today's work

Collapse

X

-

-

If you can cut, drill, saw, hit things and swear a lot, you're well on the way to building a working model sub.Comment

-

In this case it's ALL about working out a goof-proof holding fixture to secure the work as you saw away at it. 80% of a good job is selecting the right material, tools, and process. The work itself is the easy part.

DavidWho is John Galt?Comment

-

DISASTER!

Three days after splitting the top from the bottom of the 1/96 3D printed Type-21 hull I find both halves warped significantly, radially and longitudinally. FUBAR!

I've seen phenomenon like this with round and box cross-sectioned extruded tube stock. Seems the manufacturing process, with the unequal temperature dissipation after extrusion, causes internal stress that only relieves itself once the structure is split longitudinally.

Any Material Engineers want to jump in here? Thoughts? Suggestions? Accusing finger pointing in my general direction?...

Anyway, the model is ruined.

Here's the plan: get another three-piece Type-21 off the darned machine, just like this poor thing cluttering up my shop (and for god's sake, this time make it at least a .070" wall). I'll glue the sections together as before. But, this time, I make a proper glove-mother mold from which to produce proper GRP hulls -- as Nature, in her infinit wisdom, would have it. Not this good-time-Charlie, quick, no-brains-involved robot Replicator crap.

DavidWho is John Galt?Comment

-

Well that sucks. Sorry to hear this happened.DISASTER!

Three days after splitting the top from the bottom of the 1/96 3D printed Type-21 hull I find both halves warped significantly, radially and longitudinally. FUBAR!

I've seen phenomenon like this with round and box cross-sectioned extruded tube stock. Seems the manufacturing process, with the unequal temperature dissipation after extrusion, causes internal stress that only relieves itself once the structure is split longitudinally.

Any Material Engineers want to jump in here? Thoughts? Suggestions? Accusing finger pointing in my general direction?...

Anyway, the model is ruined.

Here's the plan: get another three-piece Type-21 off the darned machine, just like this poor thing cluttering up my shop (and for god's sake, this time make it at least a .070" wall). I'll glue the sections together as before. But, this time, I make a proper glove-mother mold from which to produce proper GRP hulls -- as Nature, in her infinit wisdom, would have it. Not this good-time-Charlie, quick, no-brains-involved robot Replicator crap.

David

If there is access to the original print files, it may be possible to split the model in computer land before it is printed. I can Email you my phone number if you want to explore some options in more depth.Comment

-

Very kind of you, Nick. And, I might take you up on that later. Right now I'll take a rain-check on that generous offer, sir.

The robots got my number, they're out there now, hiding in the bushes, aiming their pulse-riffles at my house, I can see their red eyes gleaming behind their synthetic skin!

It's ON!...

GRP or bust.

In the words of John Belushi: "This. Means. War!!!!"

David

The Horrible

Who is John Galt?Comment

-

Anytime Sir.

Very kind of you, Nick. And, I might take you up on that later. Right now I'll take a rain-check on that generous offer, sir.

The robots got my number, they're out there now, hiding in the bushes, aiming their pulse-riffles at my house, I can see their red eyes gleaming behind their synthetic skin!

It's ON!...

GRP or bust.

In the words of John Belushi: "This. Means. War!!!!"

David

The Horrible

That hull in grp would make for a great long lasting boat.

Nick

👍 1Comment

-

Like when the Germans bombed Pearl Harbor?

Very kind of you, Nick. And, I might take you up on that later. Right now I'll take a rain-check on that generous offer, sir.

The robots got my number, they're out there now, hiding in the bushes, aiming their pulse-riffles at my house, I can see their red eyes gleaming behind their synthetic skin!

It's ON!...

GRP or bust.

In the words of John Belushi: "This. Means. War!!!!"

David

The HorribleOf the approximately 40,000 men who served on U-boats in WWII, it is estimated that around 28,000 to 30,000 lost their lives.Comment

-

EGGZACTLY!

BlutoWho is John Galt?Comment

-

A few common 3D printing materials are listed below.

Photosensitive resin (UV) 3D printing (SLA) is more accurate and has a smoother shell, but it is obviously not suitable for RC boat models. This resin reacts in the air from the very beginning of 3D printing and can easily become brittle over time, which we don't like. So I had suggested Bob spray the outboard and interior of the 3D printed submarine with a coating like polyurea, which is used to insulate water and air, while different styles of polyurea have different hardnesses, from soft to extra hard. Polyurea is a poor conductor of heat and can withstand extreme cold and heat to protect the hull of the submarine. There is an interesting experiment: when the watermelon was coated with polyurea and then thrown from the 10th floor, the watermelon shell (polyurea coating) was intact and even bounced up when it hit the ground. When the polyurea coating was sawed off, the watermelon was crushed.

PLA or PETG is also a common printing material, cheap and very good, but PLA material is not heat and UV resistant. In contrast, ABS is better. But ABS in the printing process for the temperature control requirements are very strict(Not very stable thermally), so it may be easy to make the board distortion (if the board is too thin). To sum up, ABS we try to print some large, thicker things.

VLast edited by Sam Victory; 12-05-2021, 03:09 AM.Comment

-

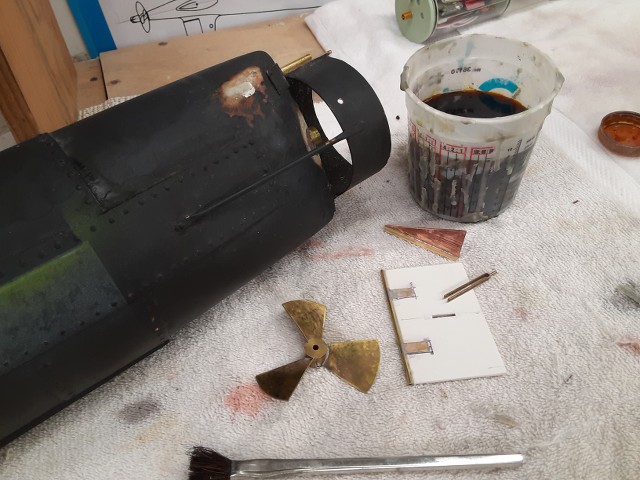

The HUNLEY is finally at that point where I can address some of the broken detail items and prepare the model parts for paint. Here I'm soldering together the broken off forward 'cut-water' that sat just forward of the forward access hatch/conning station.

Before any filler, putty, or priming the entire model was scrubbed with a mild hydrocarbon solvent to free the surfaces of any oil or other contaminants that would otherwise inhibit adhesion of the above mediums.

All raw metal parts that were to later receive primer and paint were first pickled with Ferric chloride acid, rinsed in fresh water spiked with a bit of baking soda, then thoroughly dried.

Where needed air-dry touch-up putty was applied and later wet sanded smooth.

Though no longer commercially engaged in the sale of water tight cylinders (WTC), I do have a wall full of uncompleted models that will eventually need a cylinder to make them operational. I recently sat down and banged out ten single-shaft WTC's for those upcoming projects.

The motor-bulkheads are two-piece, cast resin units that contain a 3:1 gear reduction; three water tight seals for 1/16" diameter pushrods; a 3/16" output shaft with water tight seal; antenna lug; pass-through nipples for ballast induction and discharge air; and an equalization valve.

Attached to the dry side of the motor-bulkhead is an aluminum and resin device tray and bulkhead upon which will be placed the servos, receiver, low pressure blower, angle-keeper and other devices needed to make the model submarine operational.

Sheet-metal work on display. Here I'm using templates to lay-out the aluminum parts.

Once the aluminum parts are cut to outline they are bent to shape in this poor-man's break I use for thin gauge metal work.

The metal-to-metal attachments are made with pop-rivets.

WTC's awaiting assembly. As I near completion of a model I will select a cylinder of the desired length and take it to completion, populate it with the devices and battery needed, and get that model operational. That's the plan... if the creek don't rise, that is.

Who is John Galt?

Who is John Galt?Comment

-

David,

I am really looking forward to seeing the finished Hunley. I just know it will be a real authentic looking boat, not only in structural accuracy, but also your finish work. I am very pleased you are sharing your project with us as well.

Rob

"Firemen can stand the heat"Comment

-

Score with several passes of a heavy X-Acto blade, then bend slightly on a break, back-and-forth, till it fatique cracks and splits. Tin-snips and a 'nibbler'

tool for inside cuts and curves. I'll use the band saw only for starting inside cuts and to spin-cut circular items like the bulkheads and constant radius curves.

David

Last edited by He Who Shall Not Be Named; 12-17-2021, 12:38 PM.Who is John Galt?Comment

Comment