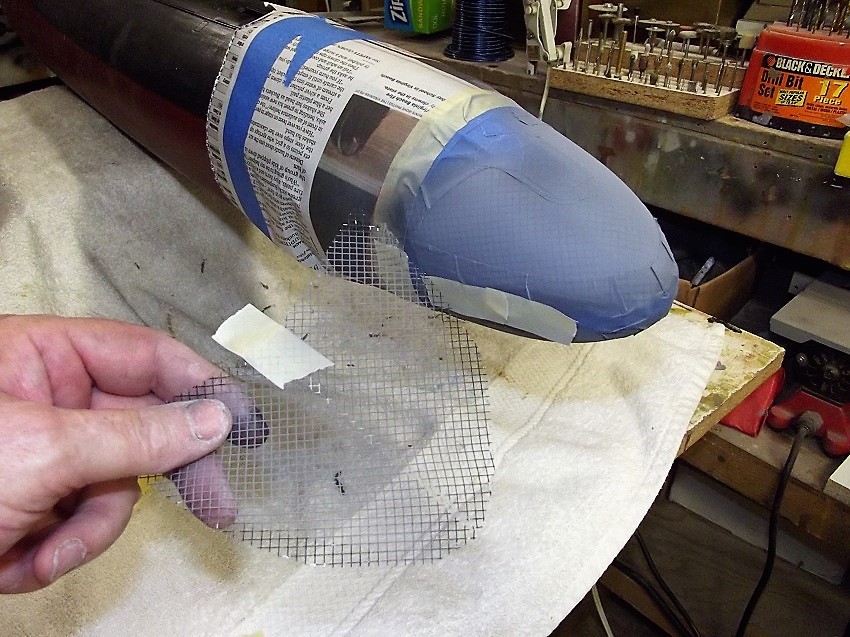

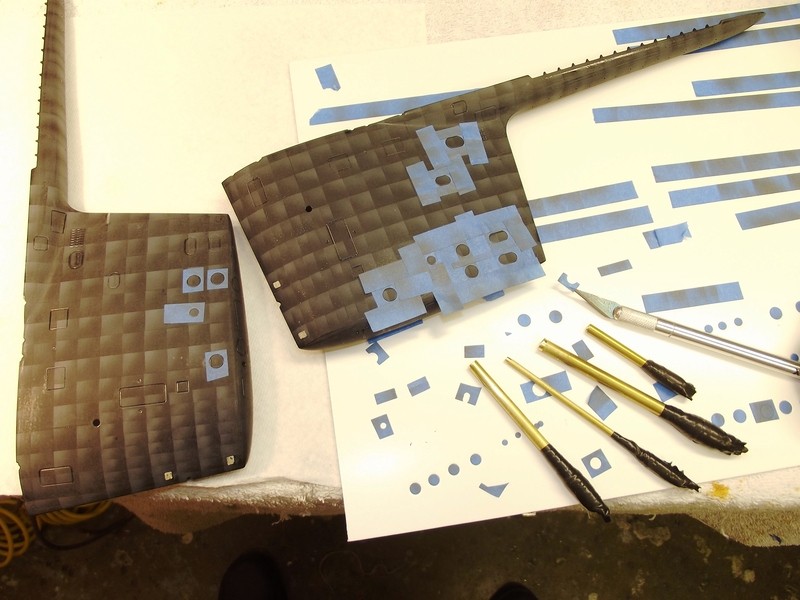

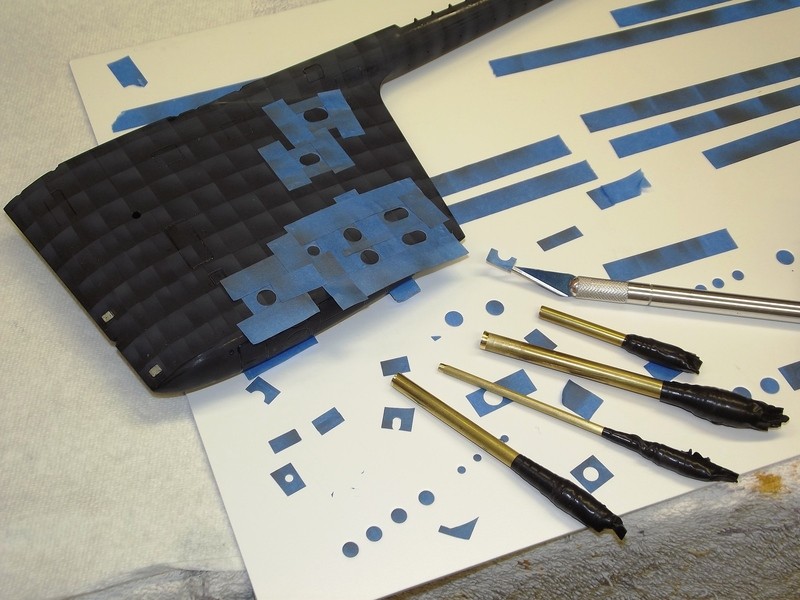

I soldered three sections of brass tube together to get the diameter of ballast blow vents. I used Dremel grinding bits to make a custom end mill, not sure what I was doing. Was able to get two decent cutting edges. I chucked up the custom end mill and floated the drill bit in the handle as a guide. Only problem is the tubing does not come in 7/64 inside dia so I went down to 3/32 for the drill bit guide. The bit has a little slop in the already drilled vent holes which are 7/64. If I try to drill the end mill tubes out to 7/64 I'm sure it fall apart.

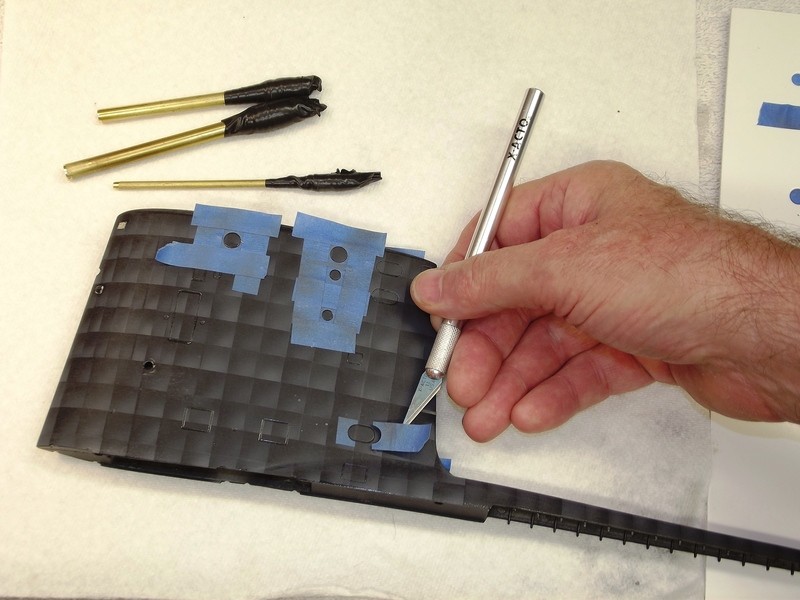

Holy cow! It actually worked! But it's only good for this one size. I did the sample by hand. Only have to remove a few thousandths.

Holy cow! It actually worked! But it's only good for this one size. I did the sample by hand. Only have to remove a few thousandths.

Comment