1/96 Project 1710 Beluga

Collapse

X

-

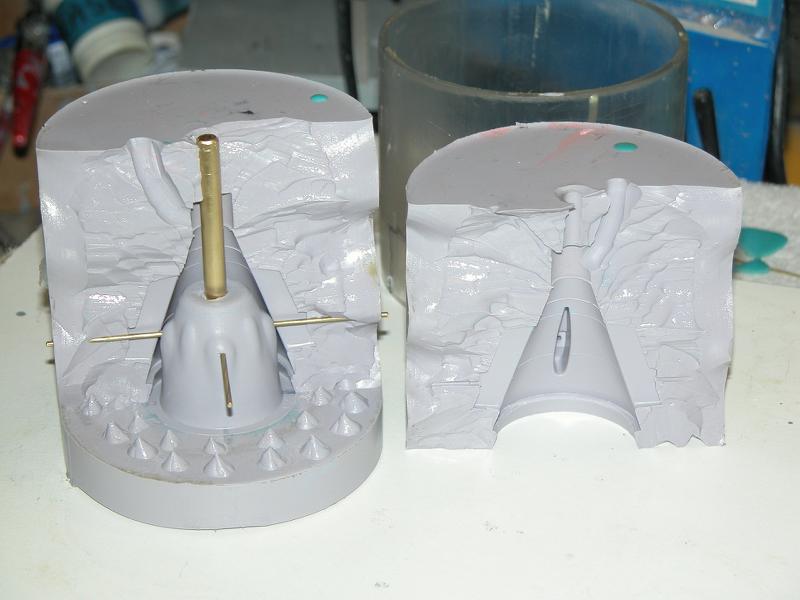

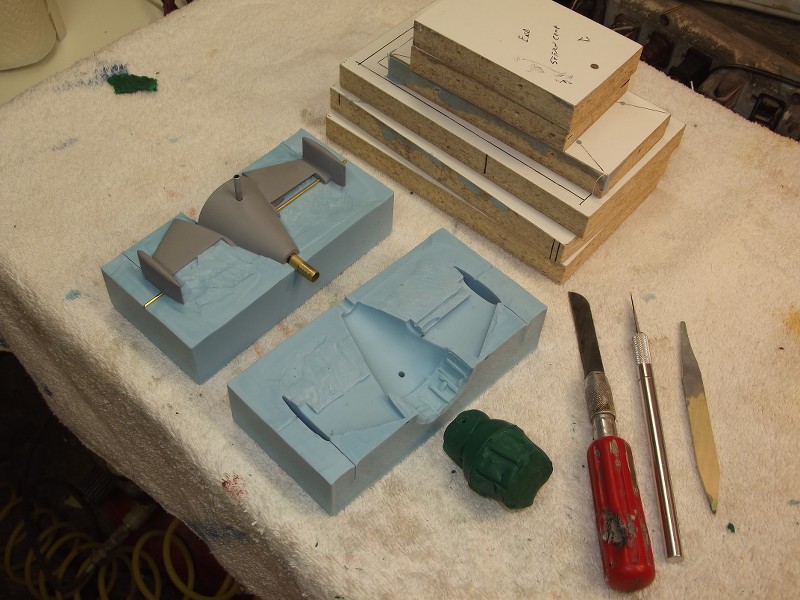

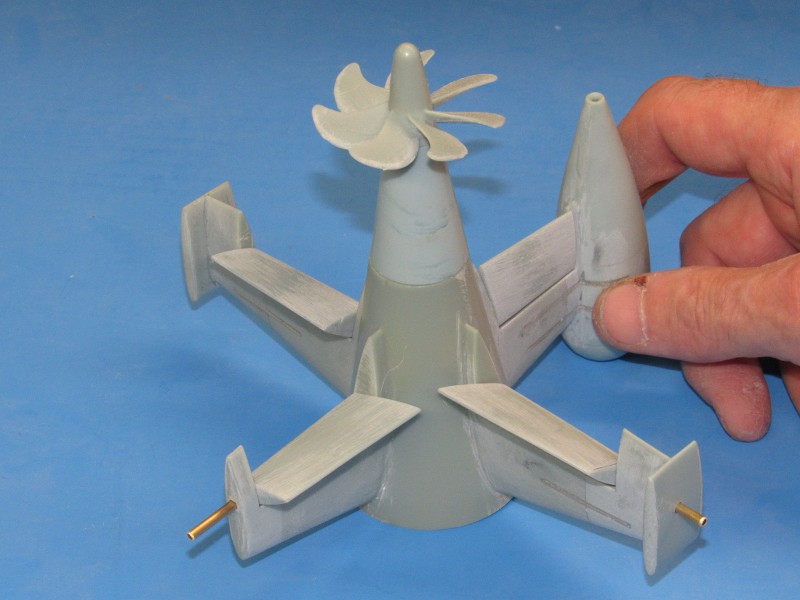

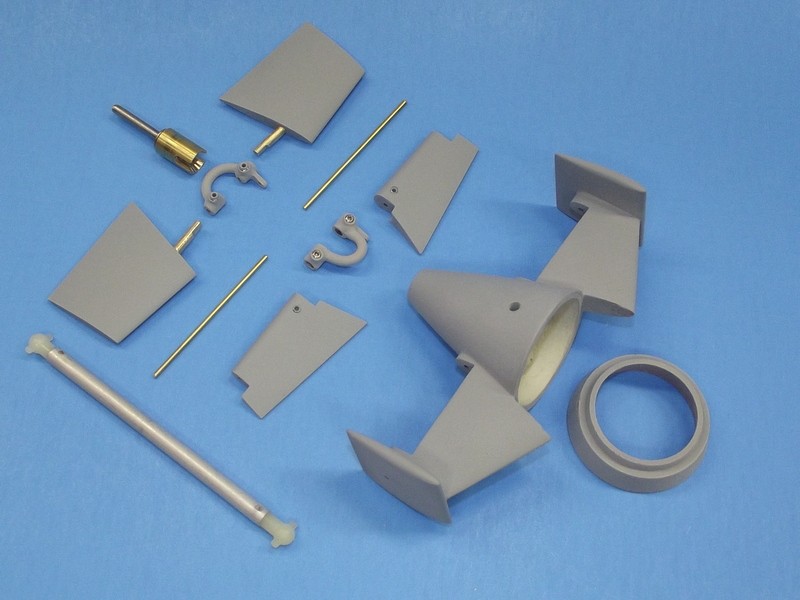

So I spent most of yesterday casting up stern planes. What a mess. Each of those things is an individual casting and it took forever to get four sets of the dammed things done. Today I couldn't face going on with all that again so I decided to have a go at casting the entire rear end in one bit (like I should have done in the first place!!!)

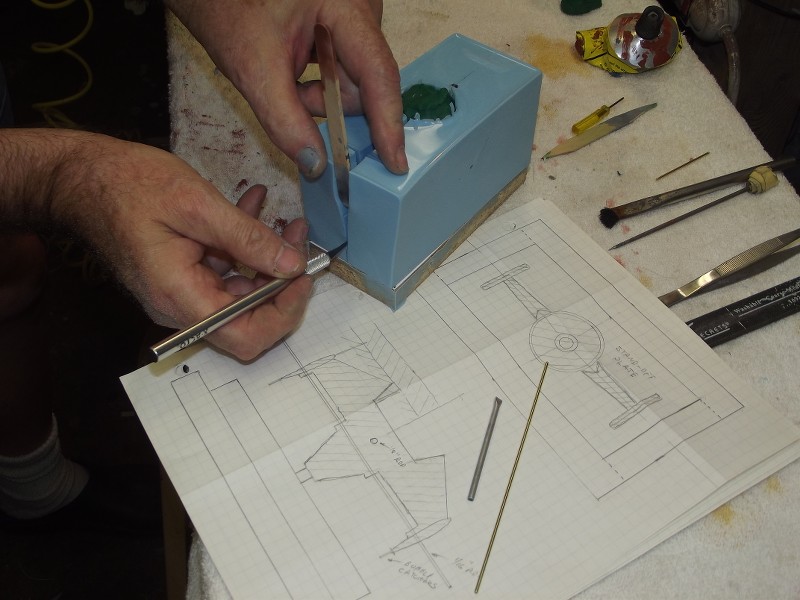

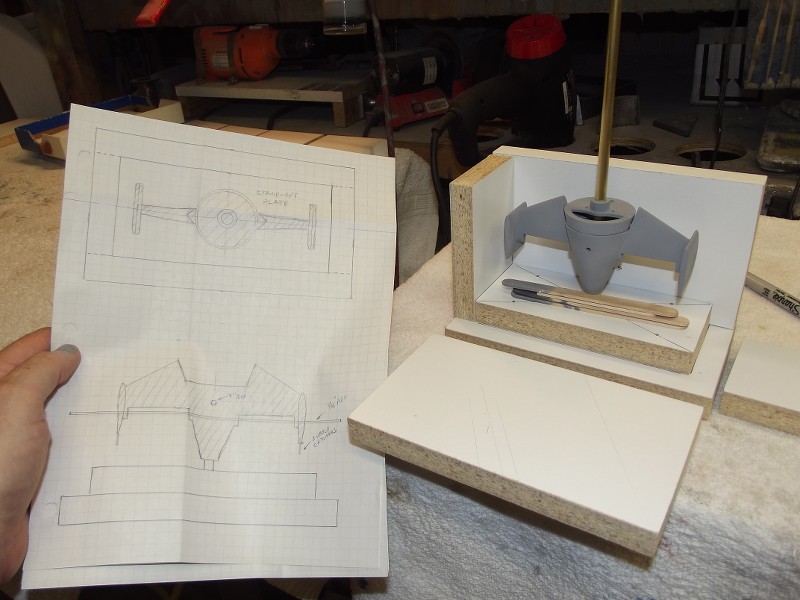

This nis the plug.

Its not finished yet but everything is in line and its fits nicely on the back of the boat. Advice on the best way to cast this thing would be appreciated. My initial thoughts are to cast the internal plug first, then cast the bottom half up to the forward edge of the control surfaces, then the top half. Three pieces in all.Comment

-

Exactly so, sir:So I spent most of yesterday casting up stern planes. What a mess. Each of those things is an individual casting and it took forever to get four sets of the dammed things done. Today I couldn't face going on with all that again so I decided to have a go at casting the entire rear end in one bit (like I should have done in the first place!!!)

This nis the plug.

Its not finished yet but everything is in line and its fits nicely on the back of the boat. Advice on the best way to cast this thing would be appreciated. My initial thoughts are to cast the internal plug first, then cast the bottom half up to the forward edge of the control surfaces, then the top half. Three pieces in all.

David

Last edited by He Who Shall Not Be Named; 03-25-2018, 10:27 AM.Who is John Galt?Comment

-

Well, on that sketch we see a right hand propeller forward, and a left-hand propeller aft. Counter-rotating, not tandem turning. Net torque on the boat: zero!

Free translation of a russian publication:

quote " it was possible to determine the ways of reducing hydrodynamic interference to the work of the SAC at high speeds, as well as to test new methods for calculating propellers (at different times, propellers of different designs were installed on the submarine) " unquote

and if we look at the below scetch it's not so unrealistic me think.

What I don't know is if they were tandem or contra-rotating props.

When built she was provided with a single 7 blade prop with actuator (It was not a highly skewed propellor).

So maybe she had different props during here lifetime but when she was scraped her original (or lookalike) prop was in place, see picture below.

Grtz,

Bart

DavidWho is John Galt?Comment

-

Who is John Galt?Comment

-

Comment

-

You lazy ****! sand off those 3D artifacts off the control surfaces!

You people: I buy you books, send you to school, and what do you do? .... you eat the teacher!

David

The HorribleWho is John Galt?Comment

-

Don't hand me that crap - a turd festooned with corn has 'texture' as well. But I don't want that hanging off the ass-end of my model submarine!

What's wrong with you people!

DavidWho is John Galt?Comment

Comment