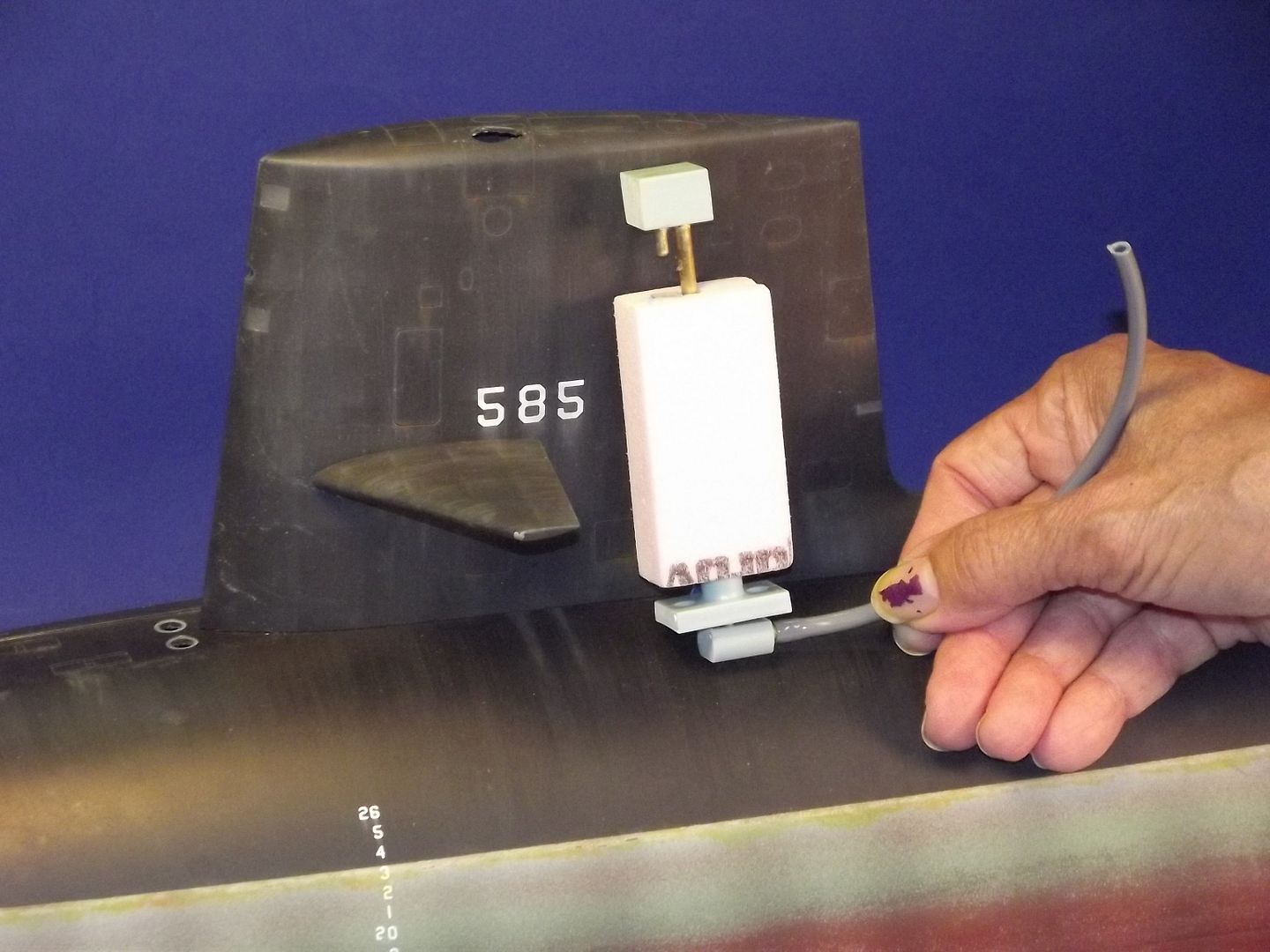

The sail has had all the holes opened to take the Photoetched parts. I'm just using the larger PE parts as the smaller ones are tiny.

The sail with the PE parts attached in the pre-drilled holes which have a backing of 0.5mm Plasticard and the hole filled with 1mm card and then the PE glued into the recess.

To be honest, apart from the vents on both sail sides which match my hull gratings nicely, I'm not sure the PE parts will add that much to a R/C model given the viewing distance, perhaps a super-detailed static model will benefit more, given this detail work took over a week of drilling, sanding and fettling.

That said, there are superb parts for the port/starboard sail lights and the radar on the PE fret which could not be produced any other way.

The Boattrainman

The sail with the PE parts attached in the pre-drilled holes which have a backing of 0.5mm Plasticard and the hole filled with 1mm card and then the PE glued into the recess.

To be honest, apart from the vents on both sail sides which match my hull gratings nicely, I'm not sure the PE parts will add that much to a R/C model given the viewing distance, perhaps a super-detailed static model will benefit more, given this detail work took over a week of drilling, sanding and fettling.

That said, there are superb parts for the port/starboard sail lights and the radar on the PE fret which could not be produced any other way.

The Boattrainman

Comment