today's work

Collapse

X

-

-

-

-

-

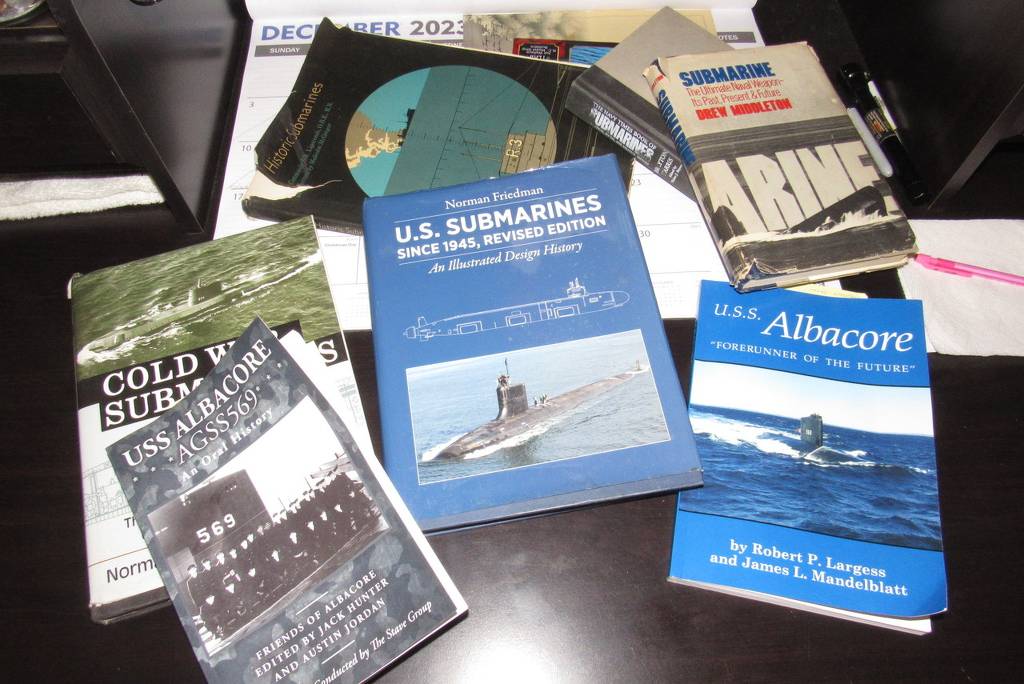

Enjoying the Albacore construction. It is important in 1953 just how new & revolutionary the many concepts introduced in this boat were when viewed, mentally suppressing present day hindsight what is commonplace now. It was an exciting time at Portsmouth NSY then what was developing and evolving.Comment

-

-

-

-

hi, question on the mold technique above (obviously I don't have much expertise on casting), I assume you are referring to the soft inner liner as the "glove" and the outer frame as the "case".

Do I assume correctly that as you make hulls the glove will wear out and that you can make replacement gloves and keep the same case?

It seems that it would be difficult to make replacement gloves that would fit tightly against the case.

This is a most interesting series. Thx for response, Khim

Comment

-

-

Correct. The rubber glove gives form to the eventual GRP laid up parts.hi, question on the mold technique above (obviously I don't have much expertise on casting), I assume you are referring to the soft inner liner as the "glove" and the outer frame as the "case".

Do I assume correctly that as you make hulls the glove will wear out and that you can make replacement gloves and keep the same case?

It seems that it would be difficult to make replacement gloves that would fit tightly against the case.

This is a most interesting series. Thx for response, Khim

The outer case (strongback/case/shell/mother-mold) keeps the floppy glove in proper shape during the lay-up process.

The initial glove is either poured into a pre-formed mother-mold (BJB's TC-5050) containing the master, or the glove is formed over the master directly, and the case formed over the cured rubber later (BJB's TC-5040).

Once production work has fried the glove you simply mount the mother-mold over the master(s), punch sprue holes into it, providing tall sprue and vent channels (gravity is your friend) and pour in a batch of TC-5050. Done. The annular space between master and case is filled with rubber.

Who is John Galt?

Who is John Galt?Comment

Comment