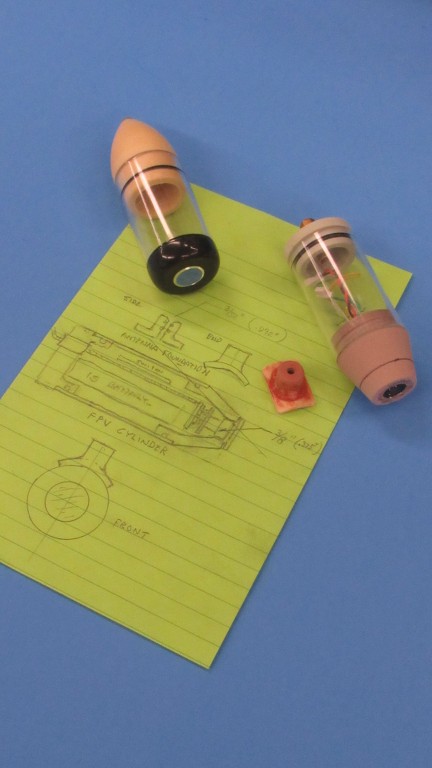

We go back in time to the initial 1.25-inch diameter Swann standard quality video camera-transmitter watertight enclosures. The upper one, with the long foil-shaped antenna fairing is the type strapped to the hull of a model submarine. A shot of how that is used posted in an earlier segment.

The lower enclosure is the type designed to be housed within the sail of a model submarine. The tools used to cast the polyurethane parts seen here are still available to me and present options applicable to the current work, such as the 1.25-inch diameter watertight enclosures housing the 'modern', High-Definition (HD) quality equipment now in development.

This new enclosure varies only in that the forward removable bulkhead -- which mounts the camera and lens -- had to be contoured sharply to get the lens to fall along the plane of the 1/35 Type-23's deck-gear access door, which projects slightly ahead of the sails leading edge.

I've nearly completed the masters of the Type-23 enclosure forward bulkhead as well as a new, more robust, antenna fairlead.

That fairlead, mounted atop the enclosures cylinder, routs the transmitters coaxial cable through a watertight gland and up into the hollow periscope cylinder where it terminates at the top as an antenna within a hollow, plastic (and RF transparent) periscope head. The 5.8gHz signal will not punch through water, hence the need to mount the antenna where it sticks up into the air as the model travels about at, 'periscope depth'.

With the FPV system installed aboard the Type-23 the only variance from scale will be the missing deck gear access door and the lens of the systems enclosure peeking out from where the deck-gear access door used to be.

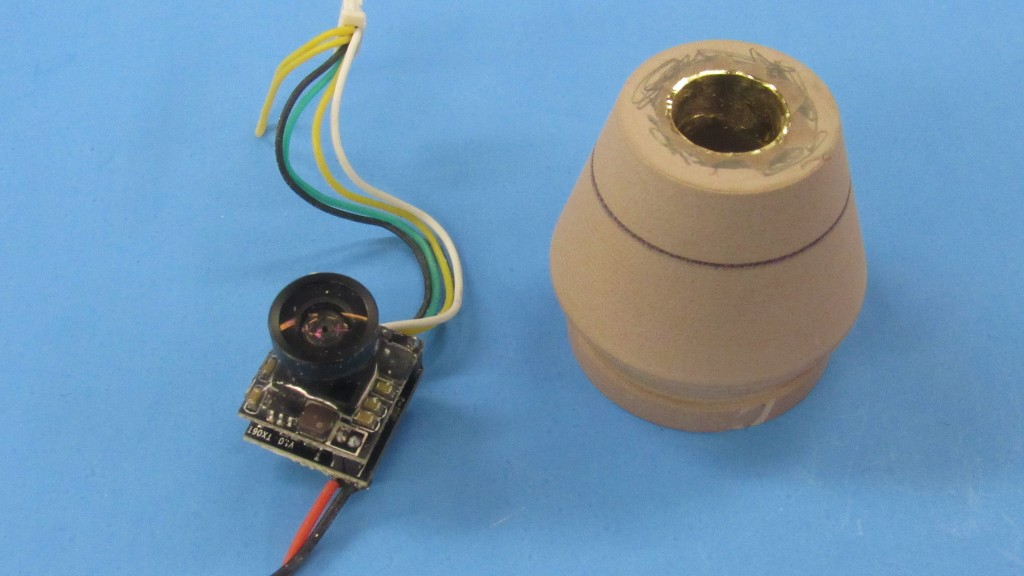

The old enclosure was too blunt at the front to get the lens far enough forward in the sail. However, the new forward bulkhead -- seen here as an in-the-ruff master with its much sharper tapper -- will.

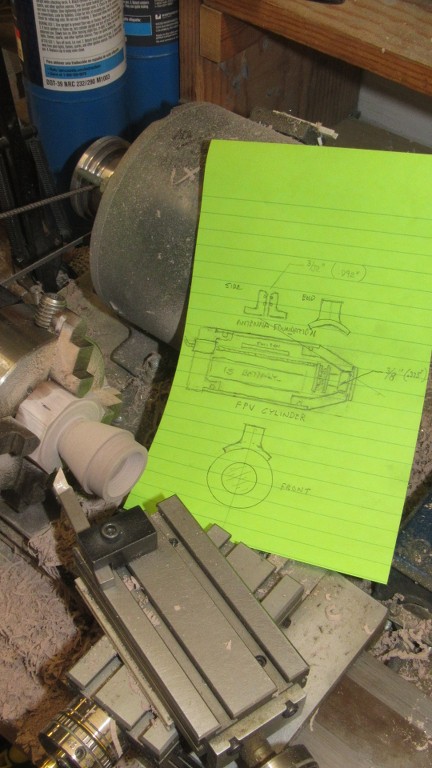

The forward bulkhead was manufactured by turning a dense piece of RenShape on the lathe. Here I'm cutting the blank out from a scrape piece of RenShape board. RenShape is the ideal medium for almost all the masters I produce these days. Expensive, but worth every penny!

First cut was to establish the outside maximum diameter of the bulkhead, equal to the 1.25-inch diameter of the enclosures Lexan cylinder.

Here I've already cut the inside and outside tappers, as well as the recessed radial flange that slips within the forward end of the cylinder. I have yet to cut the O-ring groove that will make the watertight seal between the eventual cast resin forward bulkhead part and cylinder.

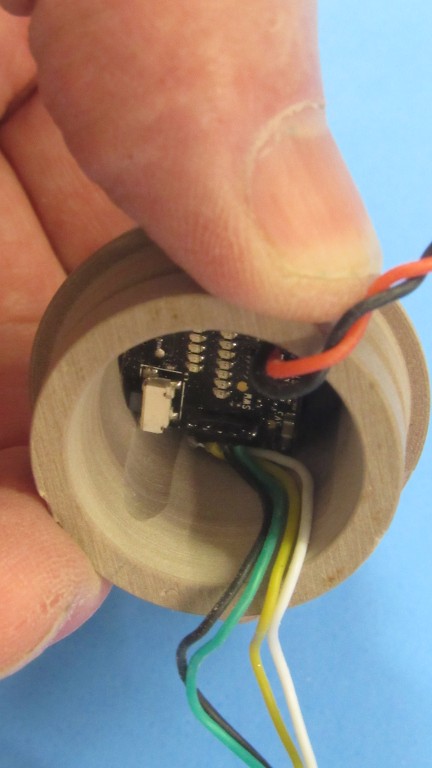

I found that the two pancaked printed circuit boards (PCB) that attached to the lens and sensor, being of square profile, became a big-time interference fit only half-way into the forward bulkhead.

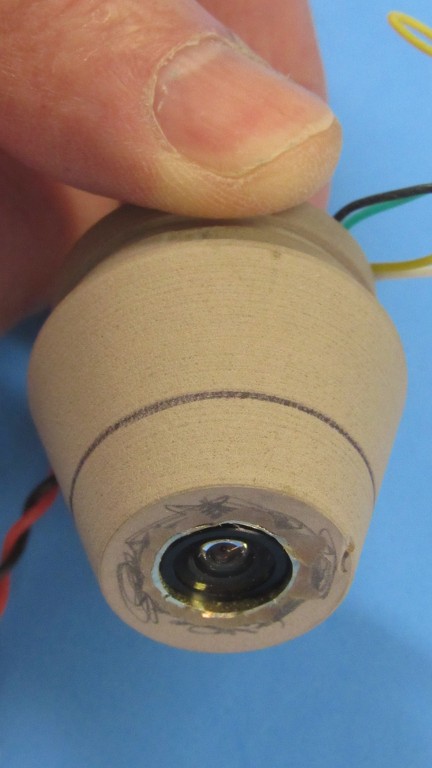

So, I moved the work over to the milling machine which had my rotary table bolted to its bed, centered the work on the rotary table and proceeded to cut four equally spaced grooves within the bulkhead. These grooves permitting complete, uninterrupted passage of the camera-transmitter all the way forward. The objective was to get the cameras lens even with the forward end of the bulkhead master.

The front end of the bulkhead needed a little putty and sanding work (damned thing kicked out of the chuck during an earlier turning set-up and got a few scares as a result). I've temporarily installed the camera-transmitter to affirm that the camera lens sits even with the forward end of the bulkhead.

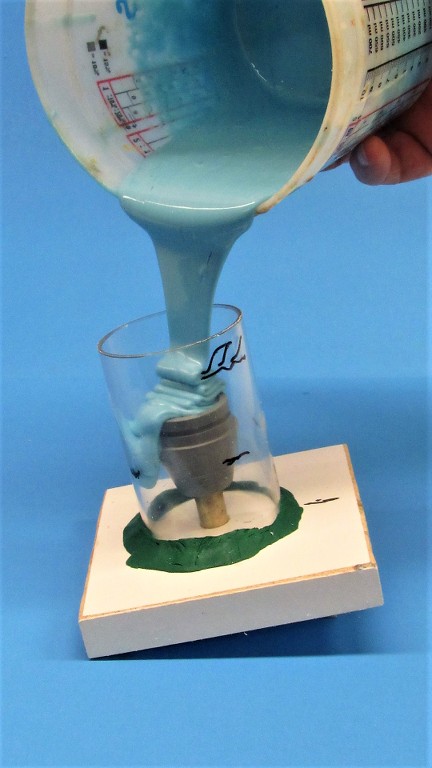

After fixing the damage the master was coated with CA, sanded, puttied where required, spot-sanded, primed and readied for use as a master to give form to a RTV rubber production tool.

Looking into the seated camera-transmitter within the forward bulkhead. Note the milled out longitudinal channels that gave clearance to the PCB's corners.

The completed forward bulkhead and antenna fairlead masters and some of the layout tools used to transfer two-dimensional graphics to the three-dimensional work. Layout is everything! Measure twice and you'll only have to cut once. The ideal I all too often fail to attain.

They used to teach this stuff in shop-class.

What? What's that you say!... they don't teach shop in school anymore?!!! No wonder so many under-forty types today can't even figure out how to stick two pieces of wood together!

To be fair, the government education system of today has taught our kids all about 'fairness'; how many sexes there are (we're up to 15 as of his writing); that all white people are stinkers; and what used to be shop-class is now, how to write code.

Yikes!

Yeah. Our future is secure with this lot.

Comment