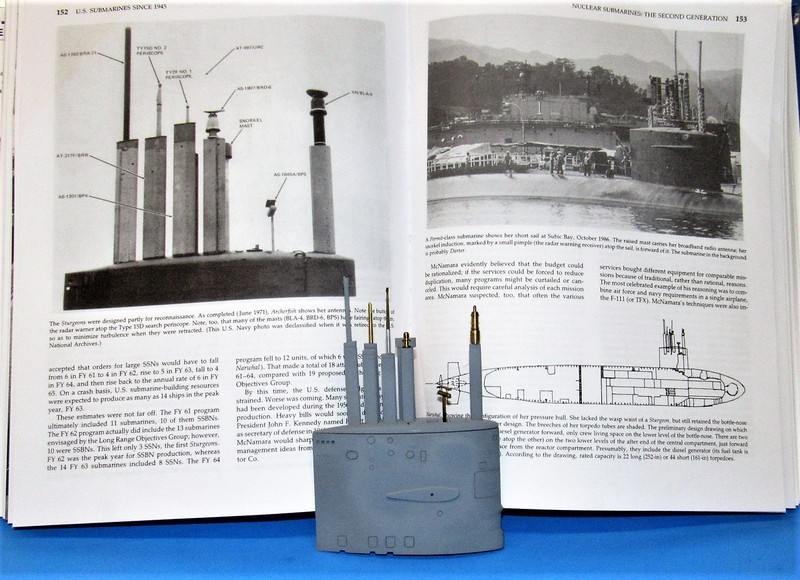

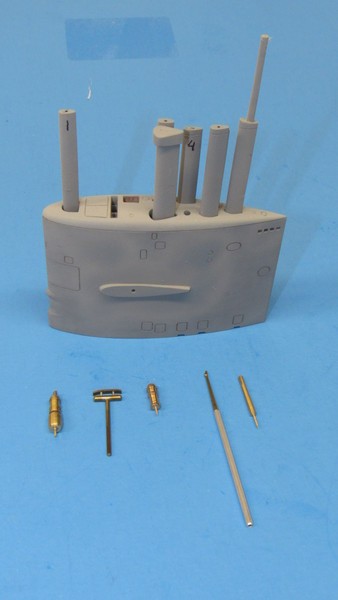

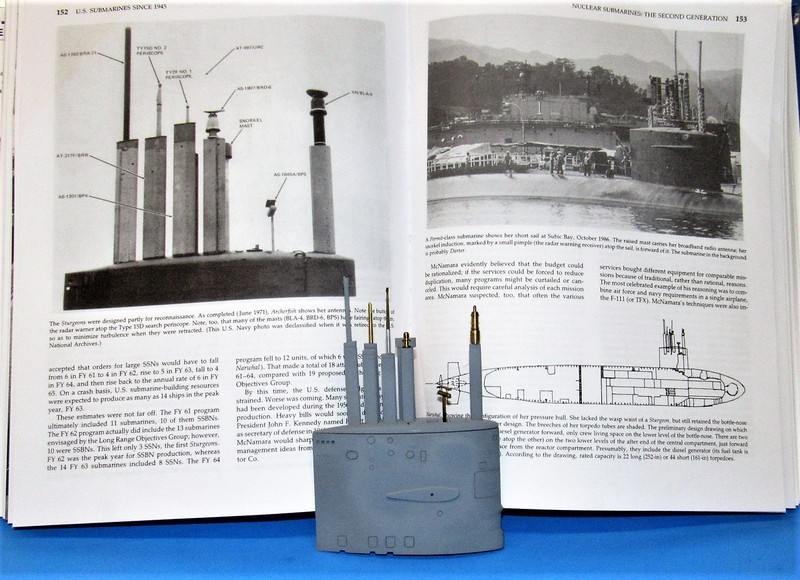

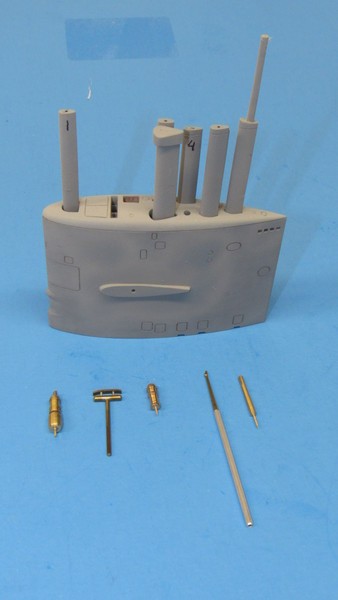

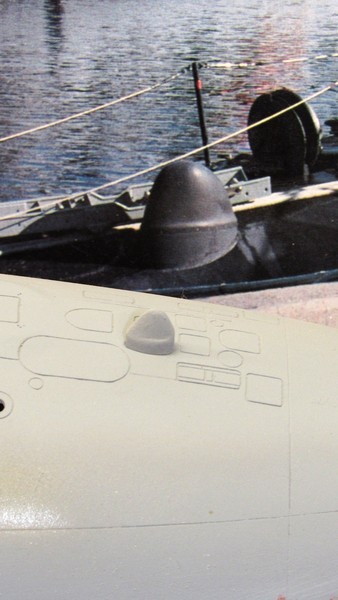

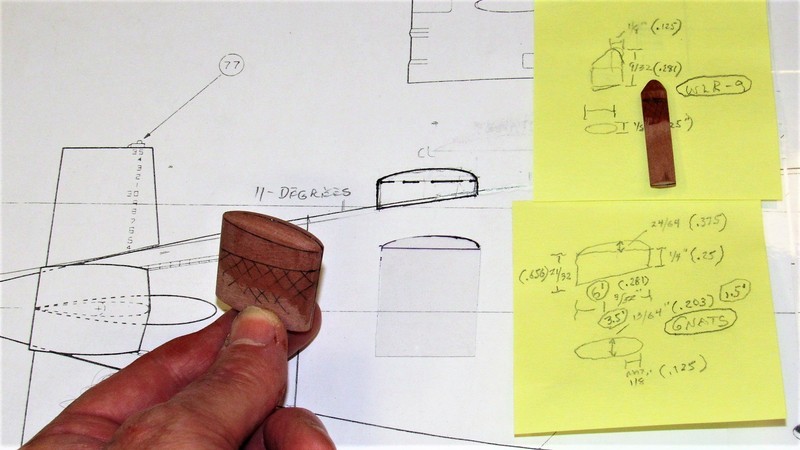

One last test fit of sail parts to insure proper fit and alignment. From here things are taken apart and the tooling started.

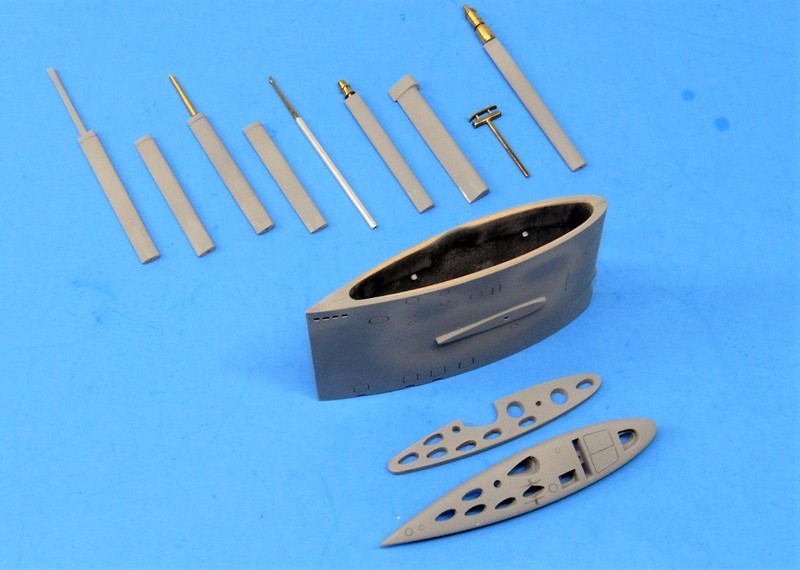

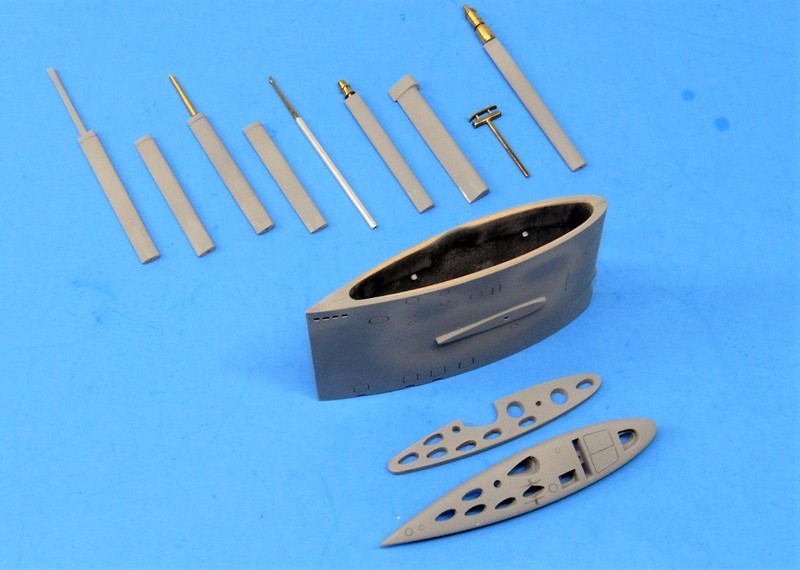

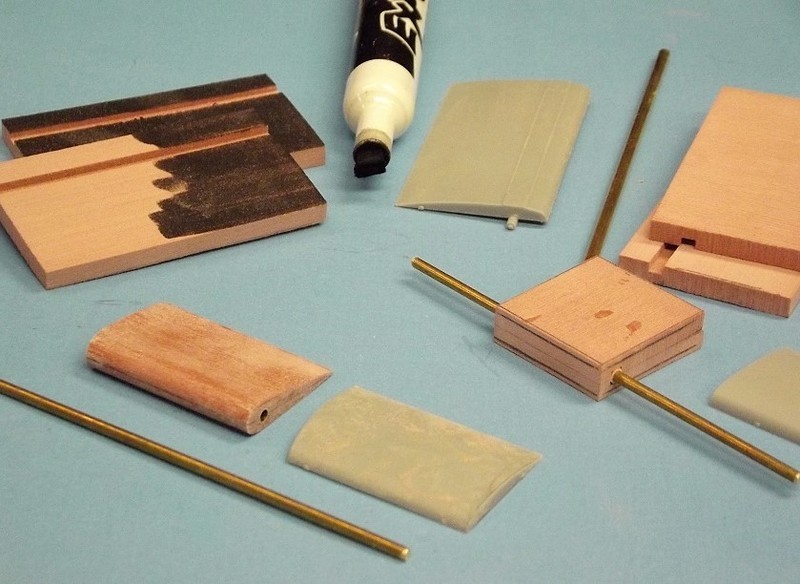

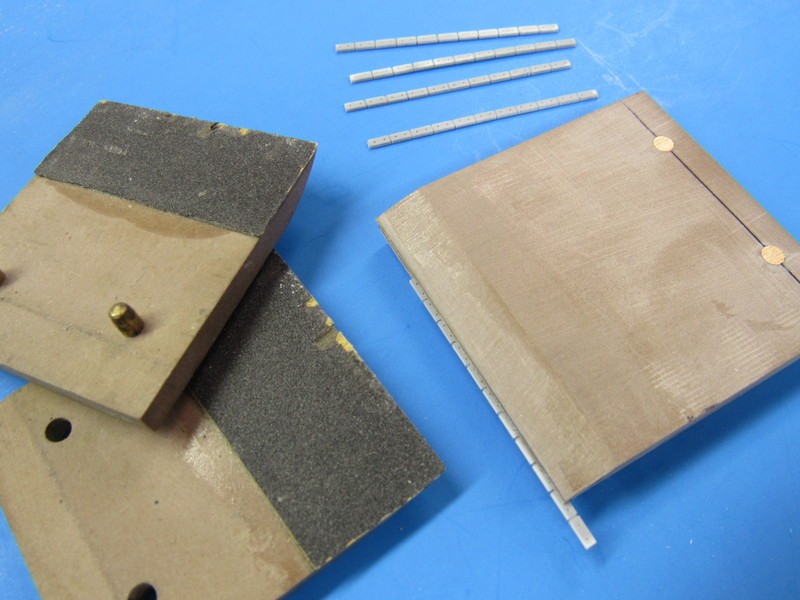

These masters represent most of the items that will be employed to achieve the tooling from which production parts will be produced to achieve a reasonably detailed sail for the eventual kit.

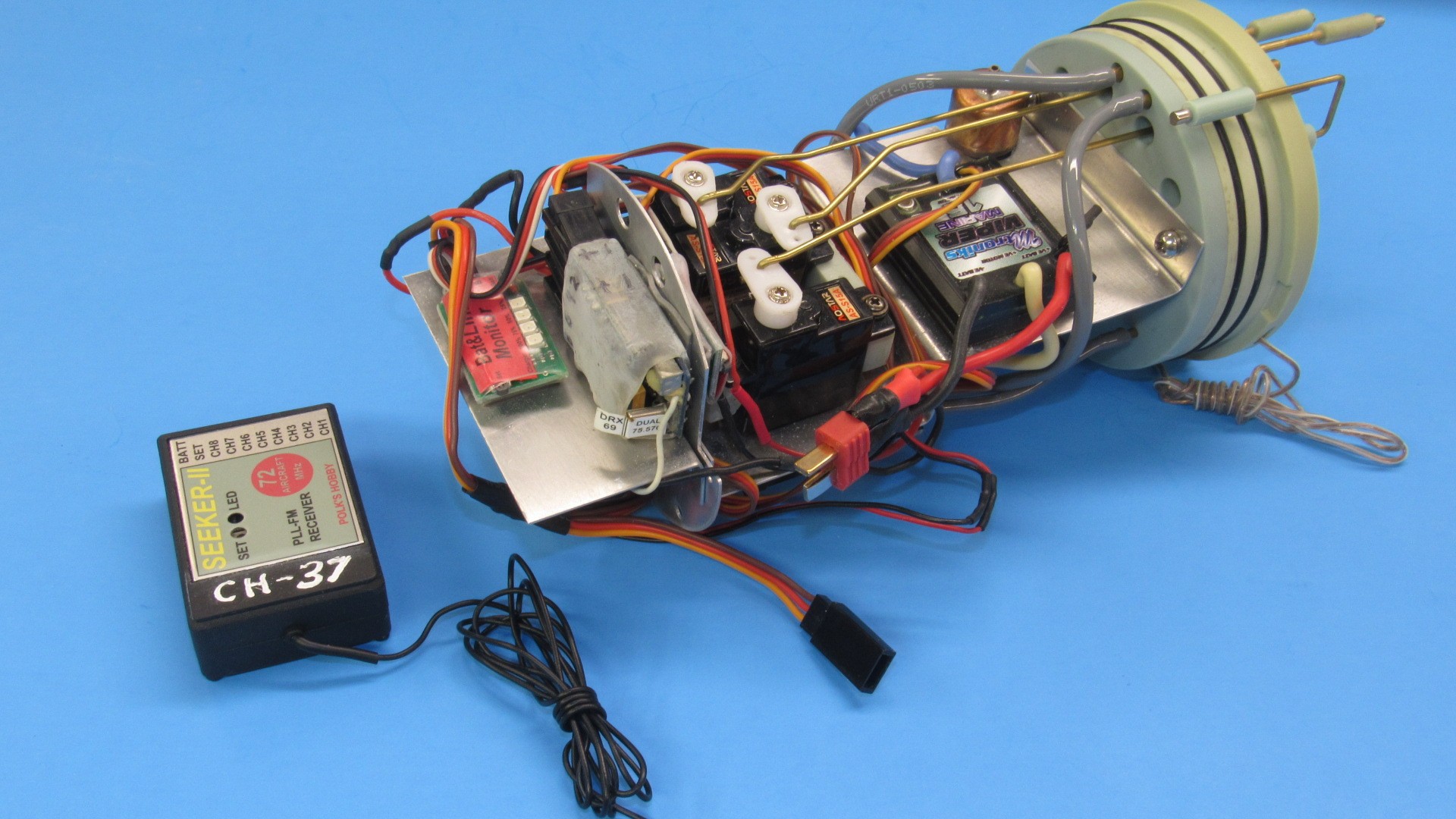

The scope heads and antennas will be ganged with other small detail items in a disc type centrifugal tool that will be used to produce white-metal production parts for the kit. Those masters in foreground.

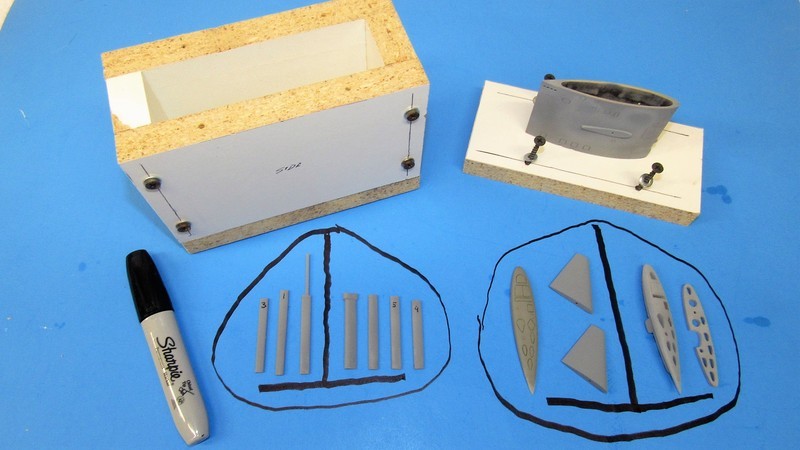

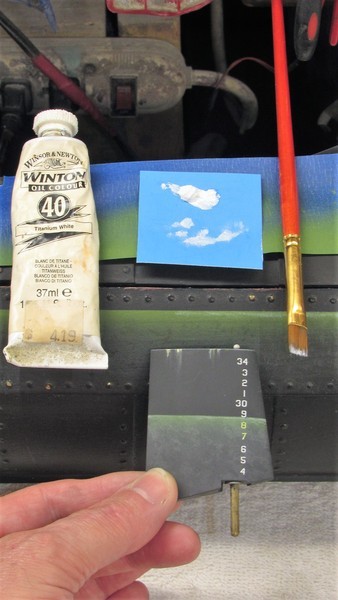

Three separate rubber tools will be created to form the production parts that make up the STURGEON kits sail. The flask you're familiar with for the sail proper; a two-piece tool for the masts; and a two-piece tool for the sail top -- two version, one representing retracted fairings and one with opening for a display of extended masts; the two sail planes (fairwater planes, for you purists); and the mast internal platform.

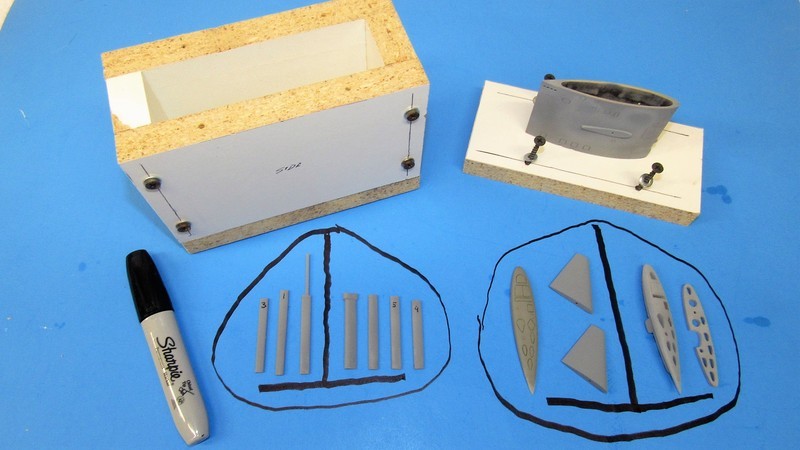

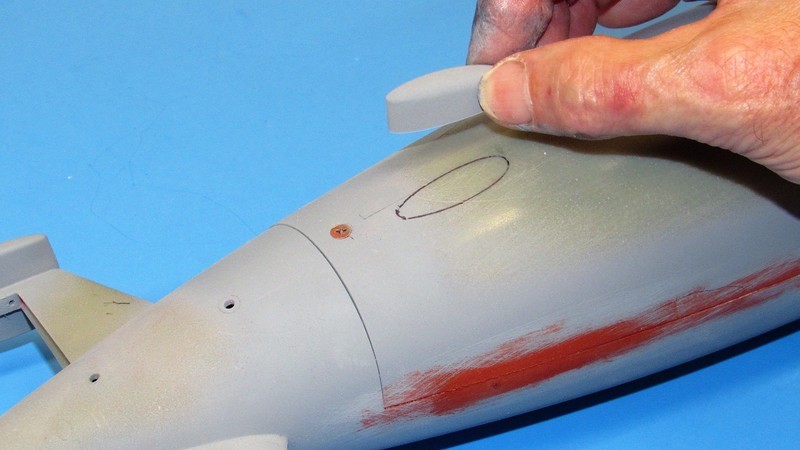

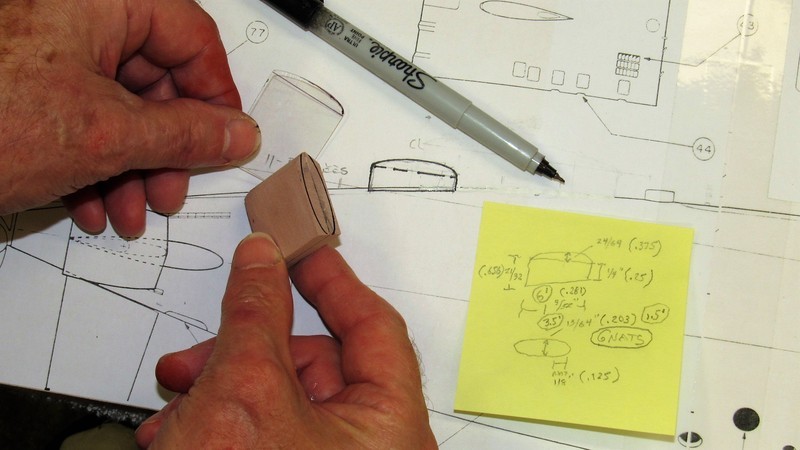

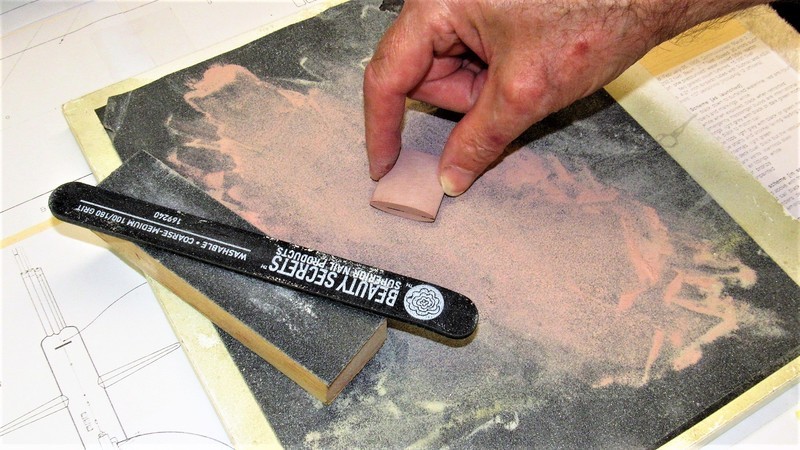

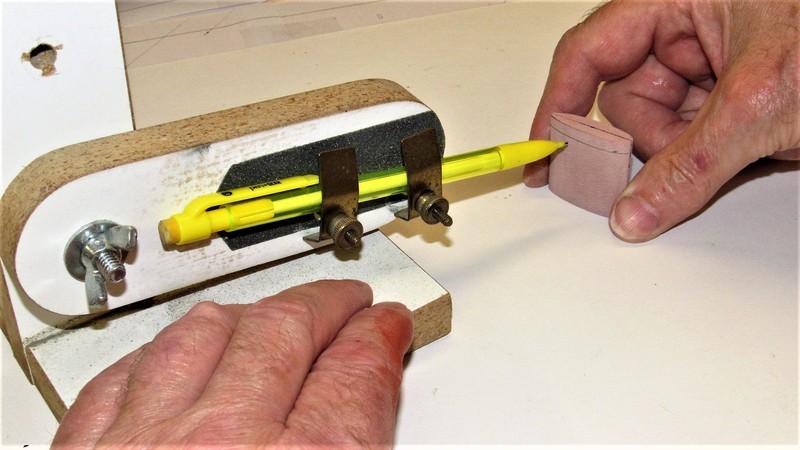

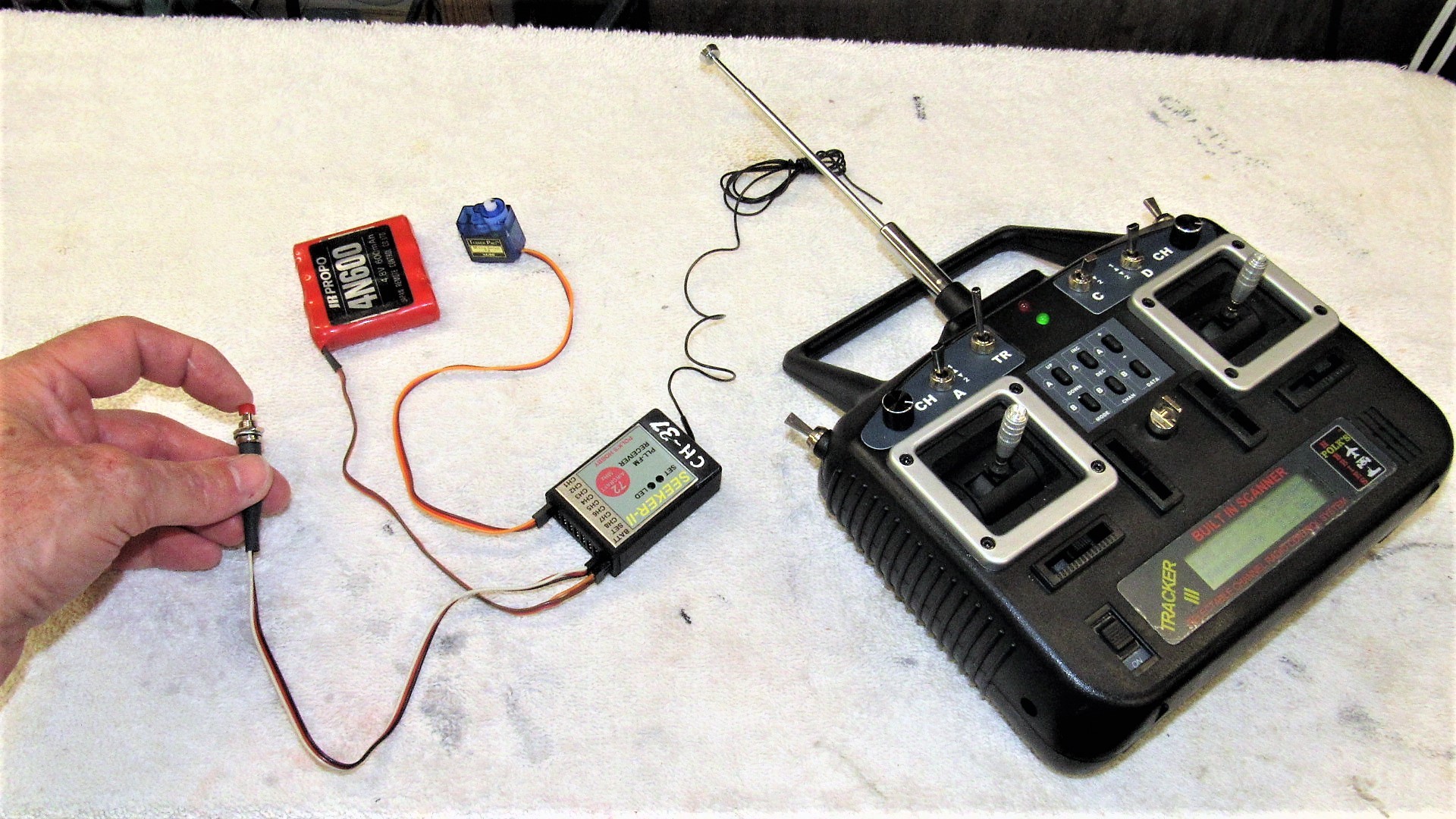

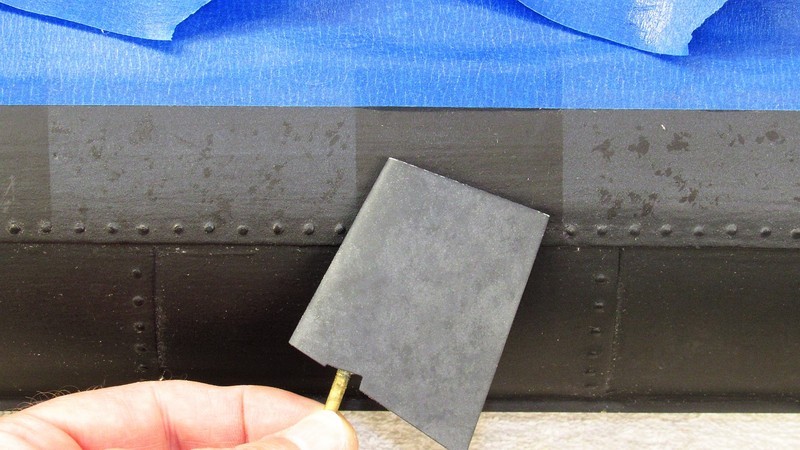

The inked outline is a study of how to arrange the masters and internal sprue and gate channels. When happy with such an arrangement I cut a piece of shelving 'mold board' to that outline, clay it up and set the masters half-way into the masking clay in preparation for pour of the first half of the rubber tool.

These masters represent most of the items that will be employed to achieve the tooling from which production parts will be produced to achieve a reasonably detailed sail for the eventual kit.

The scope heads and antennas will be ganged with other small detail items in a disc type centrifugal tool that will be used to produce white-metal production parts for the kit. Those masters in foreground.

Three separate rubber tools will be created to form the production parts that make up the STURGEON kits sail. The flask you're familiar with for the sail proper; a two-piece tool for the masts; and a two-piece tool for the sail top -- two version, one representing retracted fairings and one with opening for a display of extended masts; the two sail planes (fairwater planes, for you purists); and the mast internal platform.

The inked outline is a study of how to arrange the masters and internal sprue and gate channels. When happy with such an arrangement I cut a piece of shelving 'mold board' to that outline, clay it up and set the masters half-way into the masking clay in preparation for pour of the first half of the rubber tool.

Comment