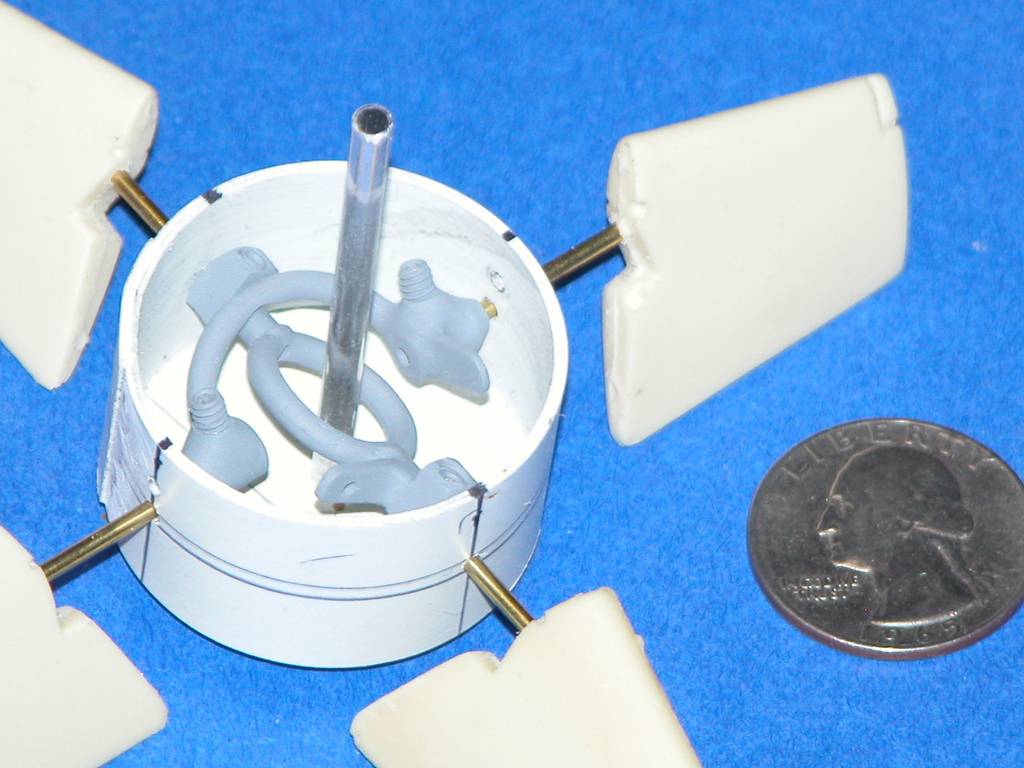

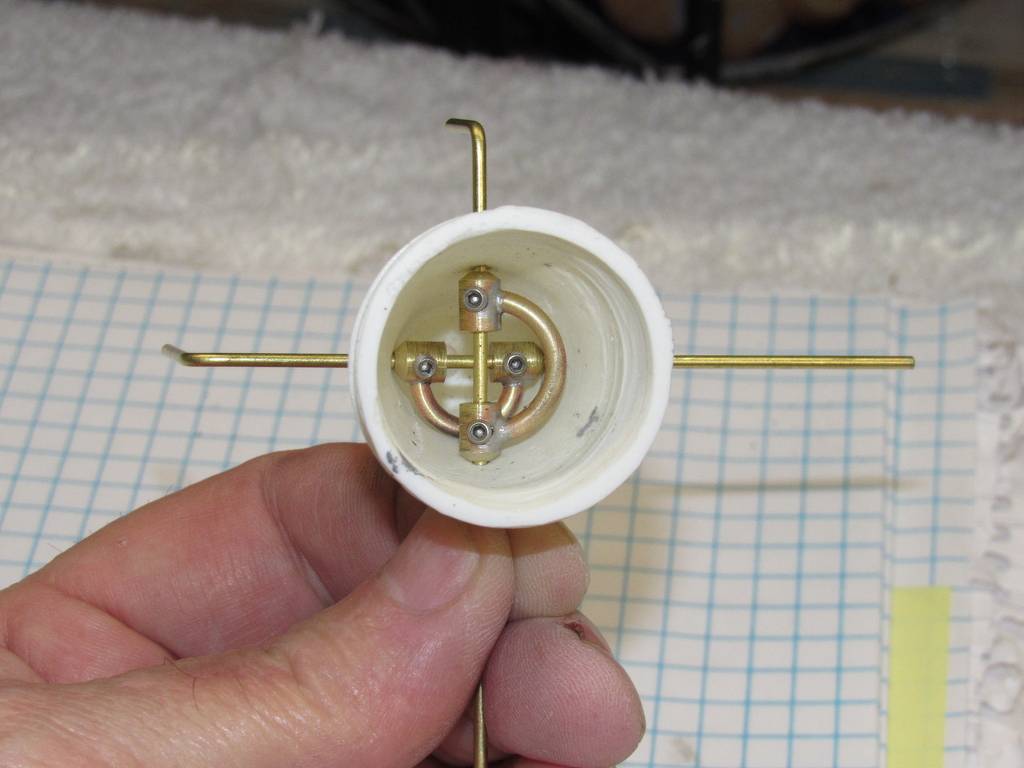

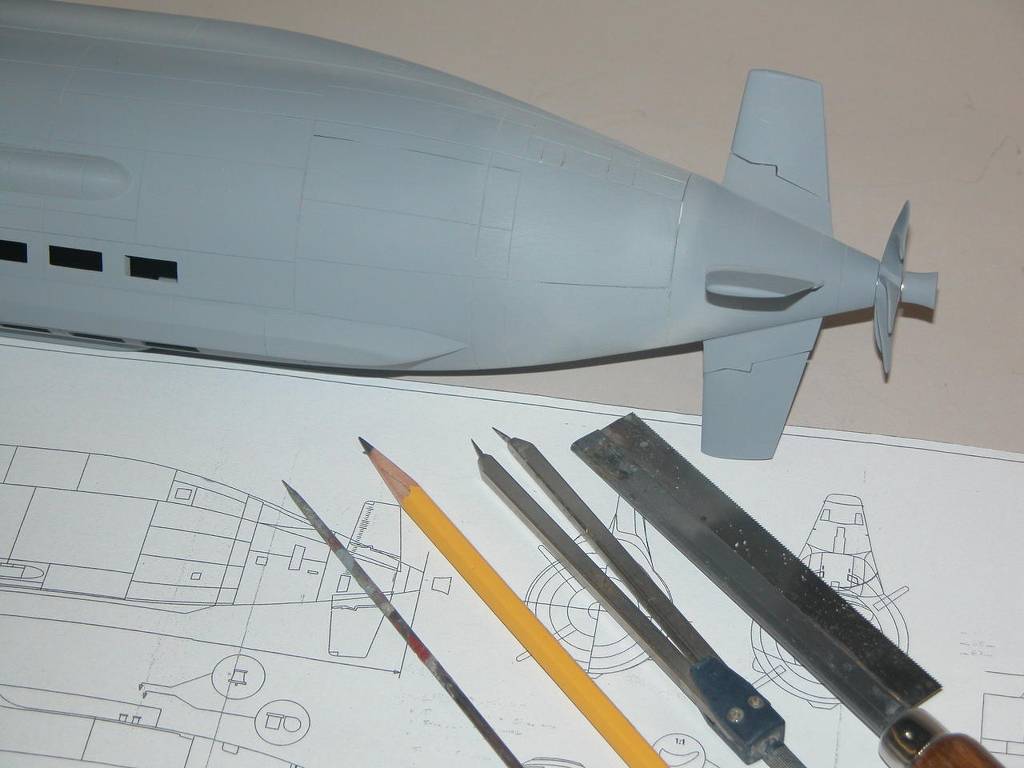

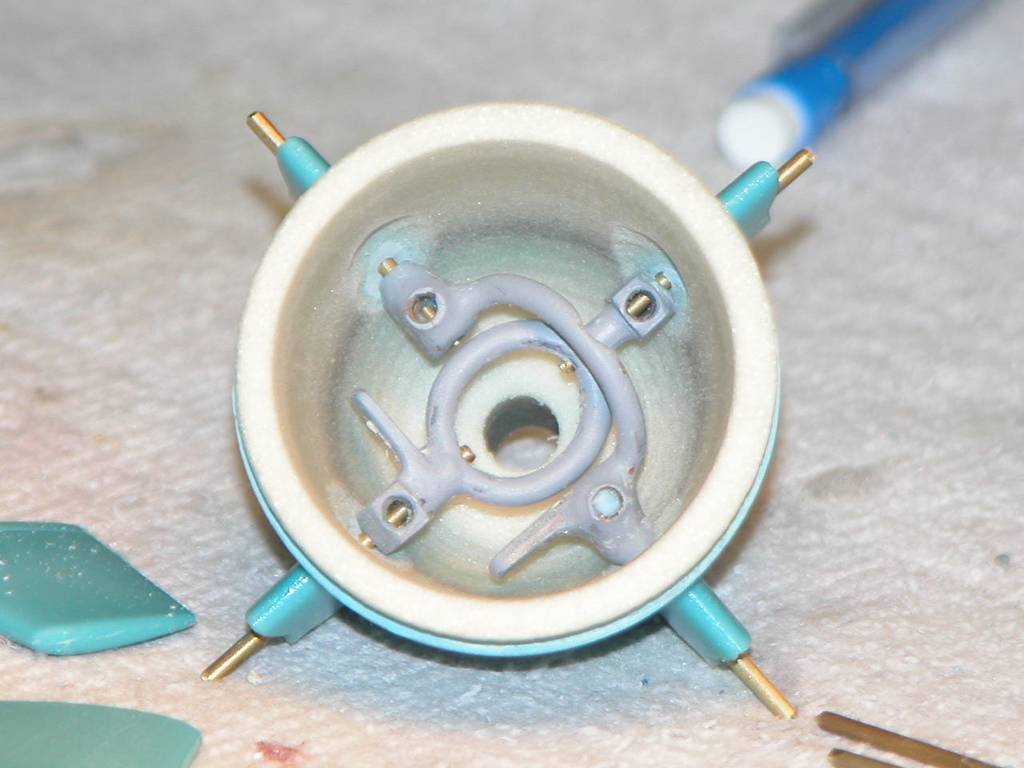

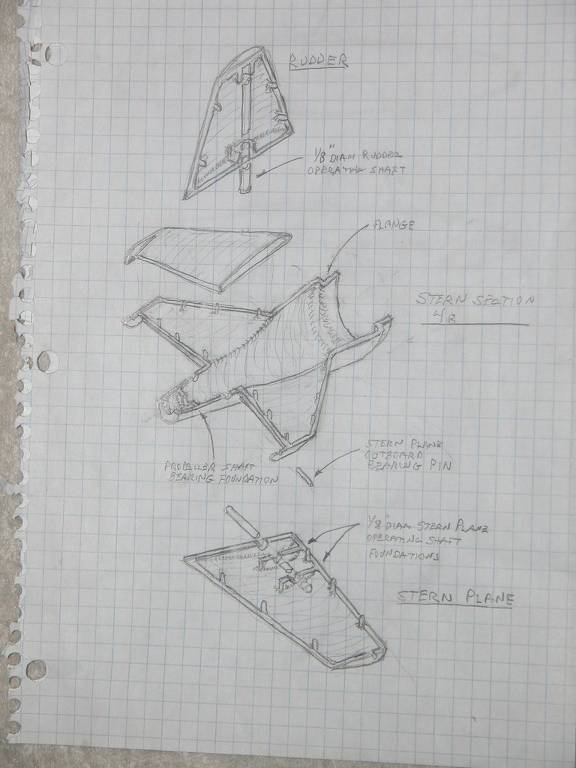

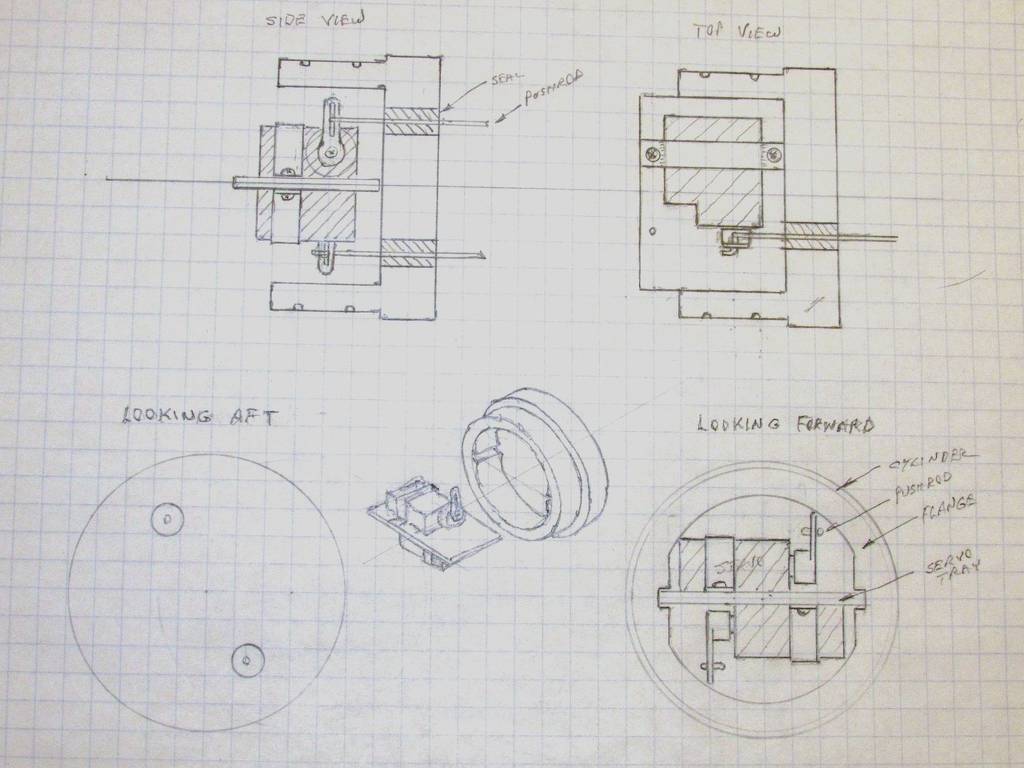

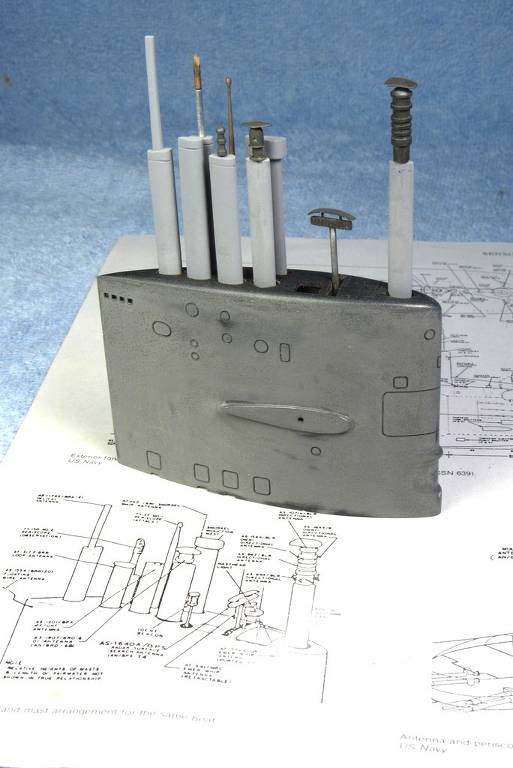

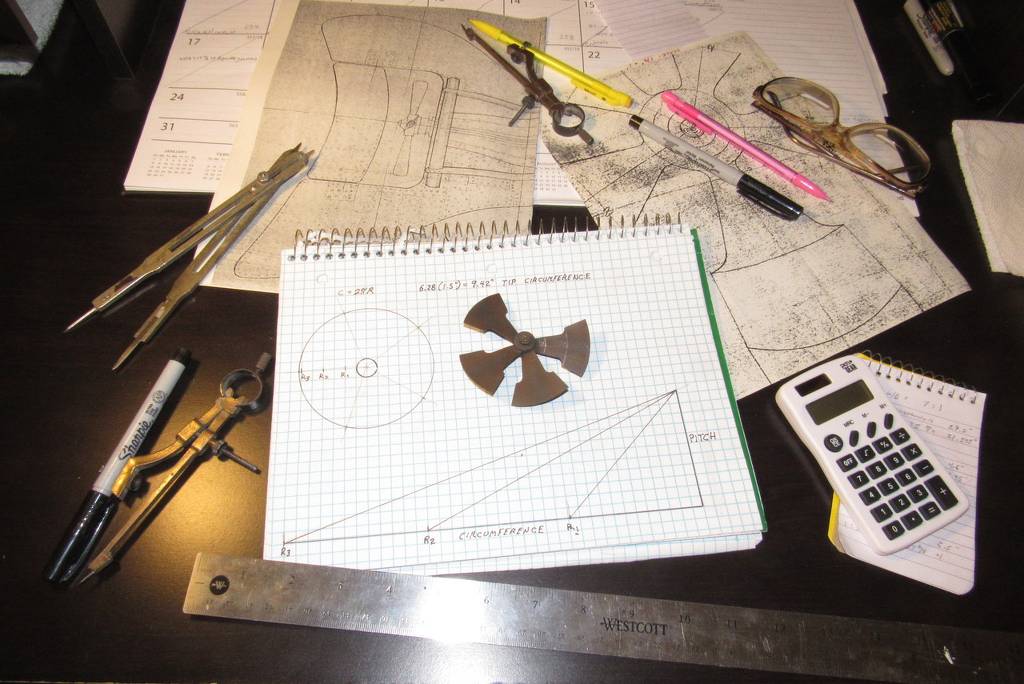

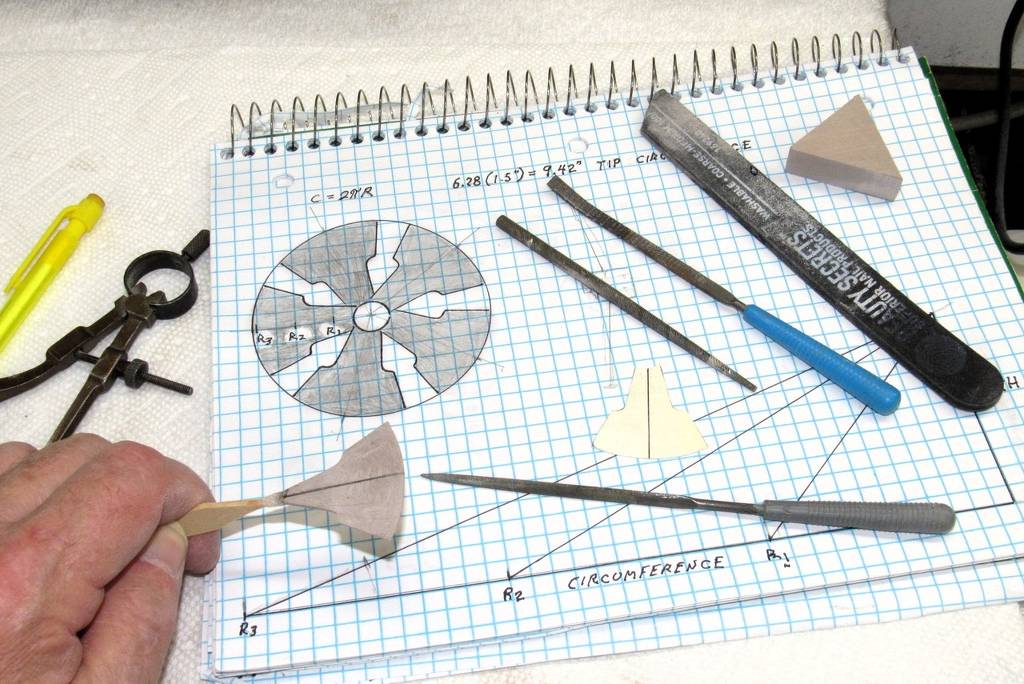

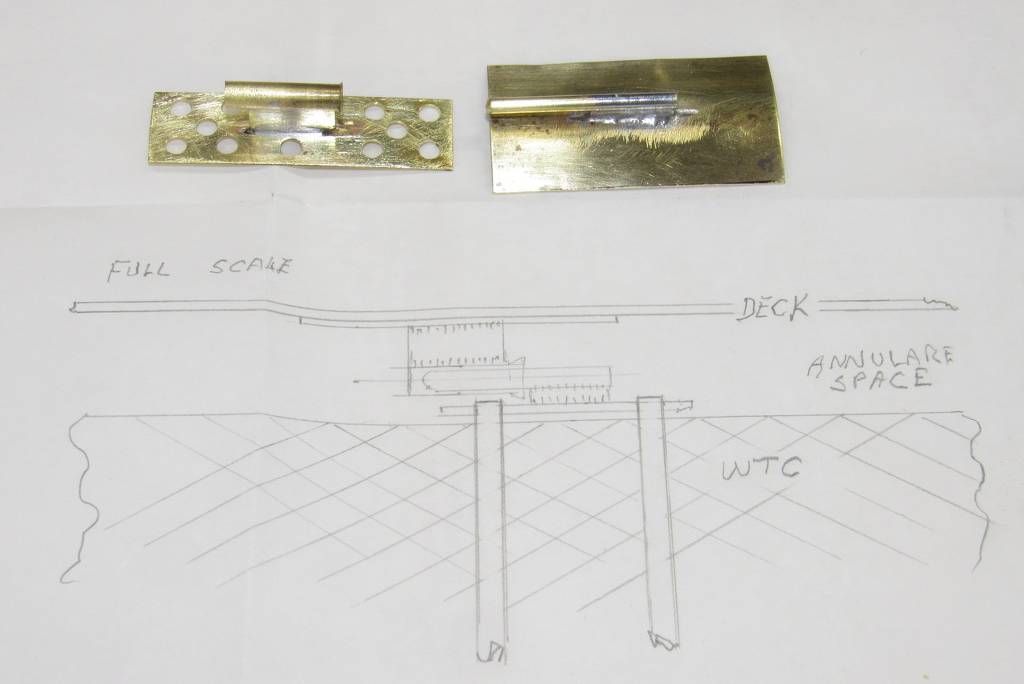

After looking at the different types of stern linkage systems, I have decided to go with the one that Bob Martin uses on his 212 A Kits.

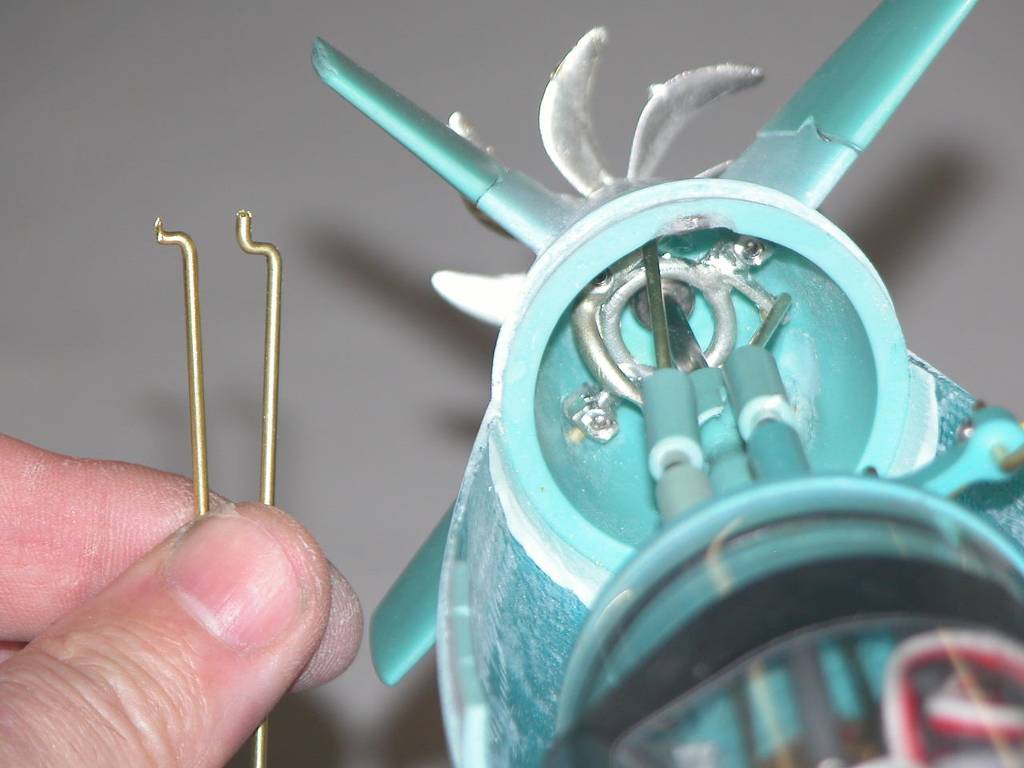

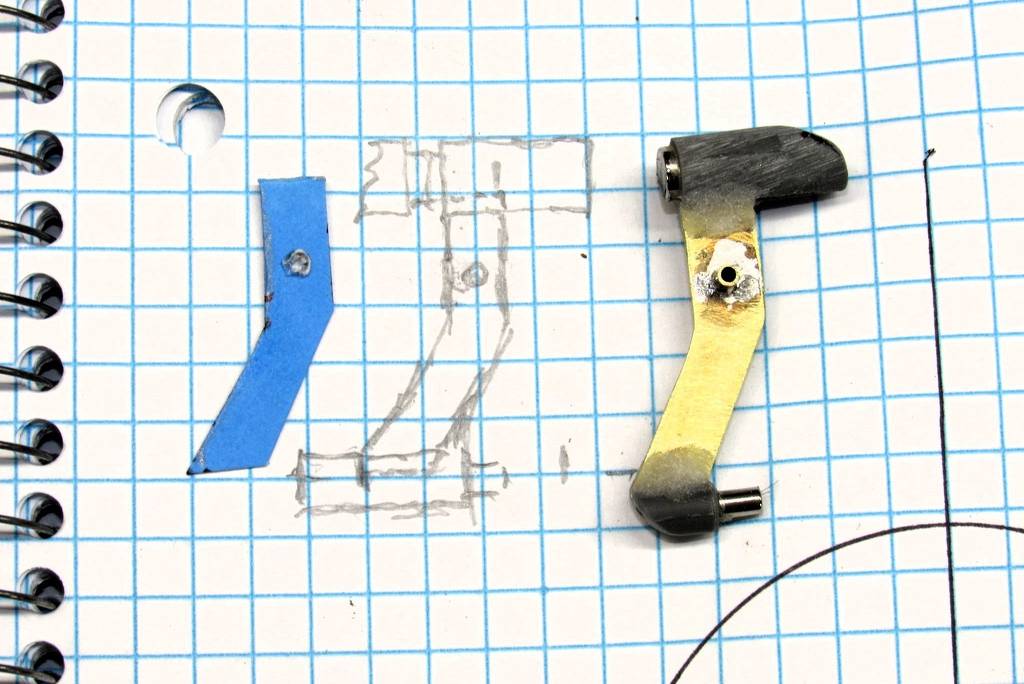

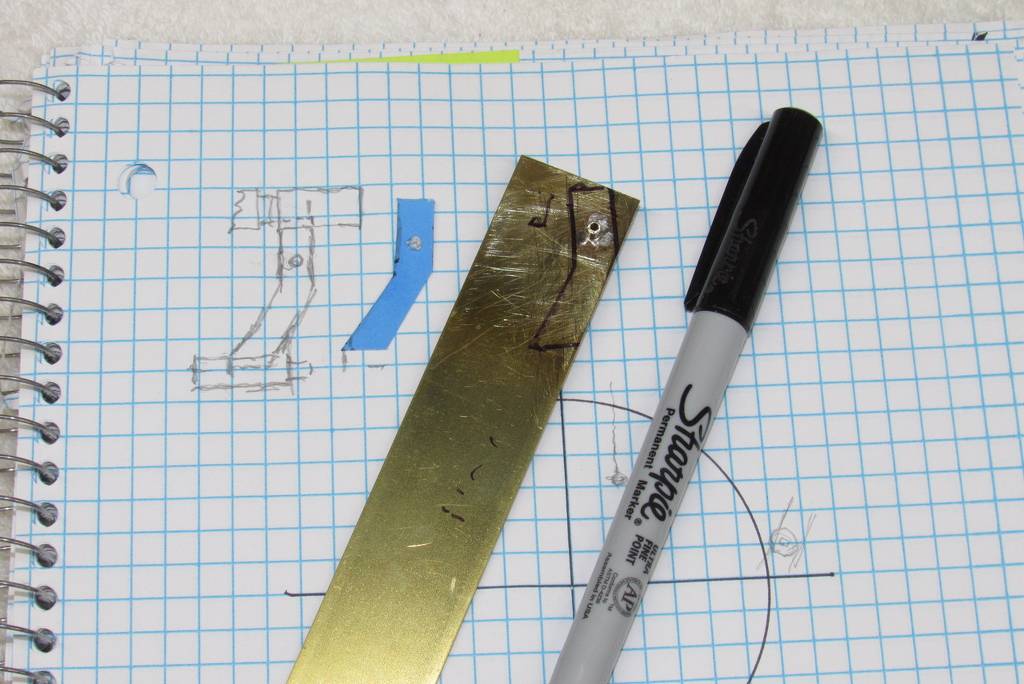

With the stern section being open as it is it should be relatively simple to put together. I soldered up the brass horns about 3 weeks ago, so I might as well use them.

Rob

"Firemen can stand the heat."

With the stern section being open as it is it should be relatively simple to put together. I soldered up the brass horns about 3 weeks ago, so I might as well use them.

Rob

"Firemen can stand the heat."

Comment