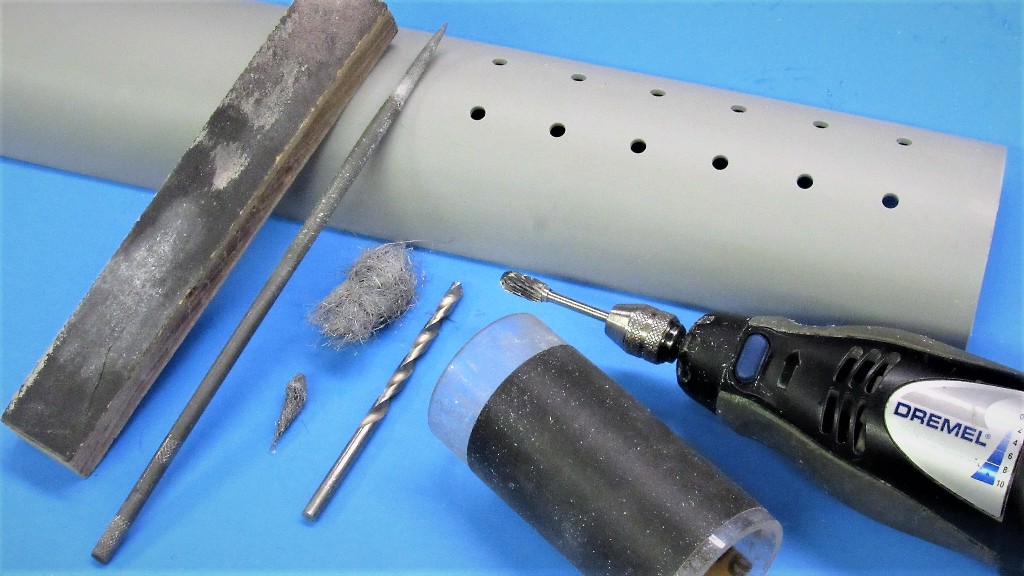

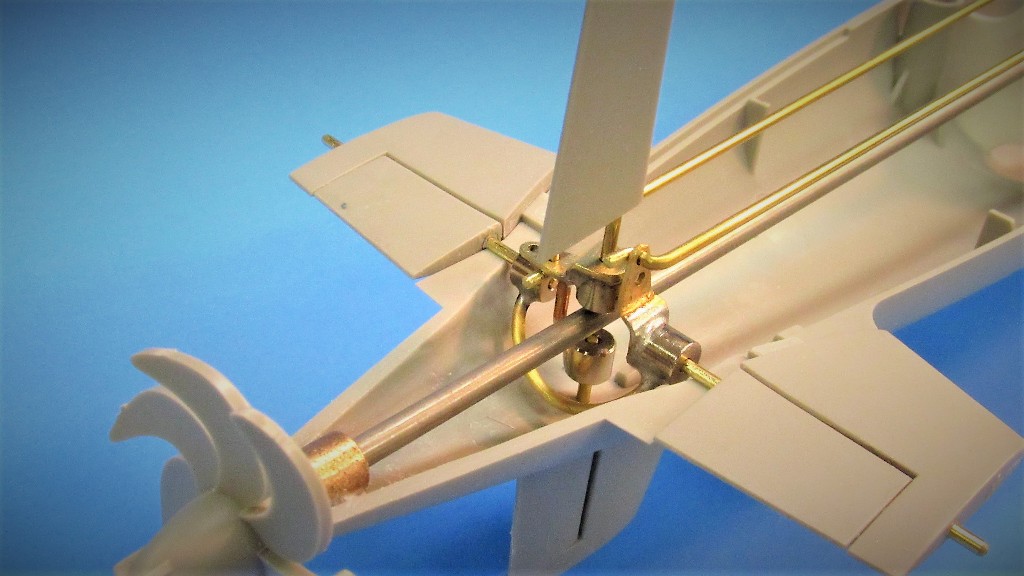

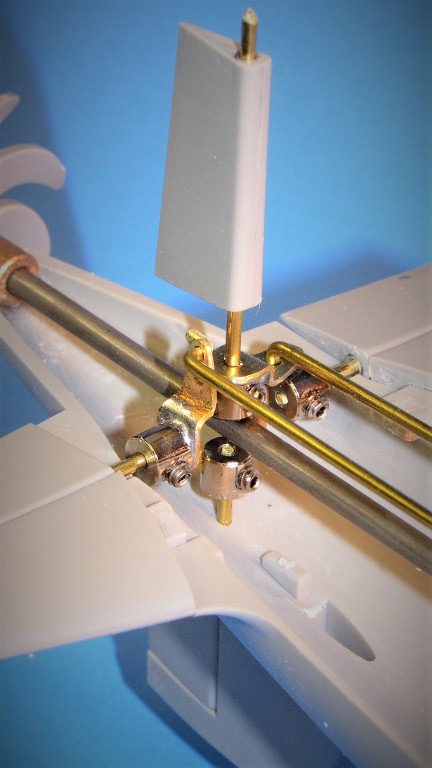

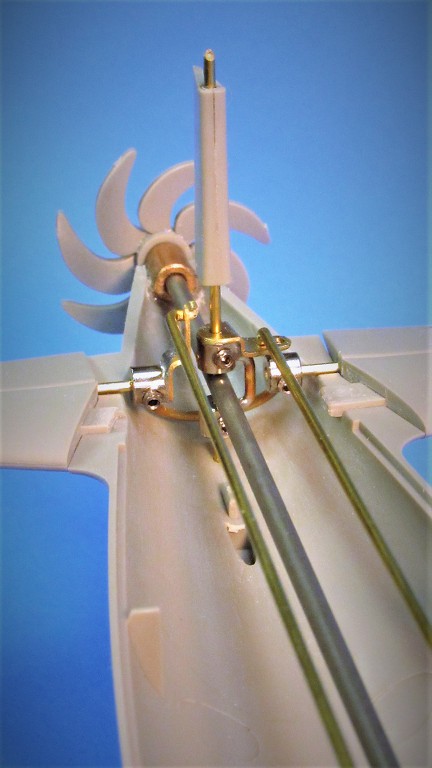

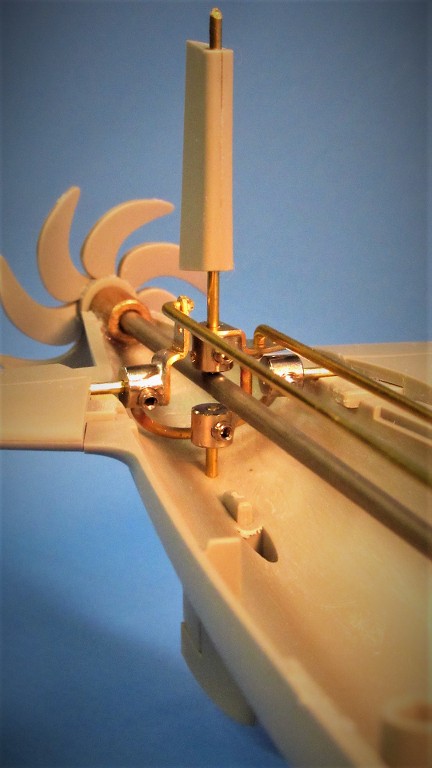

today's work

Collapse

X

-

-

-

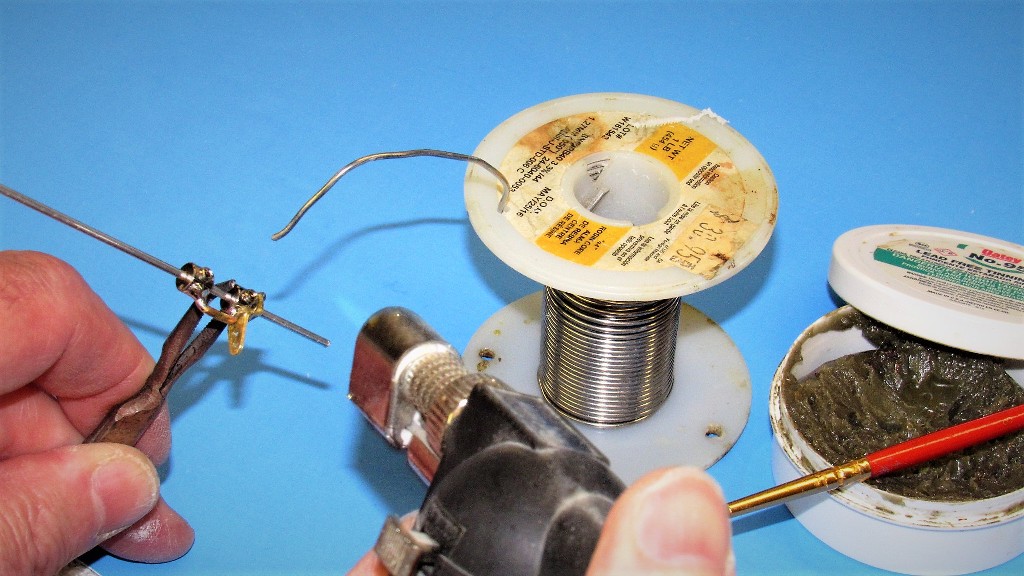

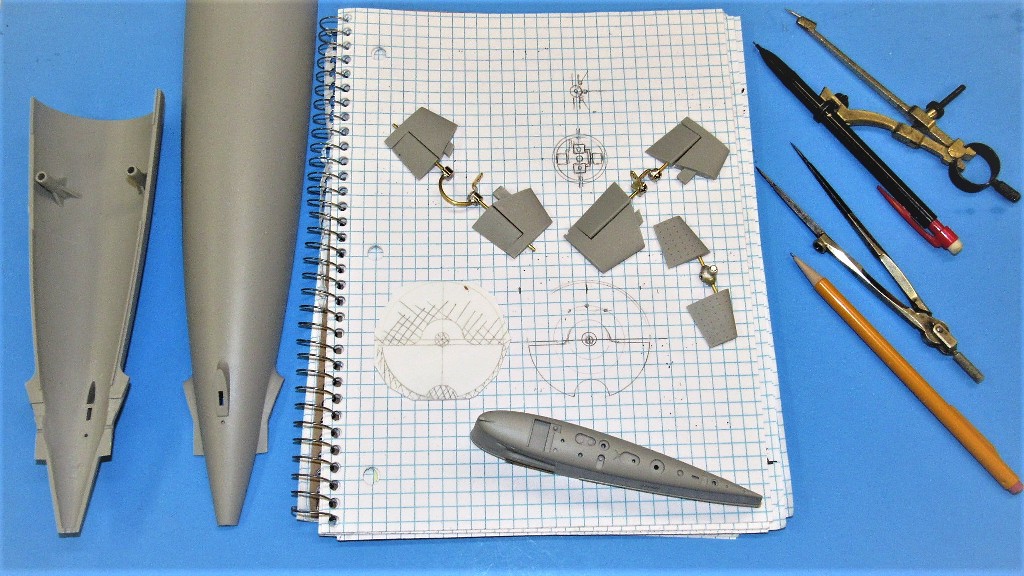

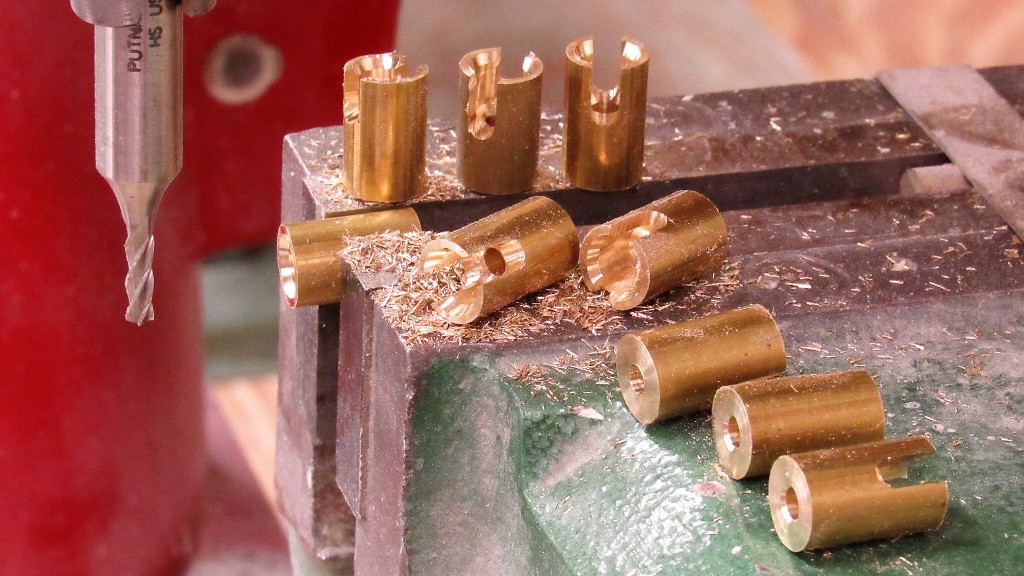

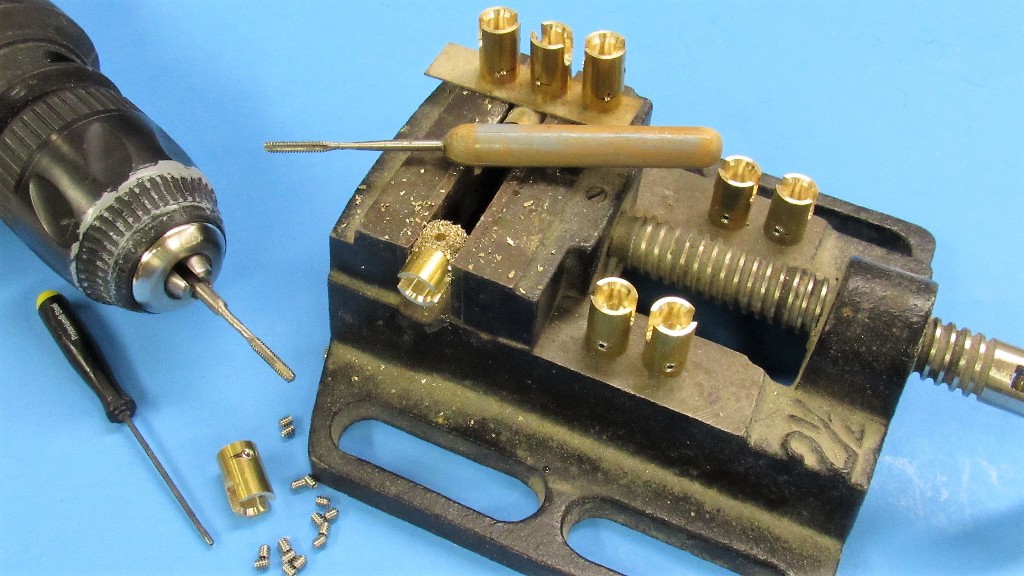

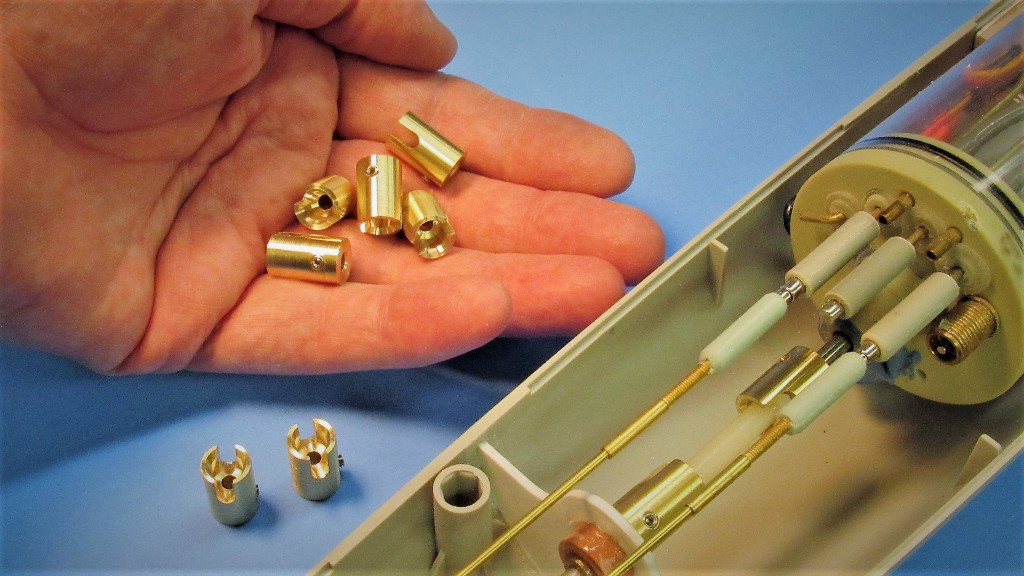

How are the shafts secured to the control surfaces?Make it simple, make strong, make it work!Comment

-

How do you secure your diveplanes to the shaft, redboat219?

Friction grip, grub screws, pins, CA glue?

Why do you ALWAYS ask questions instead of giving some insight on your own.

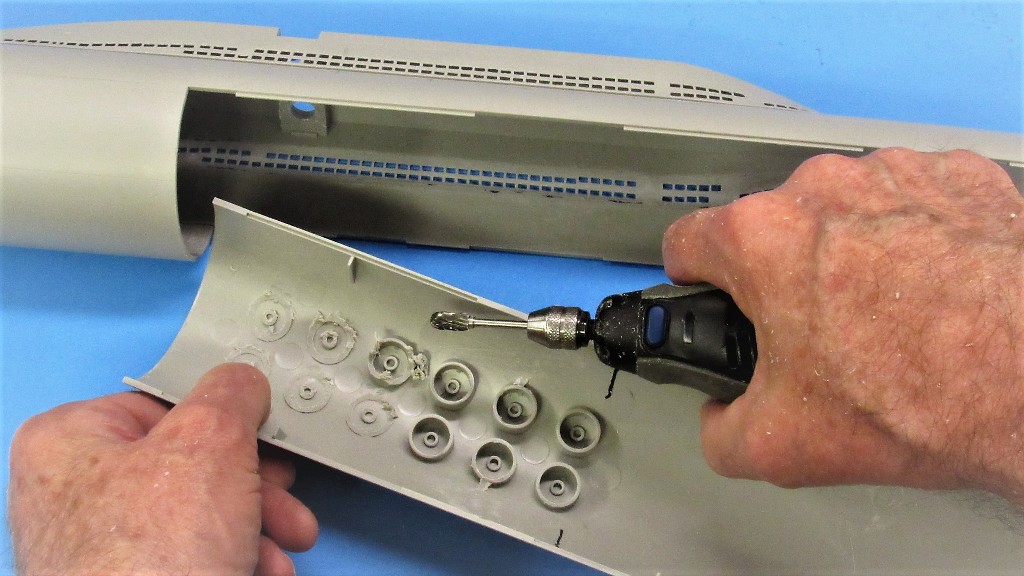

It is all in the pictures! I mean, David M. is giving us a first hand fotostory about how to convert that sub to rc.

Go get that kit and make it so!Comment

-

We can't say that asking questions is bad, what we care about is whether these questions are valuable. If you ask a question that the teacher has repeated hundreds of times in school, the teacher will be very annoyed. From 2005 to now Mr. Merriman has posted thousands of pictures on the forum, showing in detail various methods and techniques of making submarines. Even if some visitors to the forum who can't read English, just by studying the pictures posted by Mr. Merriman and then practicing a lot, I believe they won't ask so many questions.Comment

-

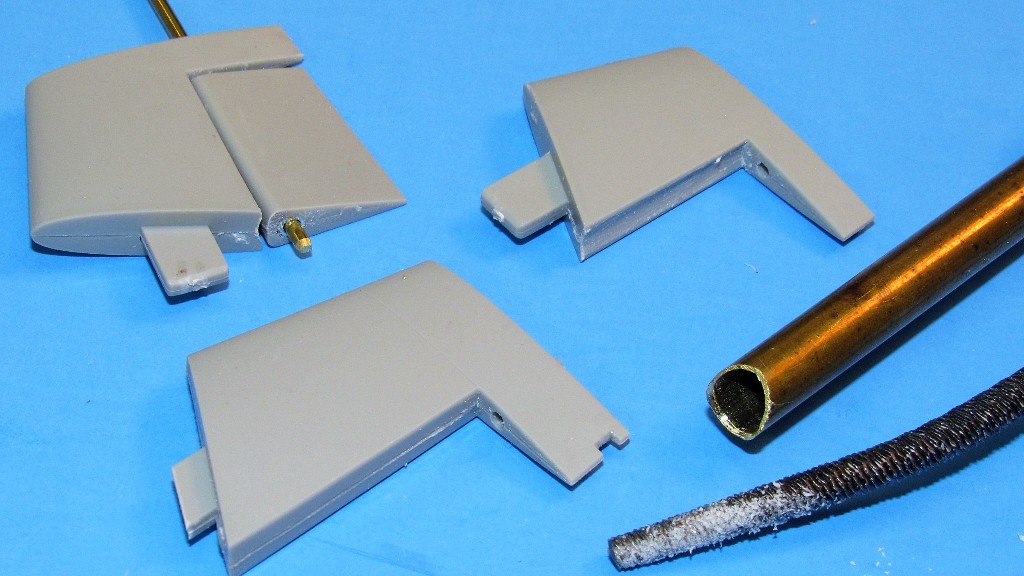

What's in the picture? All I see is a brass rod that slides inside an aluminum tube with no signs of positive locking.Make it simple, make strong, make it work!Comment

-

-

Comment

-

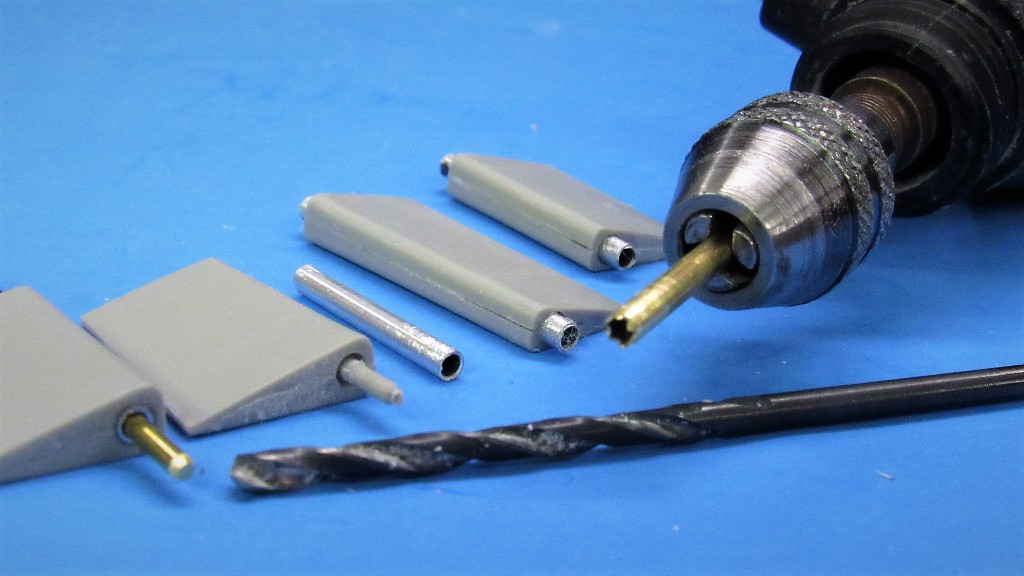

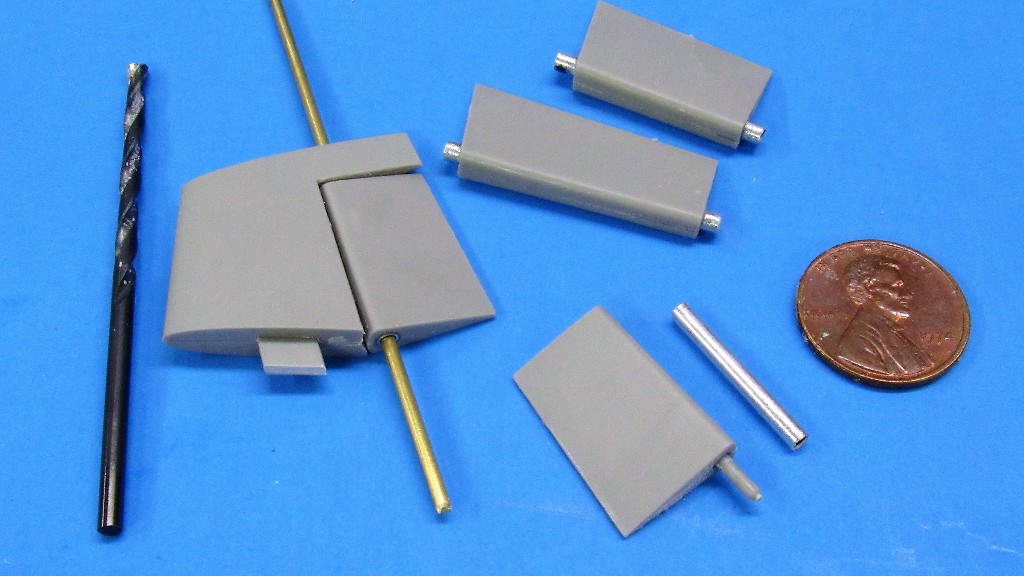

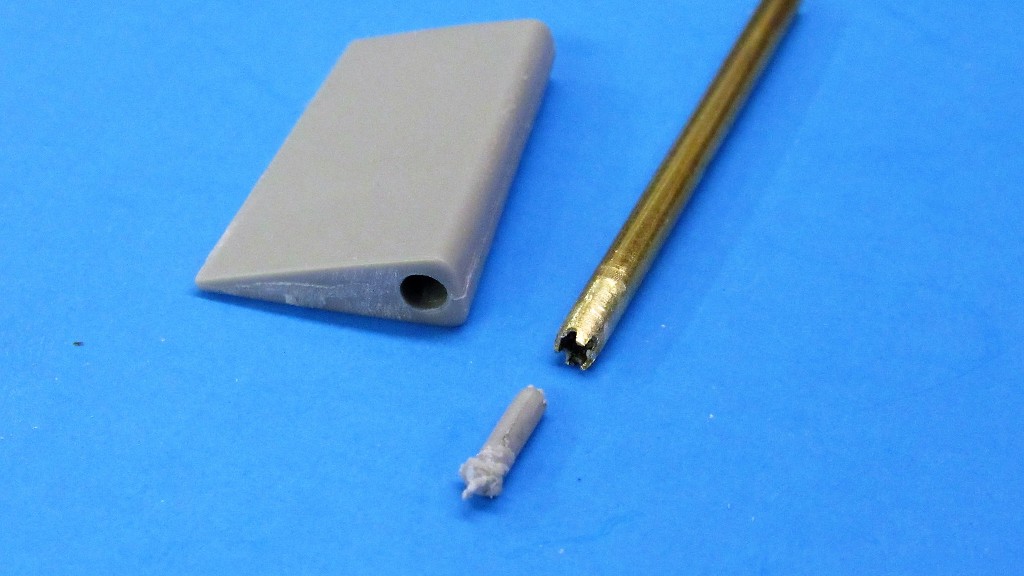

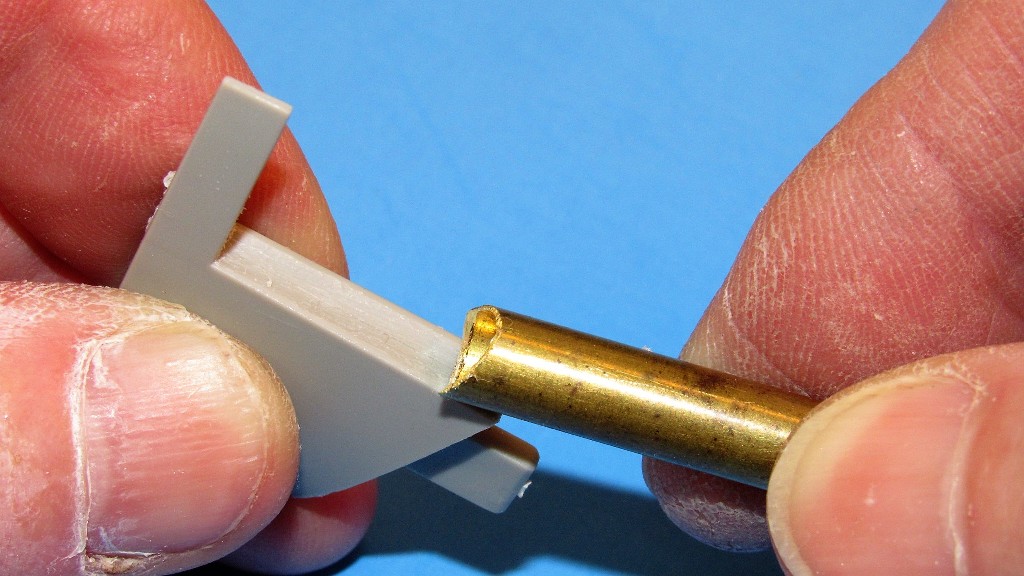

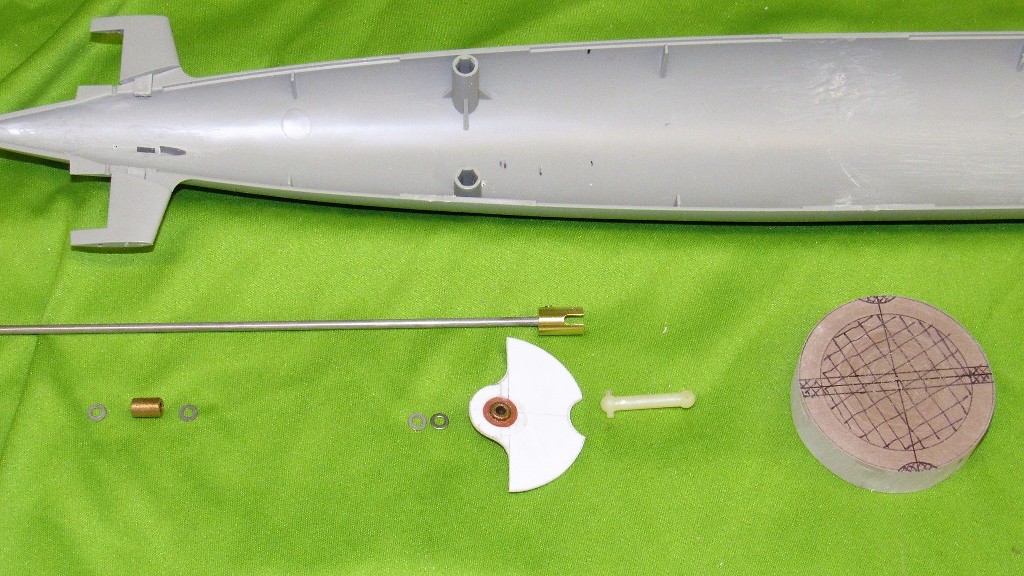

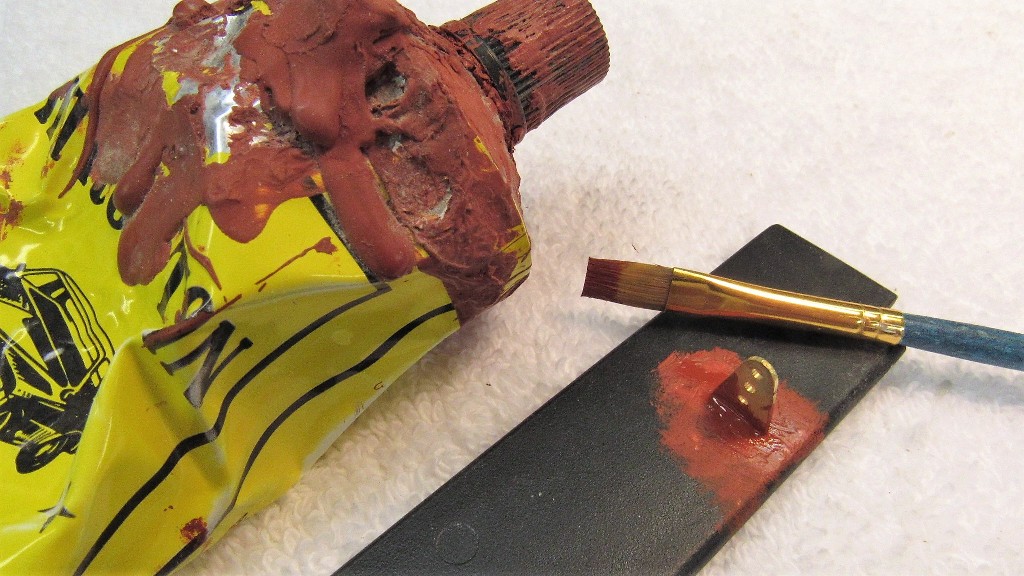

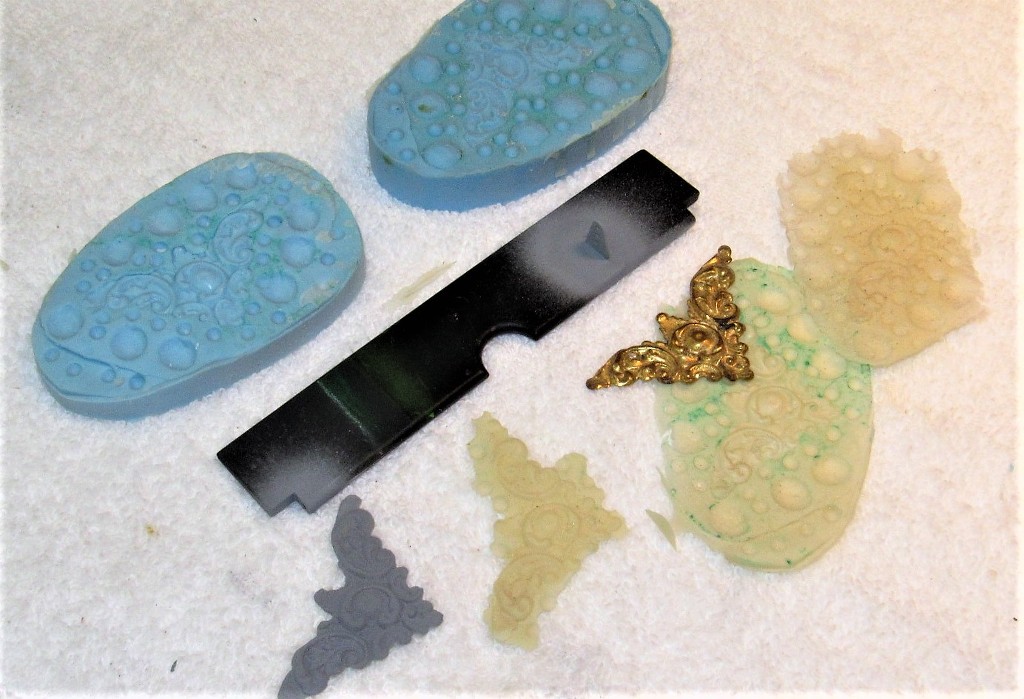

Right now the operating shafts are loose fits to the aluminum tubes glued within the control surfaces. A model this small does not present enough 'meat' on the control surface to make a securing set-screw a practical means of making the control surface rigid to its operating shaft. Before final assembly (long after the painting and weathering is completed, but before sea-trials) I'll dope the inside of the aluminum tube bores with some thin formula CA which will create a strong friction fit to the operating shafts. Anyway... that's the plan. Stay tuned for how that turns out.

DavidWho is John Galt?Comment

-

Quote: "I'll dope the inside of the aluminum tube bores with some thin formula CA which will create a strong friction fit to the operating shafts."

Nice!

I always thought a friction fit would work. My thought was to use silicone. And if the planes/rudders got bumped it would allow it to move. Then could be twisted back into position.

No actual tests have been done. So like the news slingers we will not verify if its true.Comment

-

I've tried that but found that once 'broken' the silicon bond (former bond) just let the control surface to rotate wild to the operating shaft. Hense my upcoming attempt with the CA.Quote: "I'll dope the inside of the aluminum tube bores with some thin formula CA which will create a strong friction fit to the operating shafts."

Nice!

I always thought a friction fit would work. My thought was to use silicone. And if the planes/rudders got bumped it would allow it to move. Then could be twisted back into position.

No actual tests have been done. So like the news slingers we will not verify if its true.

(And while trying to nap a few hours ago I thought up a scheme to get the operating shaft out of the aluminum tube if I had to take something apart. It came to me: make the operating shaft a tube instead of a rod and if I have to weaken the CA for extraction, just heat a brass rod that will fit the tube. Heat the rod externally to a red heat, then jam into the tube (operating shaft) and let the conducted heat bust the CA bond between operating shaft and aluminum tube).

Damn... I'm good!

DavidWho is John Galt?👍 1Comment

-

-

Comment