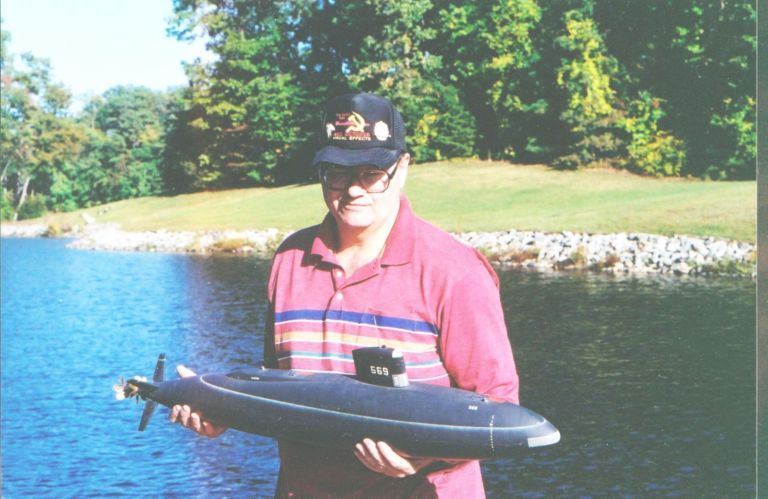

1/96 Albacore (after Phase III coversion 1961)

Collapse

X

-

Are you planning on producing this commercially, or just one or two boats?Leave a comment:

-

I've had a few goes at this;

I was never brave enough to install the last one. It was well beyond my comfort zone.

Leave a comment:

-

-

Our Navy never licked the sealing problem. Both the ALBACORE and JACK always had significant leakage at the seal(s). I think it a better solution, for us knuckle-dragging model-makers, to put most of the running gear into the wet. This position based on experience I acquired with a 1/60 scale ALBACORE, phase-3.

DavidLast edited by He Who Shall Not Be Named; 10-09-2018, 10:52 AM.Leave a comment:

-

Never did a counter rotating dsign......but I'd go for a gear in the WTC and seal the drive shafts. Shouldn't be that complicated.....Leave a comment:

-

That looks to be a very well crafted differential type gear-train. I know from hard-learned experience that if you run tightly meshing gears in the water (an incompressible fluid) that the re-bound against the gears will tear up the bearings in no time! The gears have to have a sloppy fit so water can squirt out when the teeth mesh. That warning in mind, that is a very slick looking counter-rotating drive.

DavidLeave a comment:

-

Good stuff, Doctor. Those examples take the other approach: two motors, the after one on the outer shaft to the forward propeller, the forward motor with its shaft passing through the after motors armature and on to the after propeller. No slip-rings required as the two motors case is fixed to the models structure.

The prices are too good to be true! Brushless motors are easy to blow dry and service after an afternoons play in the water.

Neat!

DavidLeave a comment:

-

Yep. I have one of the smaller ones some time ago that I was planning to use. In the end I sent it to David to play with. I've never run a motor in the wet. Wonder what the life span would be.Leave a comment:

-

-

And inherently impossible to purchase. This set up cost me exactly nothing. Made from old gears and spare bearing and shafts and it fits in the rear of the sub quite nicely.Leave a comment:

-

Helicopters don't fly … they simply beat the air into submission!

Well yes.....but no. There isn't enough room in the arse of this thing to allow much of a dog bone connection to anything. I didn't show it in the photographs but the two driven shafts line up perfectly with the output shafts of the SD. Two pieces of silicon tube will make the connection both simple, direct and noise free. No room for a wet motor either unfortunately although I did consider using a tandem out rigger (but then I realised that I sent the only one I had to YOU!) Helicopters rule - wings are for faries!

I hear you about the 'not enough room' issue. I'm working on a very short SD that will leave room for more mechanicals in the ass-end. I'm thinking of replacing the micro servos with linear microbe-sized servos -- that will free up a lot of space. Film at Eleven.

DavidLeave a comment:

Leave a comment: