Lathes

Collapse

X

-

Tags: None

-

David? Can you recommend any good straight forward metal lathes that are not too expensive? Like the ones n the photos? Thanks!Comment

-

I've got three active lathes in the shop these days. But the Taig is my baby. Get this one, Steve! Micro Lathe II Archives - TAIG Tools

Who is John Galt?Comment

-

Thank you boss! You recommend the L1015? (w Motor it looks like).

Have an old Atlas lathe I bought 20 years ago from a junior college metal shop teacher I was taking a class on lathe operating because I thought it would be fun and useful. The teacher used it as a kid when Franklyn Roosevelt was president! It must be 80 plus years old. It scares me to use it now and like to replace with something more useful and smaller and safer. Any out there collect old lathes? I'll sell. Its painted blue and is clean. It is about 36 inches long.

Last edited by Albacore 569; 12-03-2023, 07:20 PM.Comment

-

Yup. The L1015. You don't want power-feed anything. Just the basic assembled machine. Get fancy later once you become-one-with-the-machine. Take it out a few times, buy it drinks, invite it over for the night, only then dress it up with accessories.

DavidWho is John Galt?Comment

-

Comment

-

Nothing intrinsically unsafe about an older machine, they work the same as the newer ones. Just don a pair of safety specs to catch any chippings that fly off whilst turning.

Comment

-

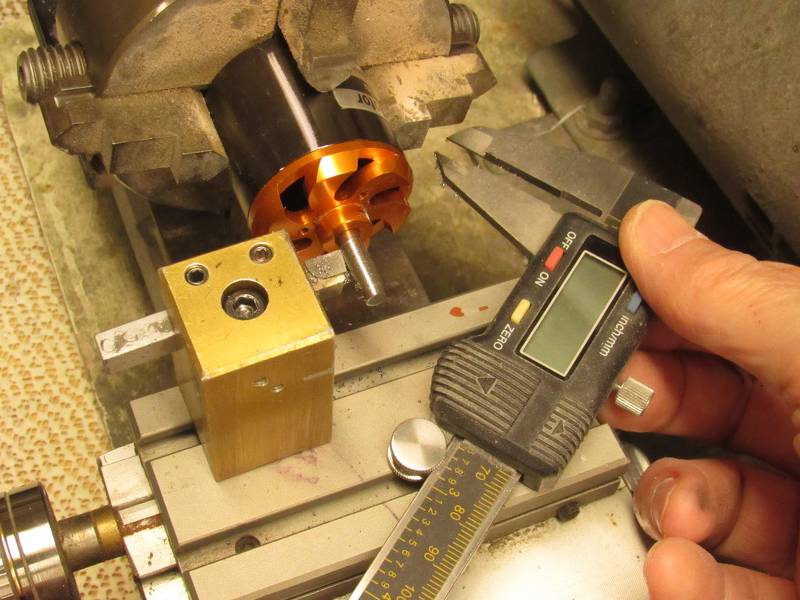

I went with this one 10 years ago. Never used it until recently after going on an accessory splurge. Can't do much without the proper tooling.

Inherited some of these from another model builder.

Made a tool tray.

And another center/chuck & tool holder.

A Quick Change Tool Post (QCTP) is a must.

After hand filing an endcap, got this 4 jaw independent chuck as recommended by David. Didn't use it on the endcap. But I now have it.

This gauge holder comes in handy for more than holding gauges.

Bit holders for the QCTP. The more you have, less pain in the a$$ to change the bits.

Good for marking up the work.

Last edited by Ken_NJ; 12-04-2023, 12:00 PM.Comment

-

Ken,

Excellent collection of measuring tools and quck-change tool holders.

One last thing to add to that managery, that will increase your productivity -- and vital if you're to make rotating holding fixtures for your bulkhead work:

A face-plate. This simple fixture attached to the head-stock of your lathe will rock your world.

David

Master of Broken ****

Who is John Galt?Comment

-

Who is John Galt?Comment

-

I like the idea of your method better! Casting. And using the tools I have. My preferred method being old school. Doing it with my hands. I'm with you!

Not so much leaving it to a computer, sending it to a printer, walking away and it's done. Yes there might be some talent that way but less satisfaction. Better building it with your own two hands.

Comment

Comment