David, why did you apply superglue on the filled seam? Regards, Jörg

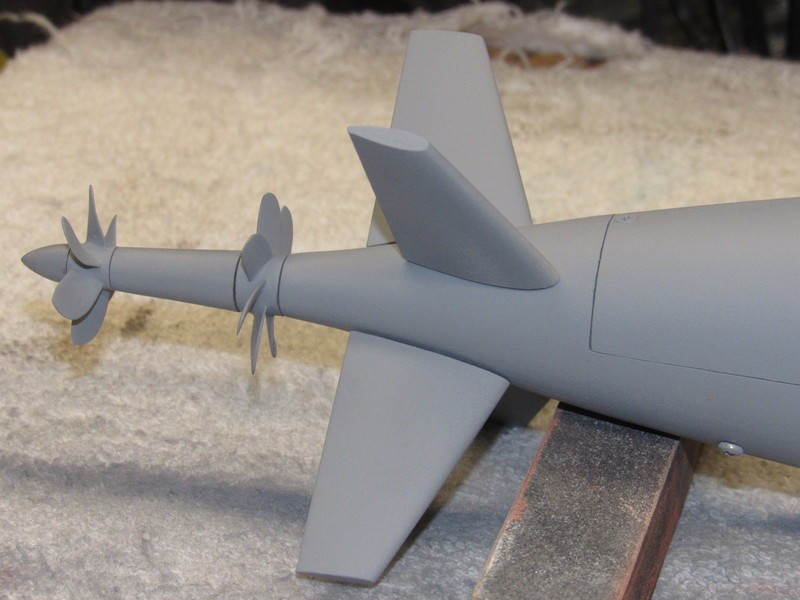

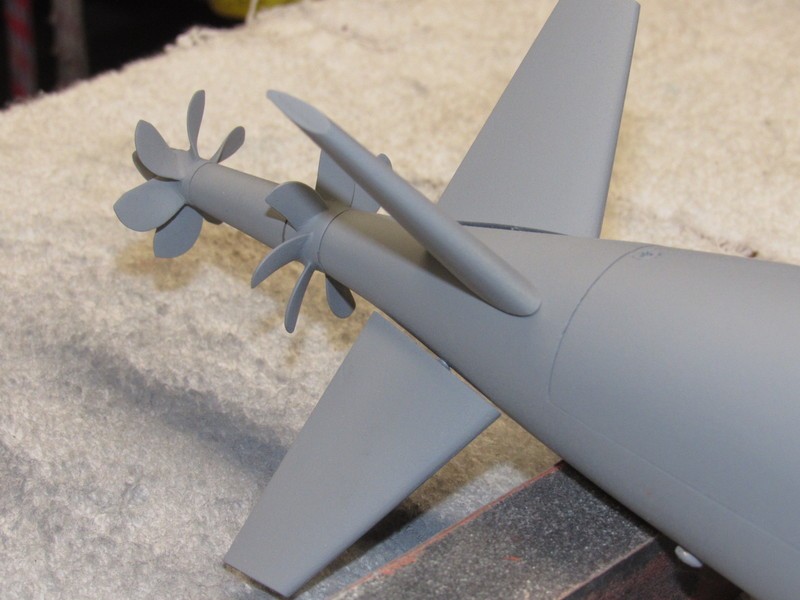

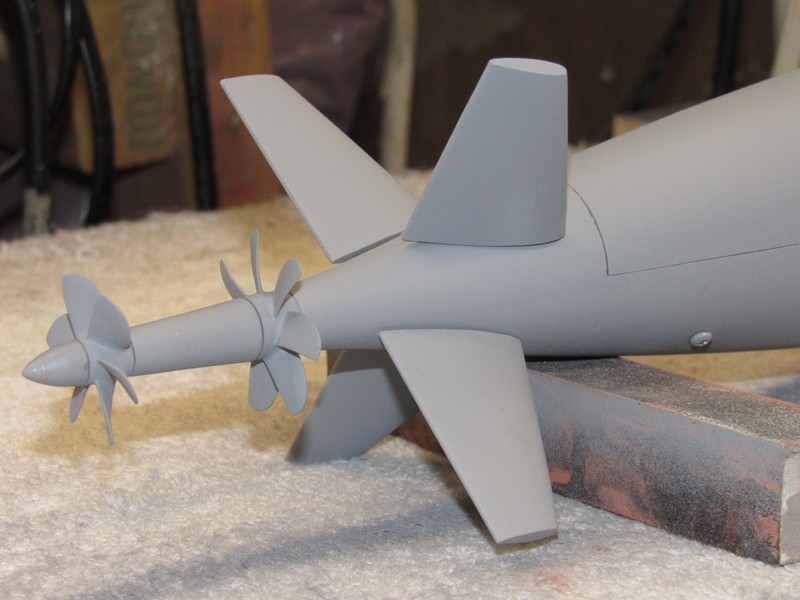

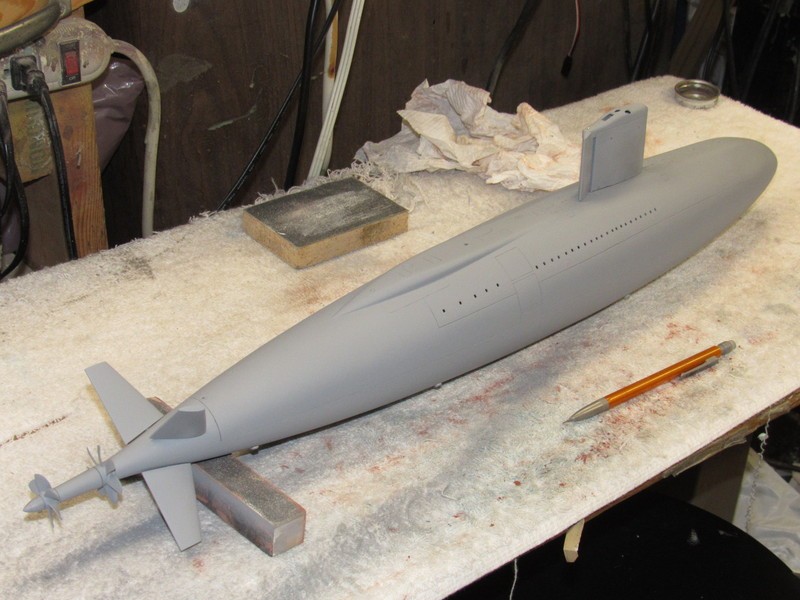

1/96 Albacore (after Phase III coversion 1961)

Collapse

X

-

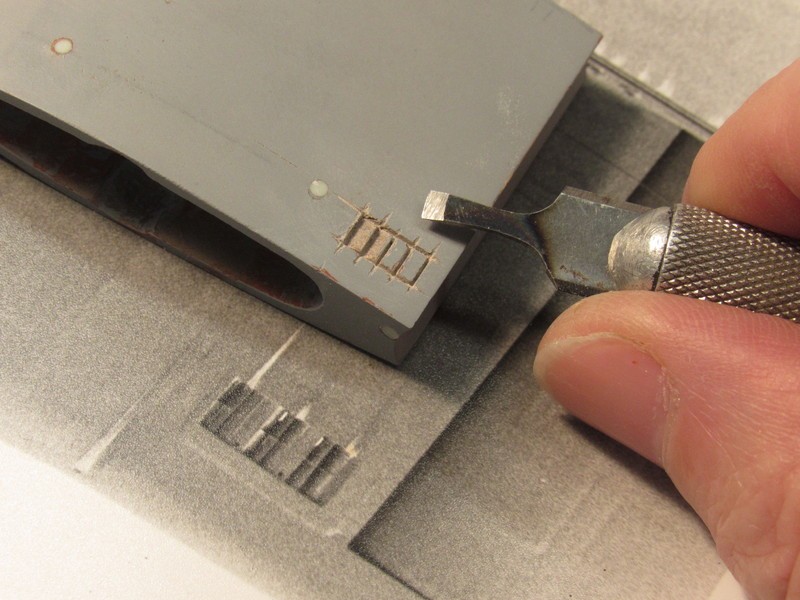

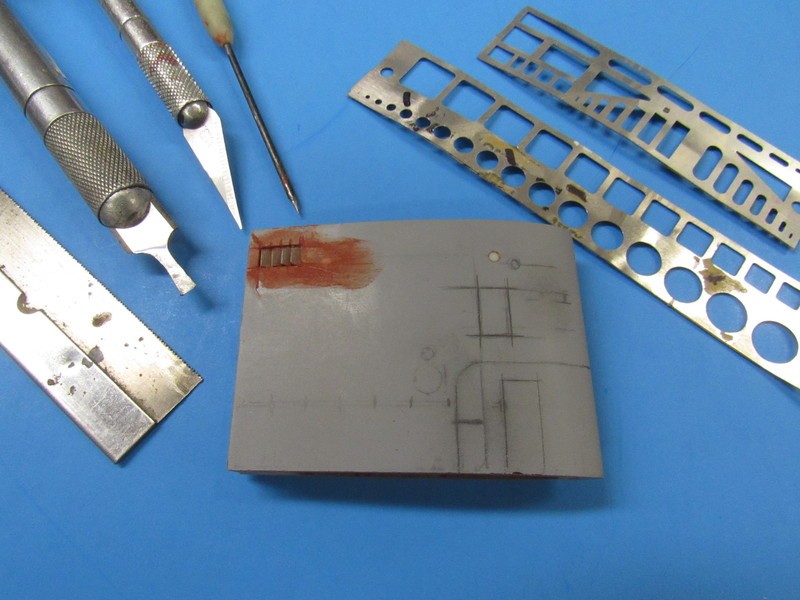

Bondo and similar automotive two-part fillers are polyester based, heavily filled adhesives. They stick well to many substrates but are relatively weak to shear and tension forces -- forces at play as the Bondo and substrate expand and contract at different amounts with changes in temperature. The thin formula CA penetrates the porous filler and bonds it to the substrate. Sticks the filler to the substrate better than just the adhesion properties of the filler alone.

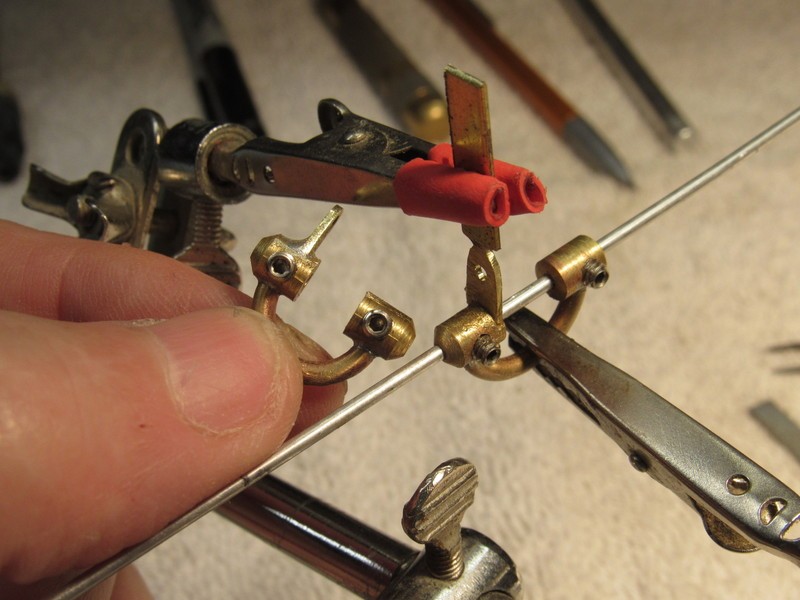

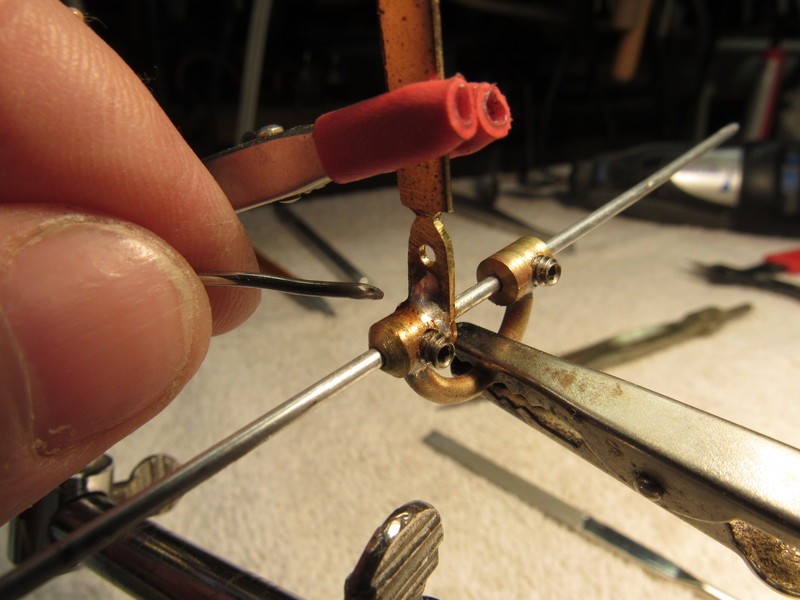

Got the full-blown running gear working -- film at Eleven!

DavidWho is John Galt?Comment

-

-

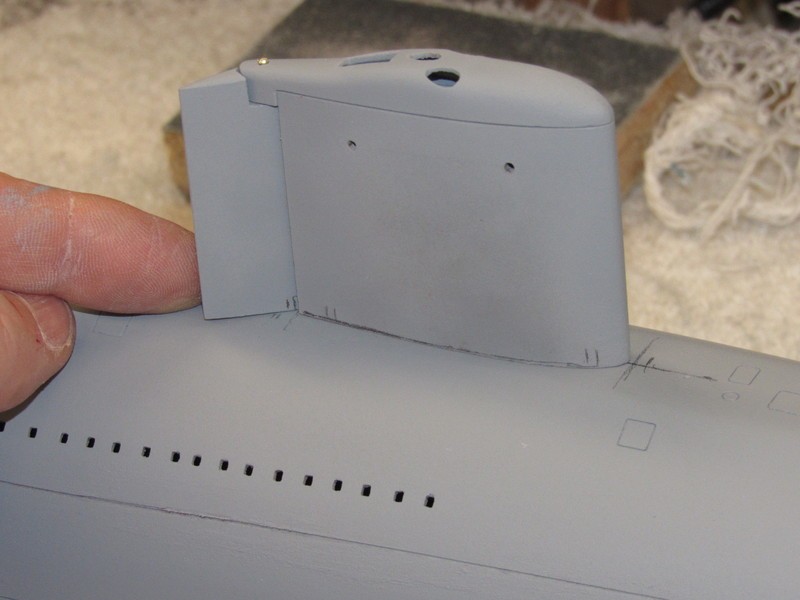

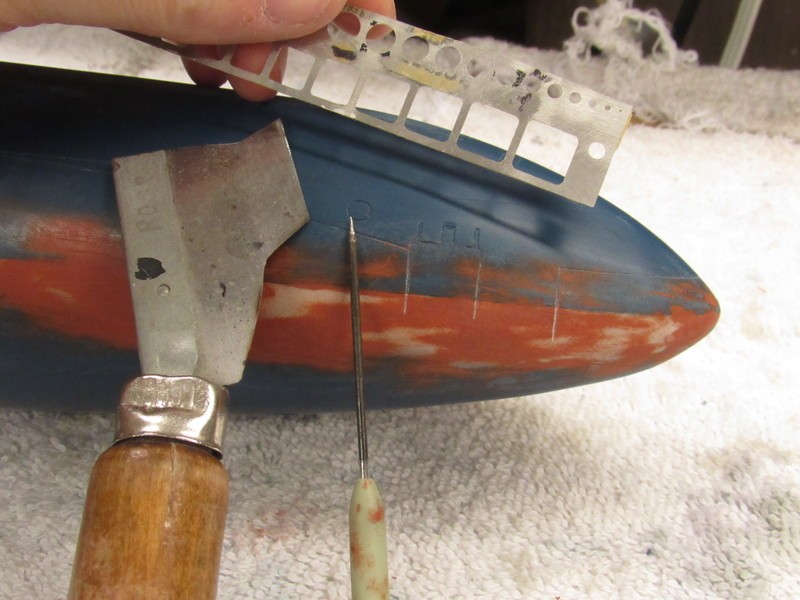

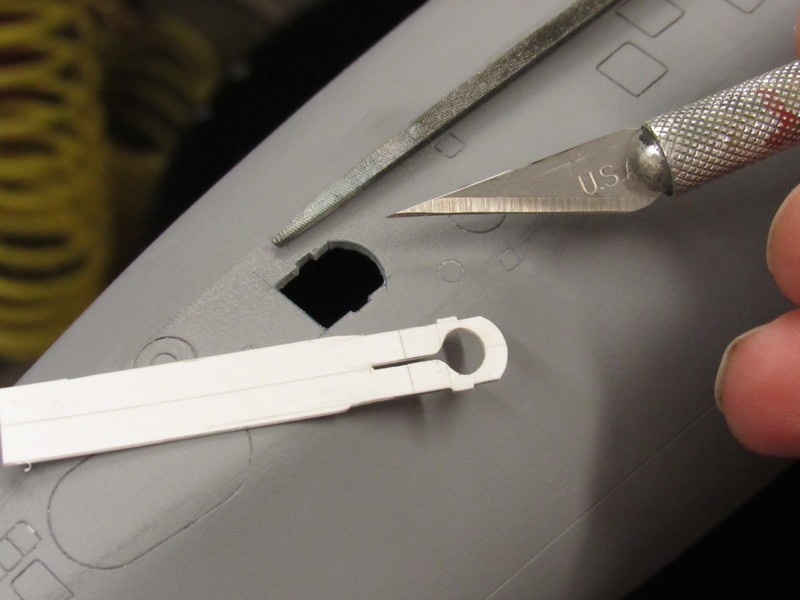

The only substrate I've found prone to crack propagation has been pure silica glass and acrylic (and, recently, some poor quality Lexan extrusions). GRP and most of the styrene and ABS injection formed materials typically don't suffer crack propagation and I can cut and machine those with no risk of shattering or cracking as a consequence of the stresses imposed during the work. So, short answer: no cracking around the square holes I punched into the GRP hull of this fine kit.

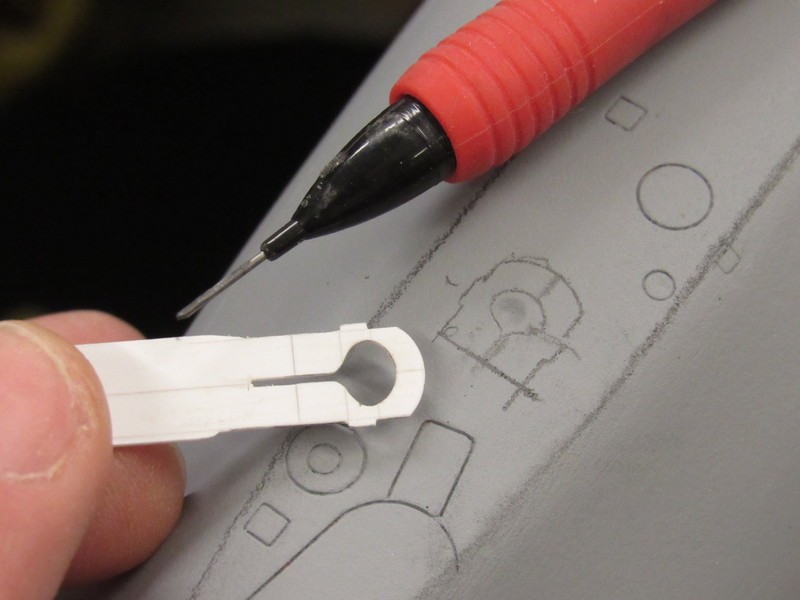

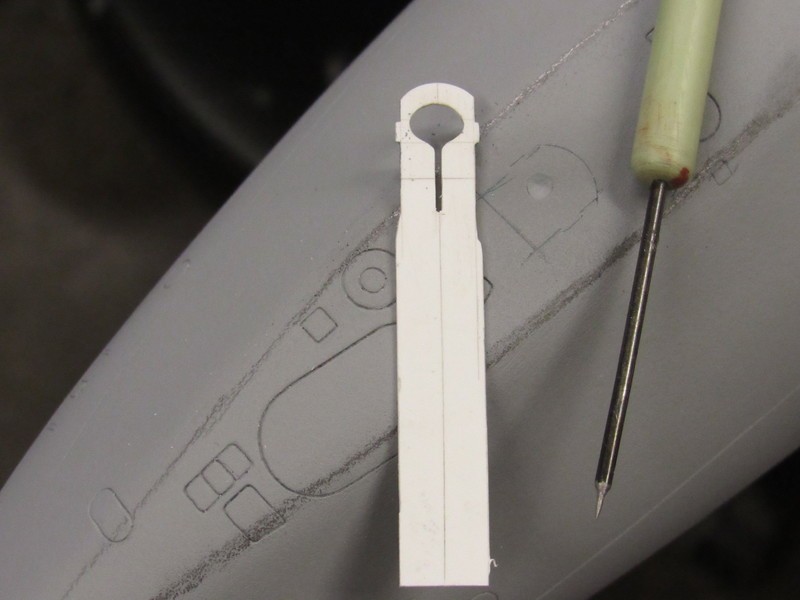

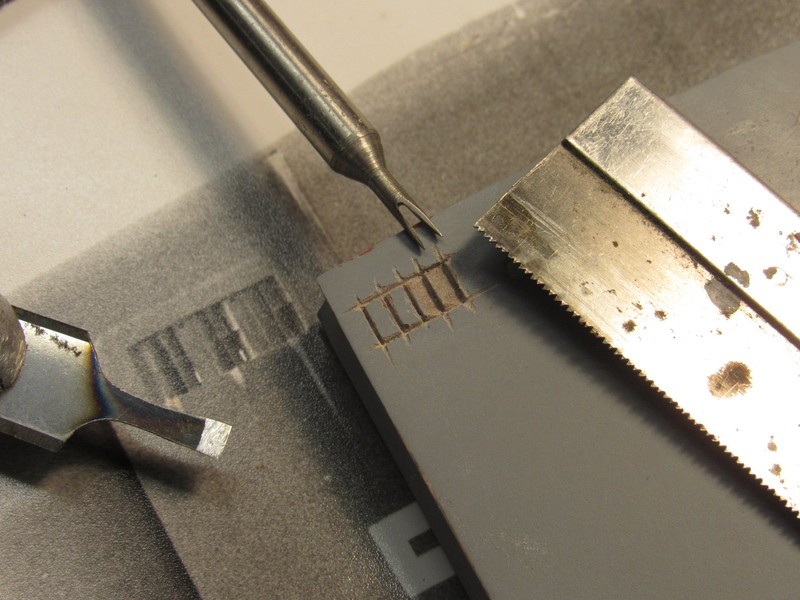

The only reason filler and putty have been applied is to cover surface scaring (scribe, knife and abrasive marks) and to tighten up the form of the square shaped limber holes on the sides of the upper hull.

DavidWho is John Galt?Comment

-

-

Yes it is starting to look like the phase-3 isn't it?

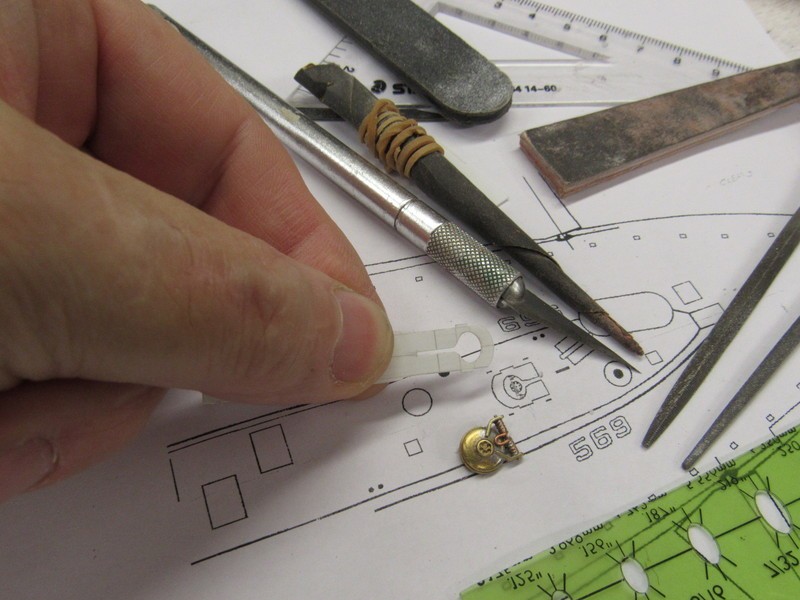

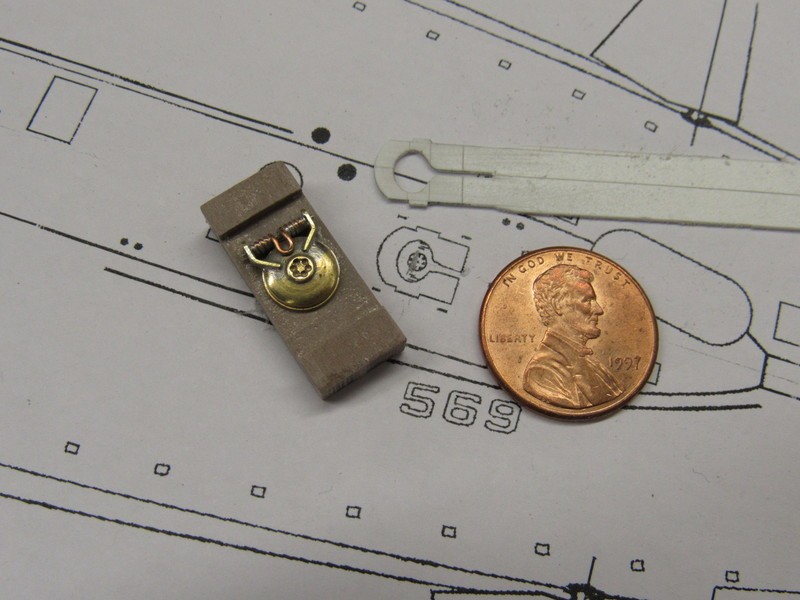

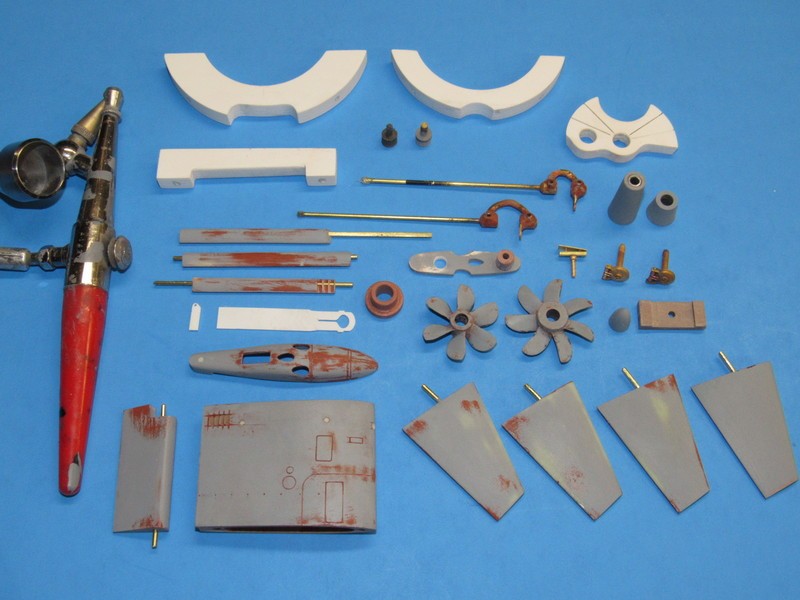

You're looking at the integrations of masters to your hull -- this to validate fit and function. All the running gear is working, the sail fits properly above the hull, and the control surfaces line up correctly without their yokes getting in the way of the outer propeller shaft. Now I can finish the detail work on the masters, make the tools, then the parts which go off to you and Bart (and anybody else on you givme list). Your SD's will follow shortly thereafter as I affirm that my SD has a ballast tank of the correct volume.

I ground off the after conduit and safety tracks for two reasons: The aft conduit got in the way of my removing the soft radius between turtle-back and hull -- I actually cut in a slight gape where the two structures intersect, more in keeping with what we see on the prototype. And the safety tracks, at this scale, were two high and wide. The conduit and safety tracks will be reestablished after all scribing and priming work is completed. Stop whining!

David

Who is John Galt?Comment

-

Comment

-

-

Hi David its been a while wanted to say hi I hope you remember me you helped me build that Gato cobia submarine. I also bought the kit from you. I'm the guy that was in the Coast Guard and flies RC helicopters on the side . This build you are doing is very impressive with all that detail your doing i enjoy watching you work. You are always giving me new ideas! I'm building the typhoon if you have any suggestion please let me know .

take care Jim AmosPut your mind to it. If there's a will there's a way!Comment

-

Hey, I'll forgive you the off-center dimple if you ignore the many ****-up's I've endowed the appendage masters with! Symmetry is the ever allusive and always unattainable objective (unless you're a ****ing robot!).

DavidWho is John Galt?Comment

Comment