David,

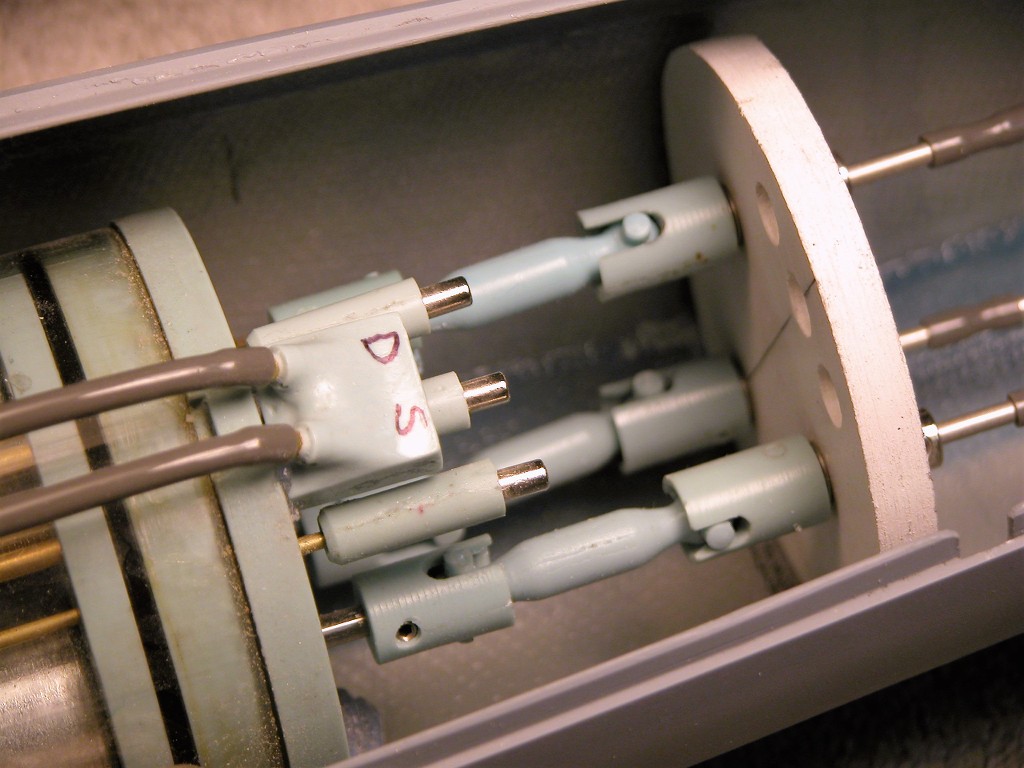

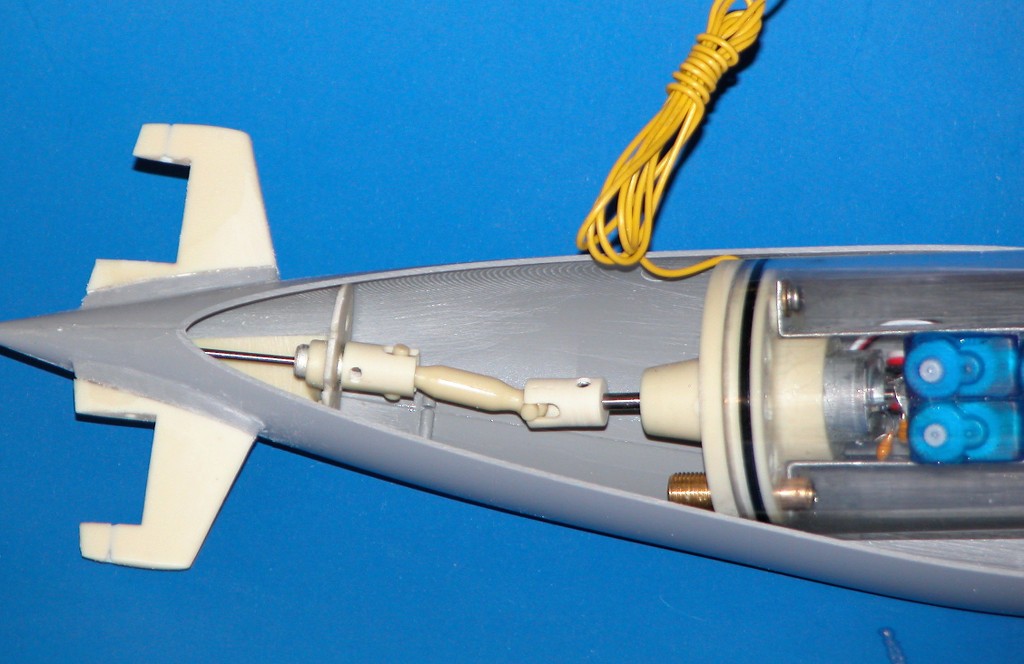

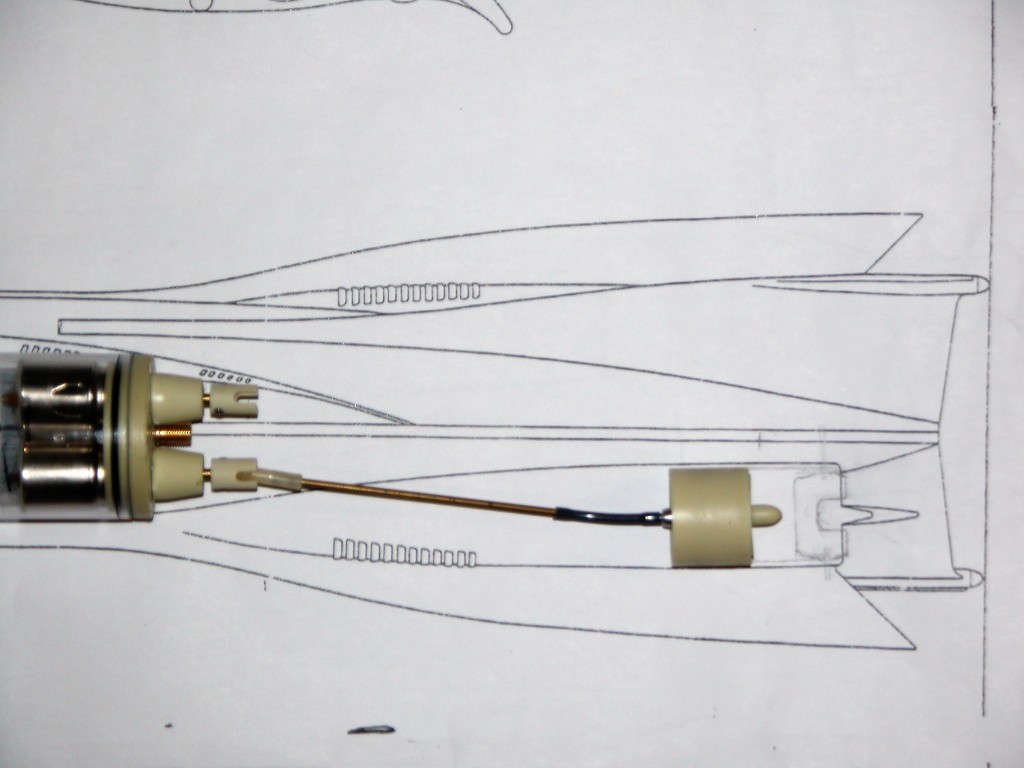

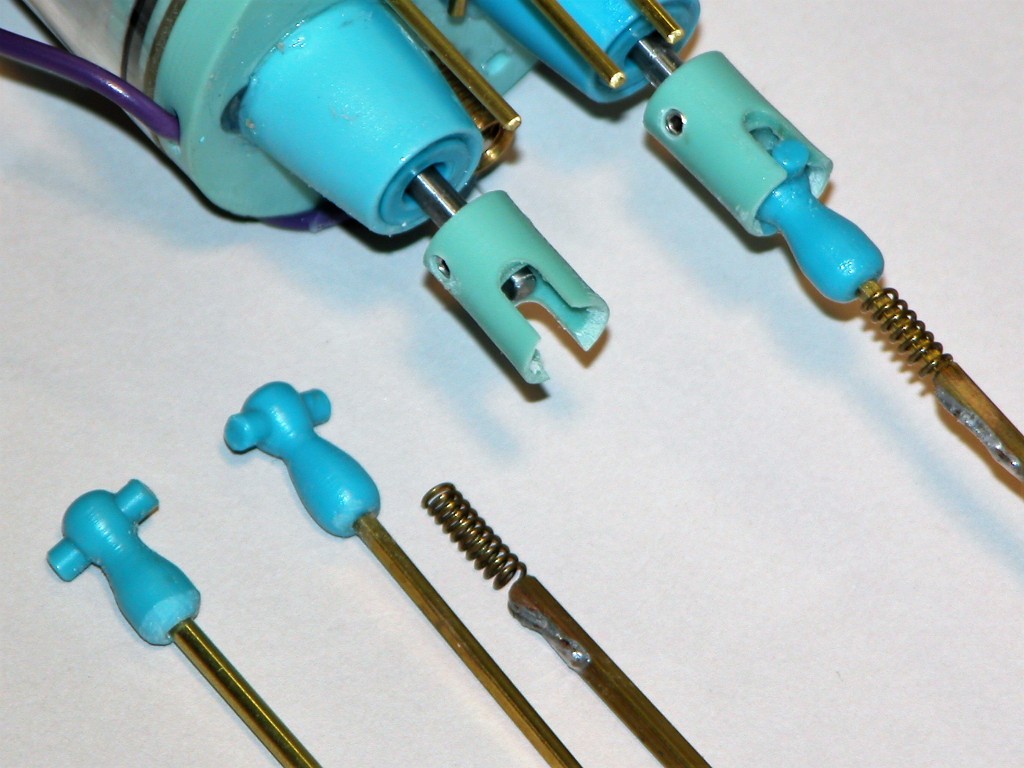

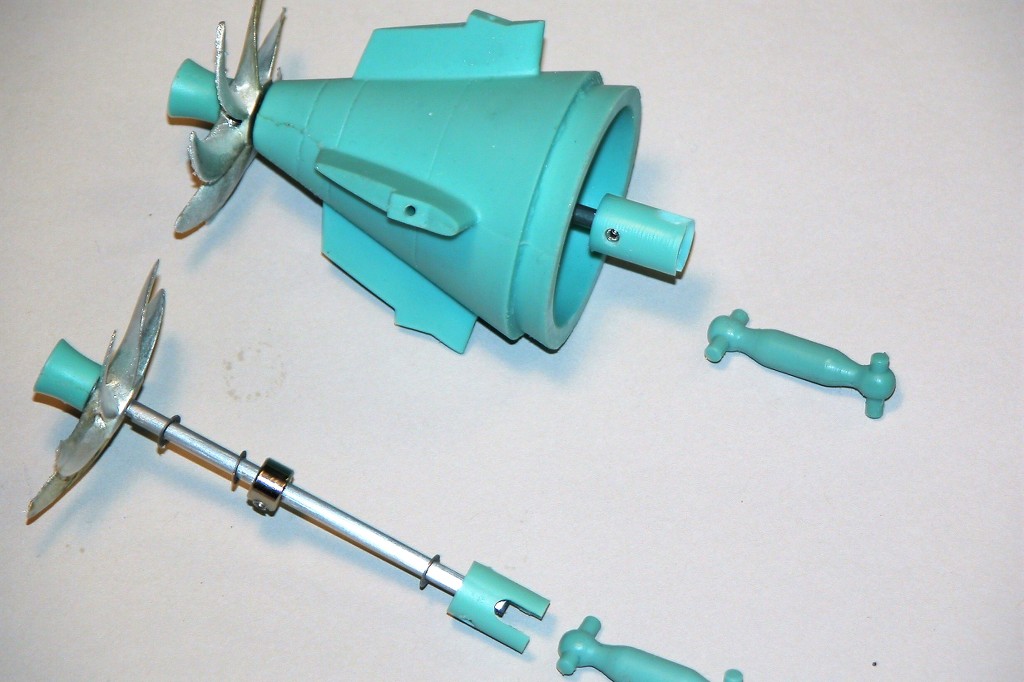

As you can see by the photo, there is already a universal joint from the motor to shaft just before it penetrates the end cap!

Do still think it needs another universal joint on the end of the shaft on the outside just after it leaves the end cap?

Rob

"Firemen can stand the heat"

As you can see by the photo, there is already a universal joint from the motor to shaft just before it penetrates the end cap!

Do still think it needs another universal joint on the end of the shaft on the outside just after it leaves the end cap?

Rob

"Firemen can stand the heat"

Comment