Getting close Rob. Looks like you are almost there. Exciting isn't it?

3D Printing Submariens and Sub Components

Collapse

X

-

Thanks Tom,

Just about done with the Redoutable boat! I am going to be using a portion of the WTC that I built for the Redoutable for my Astute. I am going to add another servo for the stern plains and along with the existing rudder servo, I am hoping to make the Astute a DYNAMIC diver! (getting closer to a full static diving Sub) I will fabricate a new 3"X12" cylinder for the servos and another motor and use the existing electronic cylinder to make up the complete system.

The Astute is just in it's primer stage right now. I have work to install the shaft and seals for the propulsion system and install the linkage for the rudder and stern plains. I will be using the oil-filled bronze bushings and the cup seals that I purchased from Nautilus Drydocks for the prop shaft and the servo rods exiting through the end cap! I will post photos as I progress on this project as well.

We are almost in total lock down until May 1st here in Gilbert, Arizona! Sure glad I have this great hobby to turn to!!

Everyone stay WELL & SAFE out there!

Rob

"Firemen can stand the heat

Comment

-

Bob,

I have not figured out how to put videos up on this forum!? My wife took some videos with an iPhone, she sent them to my computer, and from there I tried to download them using the upload attachments and it kept coming up as an error!?

Maybe you or someone else can go through the process for me so I can download some videos!

Thank you,

Rob

"Firemen can stand the heat"

Comment

-

Rob,

Typically, forums don't like direct video uploads. Way too much data to store on internal databases.

What you need to do is upload to something like Vimeo or YouTube and then post up the link here. If that's beyond your experience, get me the video and I'll look after it for you. If it's a big file (and it likely is), send it to me via WeTransfer.com. It's a free file transfer service that I've used a lot in the past with great results.

BobComment

-

Thanks for the info Bob! I will look into a YouTube account first, and if that does not work out I will send my video to you to post up on the blog (forum)!

By-The-Way! Love the look of your shop!:-))

Thank again,

Rob

'Firemen can stand the heat"Comment

-

The Redoutable project is complete! 3D printed Redoutable and the 3D printed WTC. For me this has been a 12 month journey, from design, fabrication, and final finish!

My next project is going to be to complete the Astute! The boat is built. This boat will use the WTC that I built for the Redoutable. I will post up the progress with photos on this boat as well!

Thank you! Everyone stay SAFE and WELL!

Rob

"Firemen can stand the heat"Comment

-

Tom,

Thank you! I do not have a YouTube account yet. So I am going to send a video that I took of it when I was testing it to Bob Martin and he will put it up for me. When I am sure the finish has had enough time drying I will then put it to the water again. I just shocked the pool, and I would be a little concerned about the finish coming off!

Comment

-

Today I started work on the ASTUTE propulsion system, and it did take some sanding and fitting to get everything aliened. I got it aliened and glued up the outer shroud. I did not secure the system totally into place until I get the rudder and stern dive planes installed and the linkage tied in.

I have a question? I am going to set the ASTUTE up to be a dynamic diver, and therefore I will need to add an addition servo for the stern dive planes. I am currently using a Hitec HS-311 servo in my WTC for the rudder. I am a little cramped for space to use the same servo for the dive planes. I do have standard small 9g servos that I could make work, but not sure if they have enough torque for the dive planes!?

Thanks for input!

Rob

"Firemen can stand the heat"Comment

-

Planes don't see a ton of force on them. You'll be perfectly fine (provided you have very free travel and they're not binding at all, that is).

If you get a sub with really large control surfaces, or one that really gets up and moves quickly, that might be a different story.Comment

-

Thank Bob!Today I started work on the ASTUTE propulsion system, and it did take some sanding and fitting to get everything aliened. I got it aliened and glued up the outer shroud. I did not secure the system totally into place until I get the rudder and stern dive planes installed and the linkage tied in.

I have a question? I am going to set the ASTUTE up to be a dynamic diver, and therefore I will need to add an addition servo for the stern dive planes. I am currently using a Hitec HS-311 servo in my WTC for the rudder. I am a little cramped for space to use the same servo for the dive planes. I do have standard small 9g servos that I could make work, but not sure if they have enough torque for the dive planes!?

Thanks for input!

Rob

"Firemen can stand the heat"

I do see that you and David do use them in your MSD/SD cylinders.

Rob

"Firemen can stand the heat"Comment

-

Getting closer to the end of my 3D printed Submarine projects (Astute & Redoutable) I just spent time in the pool setting up the weights and flotation on the Astute, and after about 2 hours in and out of the water a doz times I got the Astute right on the money!

A little more build work and it's off to the final finish work!

Question: I do not have an airbrush, (YET) But I do have a very fine fan brush. Has anyone used a fan brush to do the rusting and water marks on your subs?

Rob

"Firemen can stand the Heat"

Comment

-

Sure.Getting closer to the end of my 3D printed Submarine projects (Astute & Redoutable) I just spent time in the pool setting up the weights and flotation on the Astute, and after about 2 hours in and out of the water a doz times I got the Astute right on the money!

A little more build work and it's off to the final finish work!

Question: I do not have an airbrush, (YET) But I do have a very fine fan brush. Has anyone used a fan brush to do the rusting and water marks on your subs?

Rob

"Firemen can stand the Heat"

Who is John Galt?

Who is John Galt?Comment

-

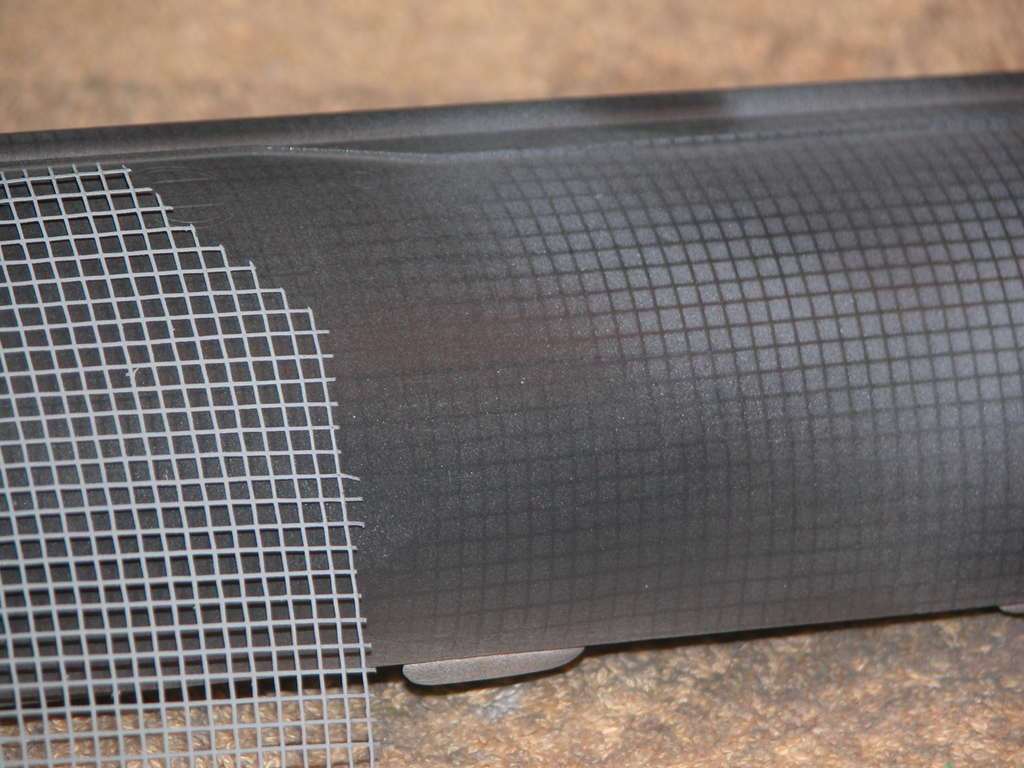

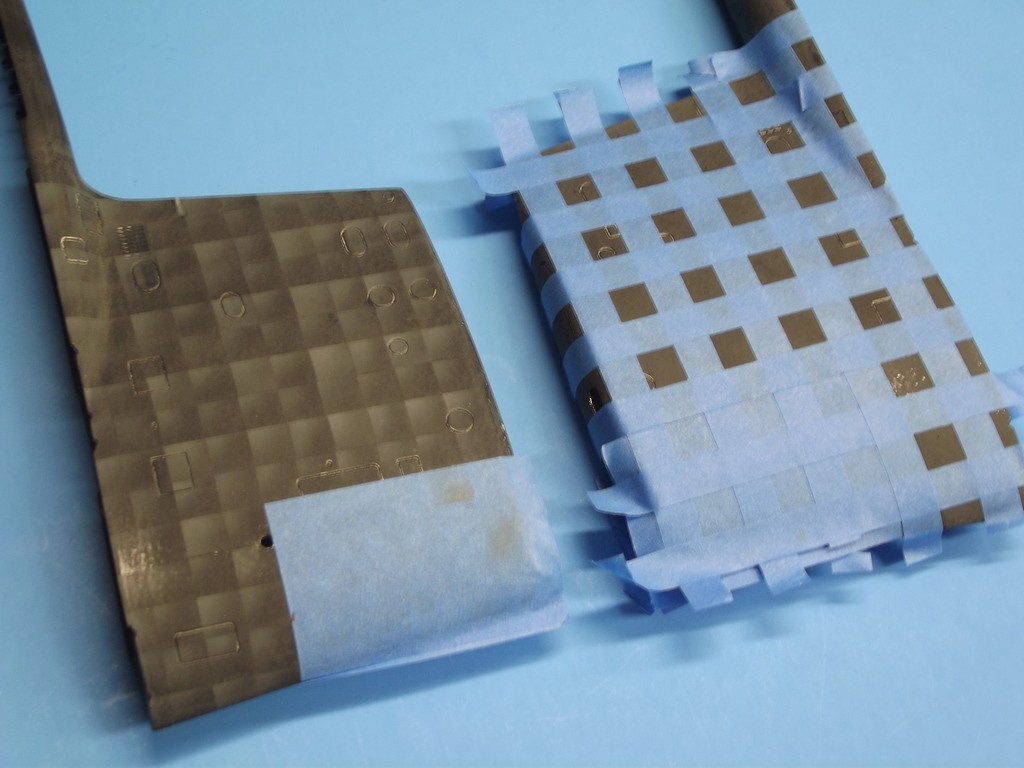

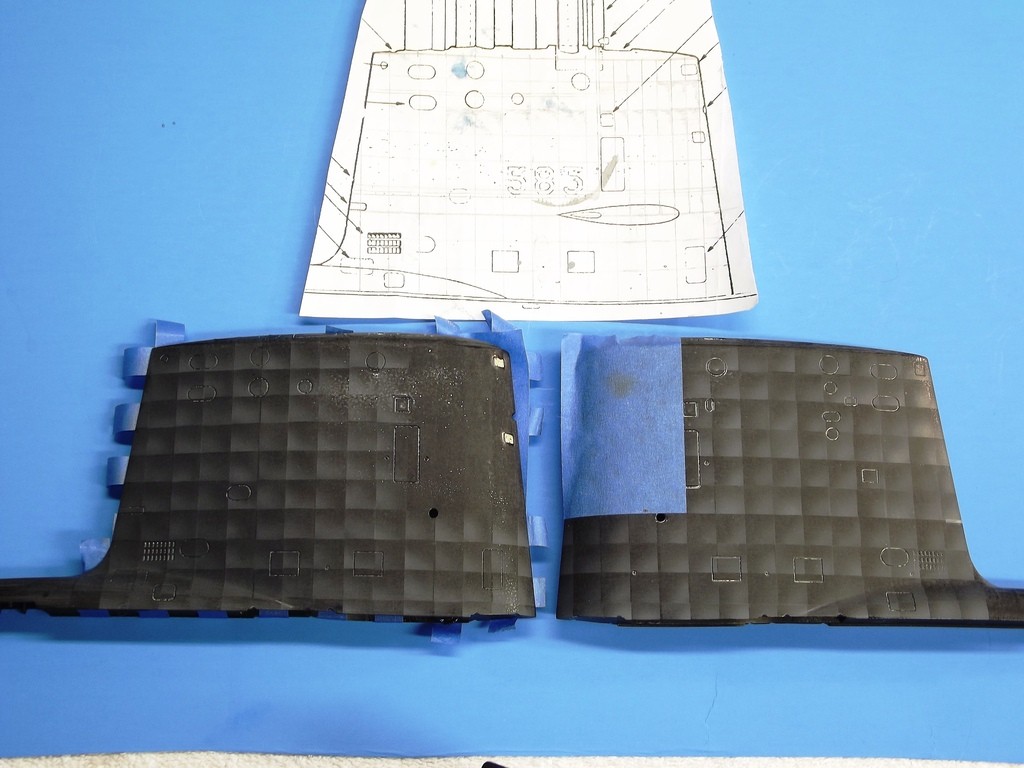

You won't see much rust on a boat, particularly the rubber-clad ones of today. Your wreathing will center on two principle types: vertical streaking (rain water run-off depositing dust, paint flakes, milk, spiled paint, spilled lubricants, bird-****, and boot grim); and 'oil-canning' -- the shadow throwing of plate going concave between stringers and frames.

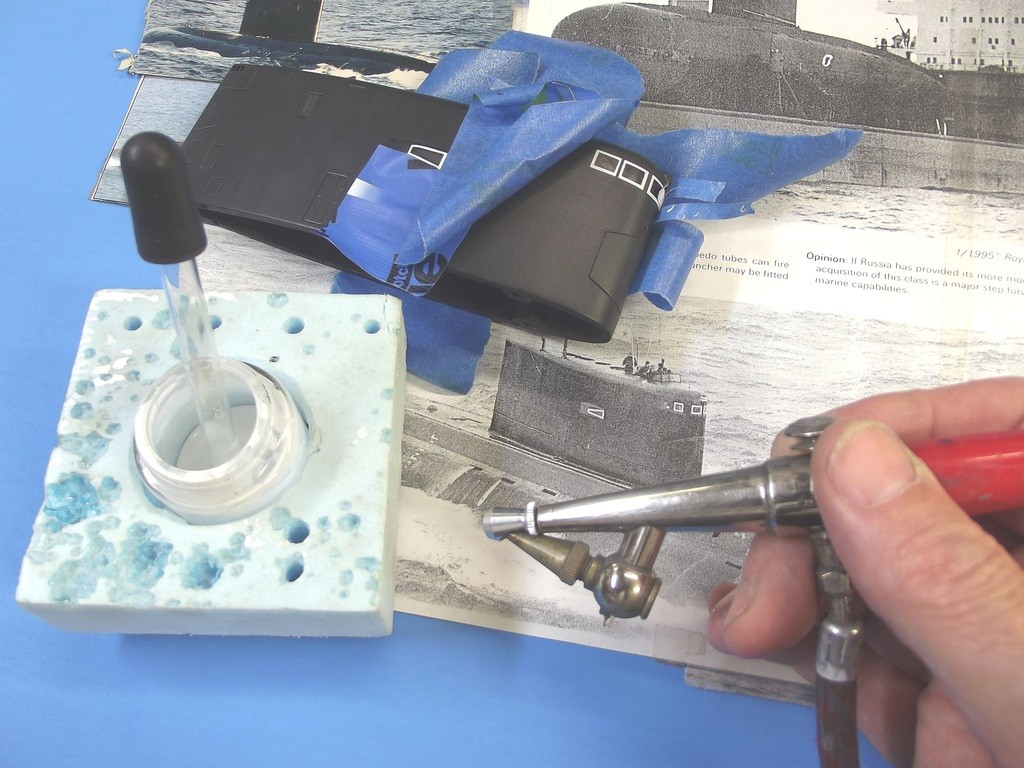

Air-gun? Only one choice: The Paasche H-Model, single-action. It's all the gun you will ever need! Install the #3 tip and you're set for life. Double-action guns are for no-talent pansies with pony-tails!

THIS is what I'm talk'n about!

GRP sonar domes usually oil-can over their geodesic support structure. You see this prominently on early Soviet era boats.

Last edited by He Who Shall Not Be Named; 04-09-2020, 06:24 PM.Who is John Galt?

Last edited by He Who Shall Not Be Named; 04-09-2020, 06:24 PM.Who is John Galt?Comment

Comment