If I was t pick on one area of your finished sub (which is gorgeous), it would be the space between the aft planes and the stern stabilizer. You have weathered the sub, but in-between this space is the original paint.

1/96 Project 1710 Beluga

Collapse

X

-

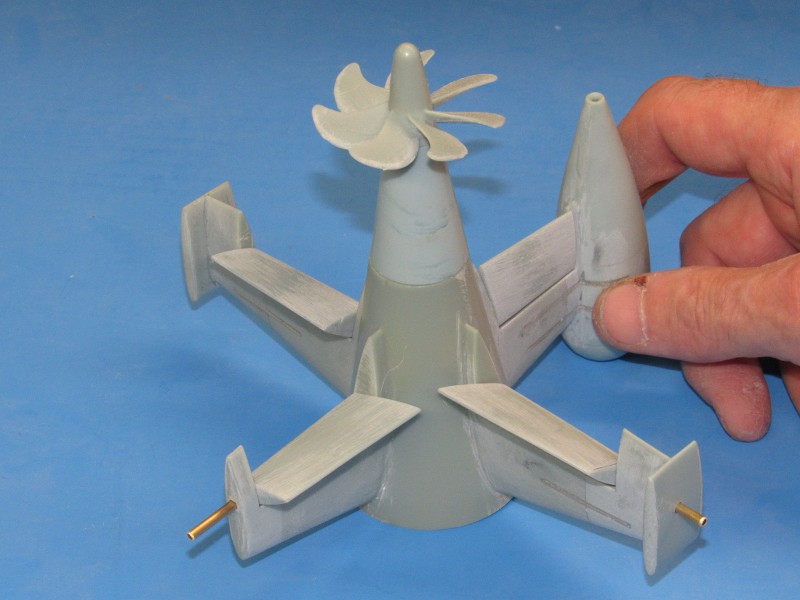

Glad to see you take on the very challenging tooling chore of producing a stern cone with all four stabilizers integrated into the eventual casting. Good stuff!

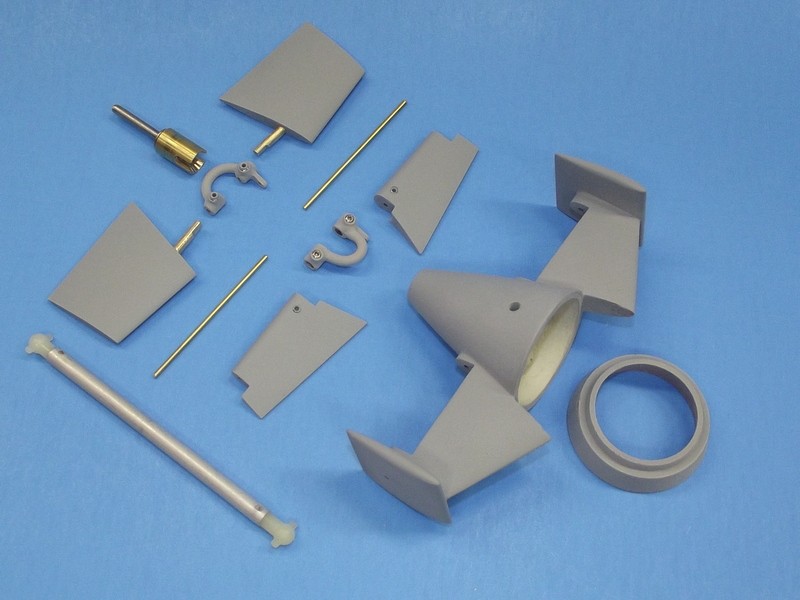

Strands of carbon fiber placed into the tips of the stabilizer tool cavities will greatly reduce the likelihood of breakage to the eventual cast resin tail-cone appendages.

More bird-****!... more bird-****!

(with apologies to Christopher Walken, the 'more cow-bells' guy).

DavidLeave a comment:

-

Is it safe to come out now? This is the upper half of the mould for the complete tail end. The brass rods are connected to the trailing edges of the thing to channel air bubbles away from the edges. I'm going to add a 10" tube at the top to provide a bit of pressure when the resin goes into the mould.

This is the finished boat. Add SD and some weight/foam for balance and off she goes.

Leave a comment:

-

-

David, You paint bird poop on and Scott can't have some large limpets? You hypocrite! Maybe if he would paint it with legs it could be starfish! Or an octopus.Leave a comment:

-

Don't hand me that crap - a turd festooned with corn has 'texture' as well. But I don't want that hanging off the ass-end of my model submarine!

What's wrong with you people!

DavidLeave a comment:

-

Ha ha. I actually cast a full set of control surfaces to send you because I knew you'd go ape-**** over the 3D items. I usually do sand them off but I like the look of them on this model. Lots of texture.Leave a comment:

-

You lazy ****! sand off those 3D artifacts off the control surfaces!

You people: I buy you books, send you to school, and what do you do? .... you eat the teacher!

David

The HorribleLeave a comment:

-

The lower mould has finally set hard. Thus:

Meanwhile the painting goes on.

Leave a comment:

-

This rubber mould is taking forever to dry. In the mean time I amusing myself with with an airbrush.

Leave a comment:

-

The lower mould for the tail section is drying today so I decided to get on with painting my own boat.

The tail on this one won't be as good as the new, all in one job but its OK.Leave a comment:

-

-

They are actually a bit smaller than that. 1.5 mm. Its a pretty small tail. I've made up some brass inserts to go in the stabiliser tips. They have a hole for the operating shalf and should end up fully enclosed in resin.Leave a comment:

-

Leave a comment:

-

I just realised that the photograph didn't appear for some reason. Here it is.

Leave a comment:

Leave a comment: