today's work

Collapse

X

-

Comment

-

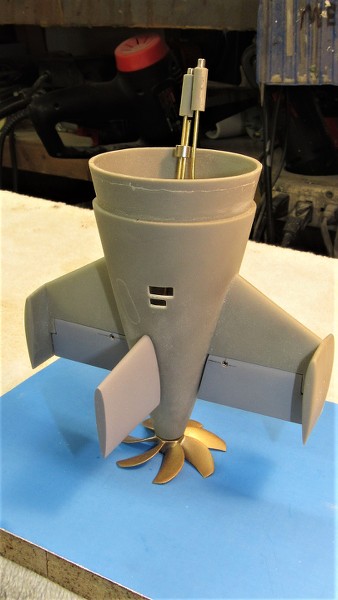

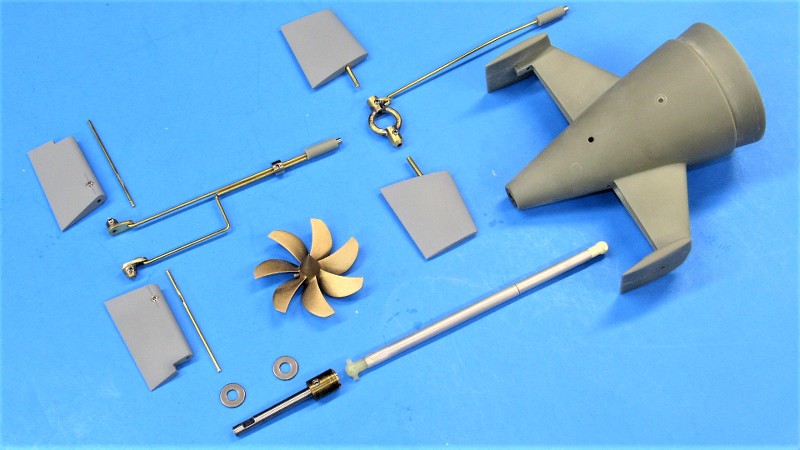

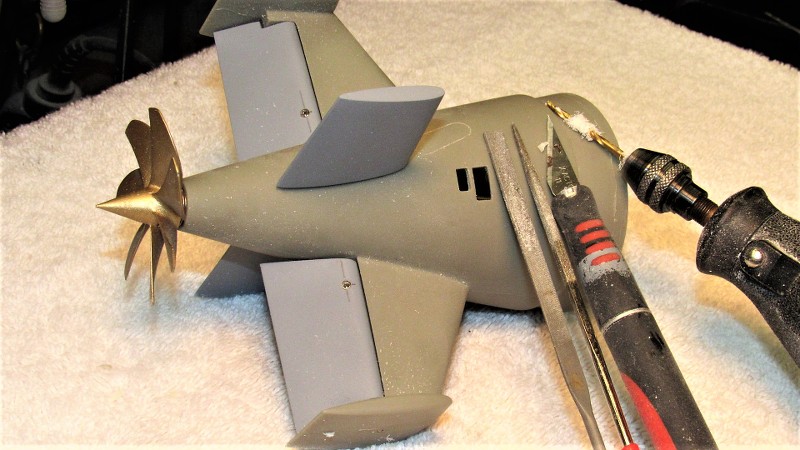

Though the tail-cone proper is a production cast resin part, the other parts -- stern planes, rudders, yoke, and stern plane bell-cranks -- are masters. I've mixed things up as an expedient, just to verify a non-interference fit of everything when assembled and that it works as intended. That done the masters are set aside for finishing and eventual tool making and the tail-cone readied for joining to the lower hull.

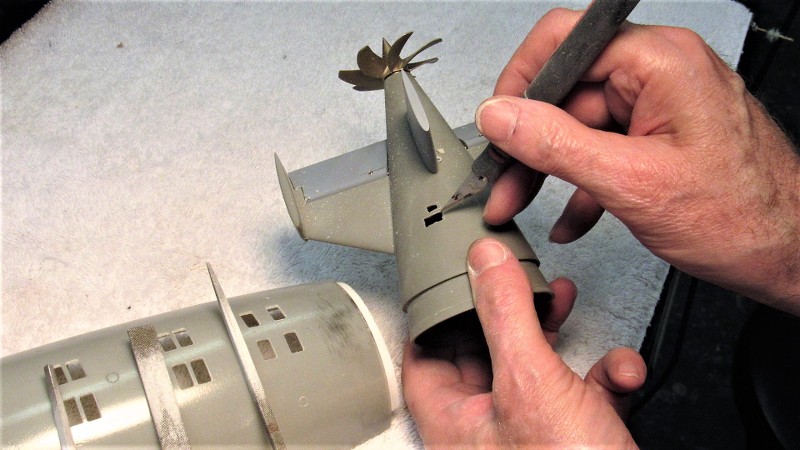

Note how the two stern plane pushrods are ganged together to work in unison. The union is made with a wheel-collar -- a solid union and is adjustable. Magnetic couplers at the forward end of the stern plane and rudder pushrods make up to the SubDriver servo output shafts through another set of magnets. No back-lash and little effort required when adjusting, servicing, or removing the SD.

These two photos illustrate the tight confines at the stern of the tail-cone. Now you can get some appreciation of the difficulty I encountered making for a non-interference fit between propeller shaft, intermediate propeller shaft, rudders, and stern planes. Note how I've put a little rudder on to show how the rudder yoke toroid gives clearance to the centrally running propeller shaft (not installed in these pictures for clarity).

The cast resin tail-cone, as any raw, out-of-the-box resin or GRP production part, was scrubbed with abrasives (greenie pad or steel-wool) saturated with lacquer thinner. This to remove all part-release oils and to also slightly scratch the parts surface to enhance adhesion of parts and primer.

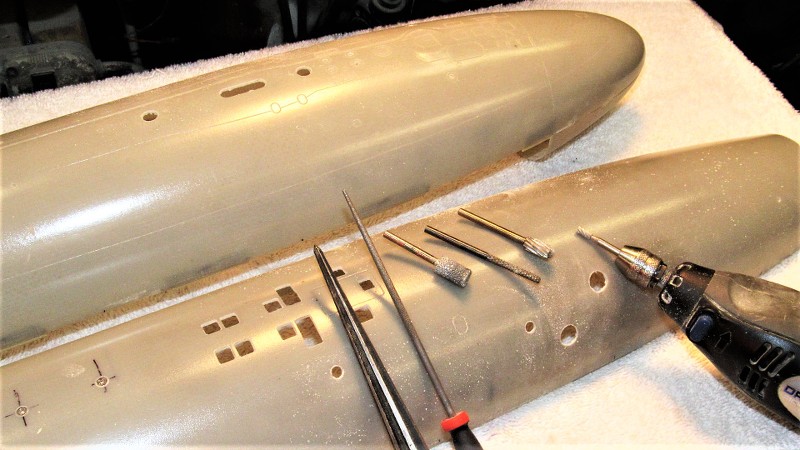

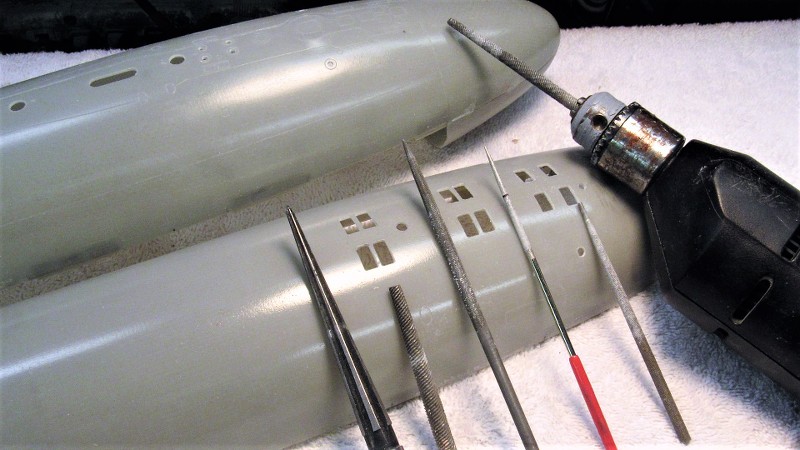

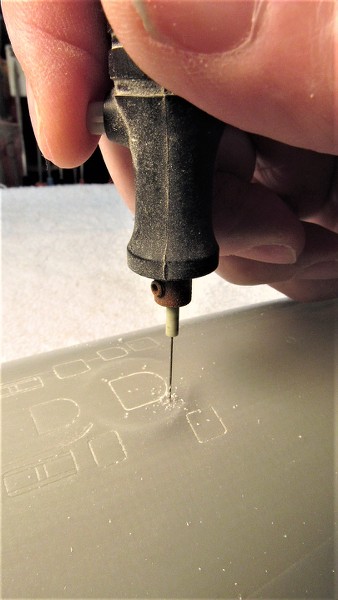

Before permanently bonding the tail-cone to the lower hull I drilled, cut, and ground open the many square and round holes into the hull and tail-cone. These openings, permitting free-flooding and draining of the hull and they represent ballast tank flood-drains, main sea water and auxiliary sea water intakes and discharges, sea sensing ports, and main ballast tank vents.

Black linseed oil paint was smeared on the hull halves and wiped off to highlight the engravings. This visual aid helped me keep within the lines as I ground, drilled, hand-milled, filed, and sanded the openings.

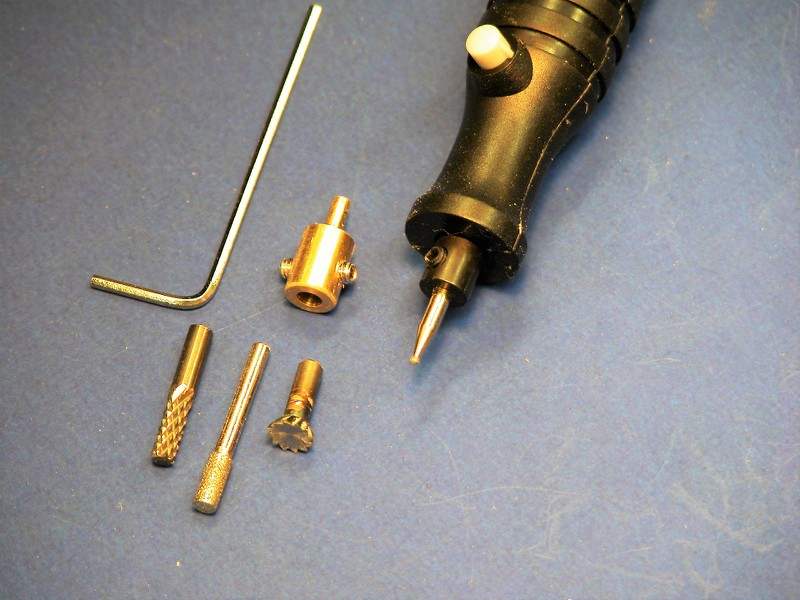

I employed a modified engraving tool -- converted into a high-speed, low torque drill motor -- to drill the very small holes near the foreword and after trunk hatches. These holes would later accept loops of small gauge wire to represent DSRV hold-down padeyes.

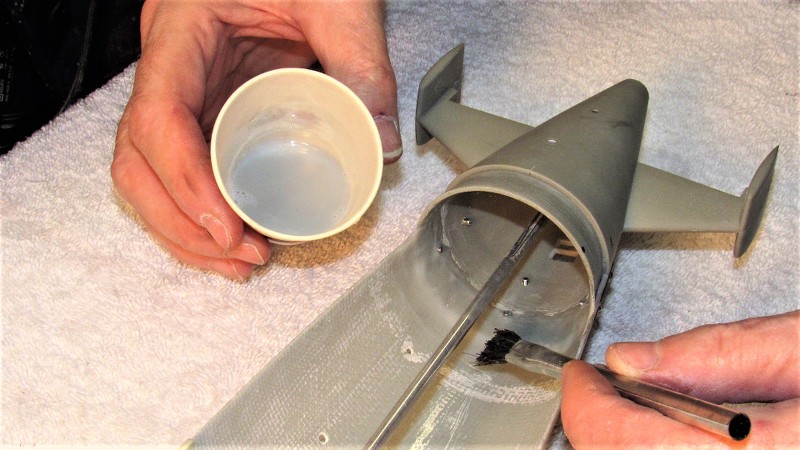

Three brass straps are used to hold the tail-cone to the stern of the lower hull. Epoxy resin is used to adhere the two structures together. The objective is to get the propeller shaft centerline running along the centerline of the hull. The pictures tell the story.

Who is John Galt?Comment

-

The fruits of all your hard work coming together as planned. Beautifully done and well executed. I hope you’re keeping this first build for yourself.Comment

-

-

David, I'm looking for a thread of yours on painting models. I started looking thru the WMU thread of what I did today, still have many pages to view to find what I'm looking for. To save time, you have links to painting submarines?

BTW, to make your head swell more from what Tom said, paging thru the what I did today, just awesome what you do!Comment

-

I have no idea how to search this site for WIP's. I'm not that computer savvy. Anyway, I assume Bob will index and re-arrange things when time permits.David, I'm looking for a thread of yours on painting models. I started looking thru the WMU thread of what I did today, still have many pages to view to find what I'm looking for. To save time, you have links to painting submarines?

BTW, to make your head swell more from what Tom said, paging thru the what I did today, just awesome what you do!

I do know this: somewhere in the Colossus-Guardian complex (AKA Nautilus Drydocks), protected by walls of intensified Gama radiation is a ****-load of my best works awaiting discovery by those who wish to better practice this craft of ours. It's in there, we just can't get at it right now.

So, In the interim, if there's a specific painting question I can help you with, post it here and I'll address it... yet again.

Who is John Galt?

Who is John Galt?Comment

-

-

Hi David sorry to hack your thread.

I was so bored with the production work I started the development of a new sub to get my brain up and running again. The V III will be finished just needed a break.

I run into an issue for the control of the propeller nozzle, the struts of the nozzle are quite narrow to take any linkage, my intention is to tale the linkage external of the hull. I need a second opinion on that. Is it possible I prep a prototype of the stern and sent it to you to have a look at possible solutions?

No is also an answer, no problem.

Grtz,

BartLast edited by bwi 971; 02-21-2021, 03:19 PM.Practical wisdom is only to be learned in the school of experience.

"Samuel Smiles"Comment

-

Unlike so many others, you actually get the work done. Physical accomplishment, not just talk, is the coin of the realm in my world -- you always come up with the goods.Hi David sorry to hack your thread.

I was so bored with the production work I started the development of a new sub to get my brain up and running again. The V III will be finished just needed a break.

I run into an issue for the control of the propeller nozzle, the struts of the nozzle are quite narrow to take any linkage, my intention is to tale the linkage external of the hull. I need a second opinion on that. Is it possible I prep a prototype of the stern and sent it to you to have a look at possible solutions?

No is also an answer, no problem.

Grtz,

Bart

I would be delighted to serve in any capacity you think I can help. Let's see this Gizmo of yours, Bart.

DavidWho is John Galt?Comment

-

Thanks David!

As you are a “Luddite” I must worn you the prototype will have been pooped out by a machine. Take some allergy medication prior and were full PPE during unboxing.

Planned to finish the prototype end of the week.

Grtz,

Bart

Practical wisdom is only to be learned in the school of experience.

"Samuel Smiles"Comment

-

Comment

Comment