Hi Guys,

I'm working off the following assumptions.

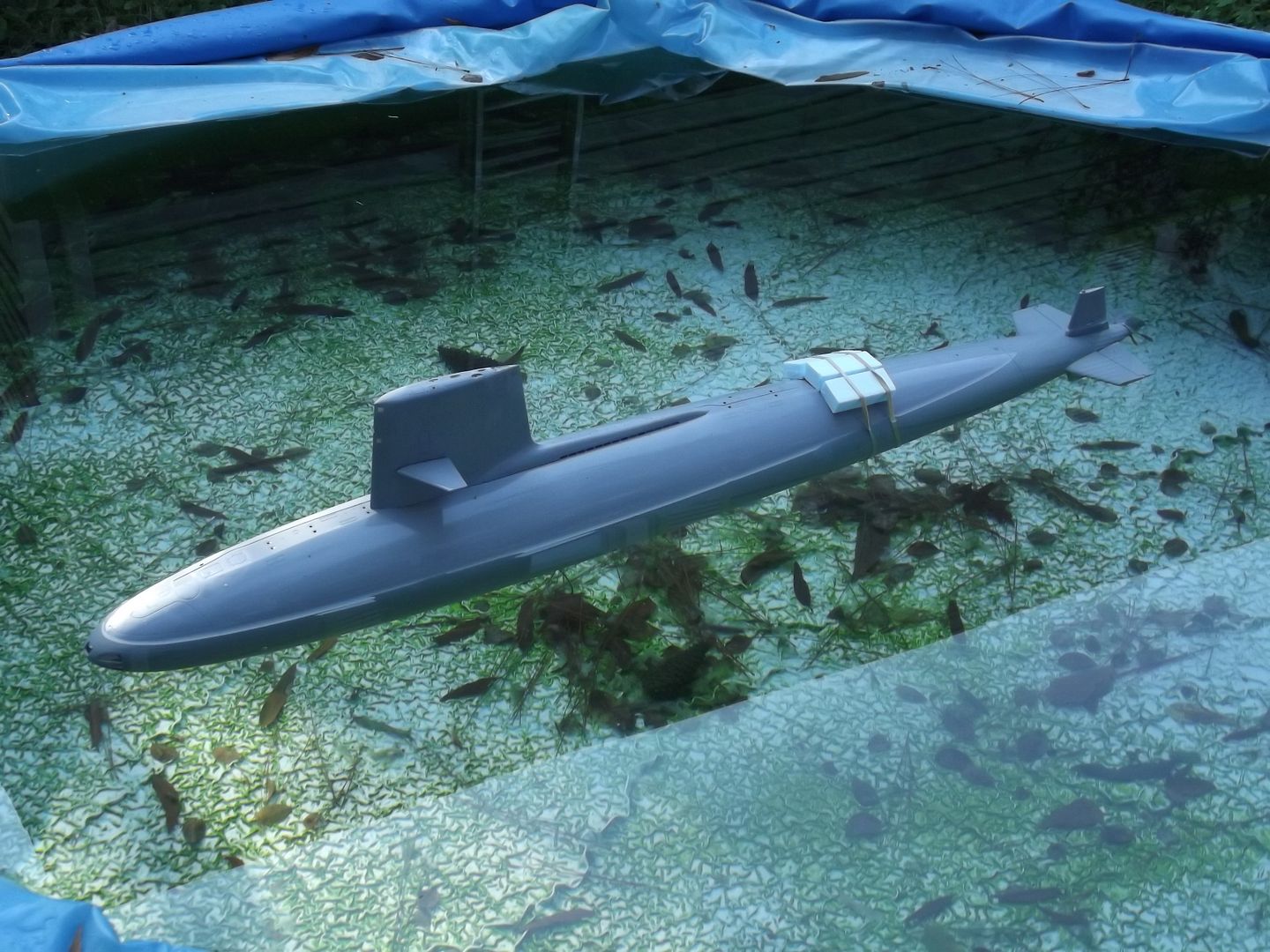

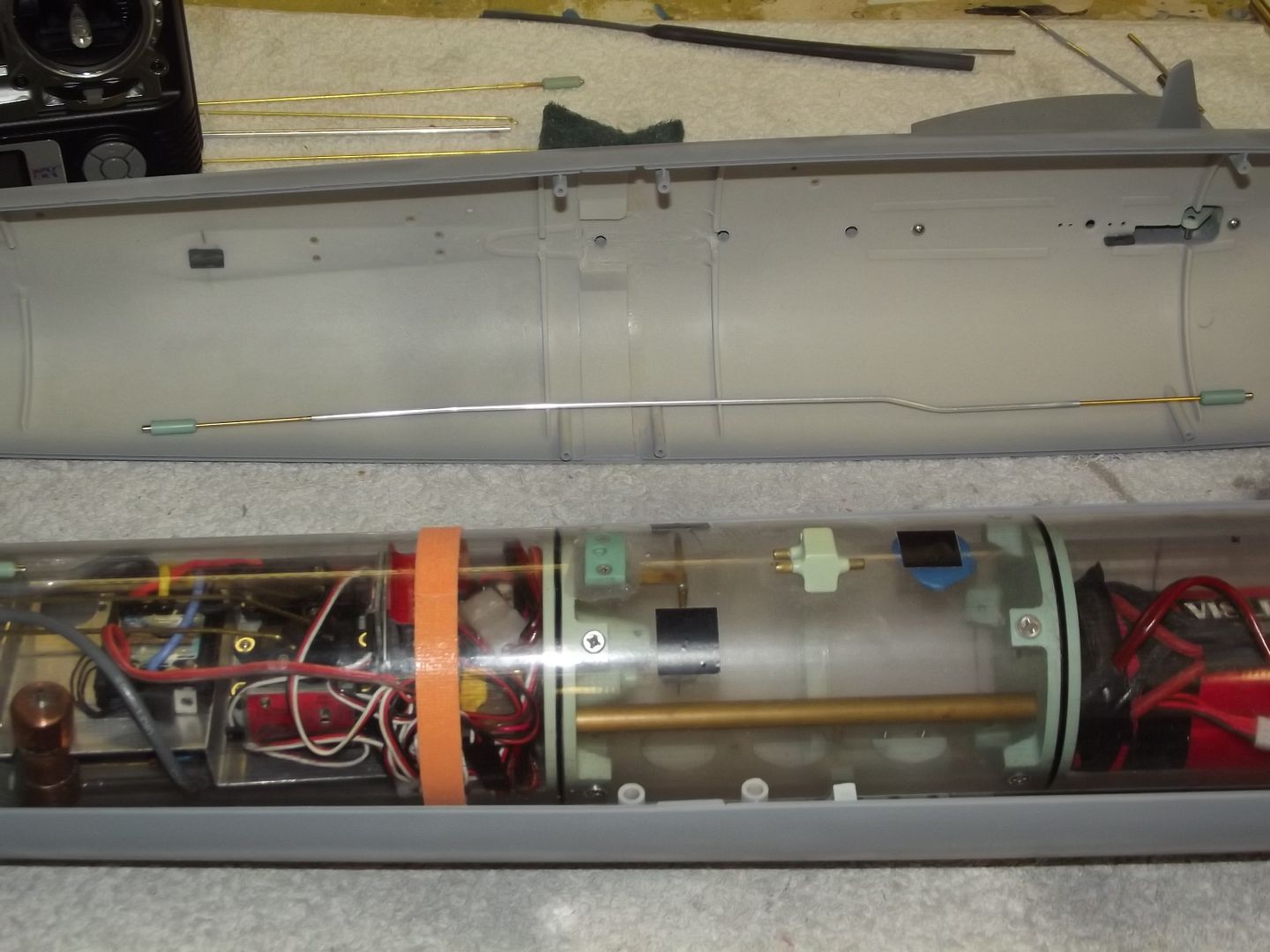

The biggest requirement to sink the sub will be getting the WTC itself below the surface as its filled with air. The volume of the WTC with no equipment inside is approx 3,300ml, and taking the accepted view of a flooding cell of 10% - 15%, this puts the 450ml piston tank at 13.5% which is right on the money. Factor in a reduction of air due to the tech rack and equipment and that percentage will be even higher ,which should cover the hull and sail above the water line, so I'm not anticipating a problem.

I have room for a 500ml tank from Engel (just about, very tight fit), I'm hoping the 450ml will give me a bit of wriggle room, and I want to try to get a tank that fills to capacity for a 1 metre dive depth, as I've managed to centre the piston tank very well along the centre of gravity of the sub so far.

Rob

I'm working off the following assumptions.

The biggest requirement to sink the sub will be getting the WTC itself below the surface as its filled with air. The volume of the WTC with no equipment inside is approx 3,300ml, and taking the accepted view of a flooding cell of 10% - 15%, this puts the 450ml piston tank at 13.5% which is right on the money. Factor in a reduction of air due to the tech rack and equipment and that percentage will be even higher ,which should cover the hull and sail above the water line, so I'm not anticipating a problem.

I have room for a 500ml tank from Engel (just about, very tight fit), I'm hoping the 450ml will give me a bit of wriggle room, and I want to try to get a tank that fills to capacity for a 1 metre dive depth, as I've managed to centre the piston tank very well along the centre of gravity of the sub so far.

Rob

Comment