Lathes

Collapse

X

-

-

Comment

-

Interesting lathe work!

Biggest Gear of Manufacturing The Largest Industrial Gear for Rolling Mill Plant HugeGear Production - YouTube

Rob

"Firemen can stand the heat."Comment

-

I can almost smell the oil-rich greensand!Interesting lathe work!

Biggest Gear of Manufacturing The Largest Industrial Gear for Rolling Mill Plant HugeGear Production - YouTube

Rob

"Firemen can stand the heat."

And no better example of radial screeding have I seen on YouTube!

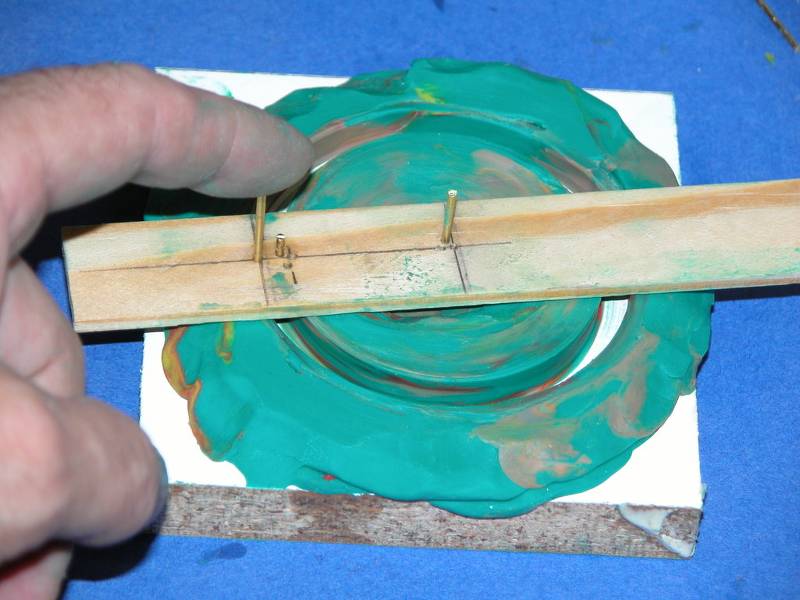

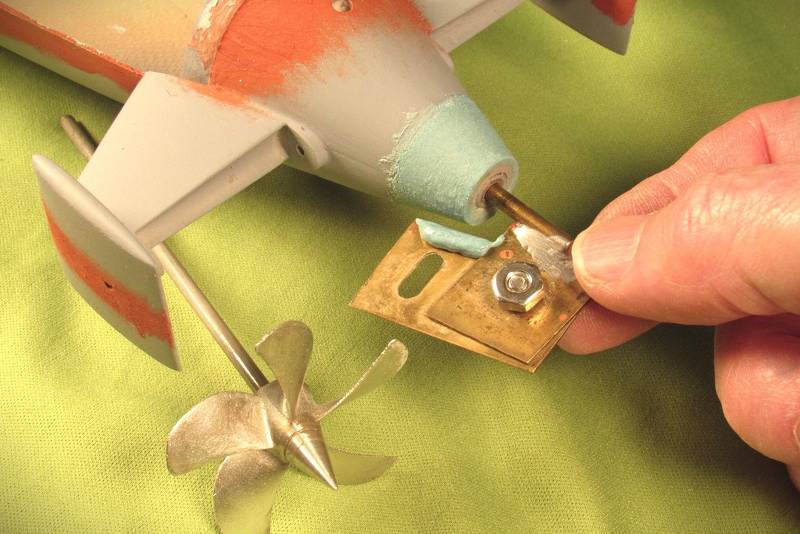

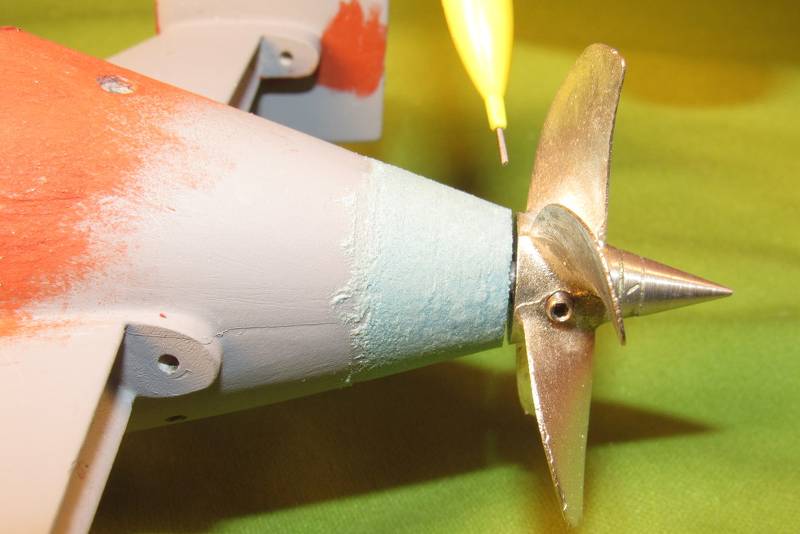

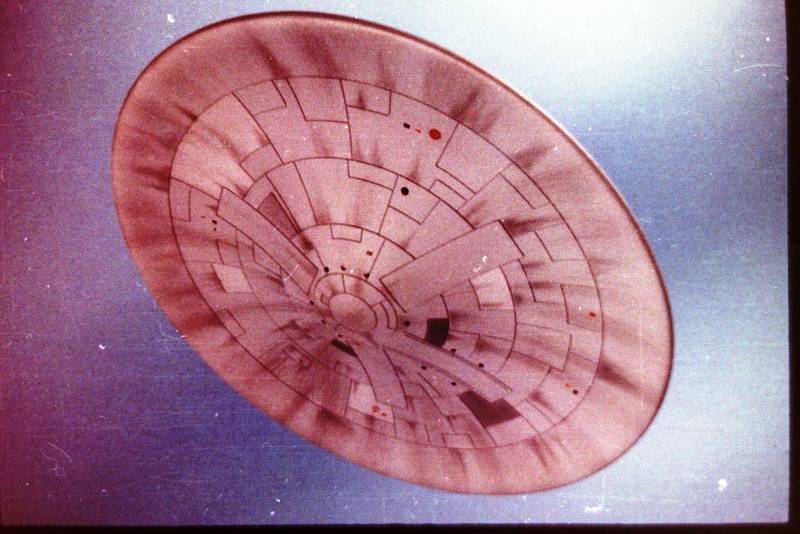

Here are some of our efforts employing that fabrication technique:

Who is John Galt?

Who is John Galt?Comment

-

And thanks, Rob, for helping to keep these Black Arts alive -- few of which solely rely on electrical energy to be accomplished -- in this age of all thing's electron dependent (the 'grid', our most vulnerable infrastructure!).

Read, One Second After.

David

Who is John Galt?Comment

-

David,

And thanks, Rob, for helping to keep these Black Arts alive -- few of which solely rely on electrical energy to be accomplished -- in this age of all thing's electron dependent (the 'grid', our most vulnerable infrastructure!).

Read, One Second After.

David

You are welcome David. I for one really enjoy watching the process of mold making that these guys use, and then to see how it relates to exactly what you are doing for sure.

For those that watched the entire video, I did notice one thing about the lathe operation. When they were turning the hub, it seemed to me (based on my woodworking experience) the hub was turning on the chuck in the wrong direction to the cutting tool!? There might have been a reason for it, but it seems to me it needed to be turning the other direction, but again because of the cutting tool holder design you have the option of either direction with that metal lathe!?

Rob

"Firemen can stand the heat."Last edited by rwtdiver; 12-07-2023, 02:22 AM.Comment

-

This video came across my Youtube feed. I thought it was interesting. It was well done and had some good ideas. Although if you are really into customization of your lathe, the lathe can be a full project just like building a model.

Comment

-

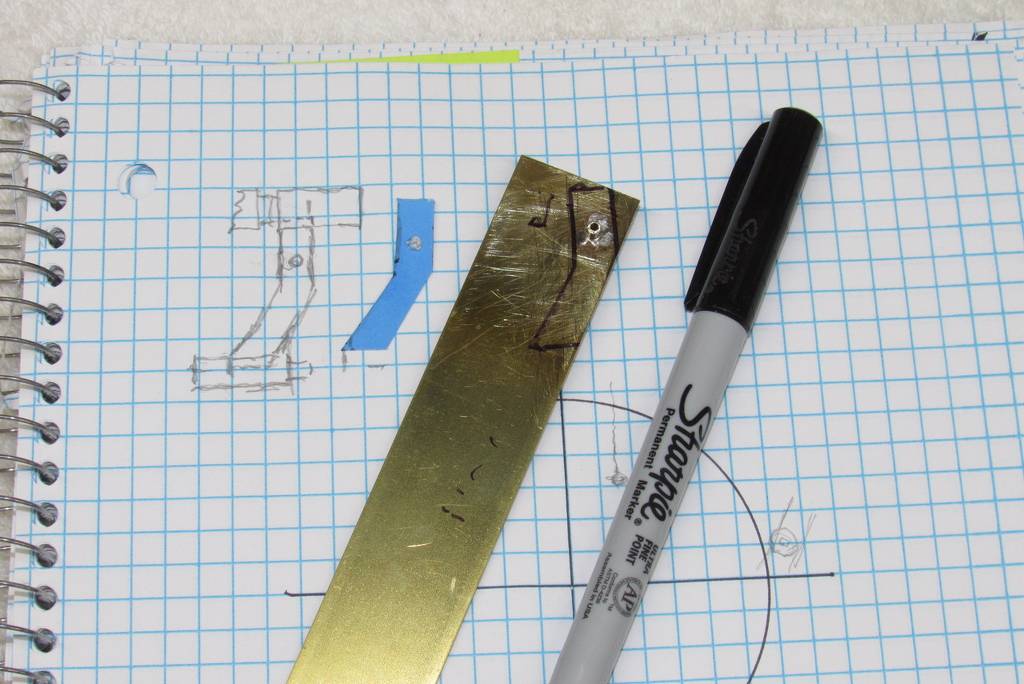

David, you mentioned in Dive Tribe the difference between K&S brass and I think you called it machining brass. Can you elaborate the difference here? Most of the brass we use in models consists of small brass rod, tube or sheet, readily available in the right sizes from K&S. When or why would we need to use machining brass?

These are some of the recent sites I've heard mention as brass suppliers

K&S Precision Metals serves retail needs for hobby, hardware, or creative motivation. If our stocked products of Brass Tubing, Aluminum Rod, Copper Sheet Metal, or Stainless Steel Strip isn't enough - then send us a message on how we can custom cut your small or large quantity job. RFQs are welcome for your OEM needs!

K&S Precision Metals serves retail needs for hobby, hardware, or creative motivation. If our stocked products of Brass Tubing, Aluminum Rod, Copper Sheet Metal, or Stainless Steel Strip isn't enough - then send us a message on how we can custom cut your small or large quantity job. RFQs are welcome for your OEM needs!

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

https://www.onlinemetals.com/Last edited by Ken_NJ; 12-19-2023, 10:13 AM.Comment

-

Your basic MK-1, Mod-0 brass is an alloy of 70% Copper and 30% Zinc. This stuff is tough to machine and will quickly dull or break tools digging into it. Cartridge brass has a higher percentage of zinc which makes the stuff even tougher to machine. Bad ju-ju if the metal is to be machined. Cartridge brass is the typical brass alloy you get from K&S.David, you mentioned in Dive Tribe the difference between K&S brass and I think you called it machining brass. Can you elaborate the difference here? Most of the brass we use in models consists of small brass rod, tube or sheet, readily available in the right sizes from K&S. When or why would we need to use machining brass?

These are some of the recent sites I've heard mention as brass suppliers

K&S Precision Metals serves retail needs for hobby, hardware, or creative motivation. If our stocked products of Brass Tubing, Aluminum Rod, Copper Sheet Metal, or Stainless Steel Strip isn't enough - then send us a message on how we can custom cut your small or large quantity job. RFQs are welcome for your OEM needs!

K&S Precision Metals serves retail needs for hobby, hardware, or creative motivation. If our stocked products of Brass Tubing, Aluminum Rod, Copper Sheet Metal, or Stainless Steel Strip isn't enough - then send us a message on how we can custom cut your small or large quantity job. RFQs are welcome for your OEM needs!

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

https://www.onlinemetals.com/

Machine Brass is the right stuff if you're going to turn, mill, saw or drill brass. This alloy features a bit of lead in the mix -- the lead permits rapid chipping of the work as a tool is jammed onto it. That means low tool wear, and the work proceeds at a rapid feed rate without overheating or drama.

Machine brass is all I get nowadays. Best source is McMaster-Carr. Look for 'machinable brass', or 'machine brass'.

Use the K&S crap as is, cut to length and fastened with solder or mechanical fasteners. If you need a hunk of brass beaten into submission with machine tools, go with the 'machinable brass'.

I HAVE SPOKEN!

David

Who's at least as good at looking **** up on the interzones as you are!Who is John Galt?Comment

-

How much of the K&S brass do you use? The K&S brass is rather convenient when it comes to push rods etc. Get it from the local hobby store, if there is one. And the small product is easily cut with a Dremel, not ruining the more expensive lathe tooling.

I would think the larger chunks of brass you show in your pictures, only available from McMaster Carr. I have one within driving distance, convenient for pickup at will-call. Last I had something shipped they were expensive, may have changed since.

What about cutting the stainless steel drive shafts we use? How is that on the tooling? Should we stick with a hacksaw? And a Dremel to grind a flat for the set screw?

That all being said, what it the best way to redress the tooling edges on those lathe bits? Stones? And grinders?Comment

-

Damn you!... can't you see I'm busy. Now I have to tear this place up to take relevant pictures; work out a syllabus; construct a thread installment; post the thing; then, before the smoke even has a chance to disperse, suffer innumerable follow-up questions from RedBoat and his crew.How much of the K&S brass do you use? The K&S brass is rather convenient when it comes to push rods etc. Get it from the local hobby store, if there is one. And the small product is easily cut with a Dremel, not ruining the more expensive lathe tooling.

I would think the larger chunks of brass you show in your pictures, only available from McMaster Carr. I have one within driving distance, convenient for pickup at will-call. Last I had something shipped they were expensive, may have changed since.

What about cutting the stainless steel drive shafts we use? How is that on the tooling? Should we stick with a hacksaw? And a Dremel to grind a flat for the set screw?

That all being said, what it the best way to redress the tooling edges on those lathe bits? Stones? And grinders?

You did this on purpose, Ken -- didn't you!

A-hole!

You just had to pull me away from my bucket-list.

You people!

DavidWho is John Galt?Comment

-

Haha, who started this thread? Who talked about lathes in Dive Tribe? Why are you even checking the forum if you're so GD busy? You love sharing the knowledge, don't you!

Yes Bill, use those tools for the light stuff, not the lathe. Got the lathe cause I wan't to learn and do more.

Besides, there's this guy on this forum, seems to know it all, so why not ask these questions, and get great answers, I'm sure there are others that may want to learn something from him.Last edited by Ken_NJ; 12-20-2023, 11:11 AM.Comment

-

Comment