I went to a tire fitter the other week and asked him for some old wheel weights and Schroeder valves, I had $10 in my pocket but after telling him what I was going to do with them he said I could have them for free, It's good when good things happen.

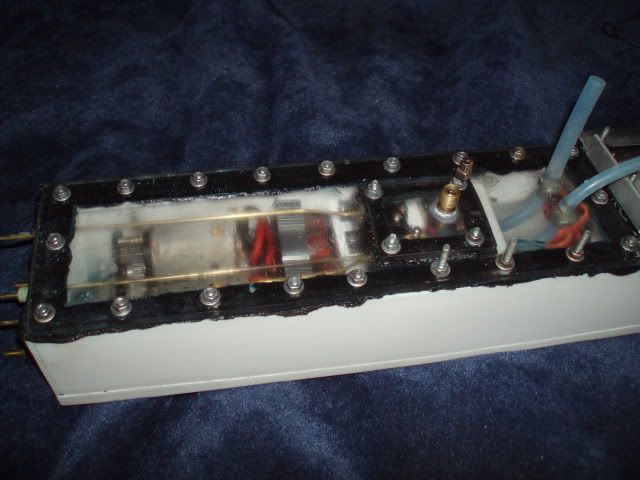

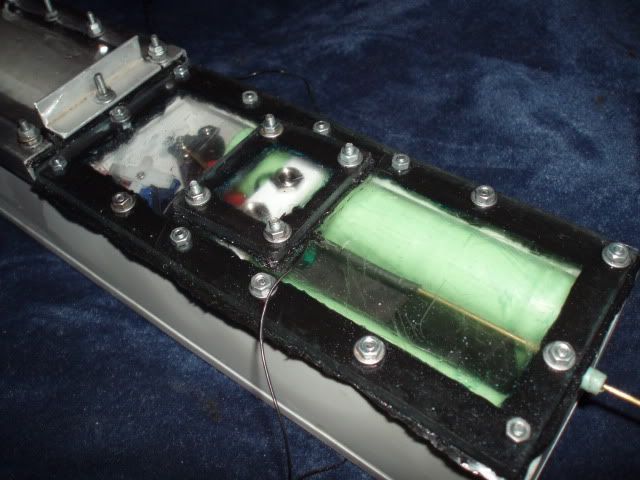

I melted down the wheel weights and poured the lead into a mold 2" wide and 18" long, let it cool. I then cut it up to fit where it will work best. I then installed the lead ballast and the "water tight thingy" holders. I made them using "L" shape aluminum, I also put some foam in areas where I knew it would be hard to do after the thingy was in place.

The lead was primed and painted before being installed and it and the foam are held in place with silicon then hit with a bit of undercoat.

Leave a comment: