Hello David,

A question about the single geared shaft design that you have shown here most recently.

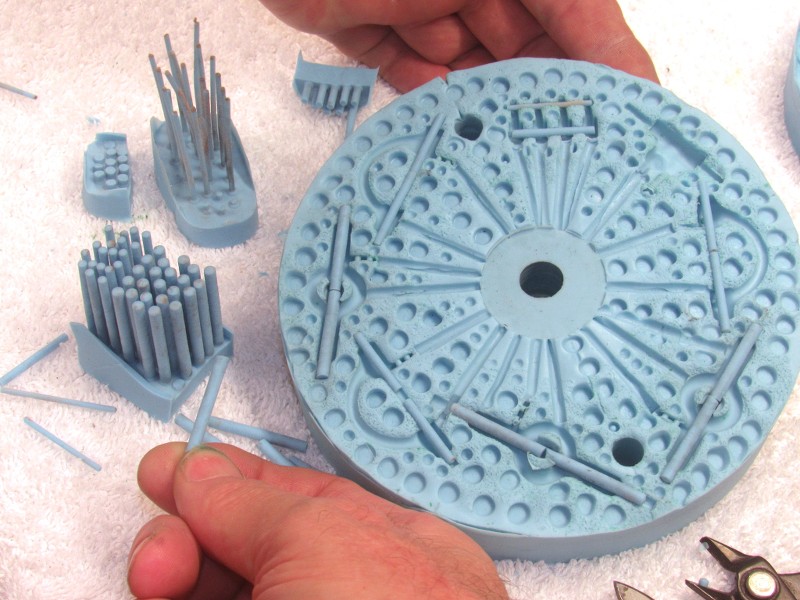

I am trying to look at how the front of the endcap which shows the recess for the gear and main shaft attaches to the other section of endcap that has the motor attached. Are these two parts glued together and once done cannot be pulled apart? Or do the brass tubes and other connectors that run through both off a means of securing that can allow the two main end caps to be taken apart if needed?

just not quite sure. I hope the question makes sense..

David H

A question about the single geared shaft design that you have shown here most recently.

I am trying to look at how the front of the endcap which shows the recess for the gear and main shaft attaches to the other section of endcap that has the motor attached. Are these two parts glued together and once done cannot be pulled apart? Or do the brass tubes and other connectors that run through both off a means of securing that can allow the two main end caps to be taken apart if needed?

just not quite sure. I hope the question makes sense..

David H

Comment