today's work

Collapse

X

-

-

Comment

-

Hi David,

I have been looking at your endcap manufacture with a lot of interest, and I have a questions.

Who is your supplier of bushings, and gears for your shafts ?

With the twin shafts off the one motor do you have any pics of how the shafts are sealed?

regards

David H

Comment

-

I get the Oilite bearings from McMaster-Carr, https://www.mcmaster.com/Hi David,

I have been looking at your endcap manufacture with a lot of interest, and I have a questions.

Who is your supplier of bushings, and gears for your shafts ?

With the twin shafts off the one motor do you have any pics of how the shafts are sealed?

regards

David H

The spur gears come from Stock Drive, https://www.sdp-si.com/

The single-shaft is the only one that needs to be watertight.

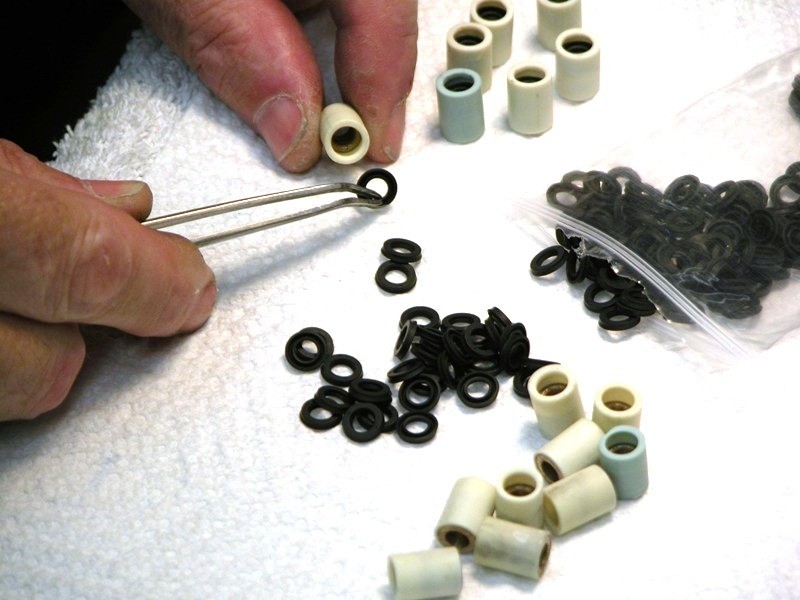

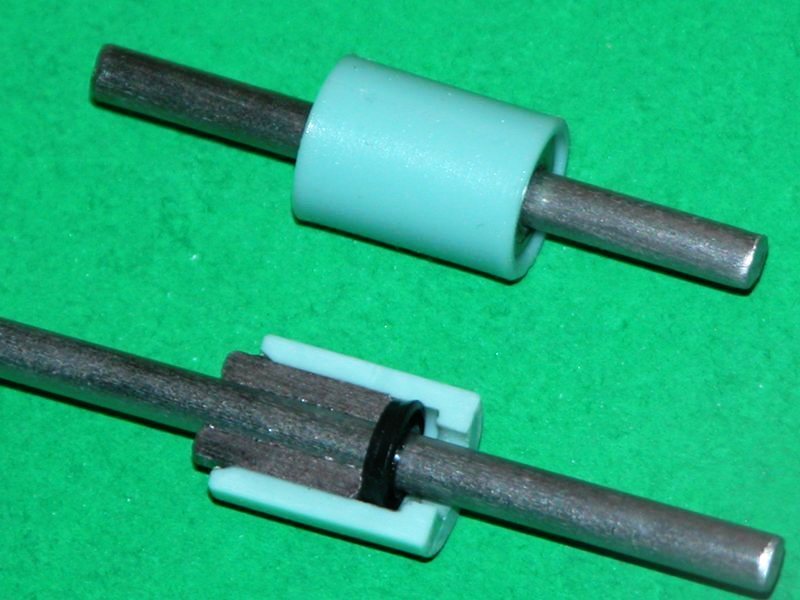

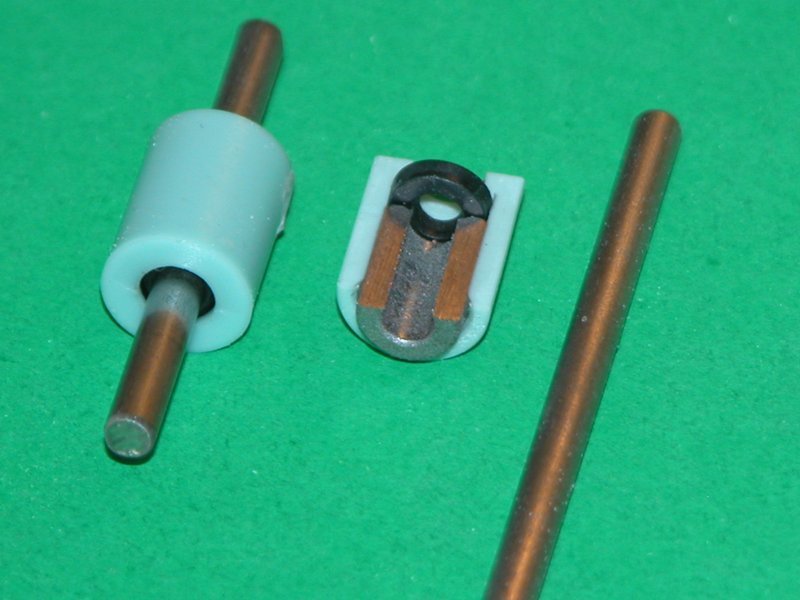

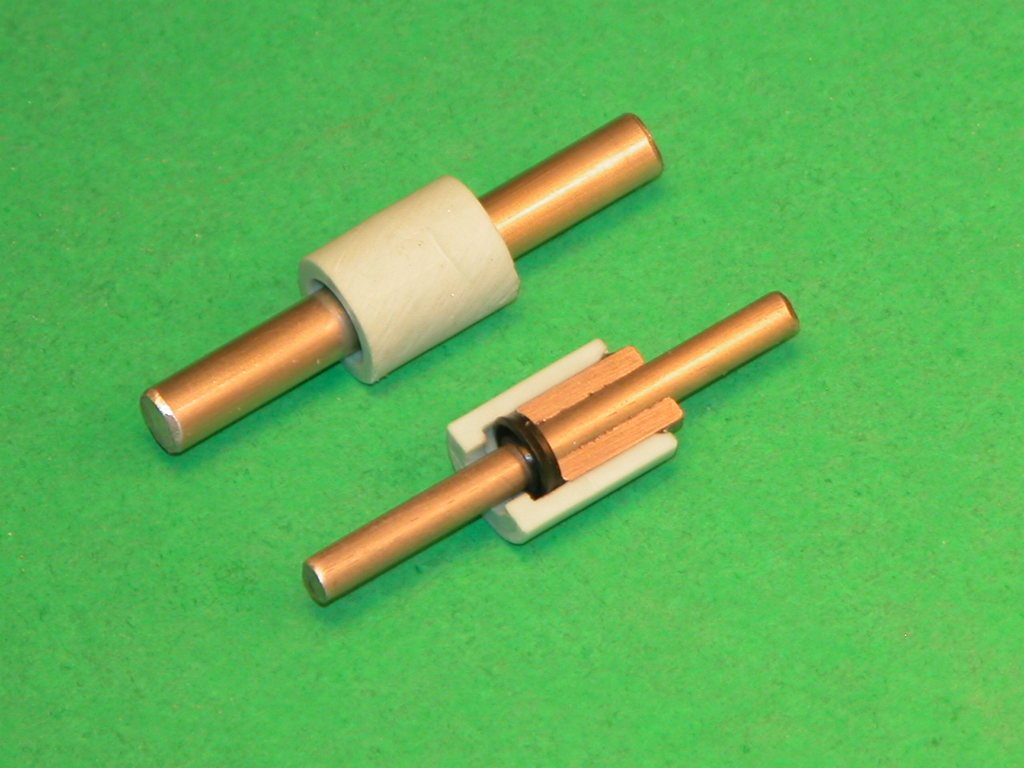

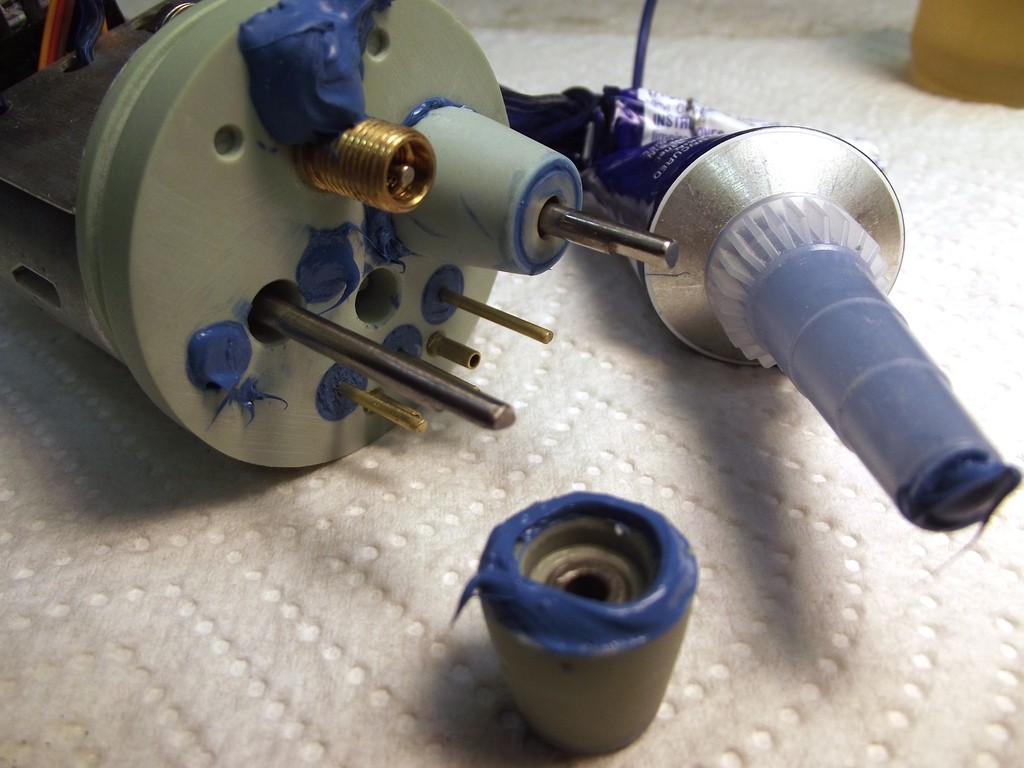

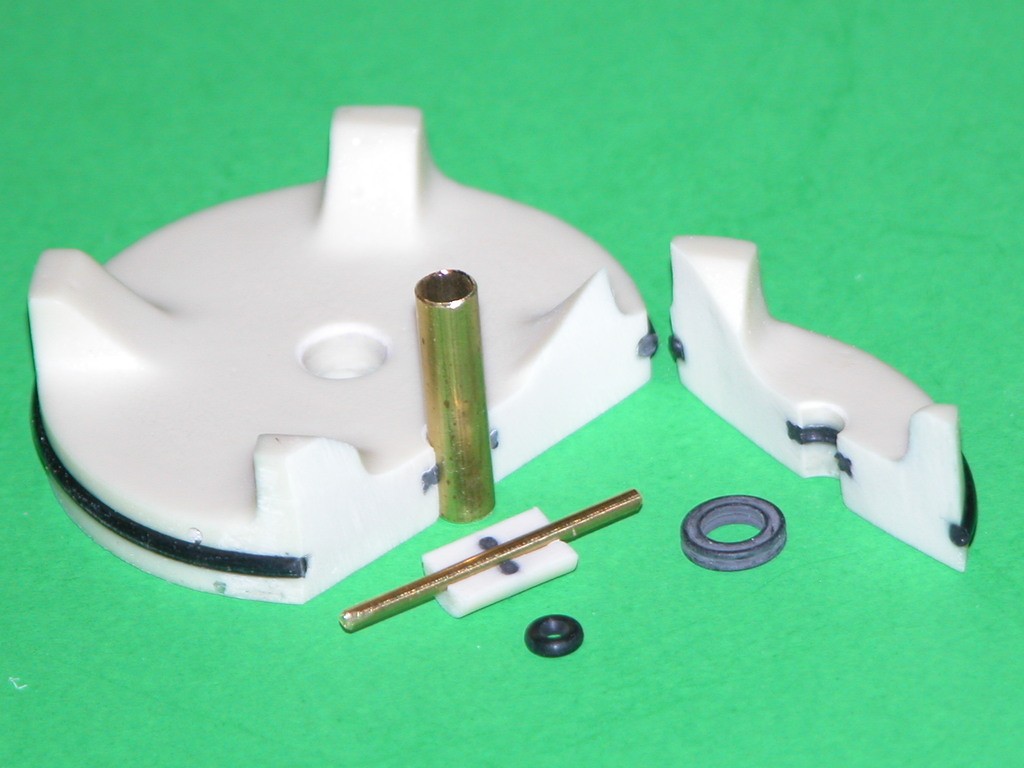

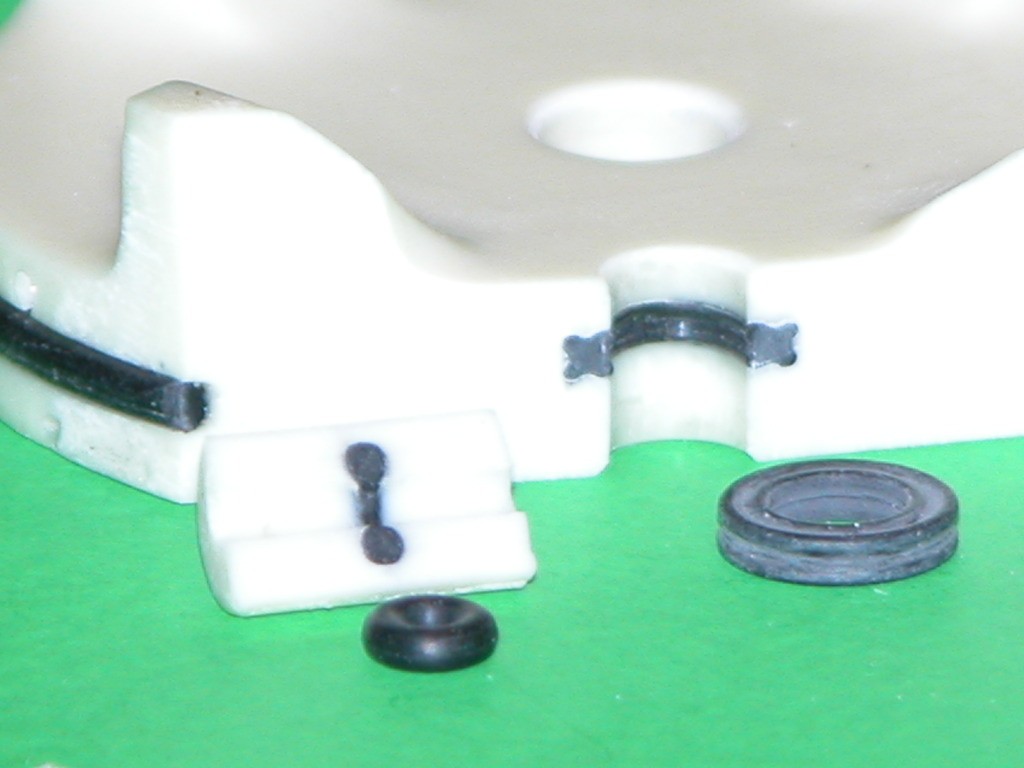

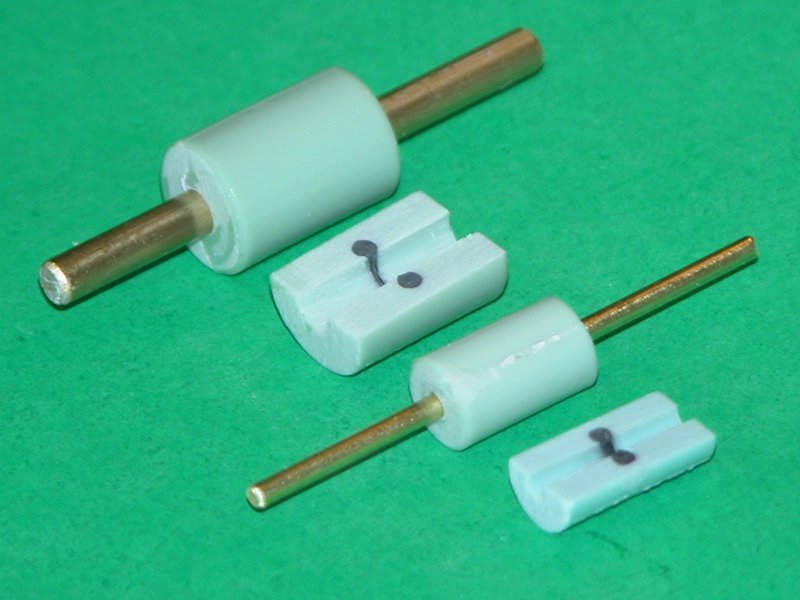

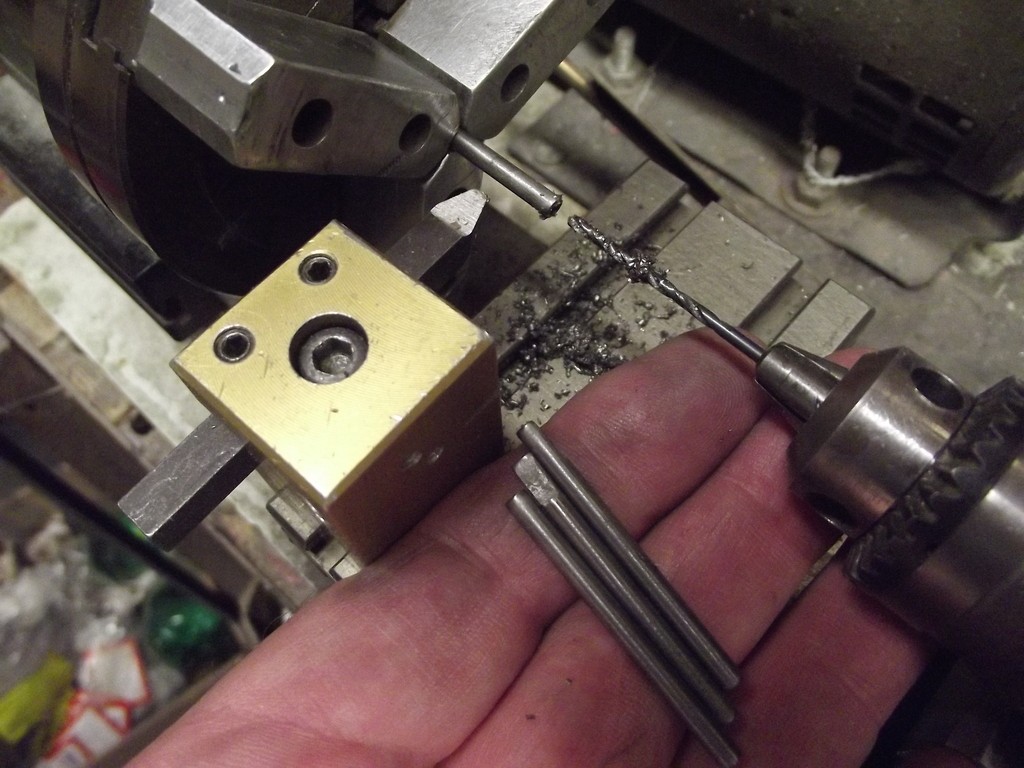

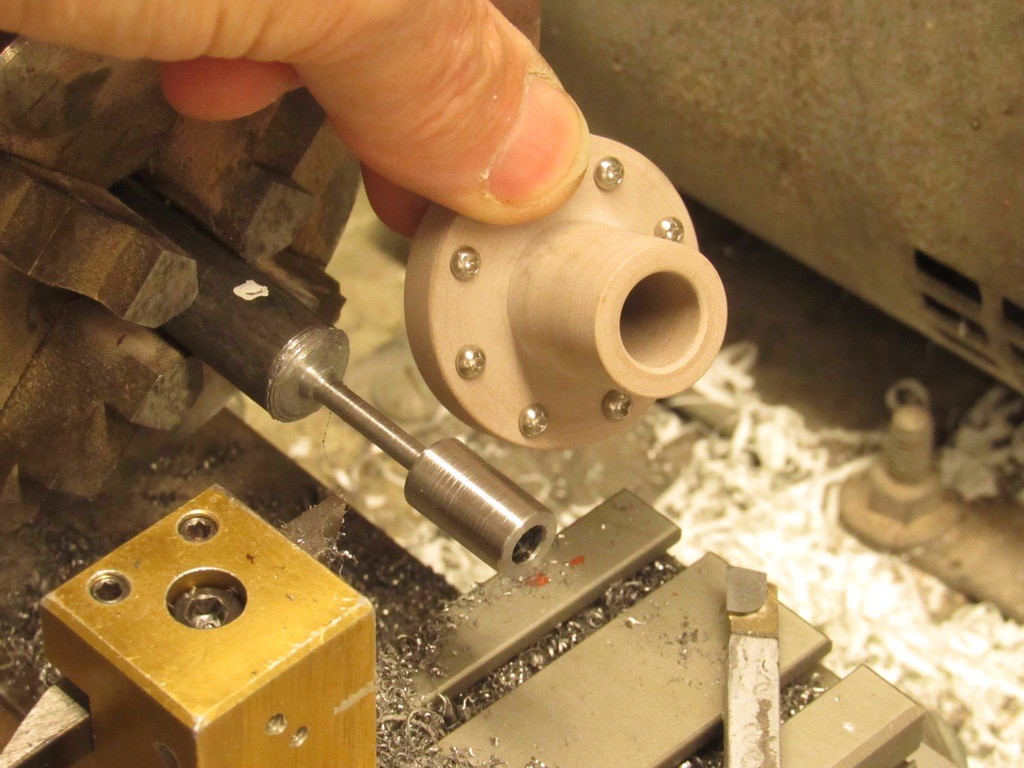

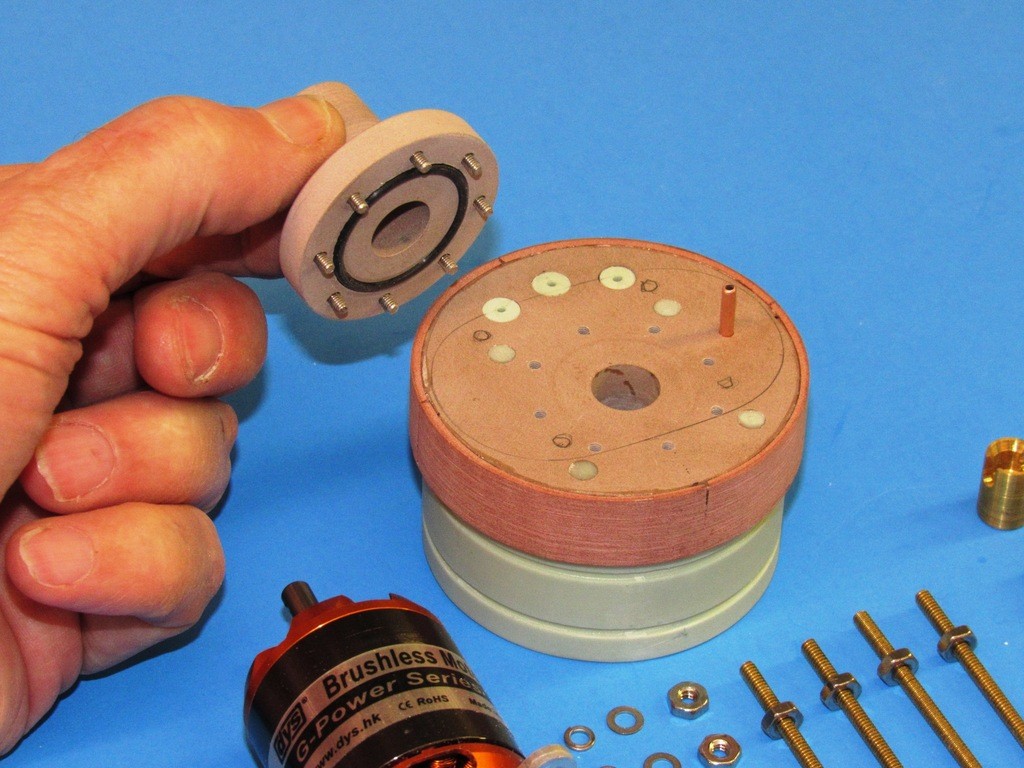

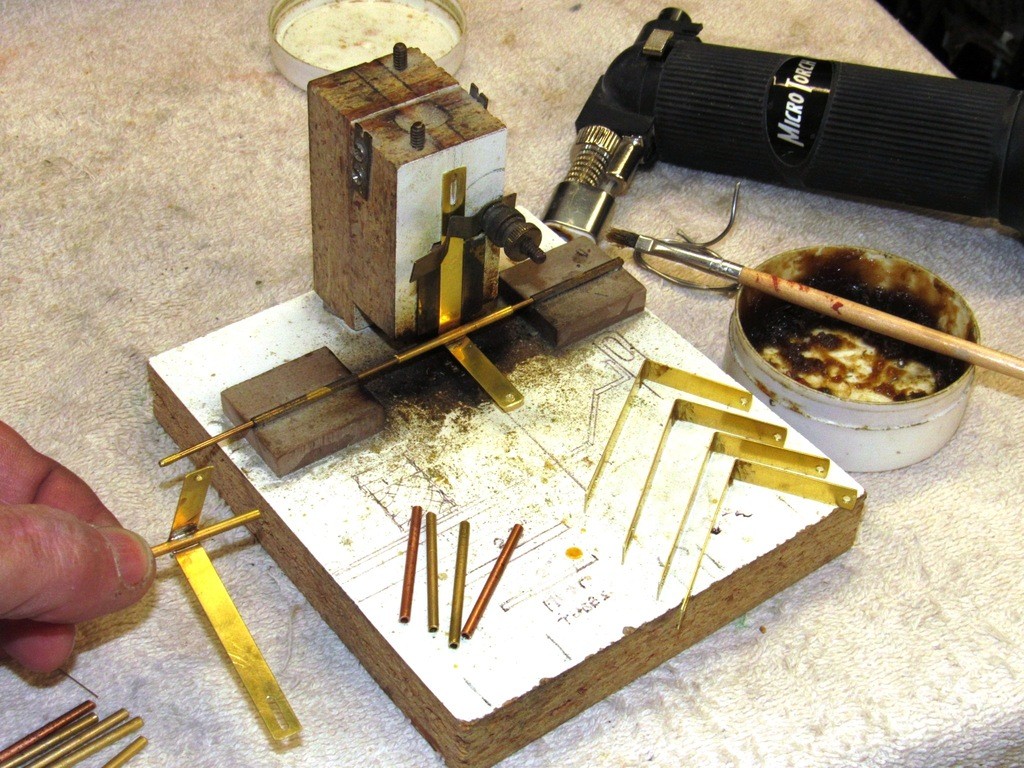

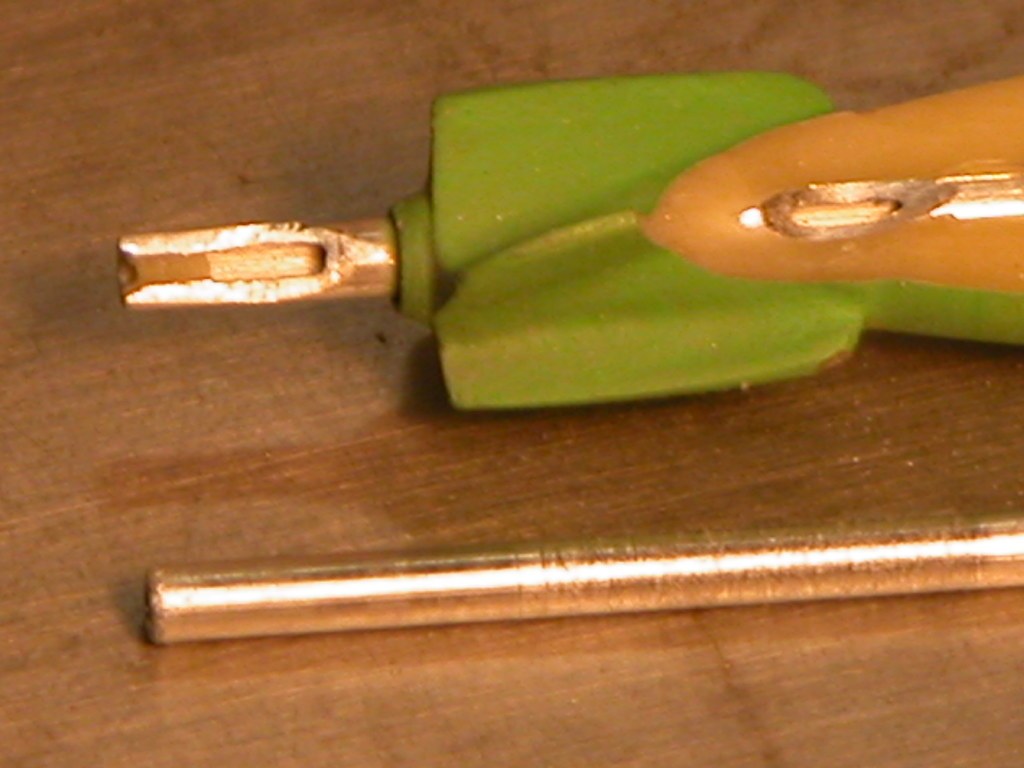

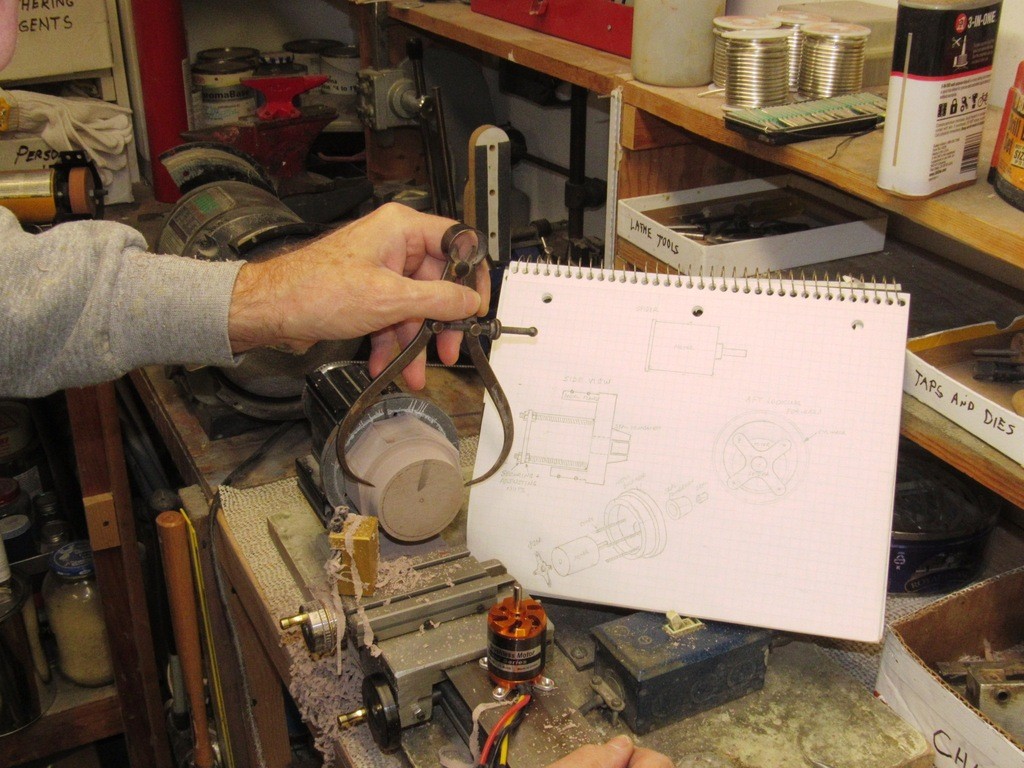

I make my own shaft seal from an Oilite bearing (unflanged), and a cup-seal. The seal body is re-purposed resin sprue. Like so:

DavidWho is John Galt?Comment

-

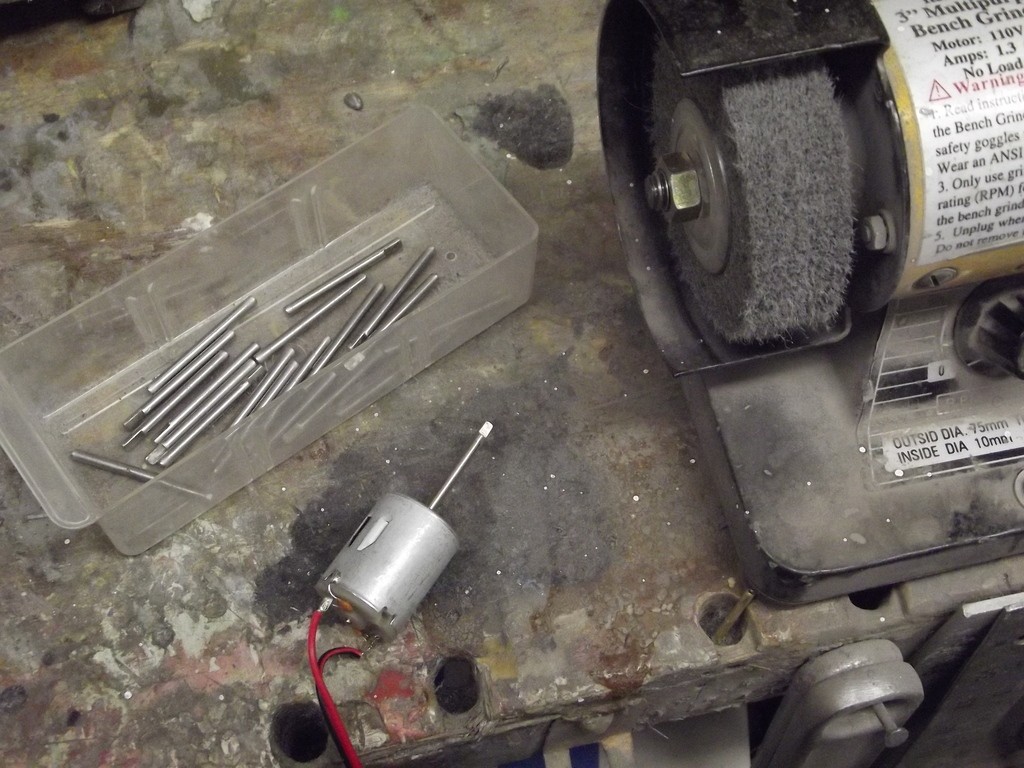

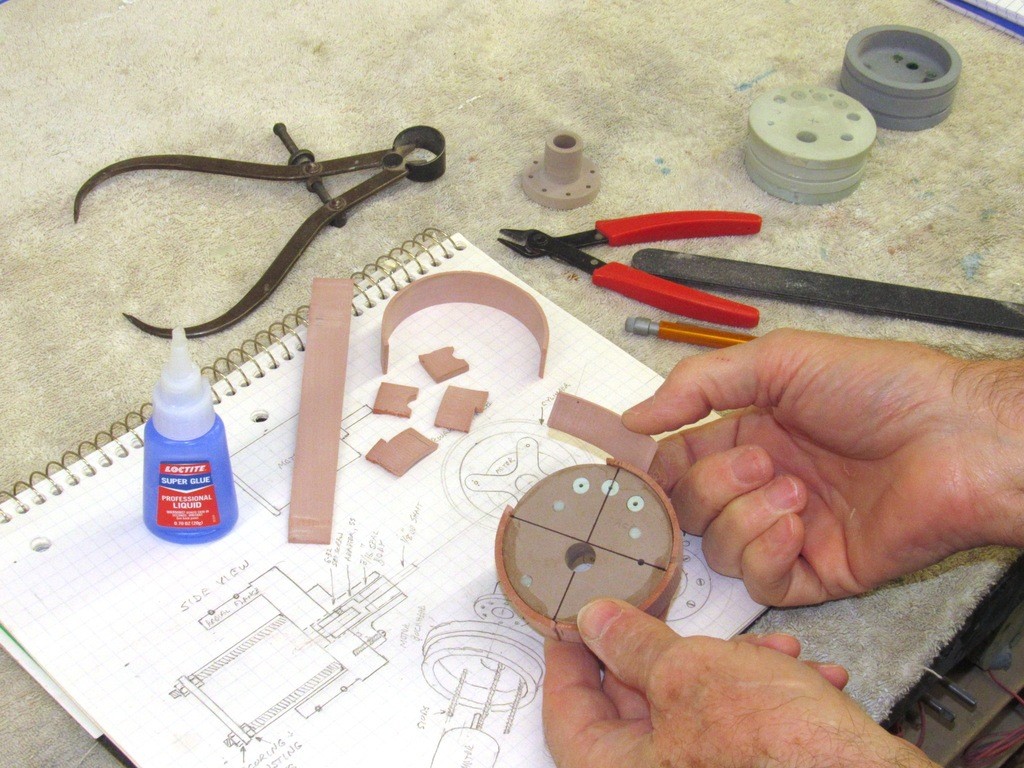

I rely heavily on reproducible model building techniques. My principle one is resin casting. Most of that work, as illustrated here, is simple pressure assisted casting. Some hum-drum piece work needed to make the parts utilized by the r/c submarine modular systems I market through the Nautilus Drydocks. Polyurethane casting resin is catalyzed, poured into rubber tools, pressurized till it hardens, then the tools are opened and the cast parts extracted, and the process repeated.

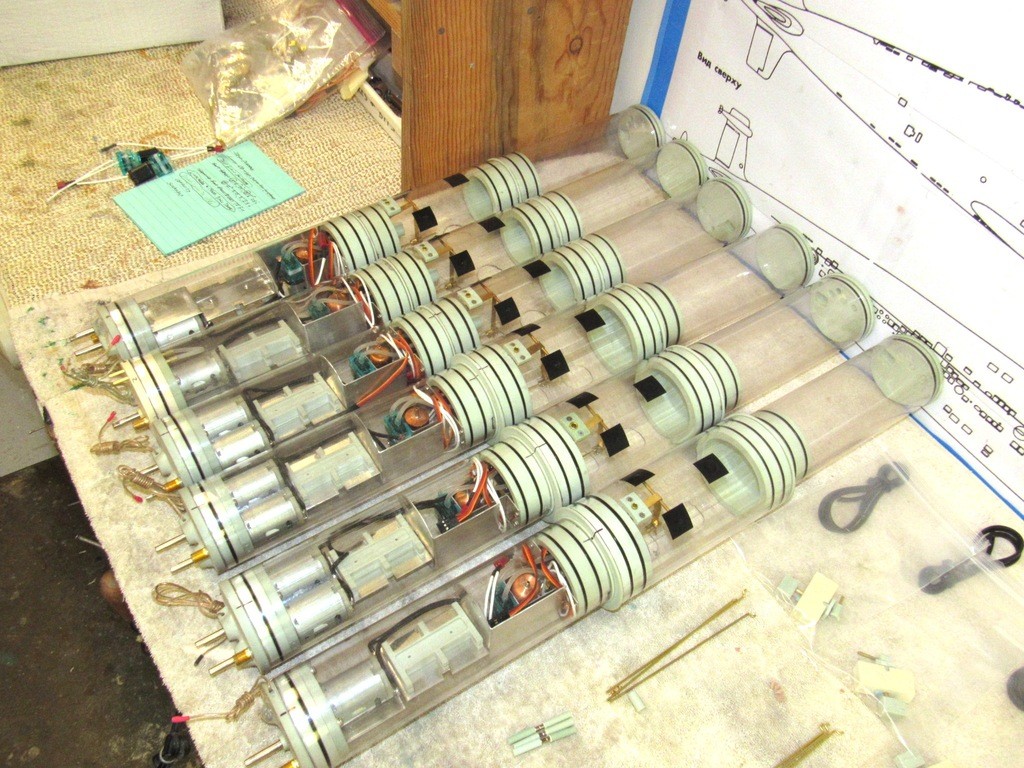

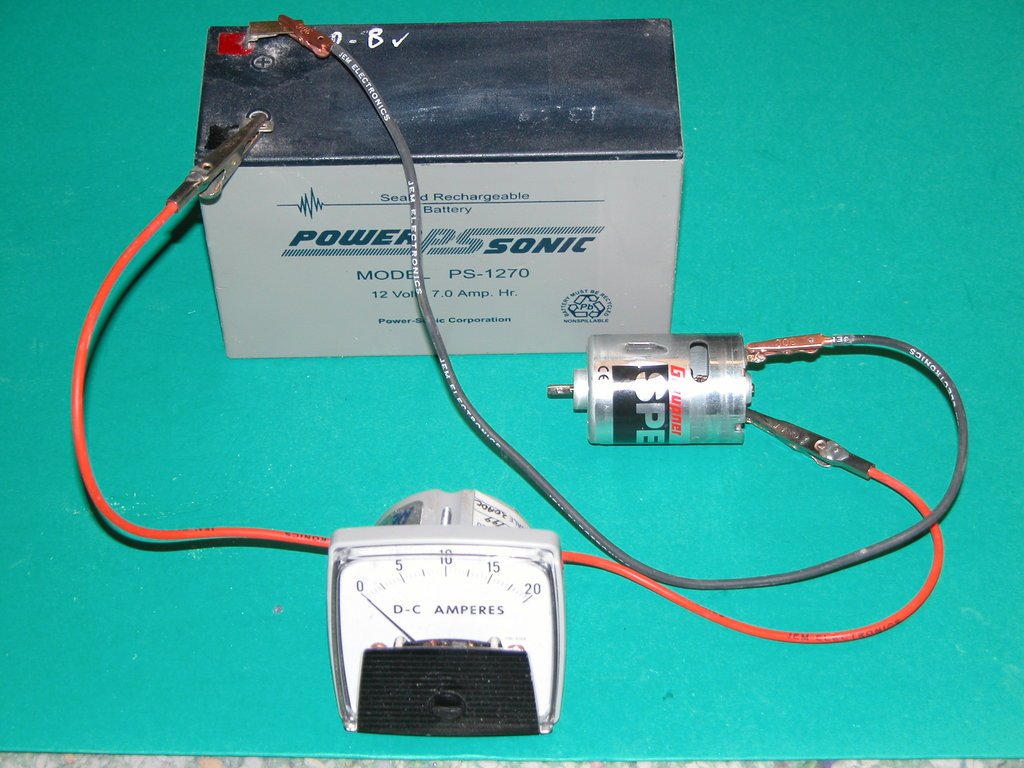

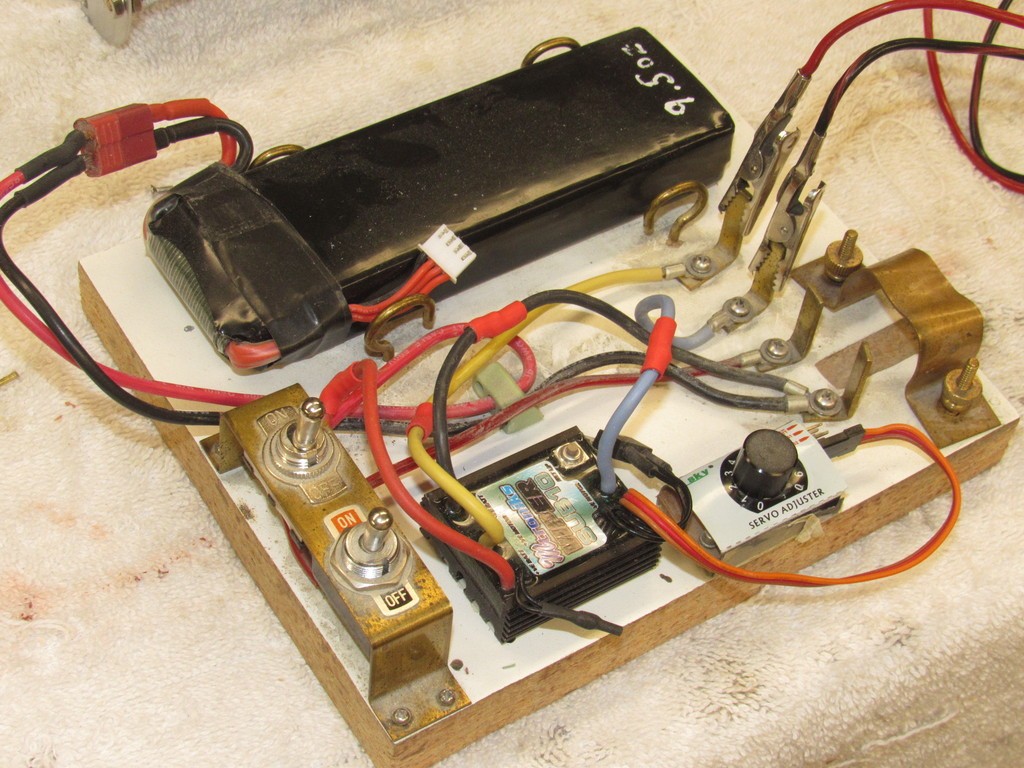

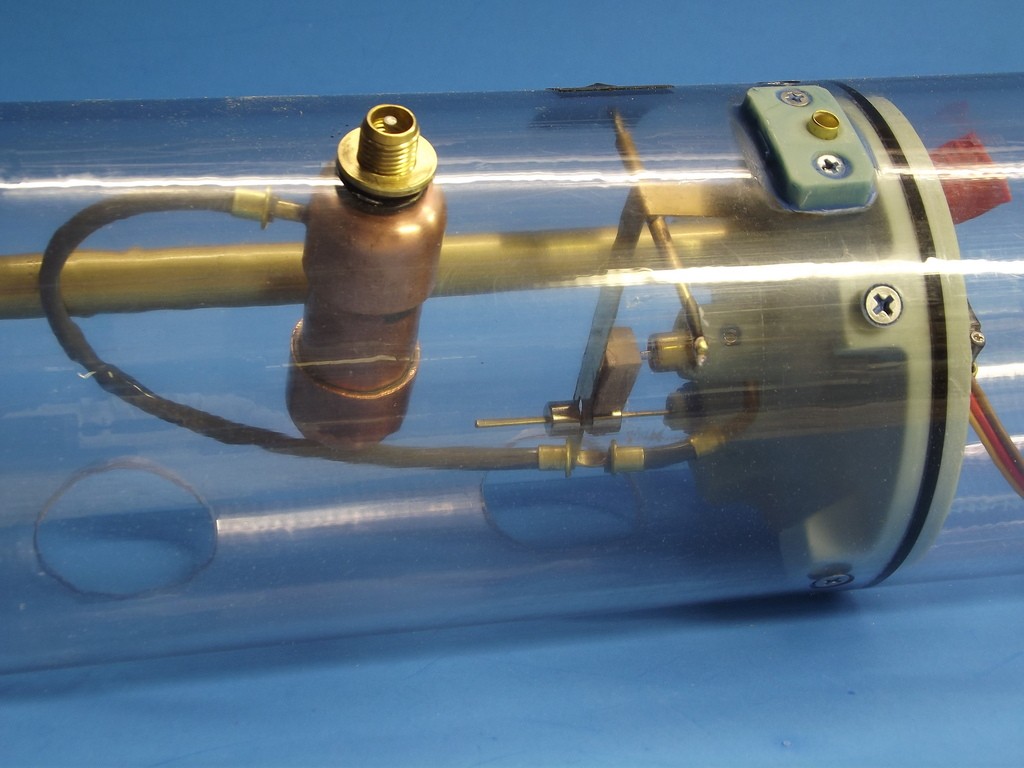

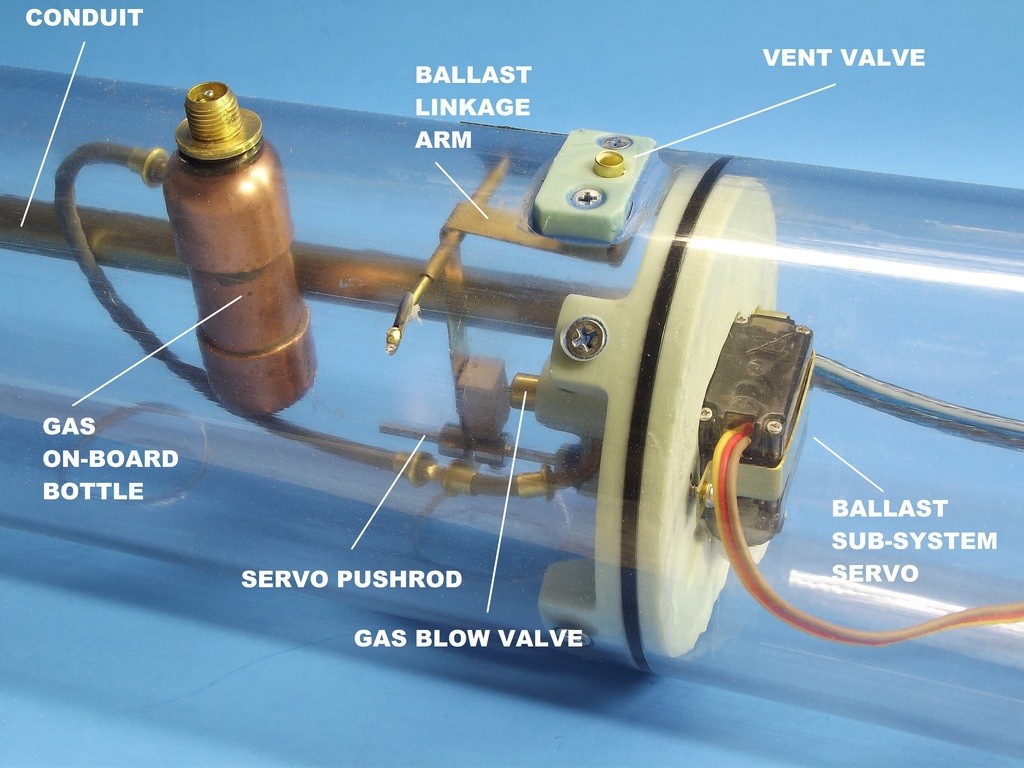

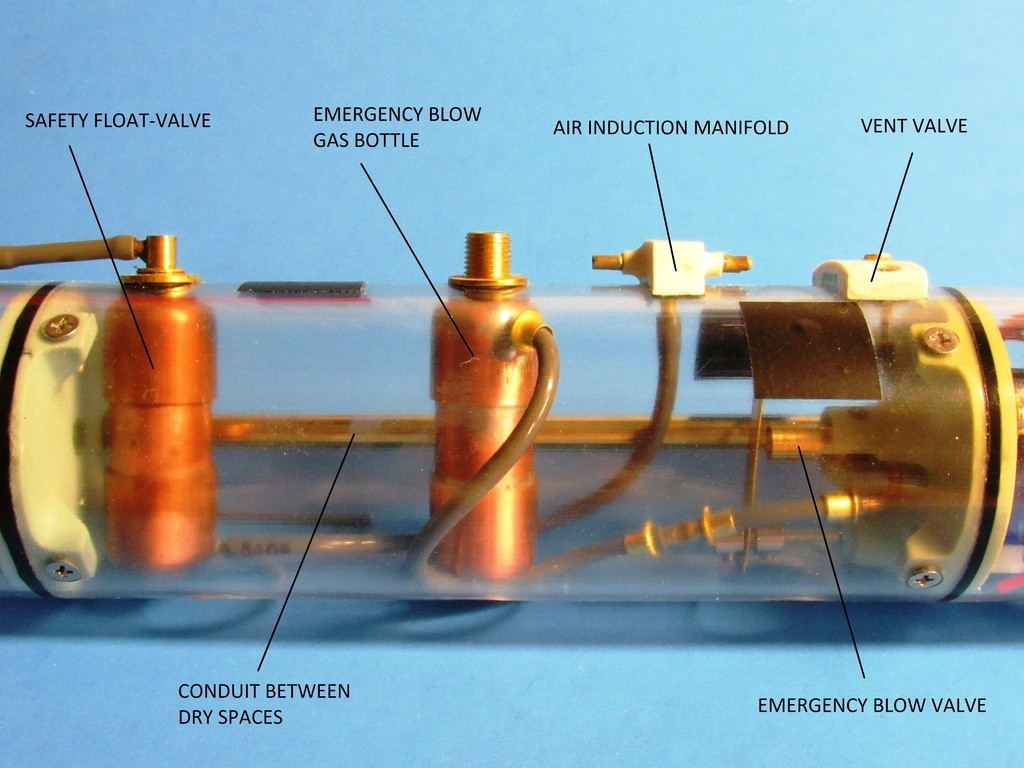

Spent most of last week leak checking and certifying a group of our major project, the SubDriver. This is a watertight enclosure containing the propulsion, control, and ballast sub-systems needed to operate an r/c model submarine. These things are our bread-and-butter. We used to do industrial displays, movie effects miniatures, private commissions, and resin kits (remember Lunar Models?). Today we support the r/c submarine hobby trade.

Who is John Galt?Comment

-

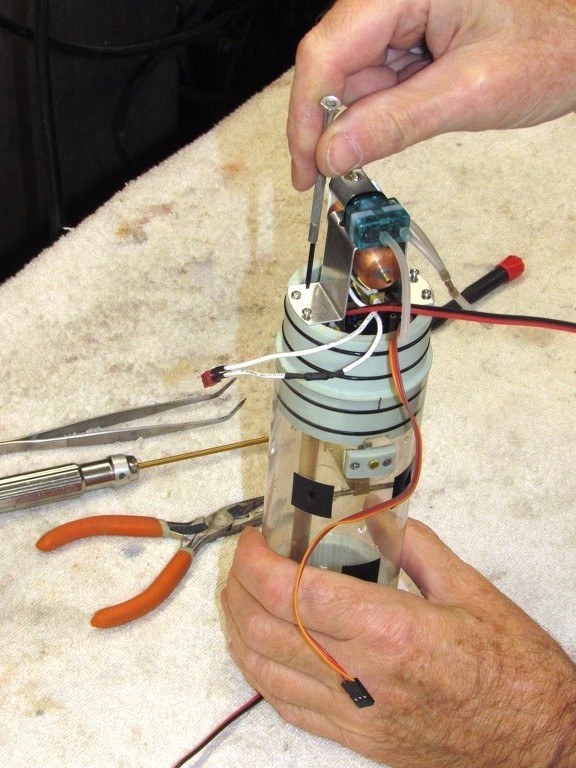

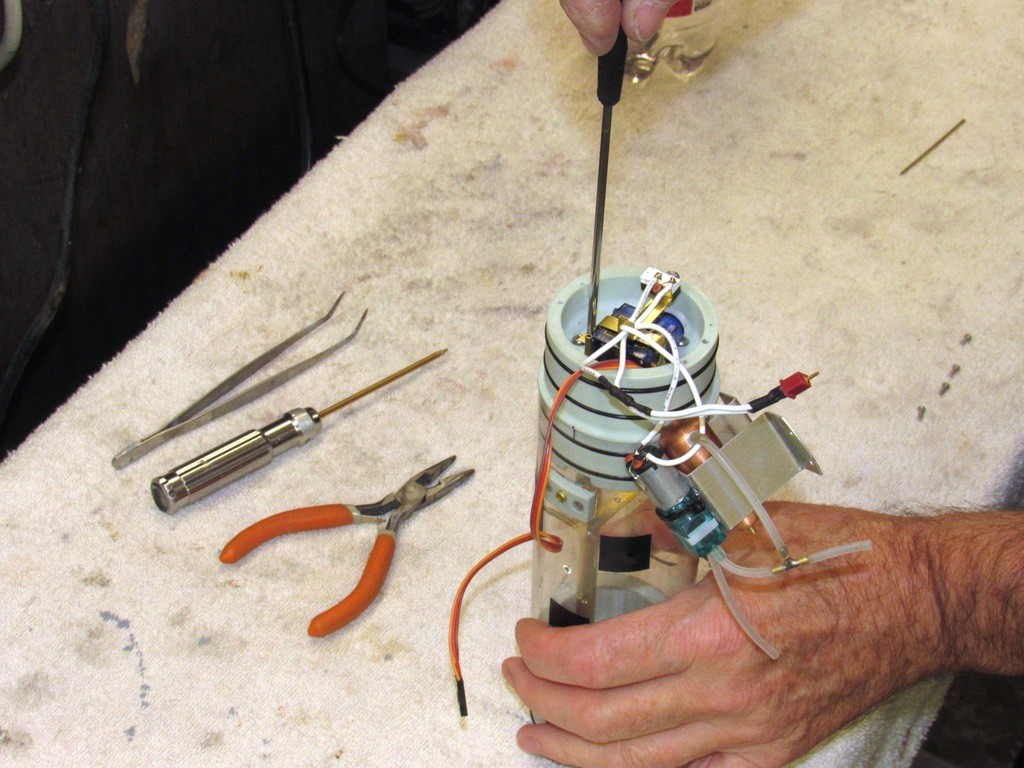

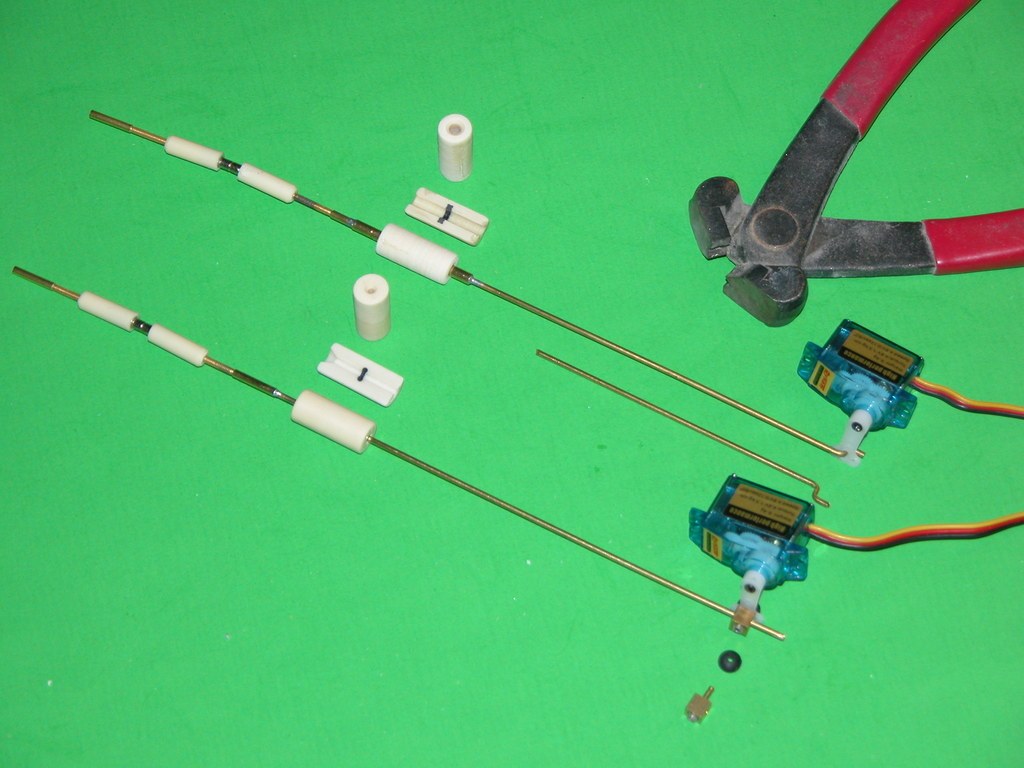

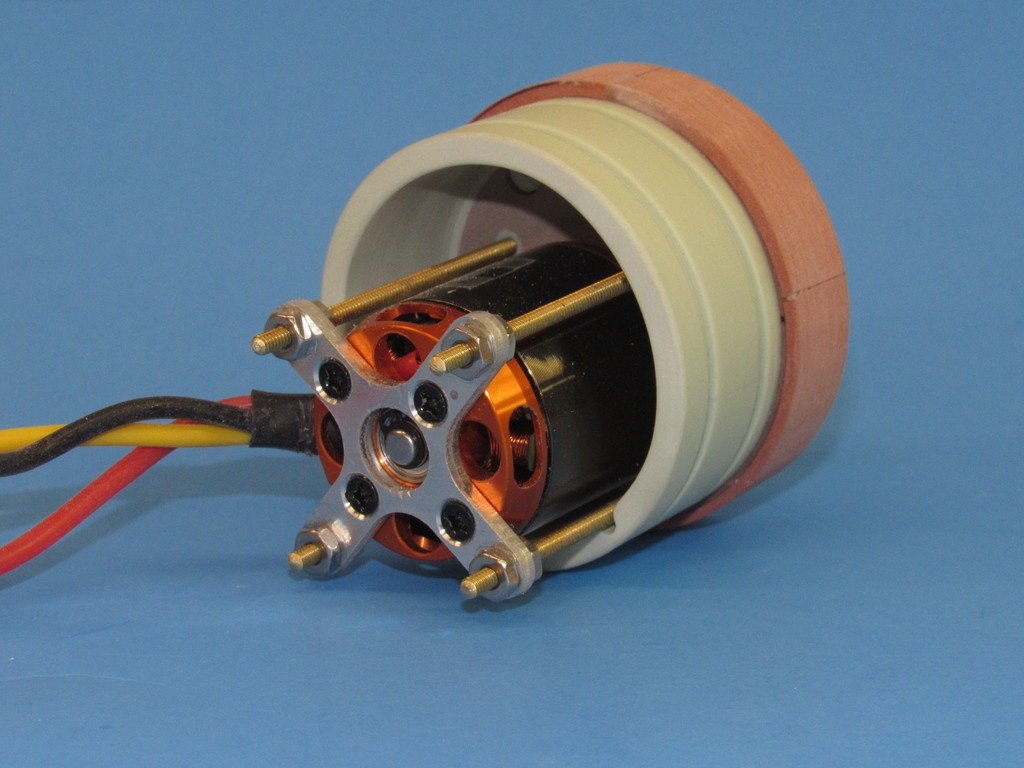

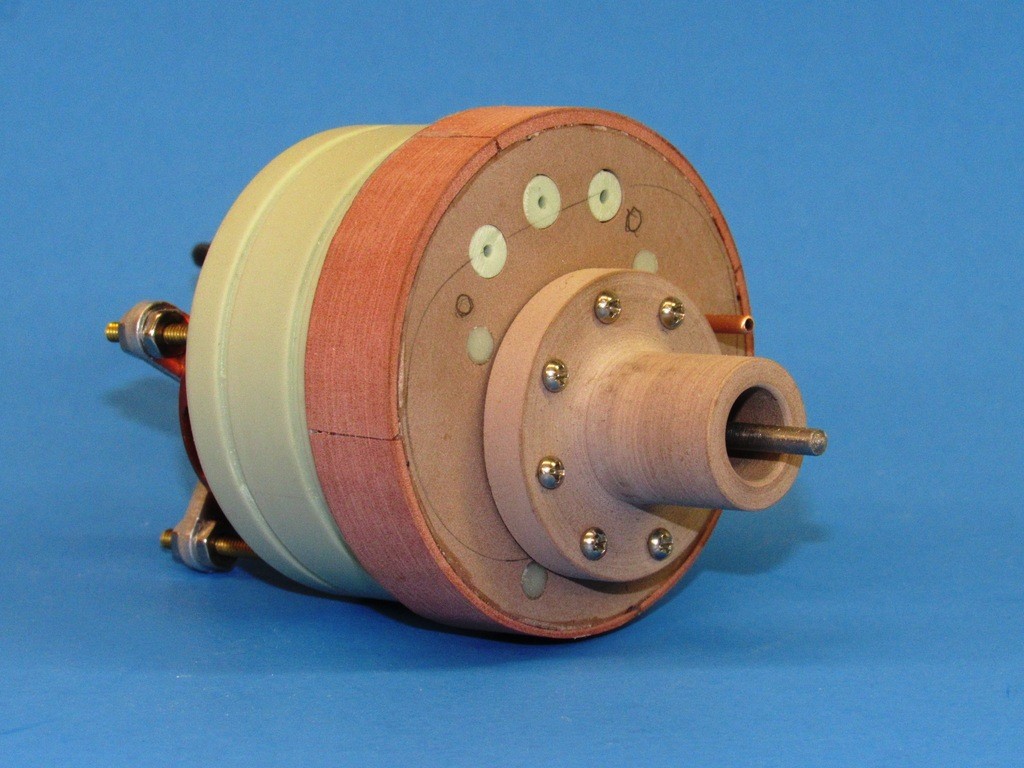

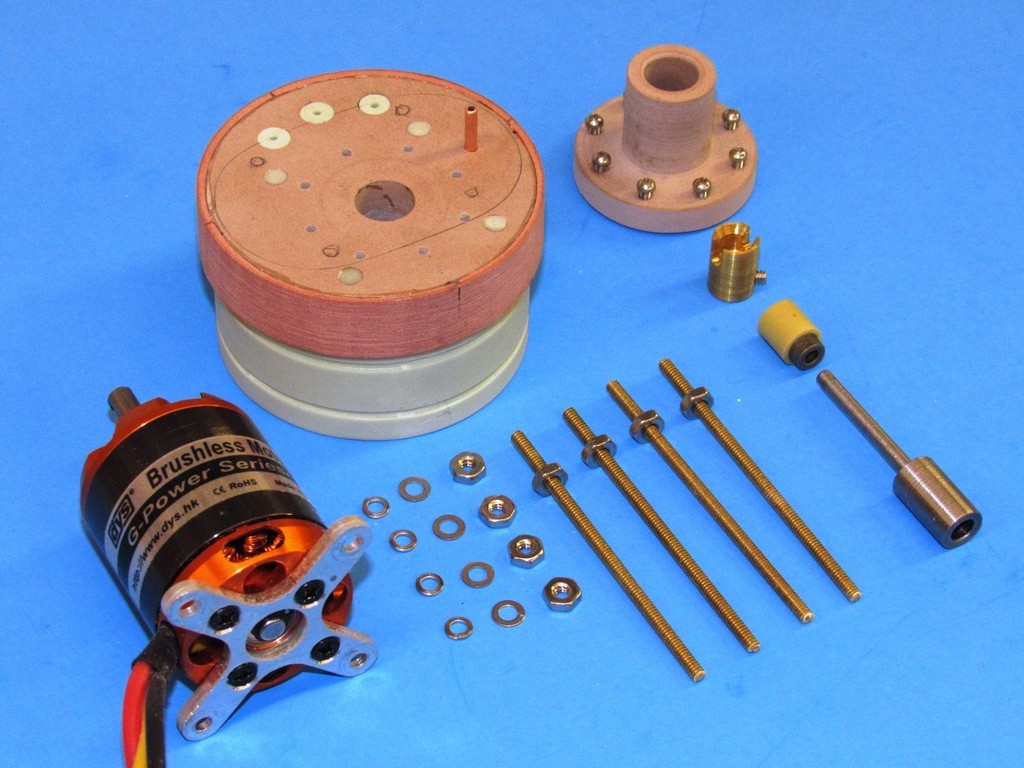

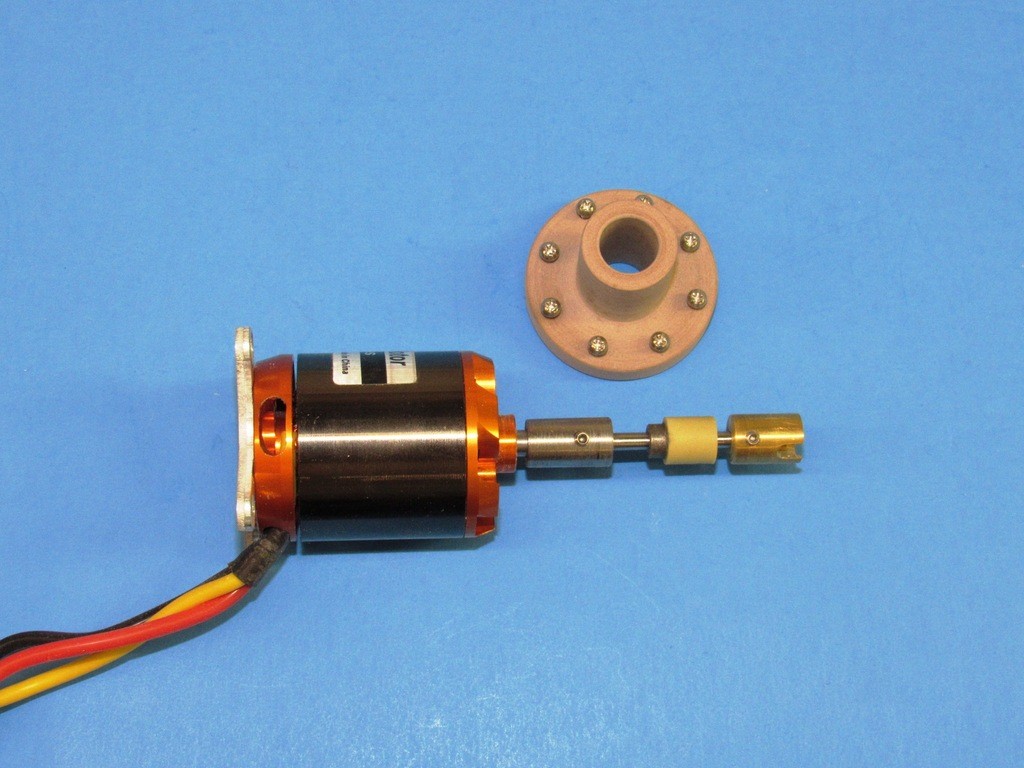

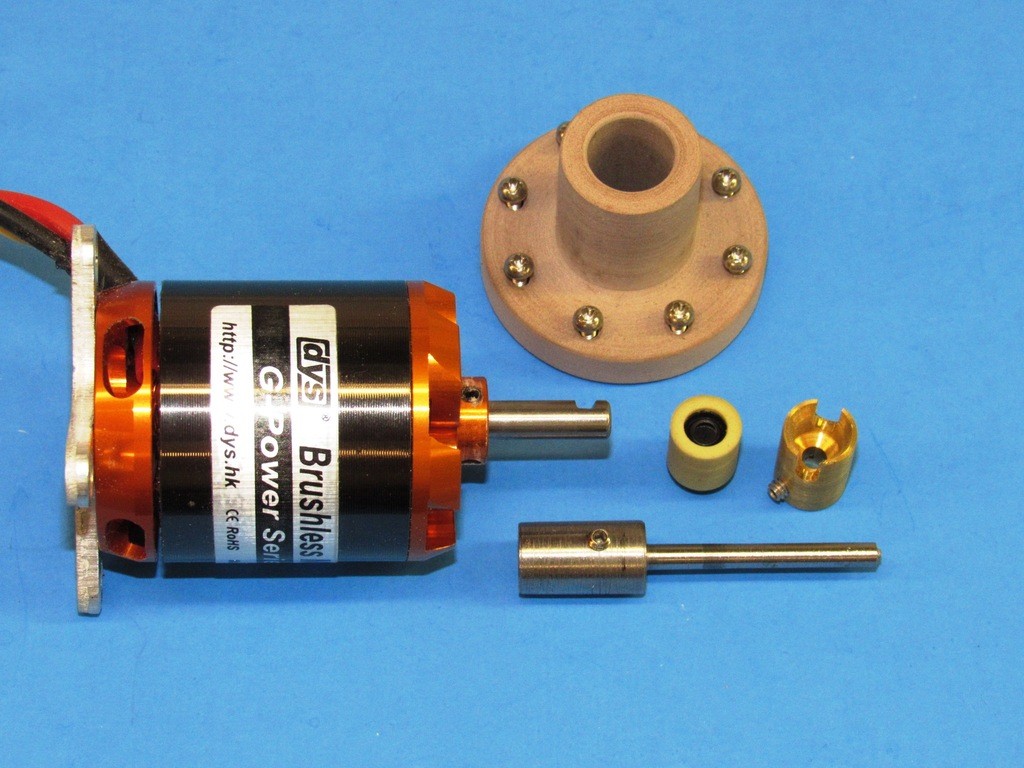

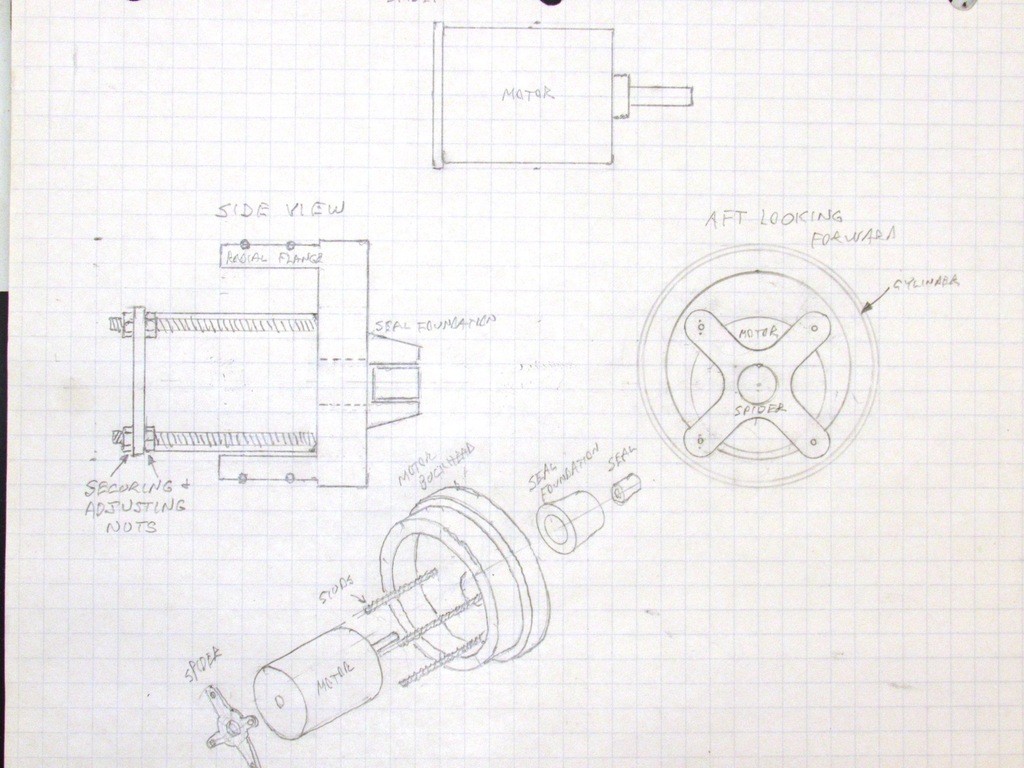

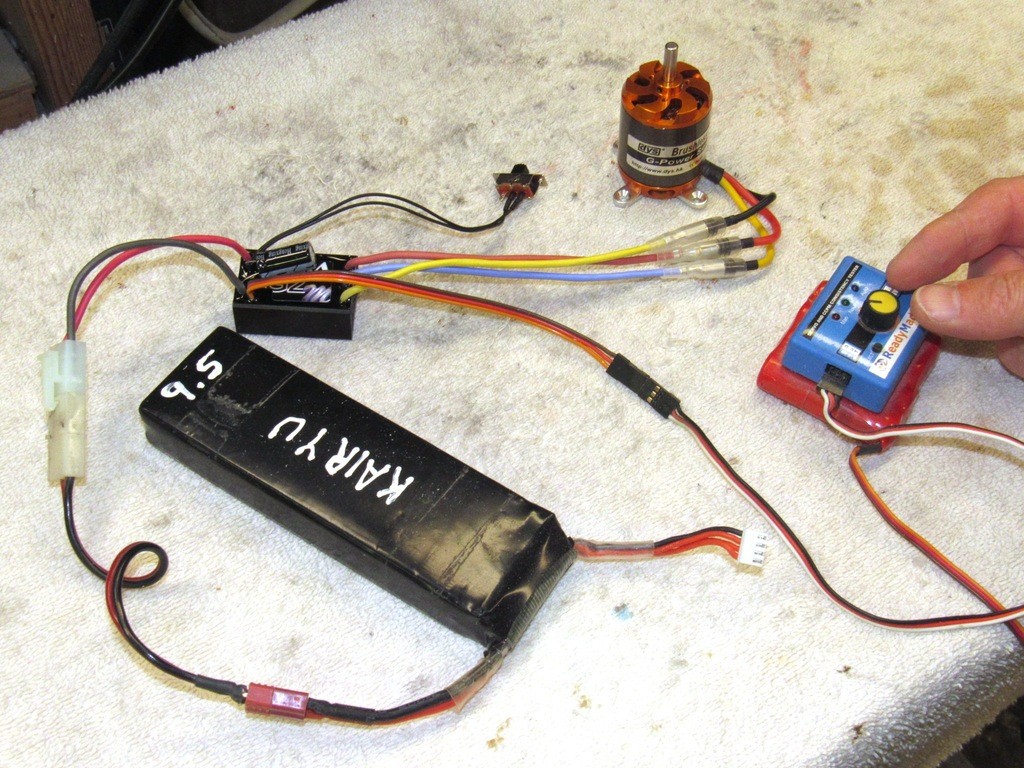

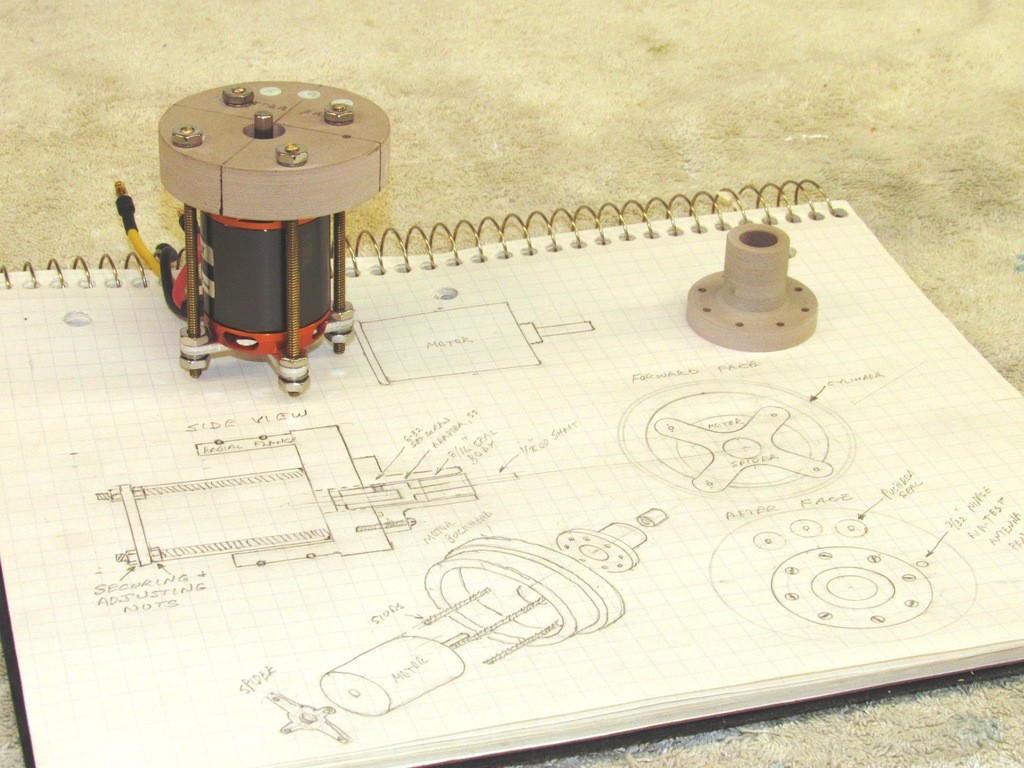

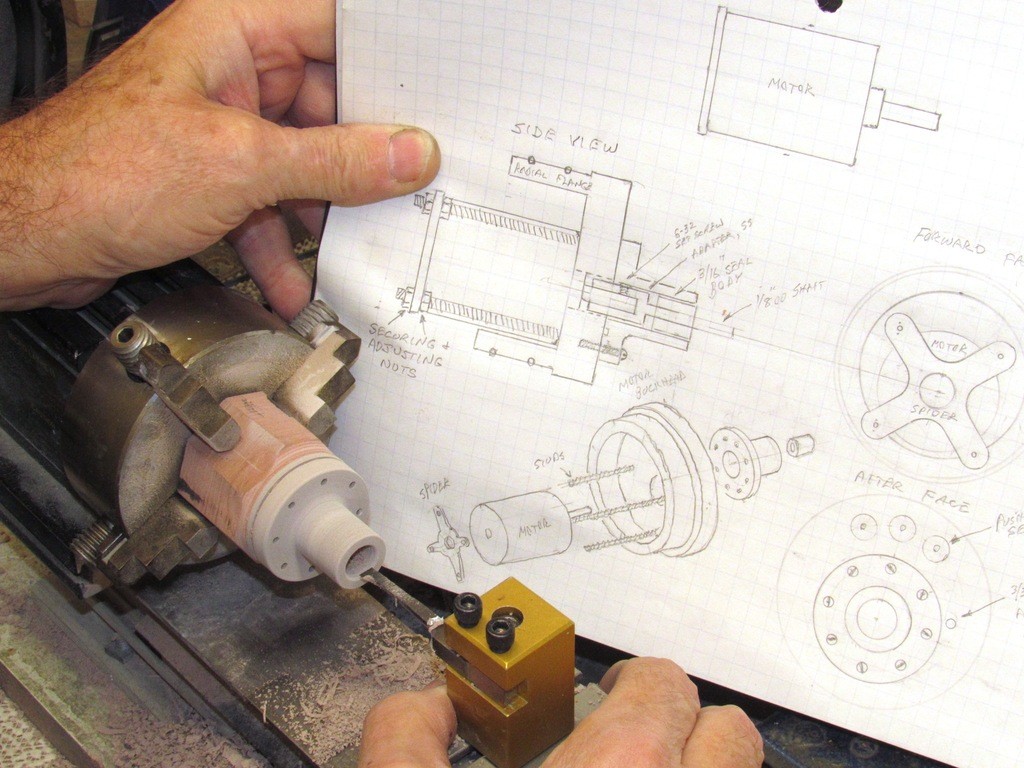

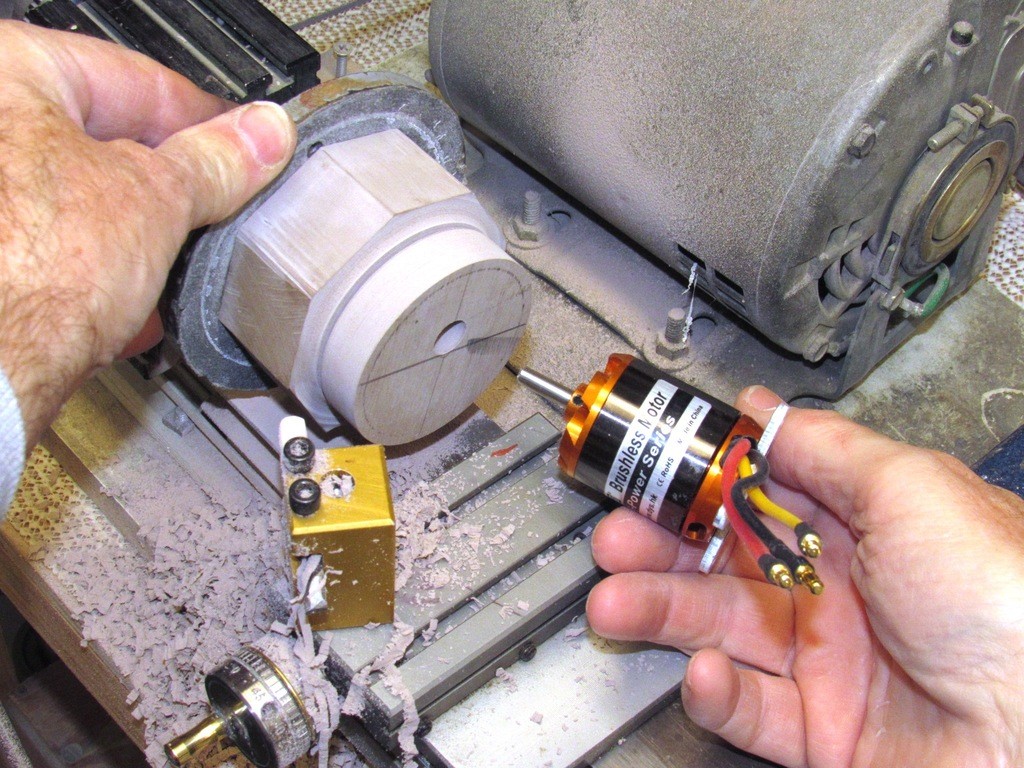

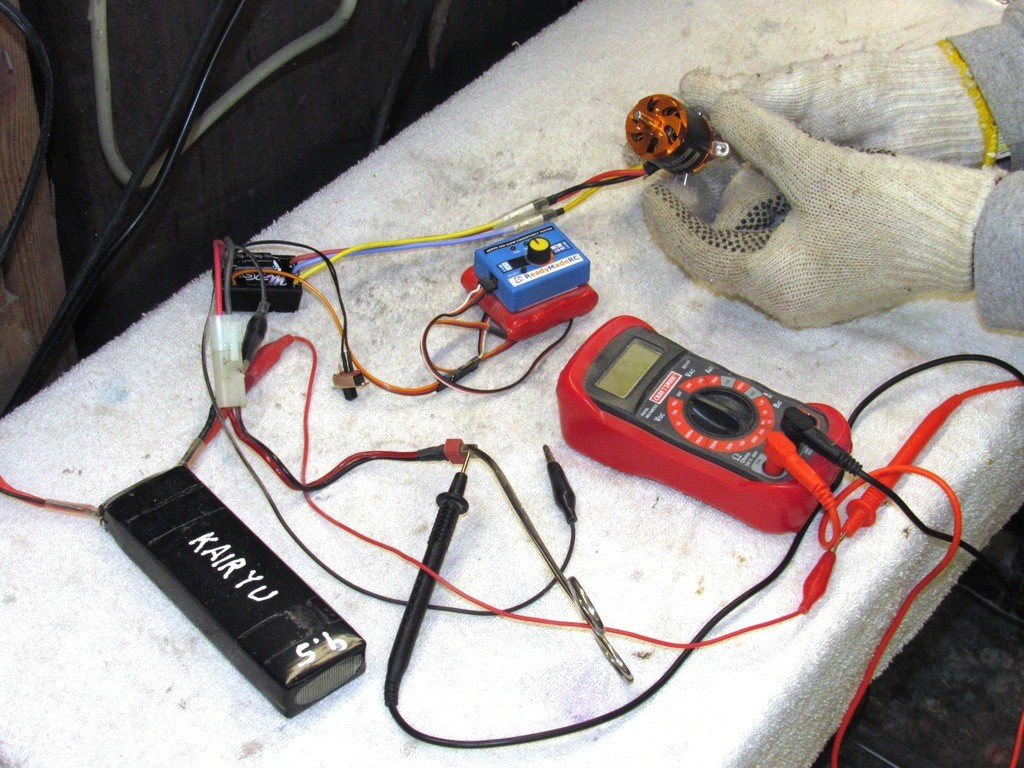

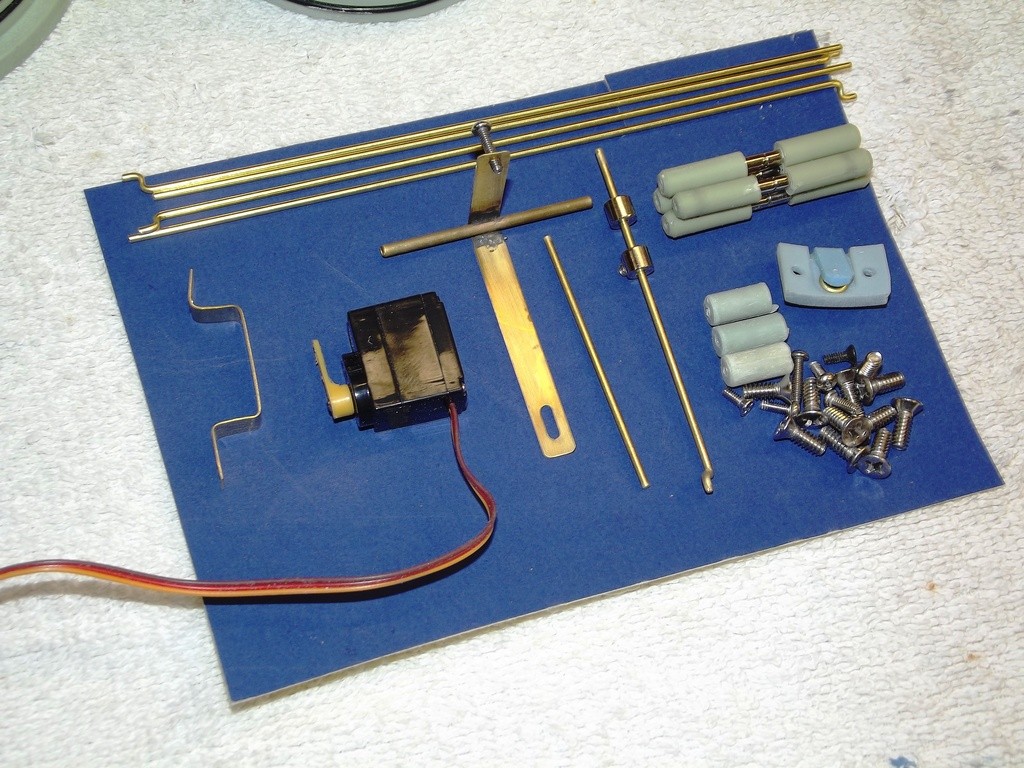

I'm in the process of joining the 21st Century: I'm switching from brushed to brushless motors. That has required some motor evaluation and development of new foundations to mount the motor(s) within the SubDriver. Here I'm mocking-up a motor-bulkhead master with motor and associated hardware. If it works in this form then it will work with the eventual cast resin pieces produced from the masters.

Just another day in the shop.

DavidWho is John Galt?Comment

-

Who is John Galt?Comment

-

Hello David,

A wealth of great info once again. I do however have some more questions mainly to do with clarity of what I’m seeing.

I notice on your end caps in the most recent pics where the pushrods are located, there is a faint ring of blue silicon around them. Are these inserts? I always assumed that your pushrod design simply meant sliding a tiny o ring on a brass shaft inside the silicon mould and the poly resin encased the o -ring after pulling out the brass core. Have I missed something here?

Also do you buy a length of stainless for your shafts, cut them to size and then drill the hole in the end to friction fit onto the shorter motor shaft? How do you guarantee that the new shaft extension is absolutely parallel with the original shaft or is any eccentricity taken by the flexing of other parts? I did read earlier thatComment

-

The only cast-in-place O-ring is the one that seals the end of the conduit that extends through the ballast tank and connects the forward to the after dry spaces within the SD. In this application I'll use either X or O-rings. No difference, just depends what I grab out of the bin.Hello David,

A wealth of great info once again. I do however have some more questions mainly to do with clarity of what I’m seeing.

I notice on your end caps in the most recent pics where the pushrods are located, there is a faint ring of blue silicon around them. Are these inserts? I always assumed that your pushrod design simply meant sliding a tiny o ring on a brass shaft inside the silicon mould and the poly resin encased the o -ring after pulling out the brass core. Have I missed something here?

Also do you buy a length of stainless for your shafts, cut them to size and then drill the hole in the end to friction fit onto the shorter motor shaft? How do you guarantee that the new shaft extension is absolutely parallel with the original shaft or is any eccentricity taken by the flexing of other parts? I did read earlier that

The pushrod and shaft seals are discrete items that are inserted and made watertight with silicon adhesive.

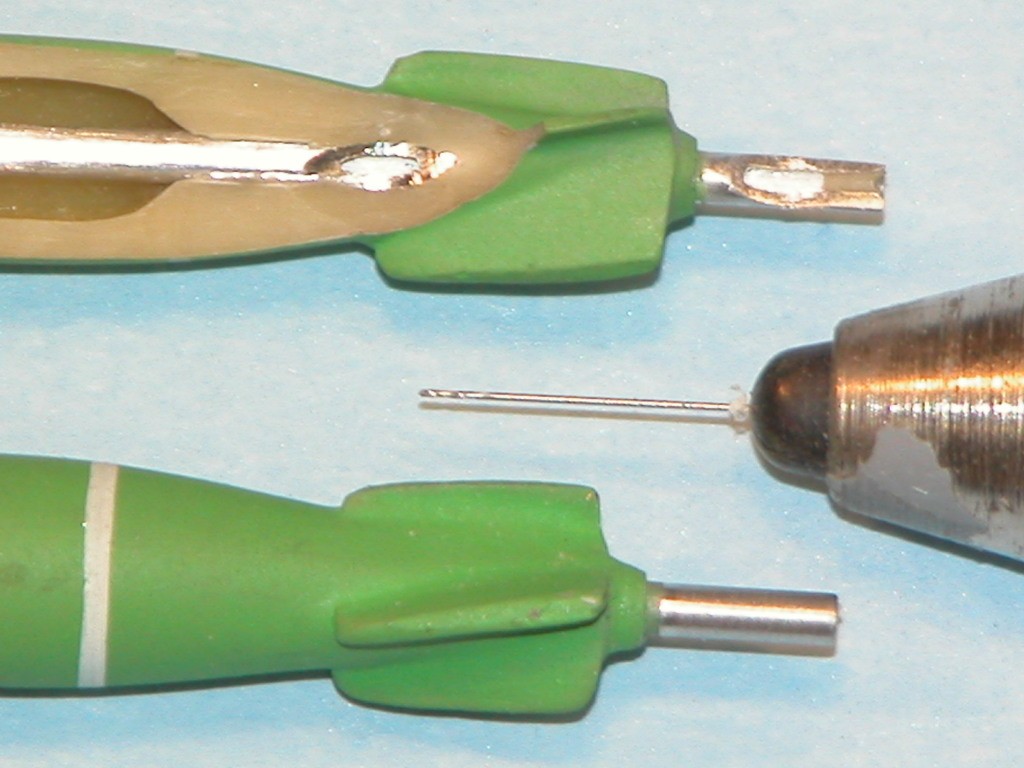

Shaft extensions are bored on the lathe. This insures exact centering of the hole to the shaft. I taper the motor shaft and make the fit between motor shaft and shaft extension a tight interference fit.

David

Who is John Galt?Comment

-

I've completed most of the grunt-work on the masters of a motor bulkhead that will mount a brushless propulsion motor for one of our SubDriver r/c submarine systems. I use the raw masters to check fit and operation in mock-up form. Once everything is working as planned (best laid plans … and all that happy horse-****), I refine the finish of the masters and turn them into rubber tooling from which production items will be cast.

David

Who is John Galt?Comment

-

Yes, the motor has a 5mm shaft. The shaft extension/adaptor in this case is 1/8", but I can make it any diameter I wish.

Bob had a good idea that would save a lot of MSD internal space: mount the motor in the wet! I'm working up a motor-bulkhead (MB) master for that arrangement today. Film at Eleven!

DavidWho is John Galt?Comment

Comment