Dave,

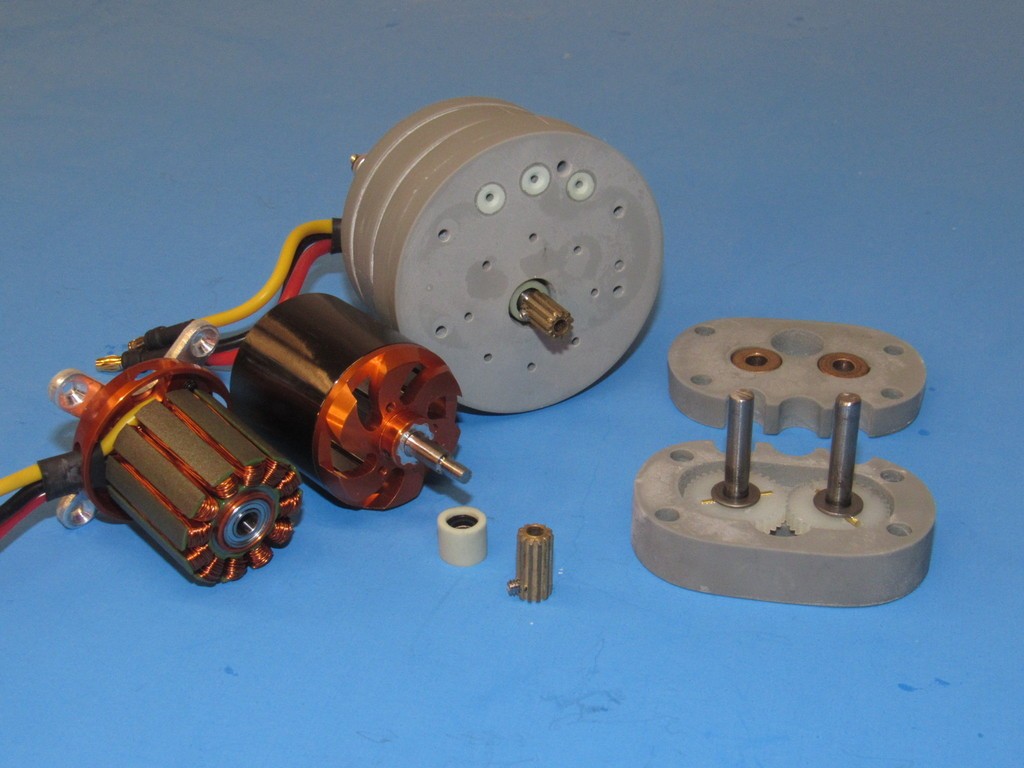

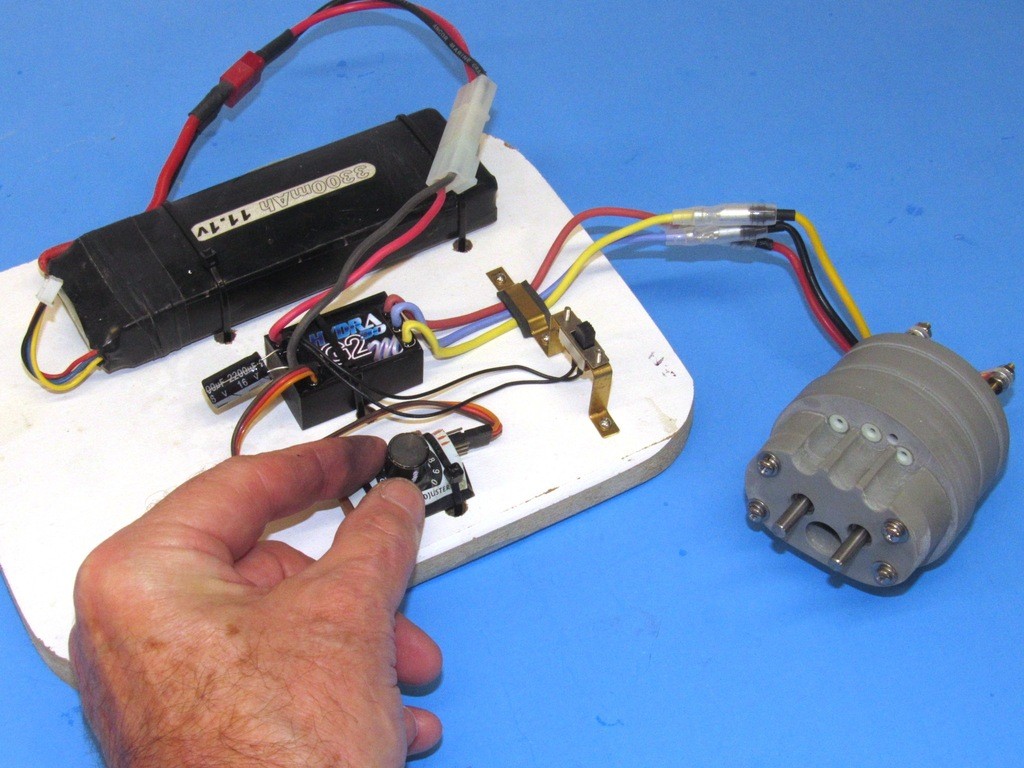

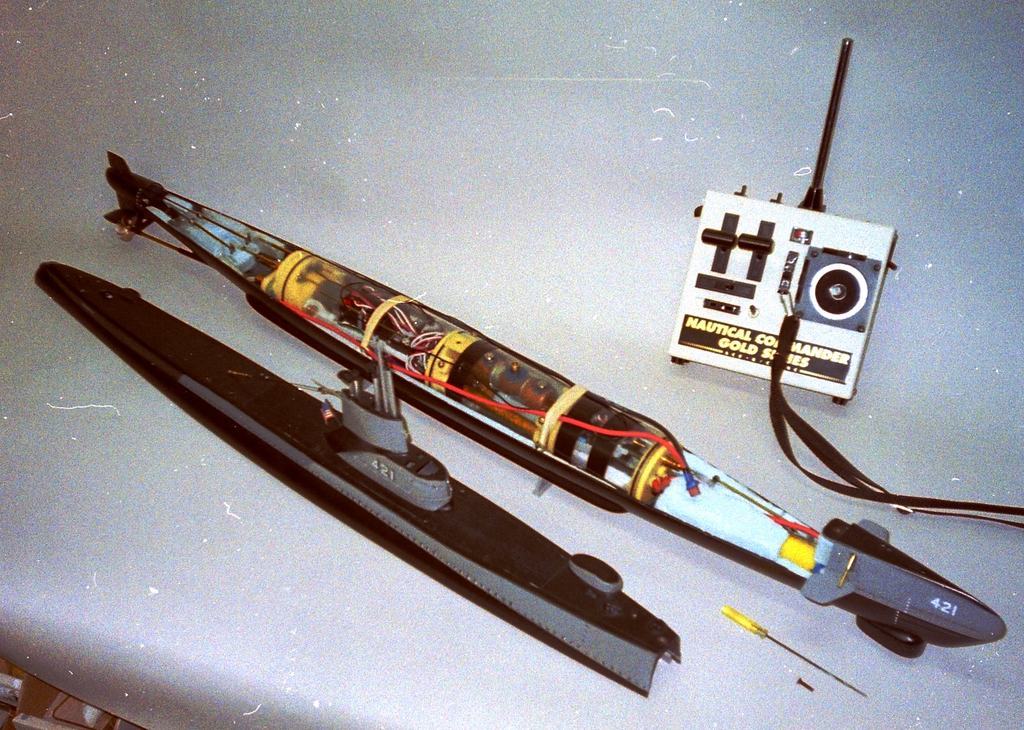

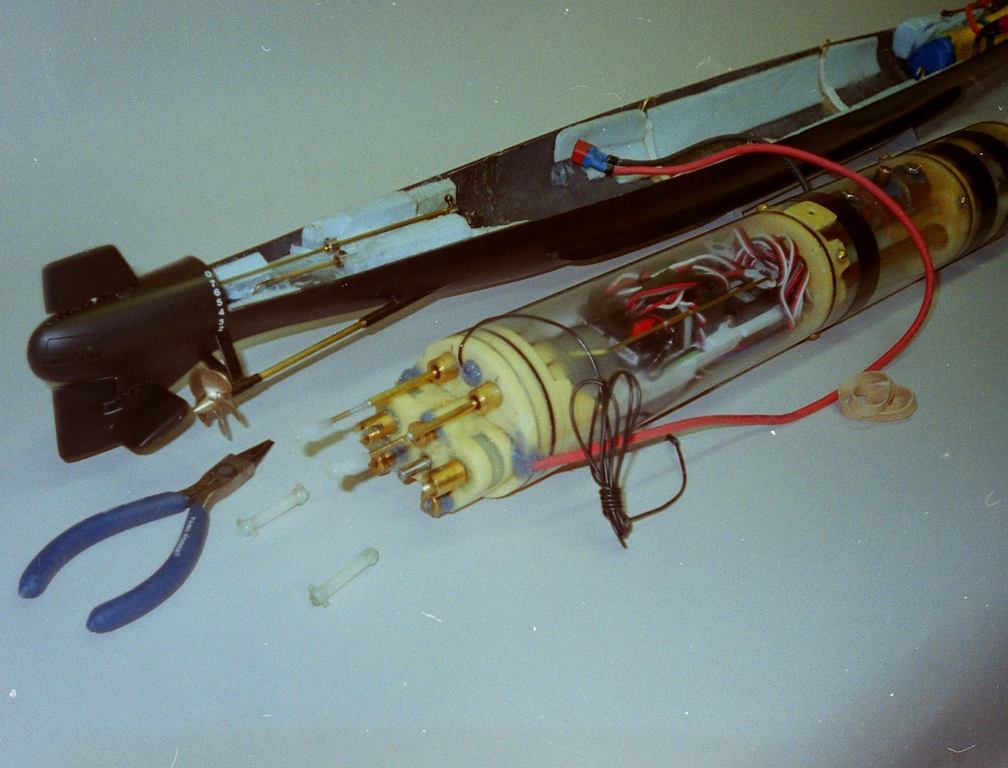

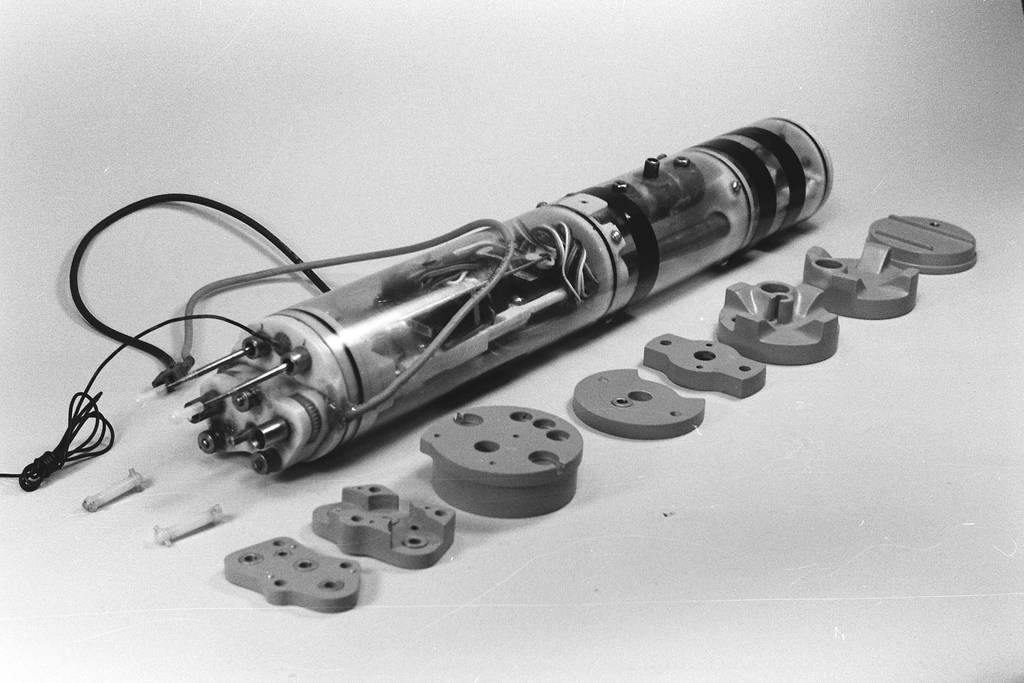

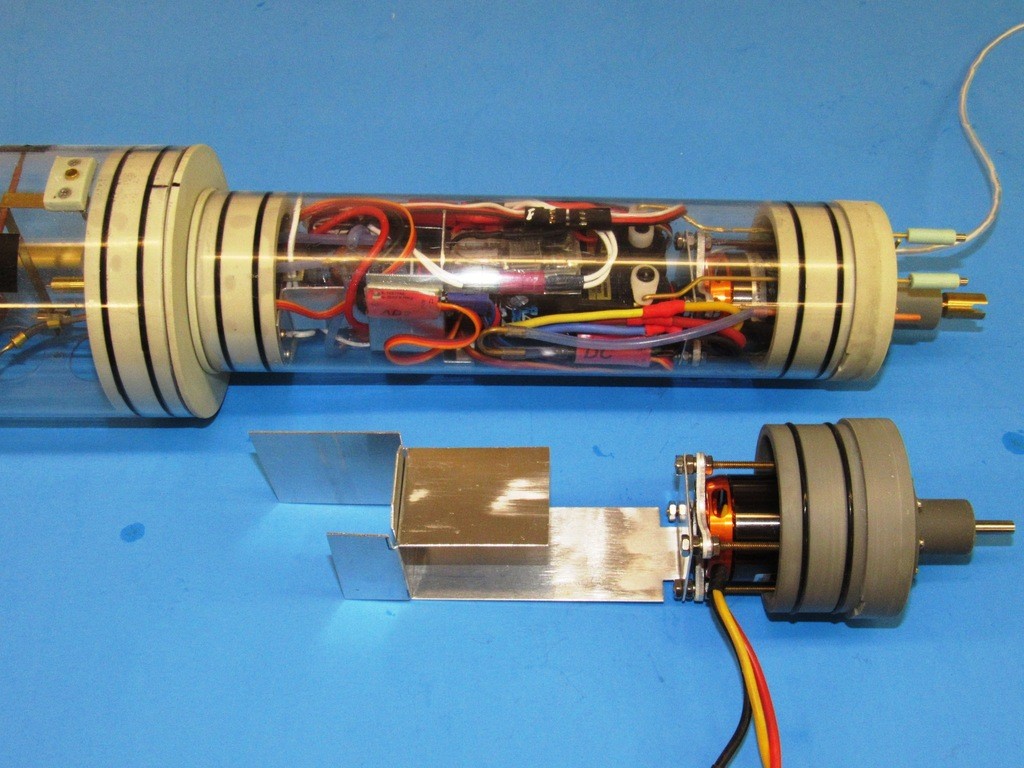

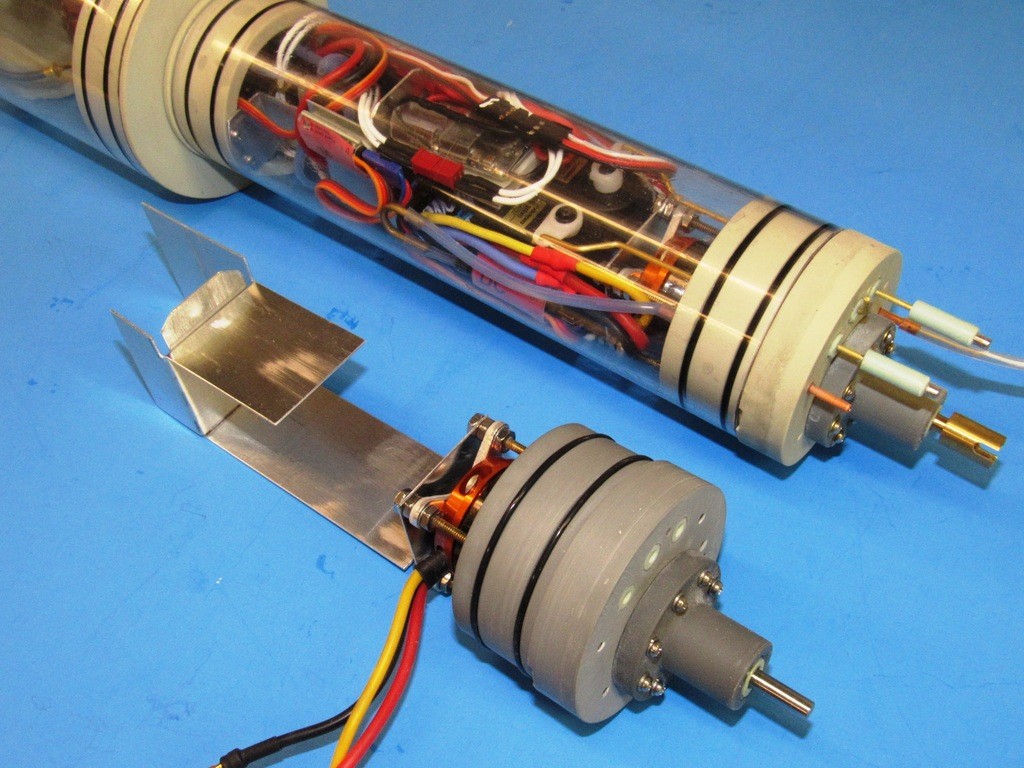

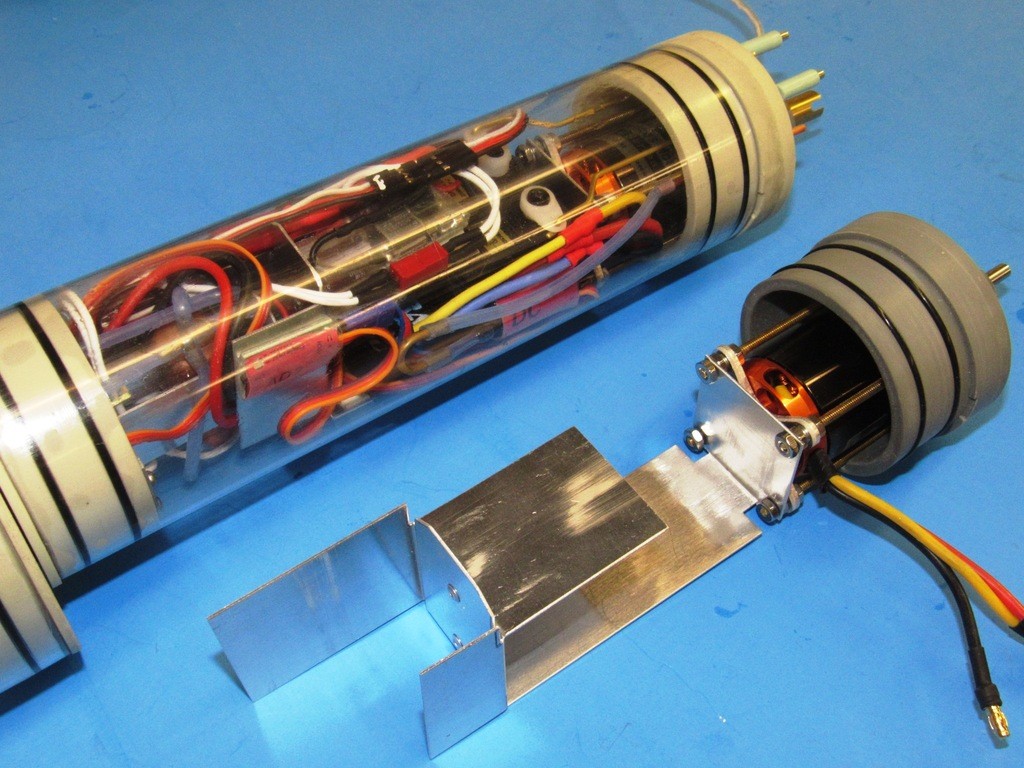

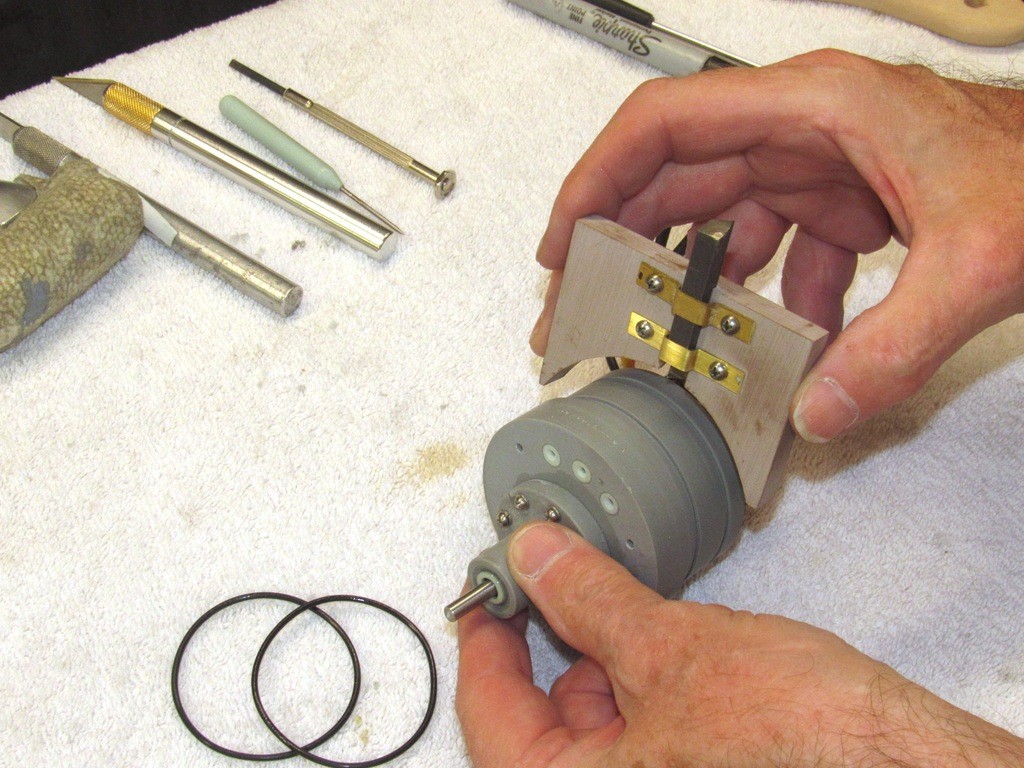

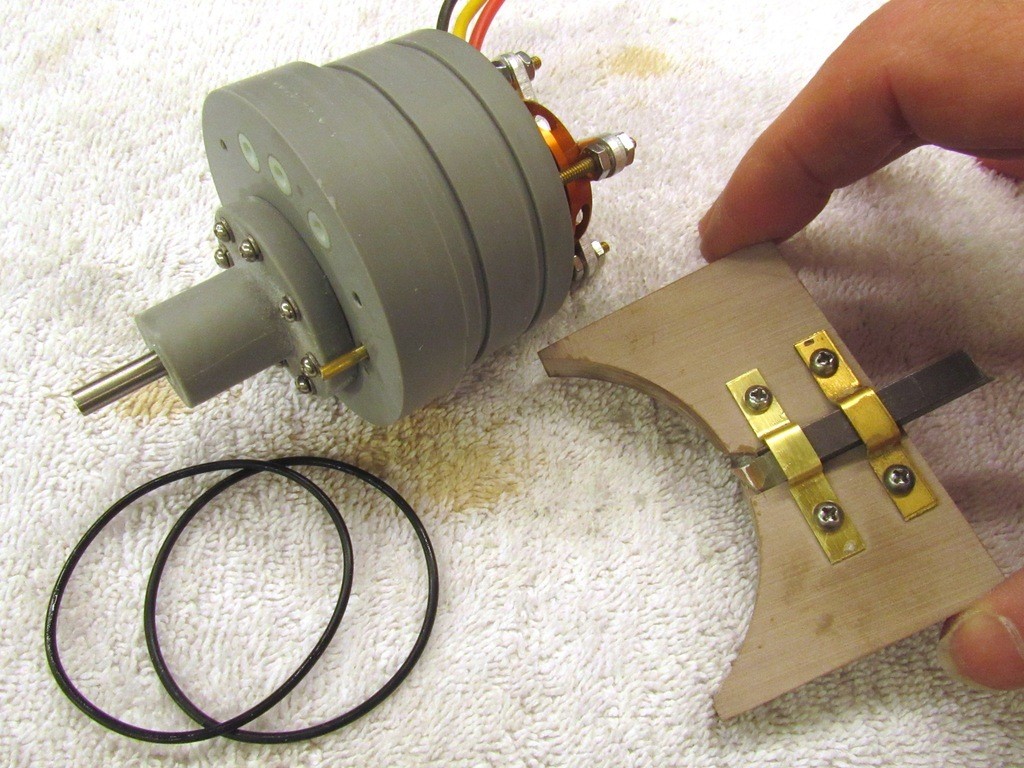

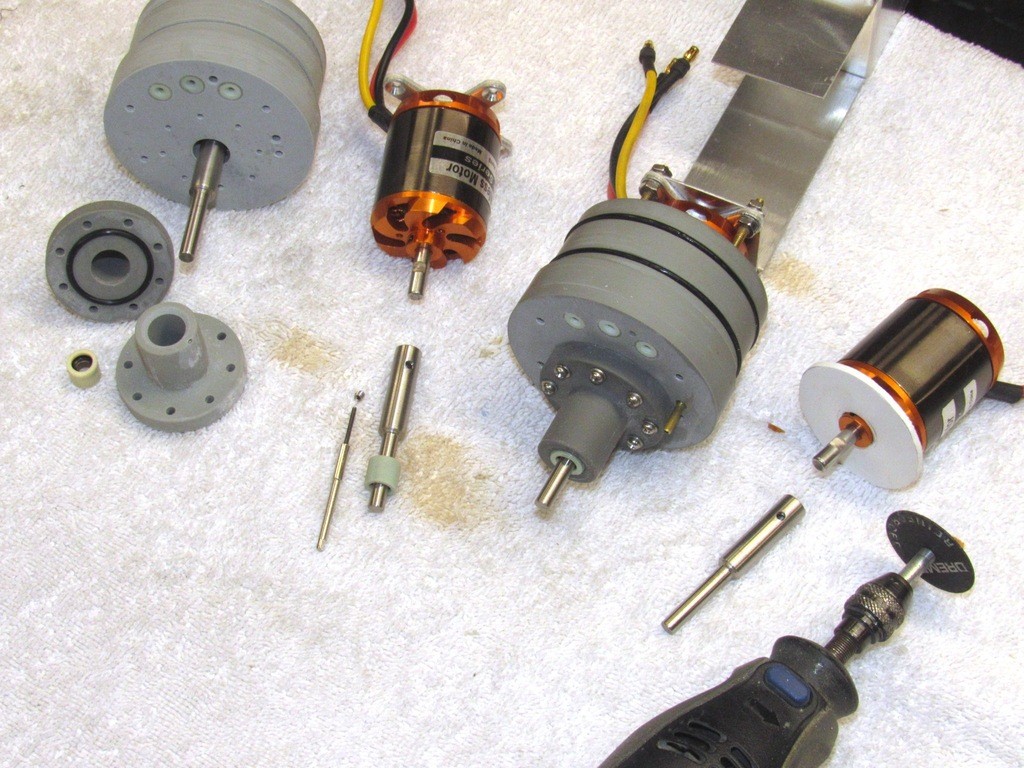

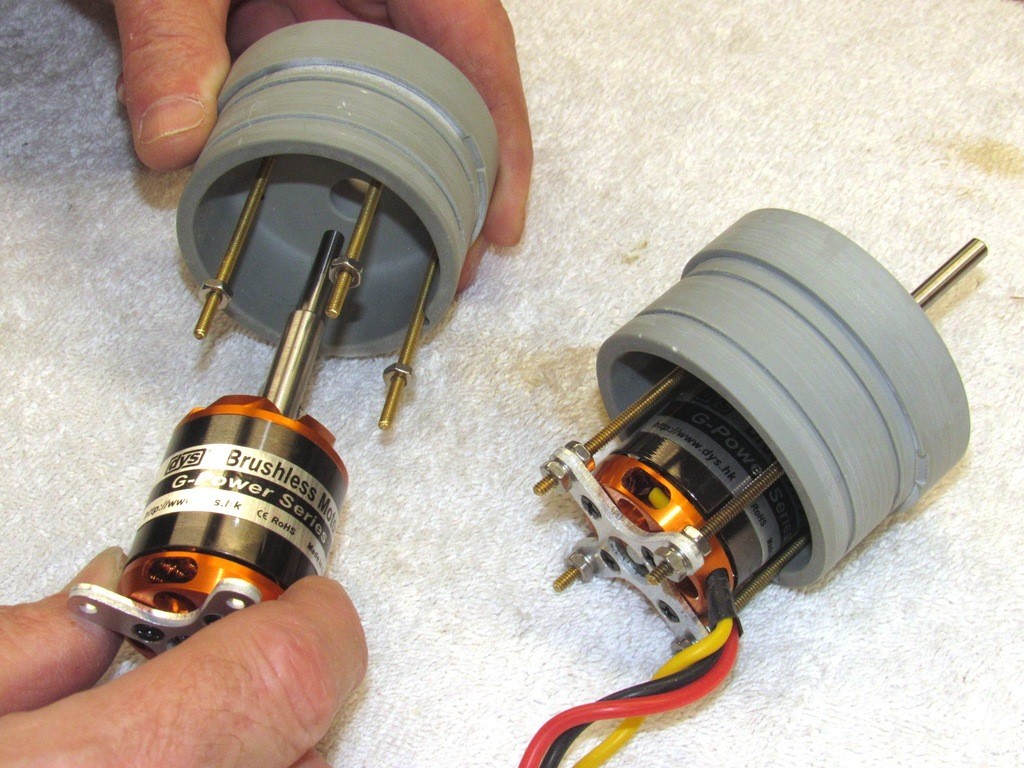

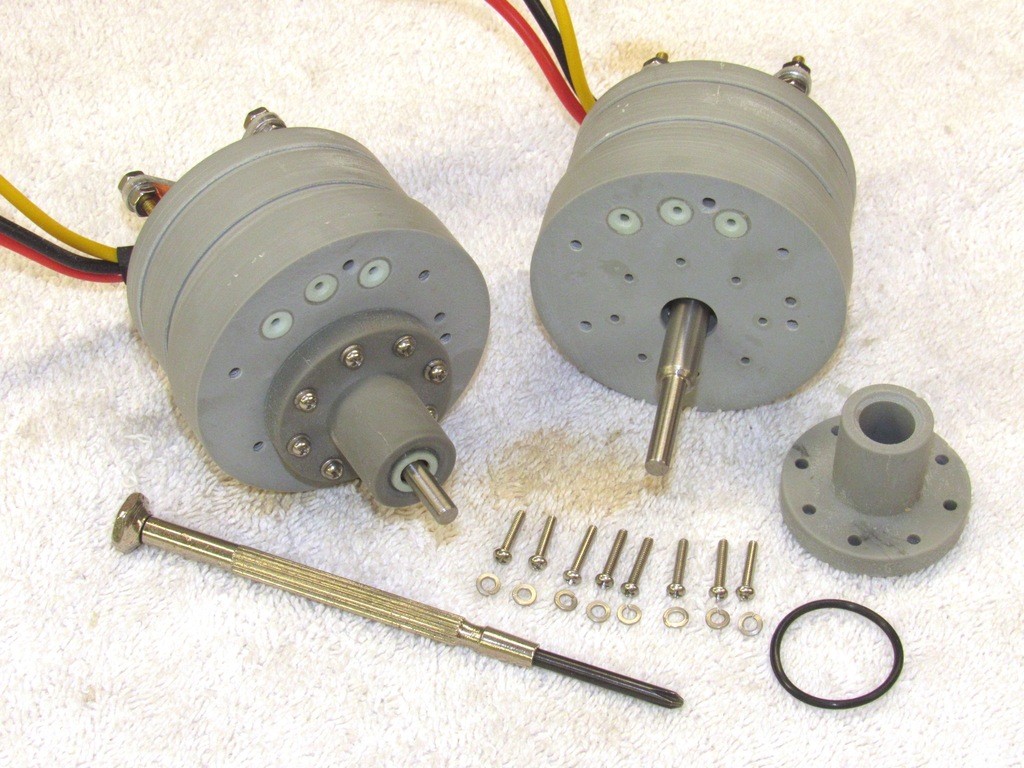

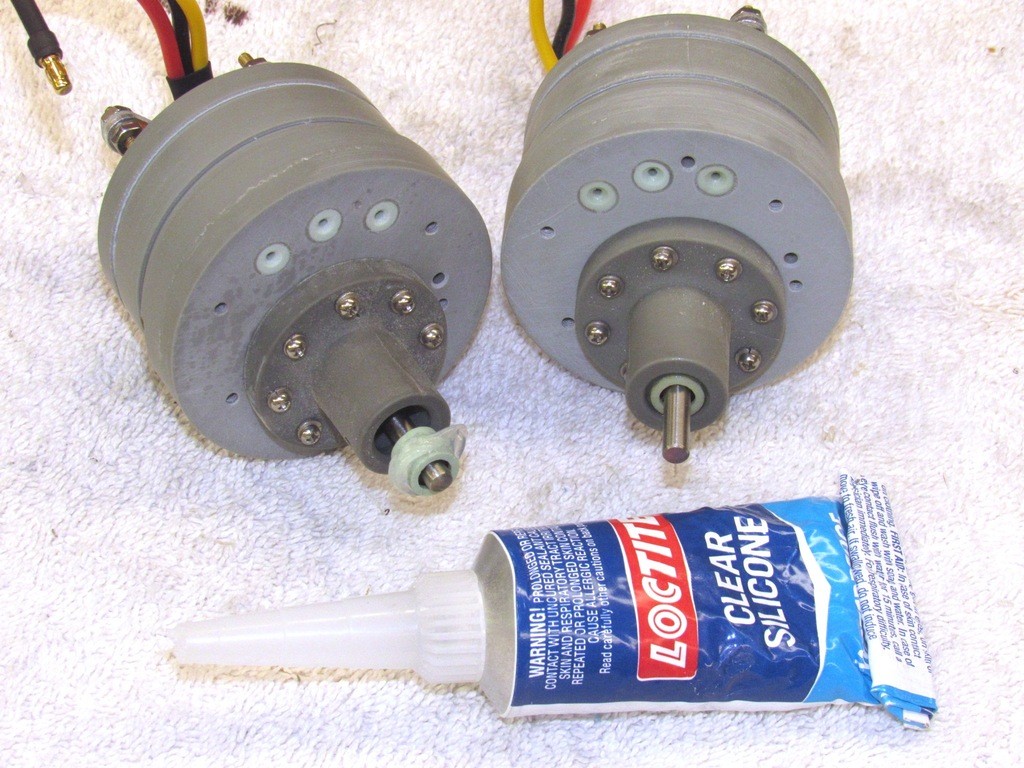

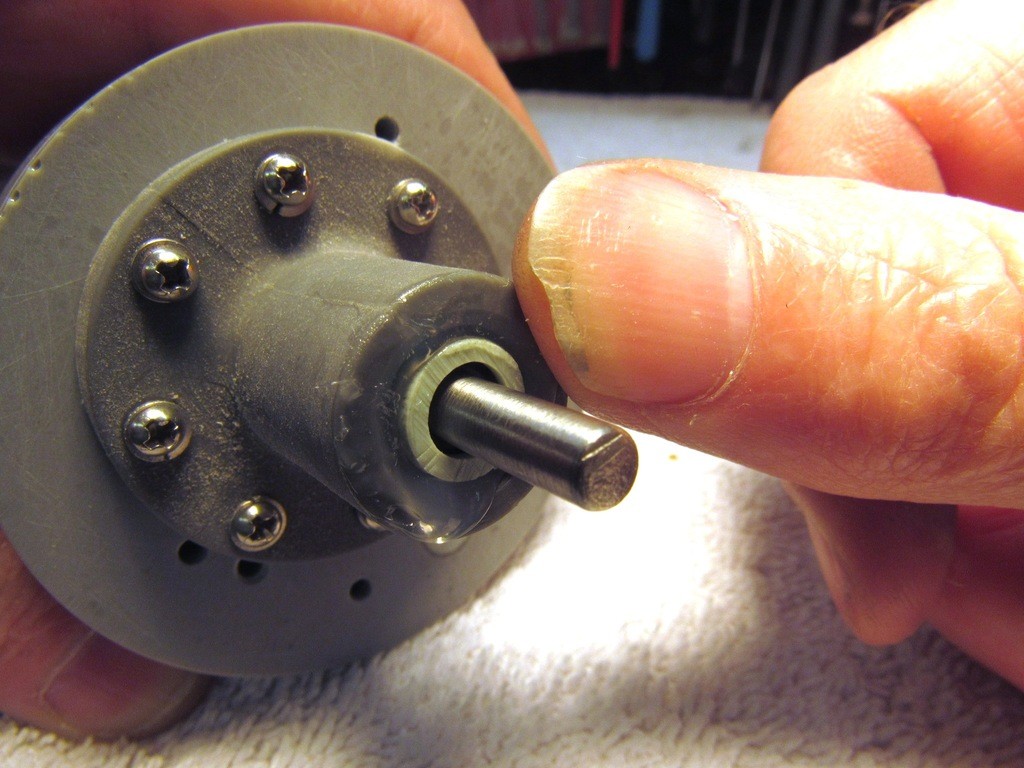

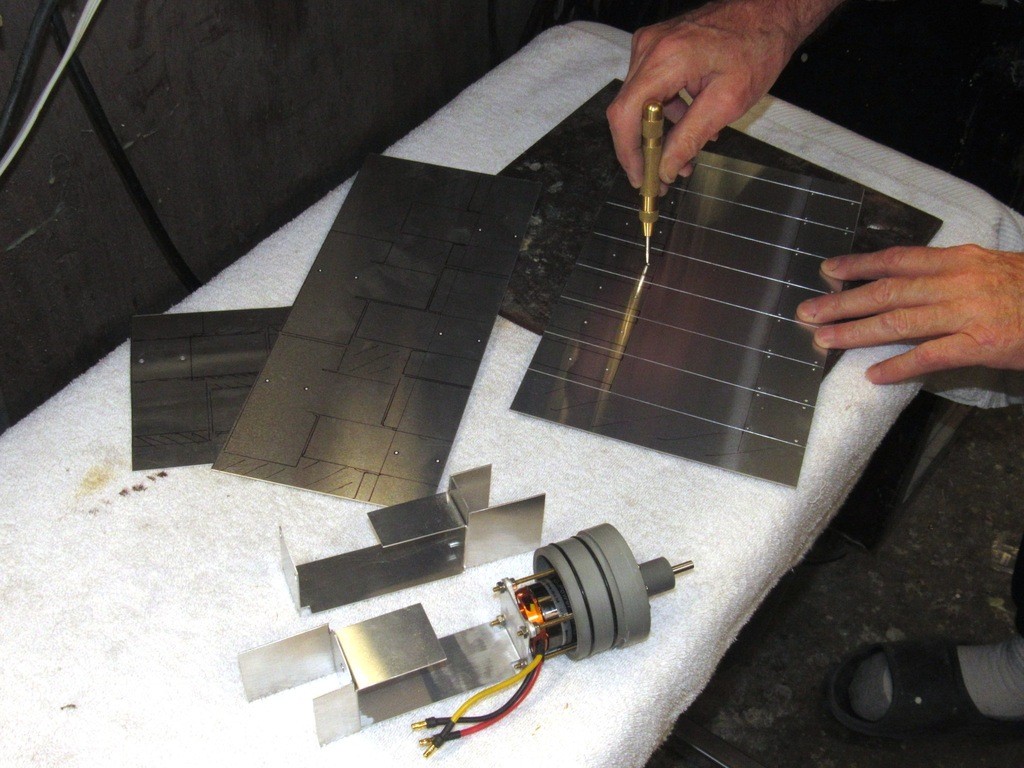

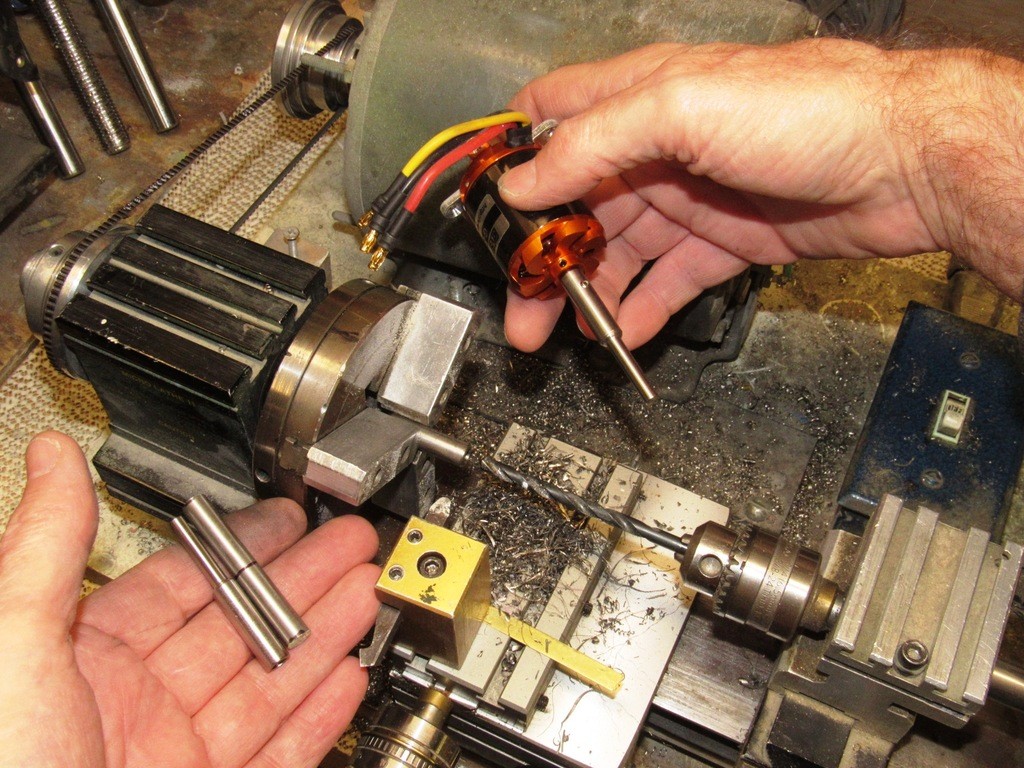

I am curious as to the KV of your outrunners? I have a pair of Graupner 500 KV outrunners, which I am installing in a Robbe U-47. I will try them direct drive initially, but I might need to go to gear reduction or belt drive if that doesn't work out. This is my first try at Brushless motors in anything but a plane. They are always so bloody fast! The 500KV Graupners are comparable to the outrunners being used by Engle in a couple comparably sized boats so fingers crossed they aren't stupid high RPMs . Up side is low current draw and longevity.

Cheers,

Steve

I am curious as to the KV of your outrunners? I have a pair of Graupner 500 KV outrunners, which I am installing in a Robbe U-47. I will try them direct drive initially, but I might need to go to gear reduction or belt drive if that doesn't work out. This is my first try at Brushless motors in anything but a plane. They are always so bloody fast! The 500KV Graupners are comparable to the outrunners being used by Engle in a couple comparably sized boats so fingers crossed they aren't stupid high RPMs . Up side is low current draw and longevity.

Cheers,

Steve

Comment