Tom, you are right, for me there are no secrets for other people which want to start and enjoy building subs, no matter how your sub will look, it's the product of your hands, we all enjoy building subs in our own way, let's keep it that way.

Red,

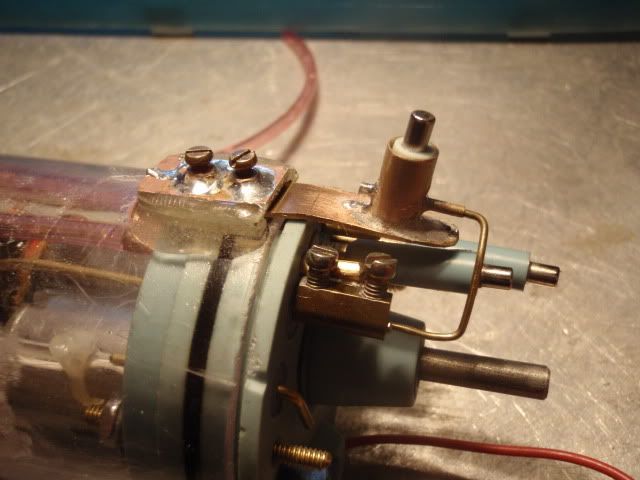

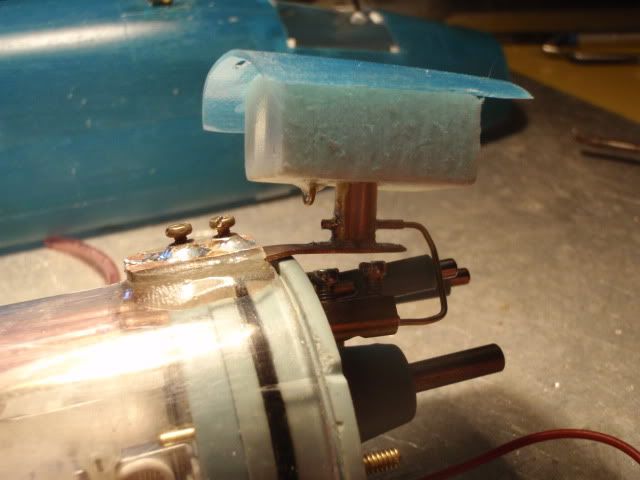

Placing the safetyvalve instead of the gas bottle was my initial thought, and then the volume issue appeared, had to find a way to give me more volume.

Testing the SD will reveal if this was the right move, only drawback is, the left room for the launchers, first i want to have a working SD equipped with SAS, from that piont i'll see if tubes are possible.

Greetings Manfred.

Red,

Placing the safetyvalve instead of the gas bottle was my initial thought, and then the volume issue appeared, had to find a way to give me more volume.

Testing the SD will reveal if this was the right move, only drawback is, the left room for the launchers, first i want to have a working SD equipped with SAS, from that piont i'll see if tubes are possible.

Greetings Manfred.

Comment