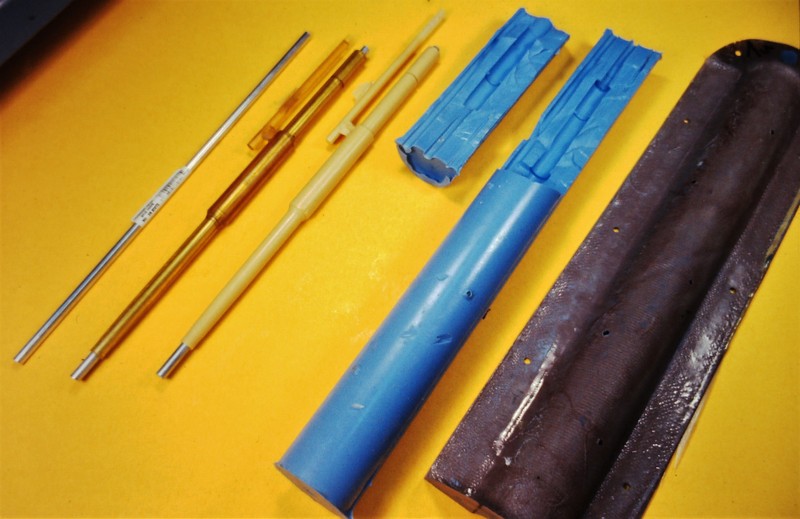

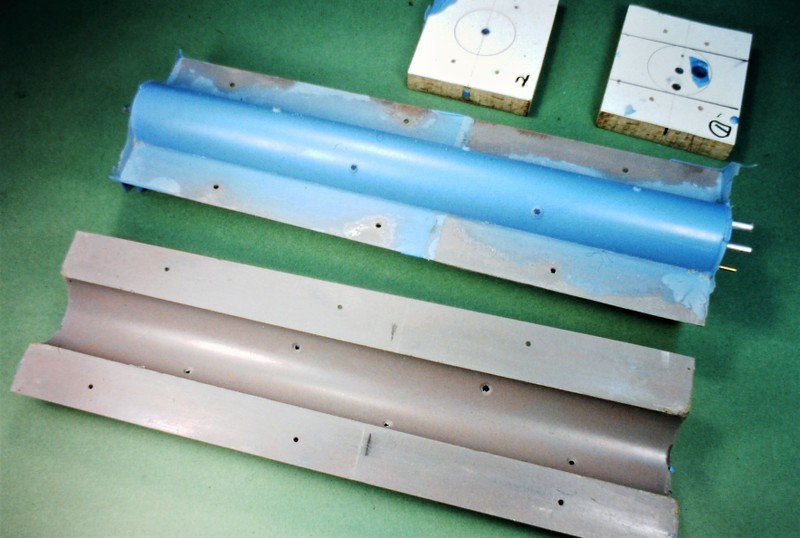

Work on Tucson continues slowly. Scraping ,sanding and filling on the hull to rid of epoxy that didn't cure. A real mess. Then my wife fell and fractured her femur so that's my priority for awhile.

Will Rogers

SSBN659

Will Rogers

SSBN659

Comment