я замерзаю

November Holiday

Collapse

X

-

Speaking from total ignorance here, as I have never laid up anything, but might it be worth it to just mark their locations and install the PE components on a completed hull?Dead men tell no tales...Comment

-

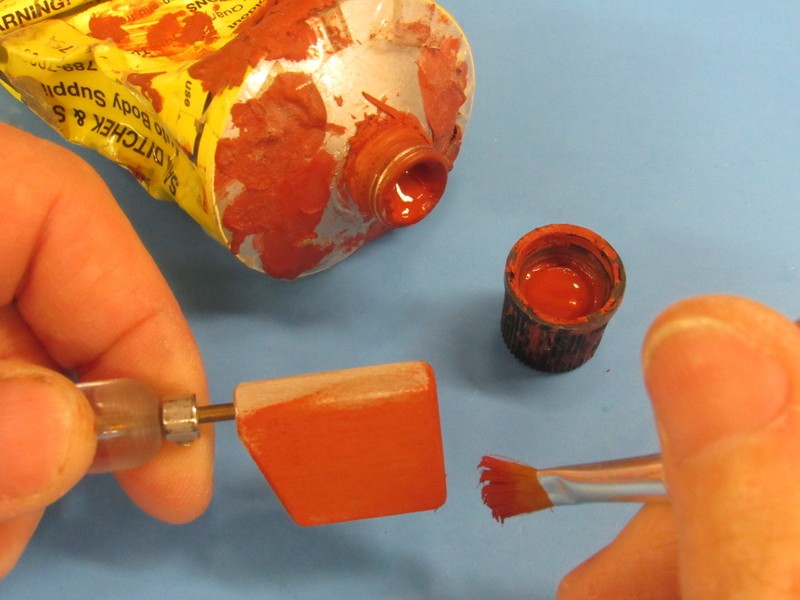

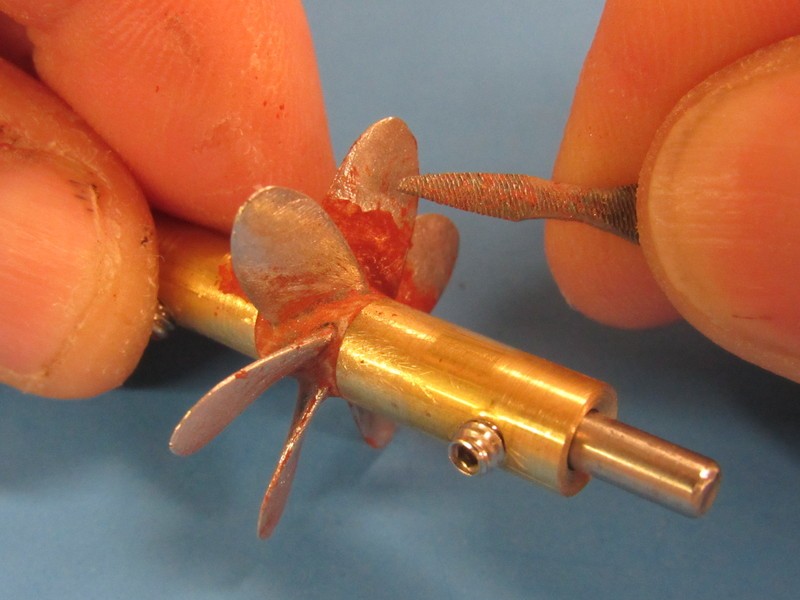

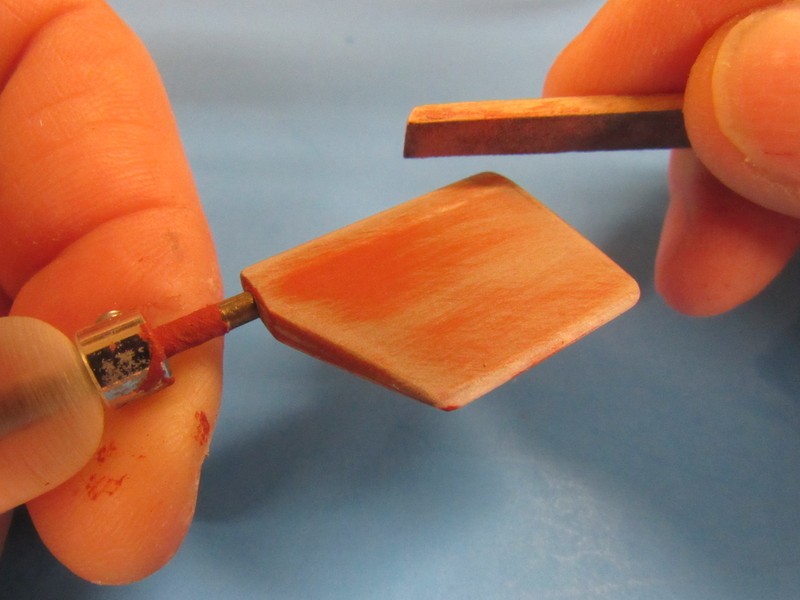

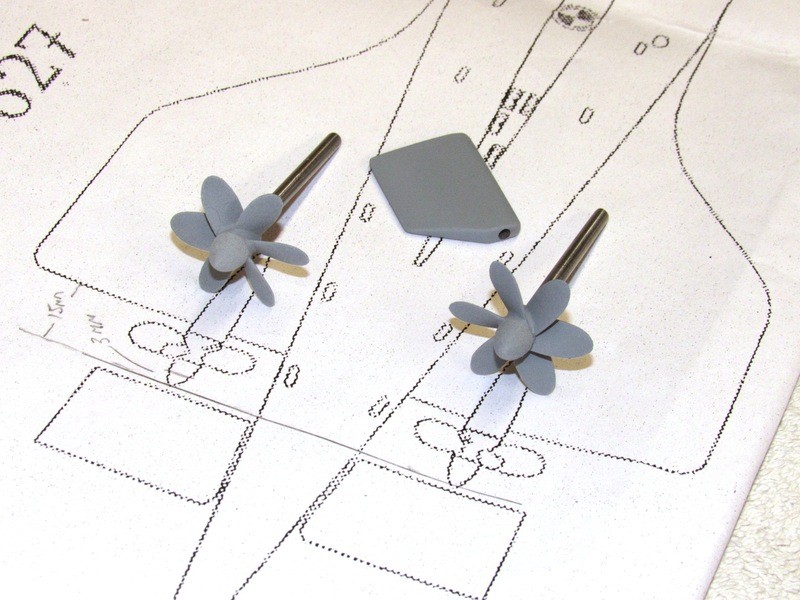

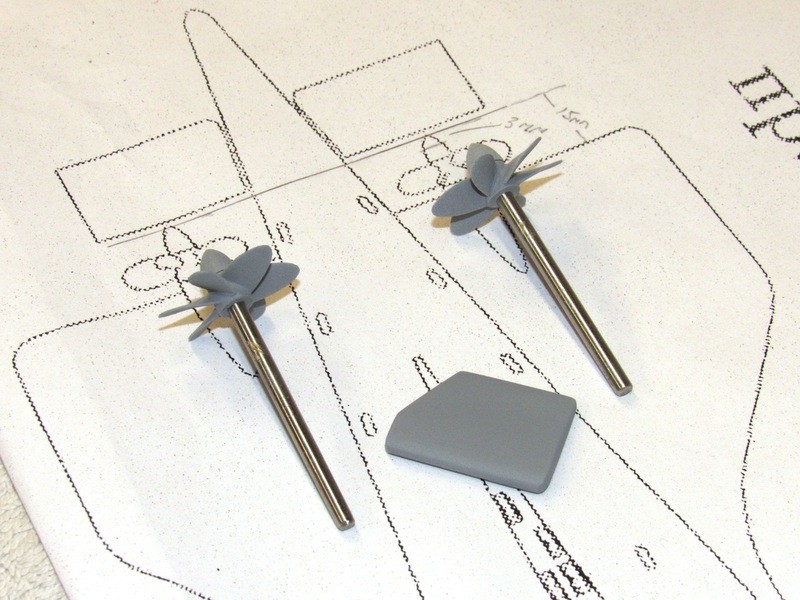

Yeh, but no. The problem is that the brass bits fall off with use in a watery environment. The idea is to capture the detail in epoxy resin that will be impervious to all the external crap that will undoubtedly be thrown at it. Also means that I only have to make one set of brass bits.

On a different track: I love your dog. I live on a farm and I can tell you that "that" dog is a hunter; as for the **** eating grin on his owner, well that's another story.👍 1Comment

-

theConcerning the circular pattern of holes on the front of the sail; they might be some sort of pressure sensor. For what purpose I do not know. This Picture (with the happy blokes) is the only I could find. Sorry for not delivering better info.

Comment

-

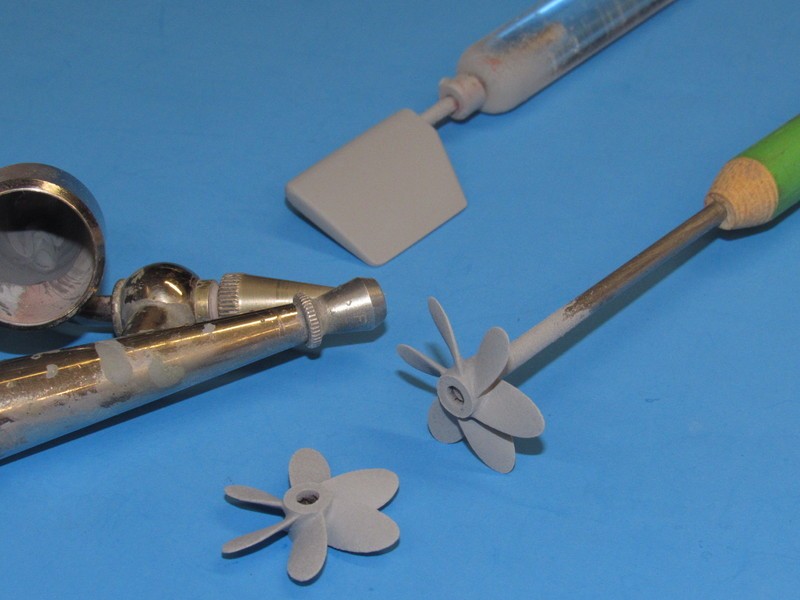

As an r/c model submarine suffers extremes of temperature rapidly -- the July sun baking the model as it sits on the bench, to the relatively cold water when you plunk it into the drink for another run -- you want as much of the structure to be homogeneous as possible. The ideal is a structure where all surfaces have the same expansion/shrinkage rate. Not so with GRP with brass or stainless inserts, or GRP with polystyrene sheeting applied (ain't that right John?!). The more unlike materials you have butted up against one another, the more likelihood of cracks and peeling of substrate over time.

If all that inlay work Scott's putting into his master eventually becomes part of the GRP hull and sail part matrix, then that's the ideal. No cracking, peeling, or widening seams down the road, and an easier assembly job for the end-user.

I HAVE SPOKEN!!! ….. SO LET IT BE WRITTEN!!!!!!!!

DavidWho is John Galt?👍 1Comment

-

-

Comment