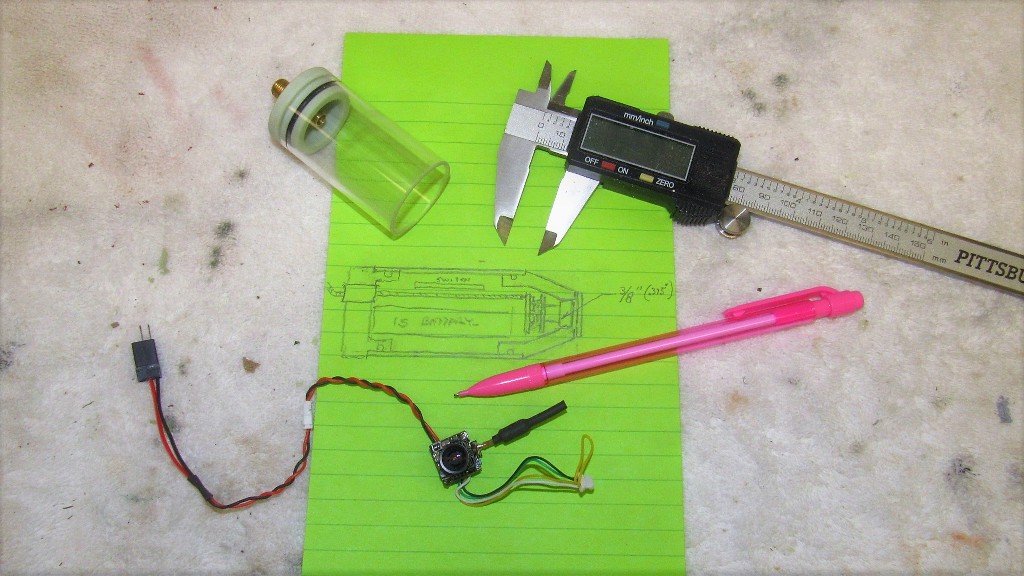

As this 1/35 Type-23 r/c submarine will be little more than a mule to move the FPV (first person view) wireless video camera around underwater, I though it wise to give a little effort to the design and construction of the 1.25-inch diameter watertight enclosure needed to house the camera-transmitter, 1S Lithium-polymer battery, and magnetically actuated power switch.

As with most gizmo's that originate here, the object began to take form while I was on the toilet. Thinking. In my head. In the head. Ah, sweet symmetry!

From there, usually at my computer workstation (when not issuing blistering rants on the few forums I've yet to be banned from), I pause occasionally from keyboard pounding to scribble on whatever scraps of paper are at hand the raw idea; then refine the work onto post-it-note or graph-paper, at which point the drawing is to scale with critical dimensions called out.

Simple structures like this enclosure warrant only a single orthographic side-view. More complicated structures get the three-view and isometric treatment.

Such was the evolution of the FPV camera enclosure. Working drawing in hand and a quick trip to the shed garnered a proper length of Lexan tube and a removable bulkhead for the enclosures after end. Now all I have to do is work up the forward removable bulkhead that will house the camera and its lens. That will start life as a RenShape turned master, from which a rubber tool will be struck, and cast resin part(s) produced.

But, first, I got to get this damned r/c model submarine done.

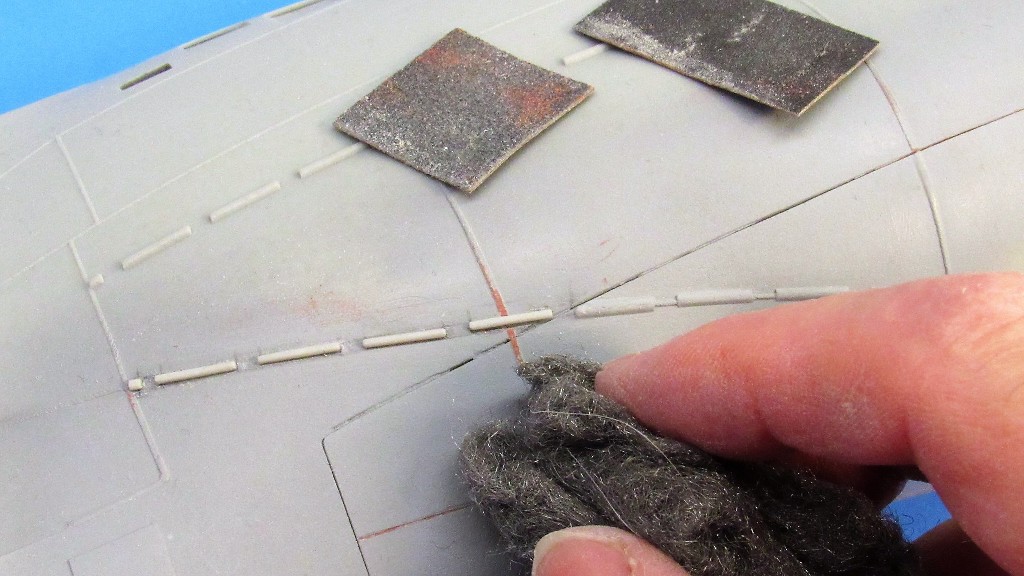

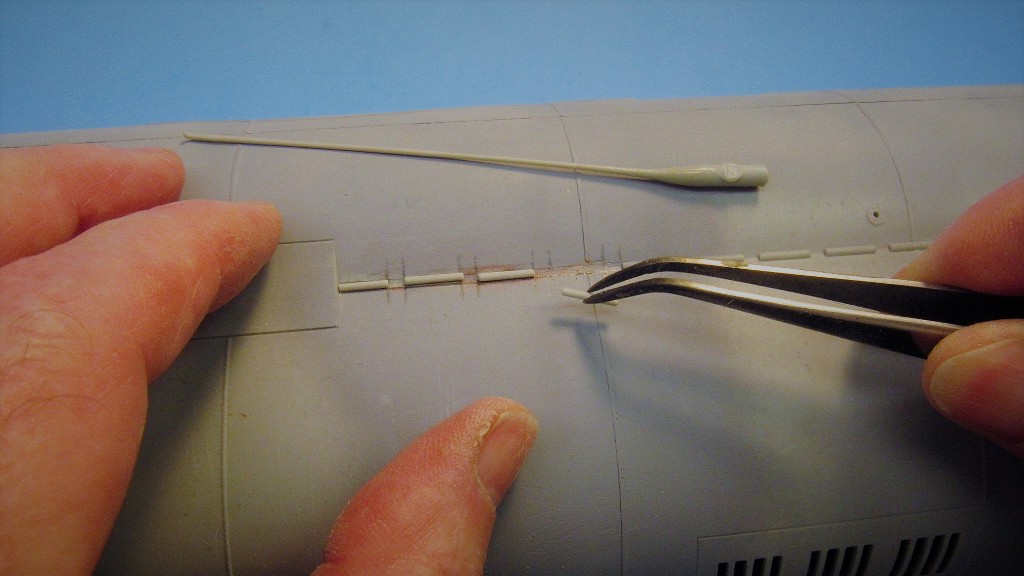

Near the stern of the submarine, each side, are two rows of what I'll call (in the absence of any authoritative explanation) 'zincs'. Near the sawing, grinding, filing and sanding I did to separate the upper and lower hull halves some of these zincs were obliterated. Time had come to scratch-build and install the missing zincs.

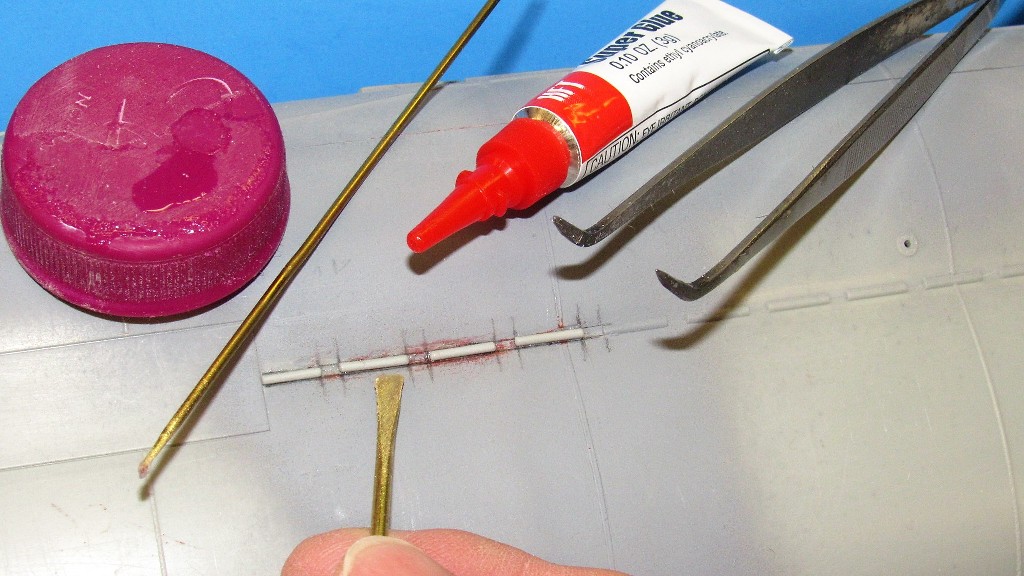

Here you see the endgame: I'm finishing off the installation of the after set of zincs on the upper row, port side (the model is upside down).

Each of the replacement zincs were a length of stretched-sprue CA'ed in place after laying out their position and spacing with a pencil.

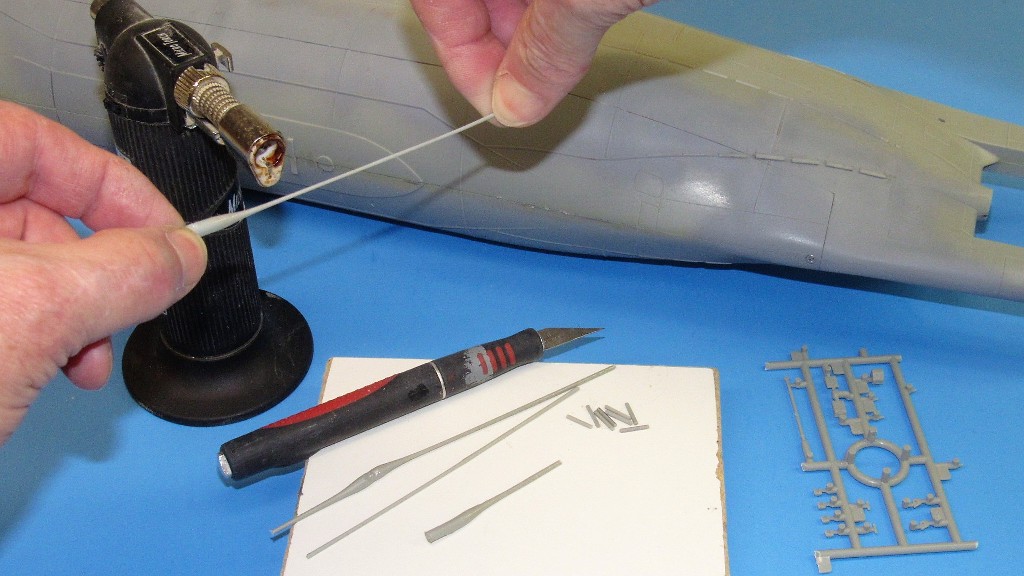

The kit provided the sprue, which I heated and stretched while semi-molten. An acquired art. The amount of heat, over such and such an area, with just so much tension applied, and that tension throttled till the desired diameter is achieved and halted till the plastic once again assumes a solid state. Much good fun. If you don't burn yourself... you're simply not trying hard enough!

CA was applied with tools, not directly from the tube. Here I'm using a spatula type application tool to drive the adhesive along the length of a zinc, bonding it securely to the hull.

A fault with the kit design was Bronco's attempt to capture the oval shaped upper limber holes (the function of limber holes is to vent and flood the spaces between inner and outer hull) at a high draft-angle of the injection forming tools hull cavity. To prevent entrapment, they made the wall thickness so thin at the extreme draft-angle point (near the top of the hull) that a complete fill during the injection of the molten polystyrene was not achieved and the resulting openings were miss-formed. That had to be fixed!

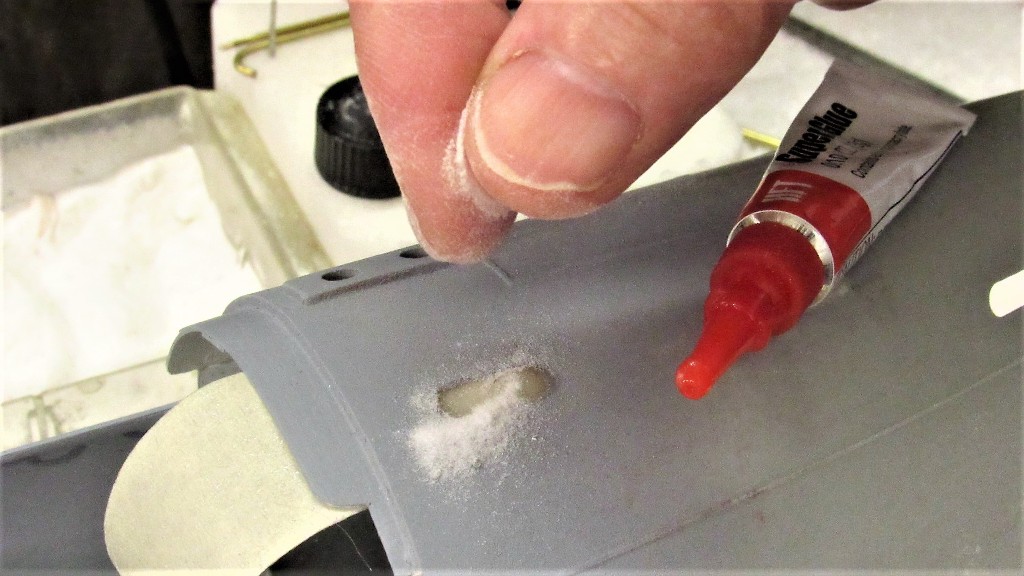

I skinned over these holes with a CA-baking soda grout, then ground out properly shaped limber holes. This started with blanking off the hole from the inside with some masking tape.

CA was squirted over the masking tape and run up to wet the edges of the hole. Then baking soda was sprinkled on. The high pH of the baking soda catalyzed the CA almost immediately. This build-up continued till the hard grout was well over the contour of the bow.

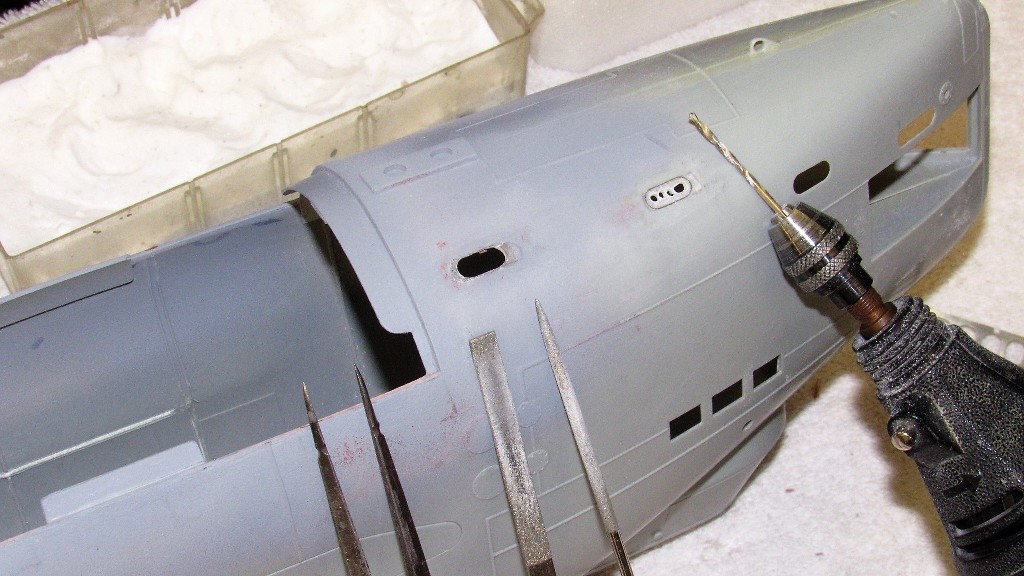

Before going to town with rasp and second-cut file I outlined around the grout with a pencil. The pencil hashing would tell me to stop with the file work. To the right is a contoured grout filled hole that has already been marked, with the aid of a stencil, to indicate the desired shape of the 'new' limber hole.

To the right is how I make the rough-cut to the limber hole -- using a 1/16-inch drill bit as a hand-held mill. To the left you see a finished limber hole, given final form with careful use of flat and round diamond files. Nothing to it!

Invariably there will be pits and scratches around the work, so I rub in some touch-up putty. I permit the putty to get onto the inside edges of the limber holes. That still pliable putty is then pushed into the edges with a rod of a diameter slightly smaller than the width of the limber hole. The rod is swished around a bit and pulled out. Once the putty dries, the surface is wet-sanded and primed.

Comment