Russian Alfa Class

Collapse

X

-

-

-

It's not the reinforced areas you need to worry about as much when it comes to heat and PLA. The less reinforced sections, (especially the areas surrounding the MBT grates) will deform very easily, and ripple outwards circumferentially. Don't ask me how I know . . .Comment

-

Print another one in 1/144 and you can then nestle them one in another like those Matryoshka dolls. Lol.Make it simple, make strong, make it work!Comment

-

To me, the Alpha Class is just boring. There's been so many of them done. Give me the November, Hotel or the Yankee Class any day.Of the approximately 40,000 men who served on U-boats in WWII, it is estimated that around 28,000 to 30,000 lost their lives.Comment

-

I happen to have a built up 1/96 November for sale in my shop! :)

https://www.rc-submarine.com/product...-finished-hull

Comment

-

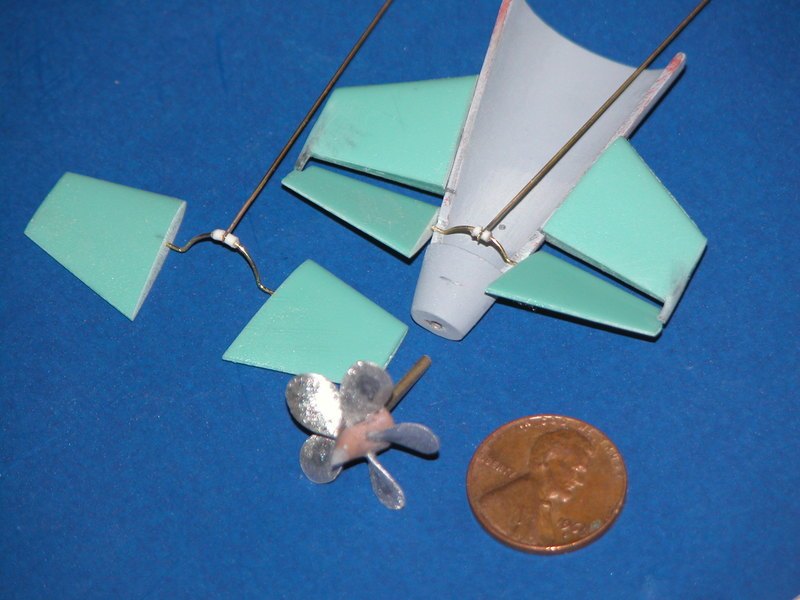

I have finally finished up the 3D printed roughly 1:72 scale Alfa!

As I stated before, this is just me messing around with my own off the wall design! The files for this boat hull are from Nautilus Drydocks 3D files of the 1:96 scale Alfa, which I have built! I am going to be using a 3.5" WTC cylinder, and using my own design for a piston type ballast system! This boat is completely scratch built and not a true 1:72 scale! I am not going to explain how I do this build! But, I will make sure to have lots of photos as I go with it.

Rob

"Firemen can stand the heat"

Special Note: I am going to move ALL my builds to one build blog in this forum! NOTE: New build blog: "Unorthodox Submarine Building"Last edited by rwtdiver; 09-11-2021, 11:03 AM.Comment

-

Today I finished up the two Alfa hulls!

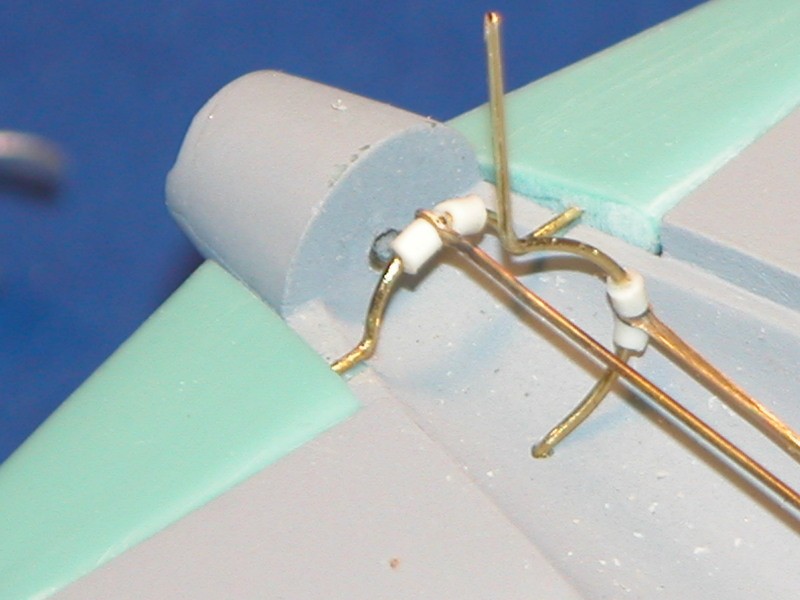

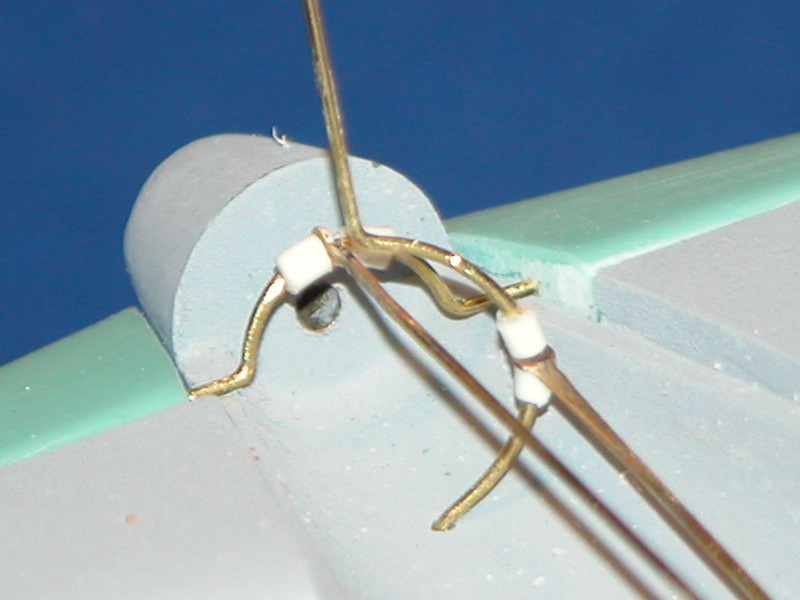

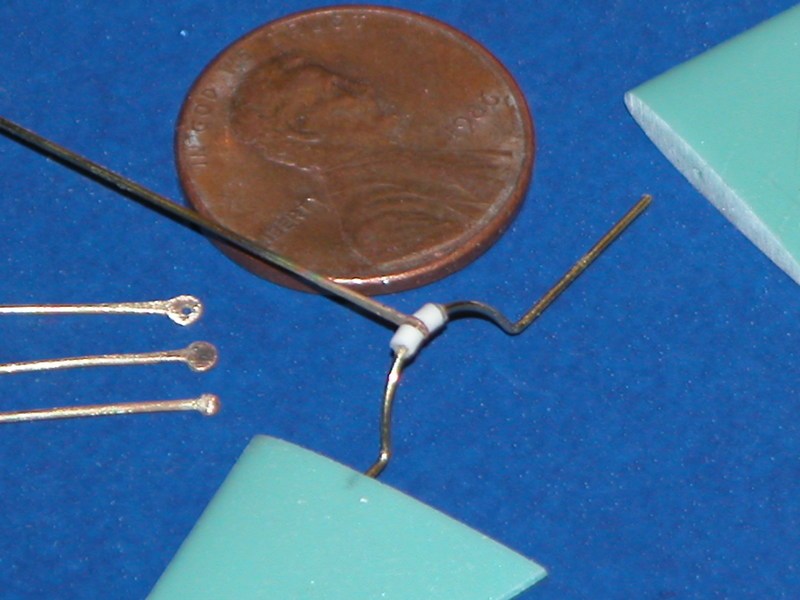

Next up is to fabricate the stern linkages (upper & lower rudder and dive planes) for the 1:72 scale, then I will fabricate the bow dive plane linkage system for both boats! The bow plane 3D files came out small, so I will be enlarging them a little off scale to enhance there operation!

Rob

"Firemen can stand the heat"Last edited by rwtdiver; 09-11-2021, 11:03 AM.Comment

-

Off to a good start Rob! The Alpha is one of my all-time favorites. The Russians really pushed the technological envelope with this project at a time when we had no torpedoes to stop this thing (unless you could get in a close trailing position and launch before they detected the weapon.)

I am extensively changing some aspects of this model. The joints between T2/T3 use a single frame, instead of 3 for a larger bonding surface. T3/T4 will get the same treatment. I've also increased the thickness of the frames from 7.5 to 12mm, which not only adds more structural integrity to the bond joint but significantly increases the size of the "lip" when aligning the hulls. I'm a big believer in index marks as well for precision alignment.

My references show a much longer bow plane, which almost doubles the size; I started added trim tabs to them last night while overhauling the bow, which I reduced the taper a bit on and added more topside to. In addition, the bow planes are relocated lower, rather than near the center of the sides.

Mesh-wise, there is a lack of geometric symmetry on all parts, making mods a lot more work but the end result is worth the effort and makes later changes much simpler. That's one of the huge differences between modeling in CAD and modeling in a straight 3D environment where the mesh is directly manipulated. Once a CAD program does the STL conversion for printing, the mesh gets completely asymmetrical (The measurements are correct, but the geometry is out of whack.) Re-building the mesh puts this right and the subsequent STL conversion keeps both the mesh symmetrical and measurements as intended. A lot of the scribed details are not perpendicular to the faces they're placed; in the case of the bow sonar dome, the depth varies in multiple places. This is not really noticeable by eye, but it's the kind of issue I try to avoid in my modeling - all depths stay equal.

There are very few sources of submarine modeling-specific information available for those who want to make their own hulls. If there's enough interest, I'll create a modeling series using Fusion 360 and my 3D modeling software together describing how to optimize a mesh for easier/faster printing at some point. I think now, more than ever it would be beneficial to give people another resource to learn about the foundations of 3D modeling/printing to help them explore other aspects of the hobby and allow them to make changes when desired. It isn't a skill that is learned quickly or easily; there's a lot of time and effort required to get good at it, but for simple things like designing your own endcaps or control surfaces, those aren't too difficult. So while it isn't for everyone, I'm sure some would benefit from it.Last edited by CC Clarke; 09-03-2021, 10:38 AM.Comment

-

YES, a series like that would be so helpful!There are very few sources of submarine modeling-specific information available for those who want to make their own hulls. If there's enough interest, I'll create a modeling series using Fusion 360 and my 3D modeling software together describing how to optimize a mesh for easier/faster printing at some point. I think now, more than ever it would be beneficial to give people another resource to learn about the foundations of 3D modeling/printing to help them explore other aspects of the hobby and allow them to make changes when desired. It isn't a skill that is learned quickly or easily; there's a lot of time and effort required to get good at it, but for simple things like designing your own endcaps or control surfaces, those aren't too difficult. So while it isn't for everyone, I'm sure some would benefit from it.If you can cut, drill, saw, hit things and swear a lot, you're well on the way to building a working model sub.Comment

-

I don't want to thread-jack here, so if someone starts a new thread asking for specifics of what they would like to learn, and there's enough interest, I'll begin work on a beginner series starting with modeling and applying it toward 3D printing as the end result. Fusion 360 is preferred because it's powerful and free, but is not the only program I use to create 3D models. There are multiple modeling techniques and most importantly, no one right way to create anything.Comment

-

I would be in for that. What should it be called?

I don't want to thread-jack here, so if someone starts a new thread asking for specifics of what they would like to learn, and there's enough interest, I'll begin work on a beginner series starting with modeling and applying it toward 3D printing as the end result. Fusion 360 is preferred because it's powerful and free, but is not the only program I use to create 3D models. There are multiple modeling techniques and most importantly, no one right way to create anything.Comment

-

CC Clarke,

Thread jacking is not a problem here, and if this Alfa boat is one of your favorites, it may be an interesting side by side look at the two methods of printing! Non the less I think you have an idea that would show there are other ways to enhance the design and building methods used in our hobby!

I may be in someway past the point of truly understanding and comprehending these new design techniques (old dog new tricks) but I for one would say go for it!

Rob

"Firemen can stand the heat"Last edited by rwtdiver; 09-11-2021, 11:04 AM.Comment

Comment