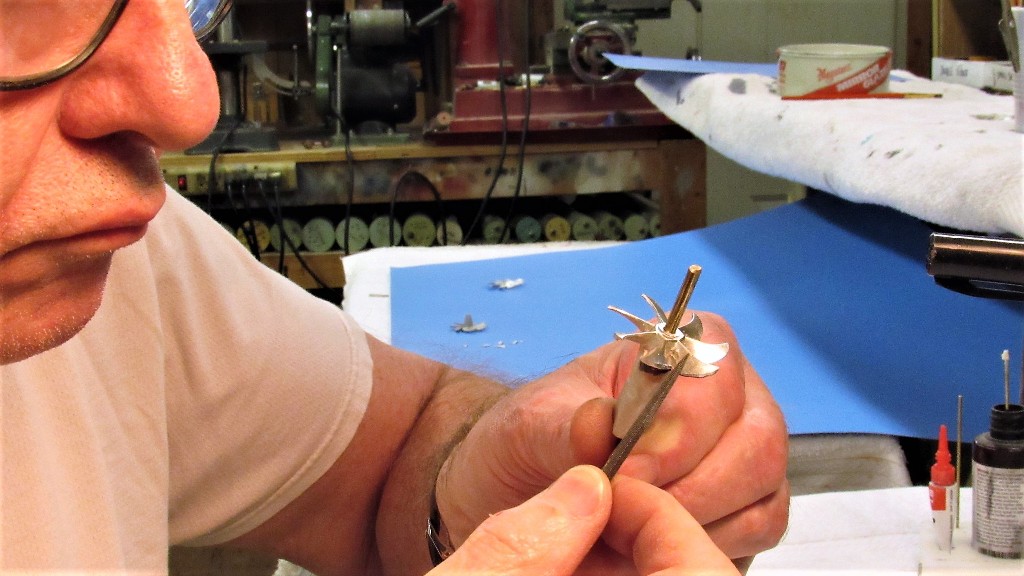

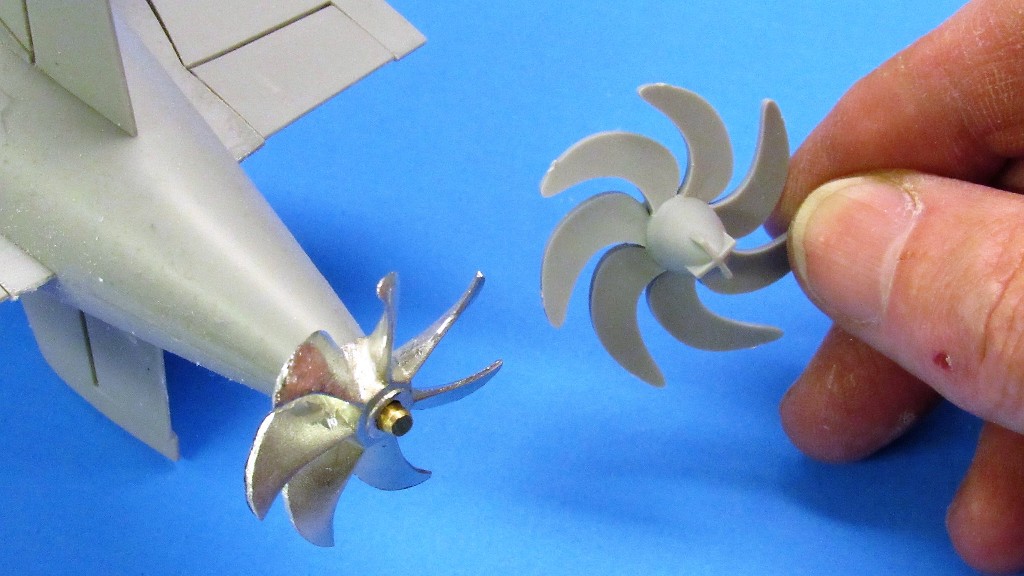

Looks like you're using a trimmed down scimitar prop from either a 1/96 German Type 212/214 or a 636 Kilo.

Is the prop meant for the 1/144th 636 version of the Kilo too small for use here?Last edited by redboat219; 04-15-2022, 04:27 AM.Make it simple, make strong, make it work!Comment

Comment