Cleaning up the over-strikes and poor quality engravings, I can assure everyone, is at least as mind-numbing a task as it is to read about it. But it's a task that's gotta be done if a quality product is to be the result!

So, strap yourself in and make what you will of the following procedural.

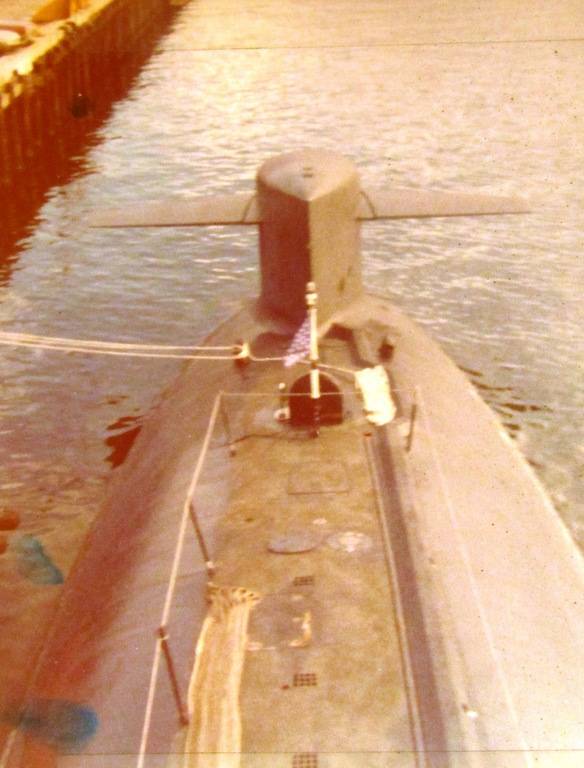

The initial scribing done forward I've applied some putty.

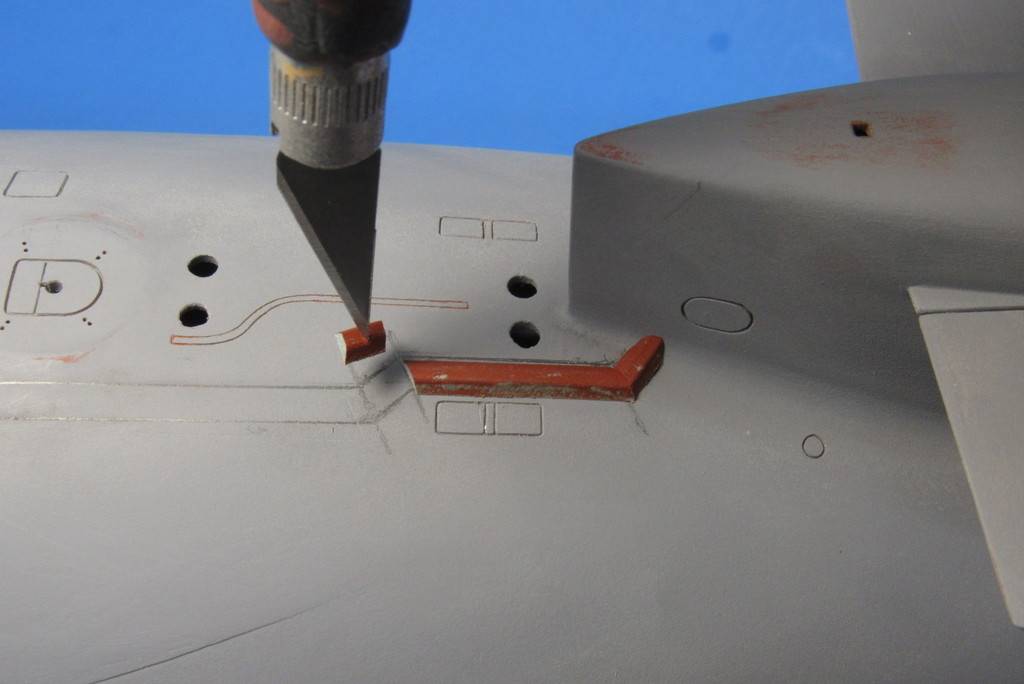

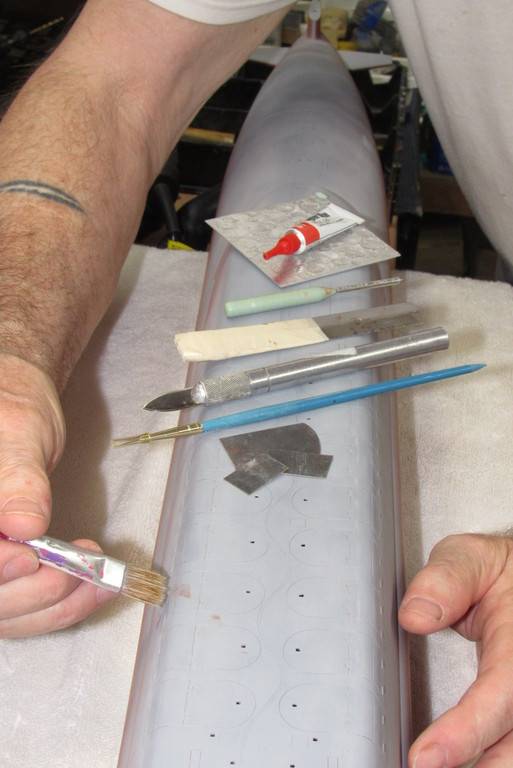

Here I'm deepening the straight running engravings with the modified razor-saw. While continuing aft along the model deck with scribing tool and saw, the putty, up forward, has plenty of time to dry.

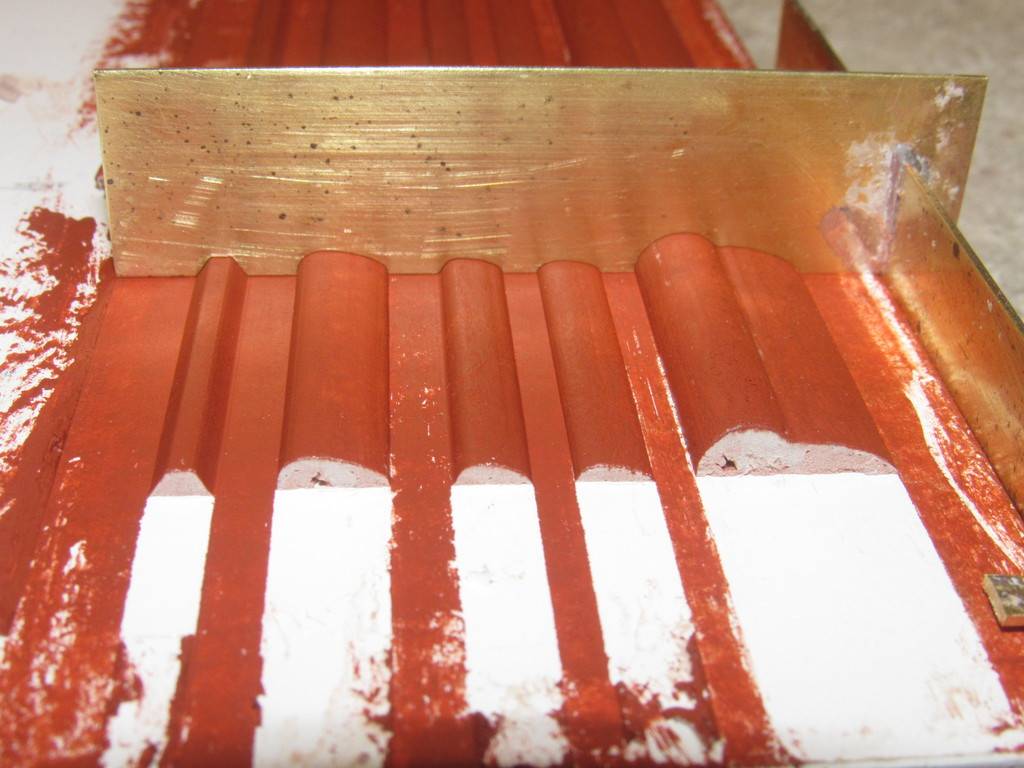

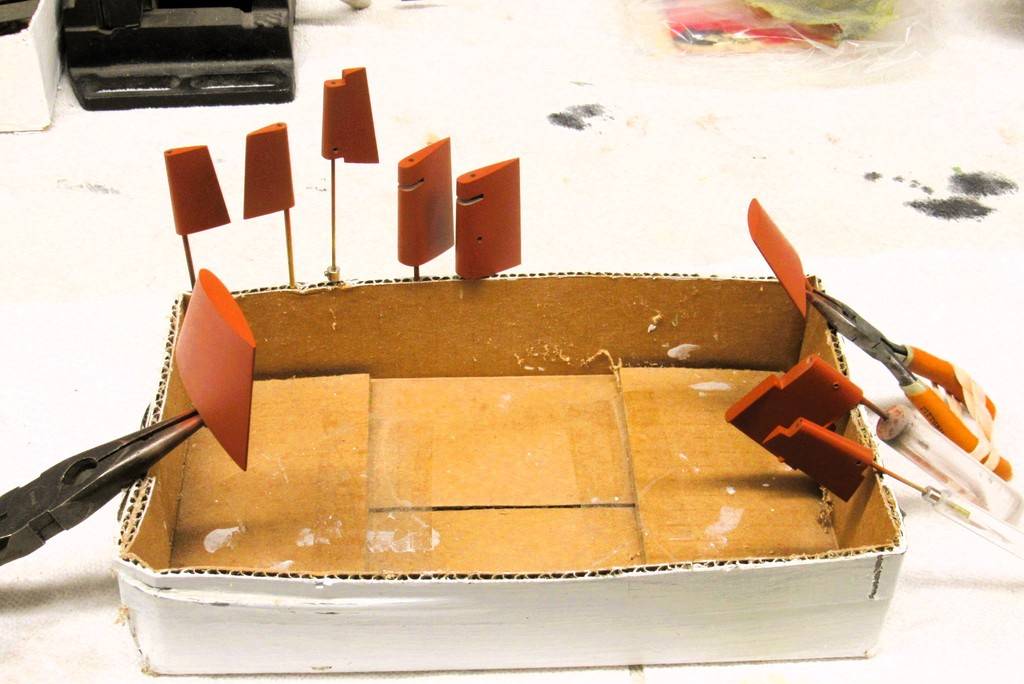

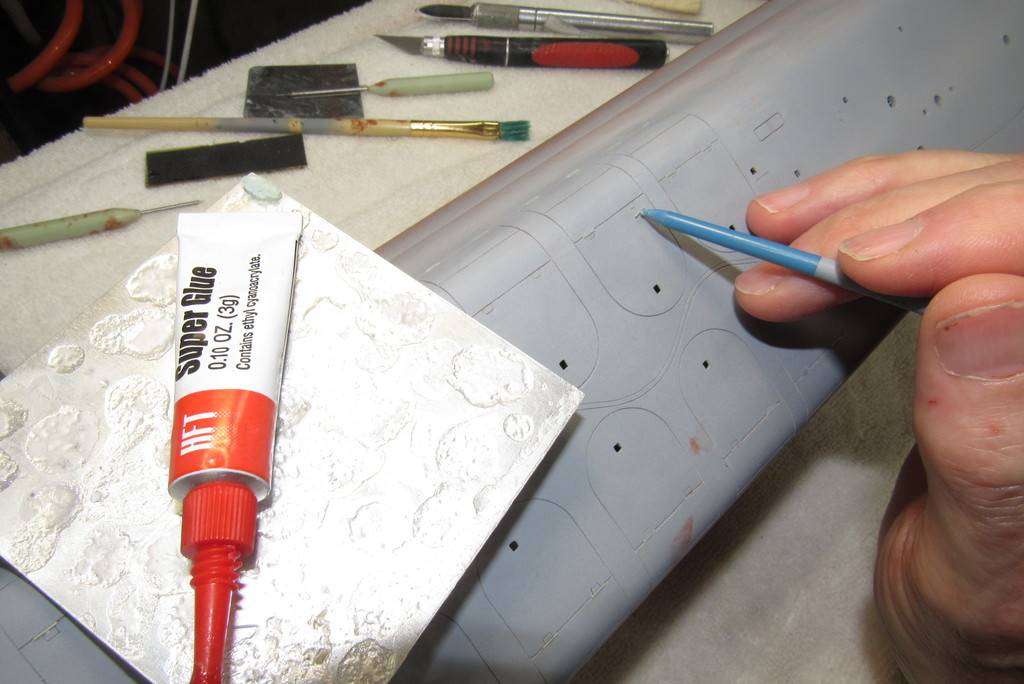

As soon as an engraving task was completed, I brushed on air-dry Nitro-Stan touch-up putty over that work, promptly chasing out any putty that gets into the engravings.

Air dry putty is never applied thick, its only to address shallow scratches and gaps. Since this putty polymerizes (changes state from liquid/paste to solid) through evaporation of its solvent – if put on too thick it takes forever for the buried solvents within the mass to be liberated to the air. The top surface will skin hard, but underneath that the putty is still soft. A killer later!

(Two-part fillers, on the other hand, change state quickly if put down thick as the polymerization process – how the filler changes state from liquid/paste to solid – is through an exothermic reaction between the resin base and catalyst. So, with a two-part filler, the denser the mass the greater the heat generated, the quicker the cure of the filler.)

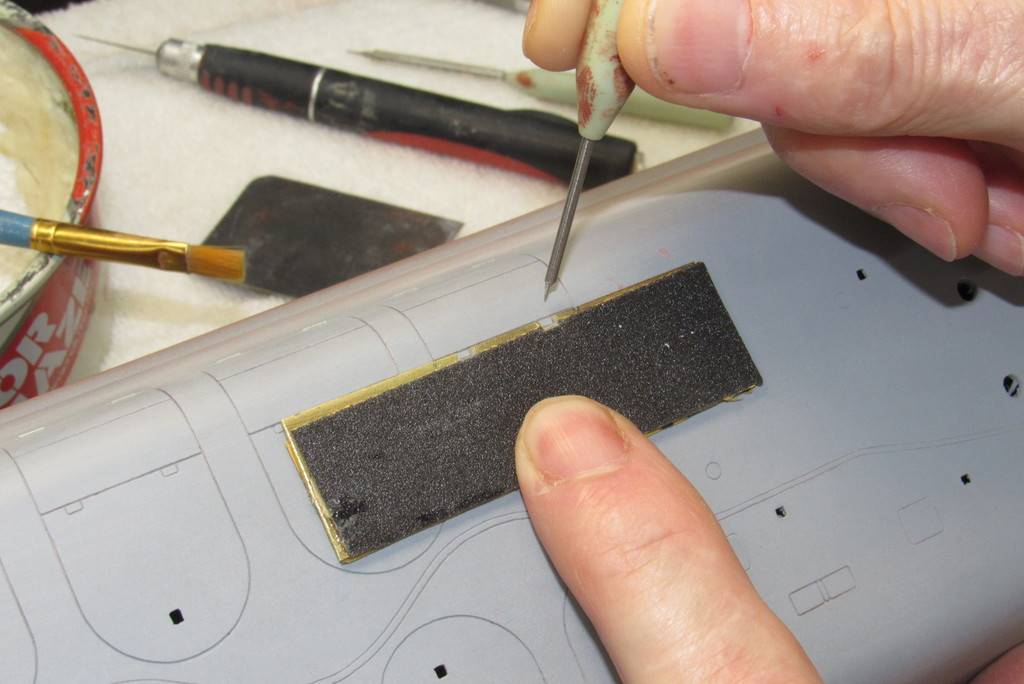

The dried putty is wet-sanded with a small hard-rubber sanding-block backing up a piece of #400 grit sandpaper. Copious amounts of water are the order of the day.

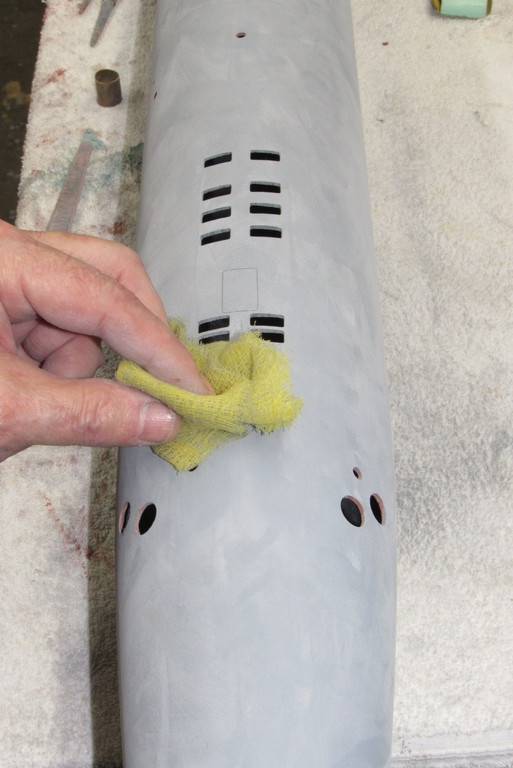

The sanding done; a wet paper towel is used to remove the water suspended sanding dust.

Followed by a blow-down with low pressure air to chase out any water still hiding in the engravings.

And... just to be sure... some hot air to evaporate the last traces of water.

At this stage I'm chasing out sanding dust from the THIRD scribe-putty-sand cycle!

God!... will it never end????

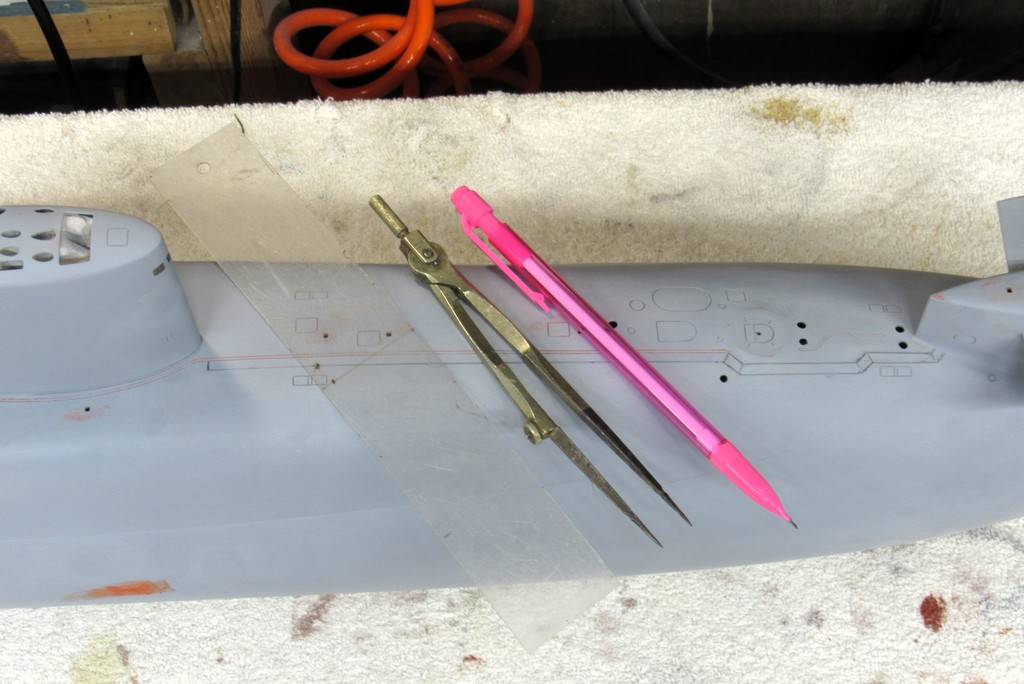

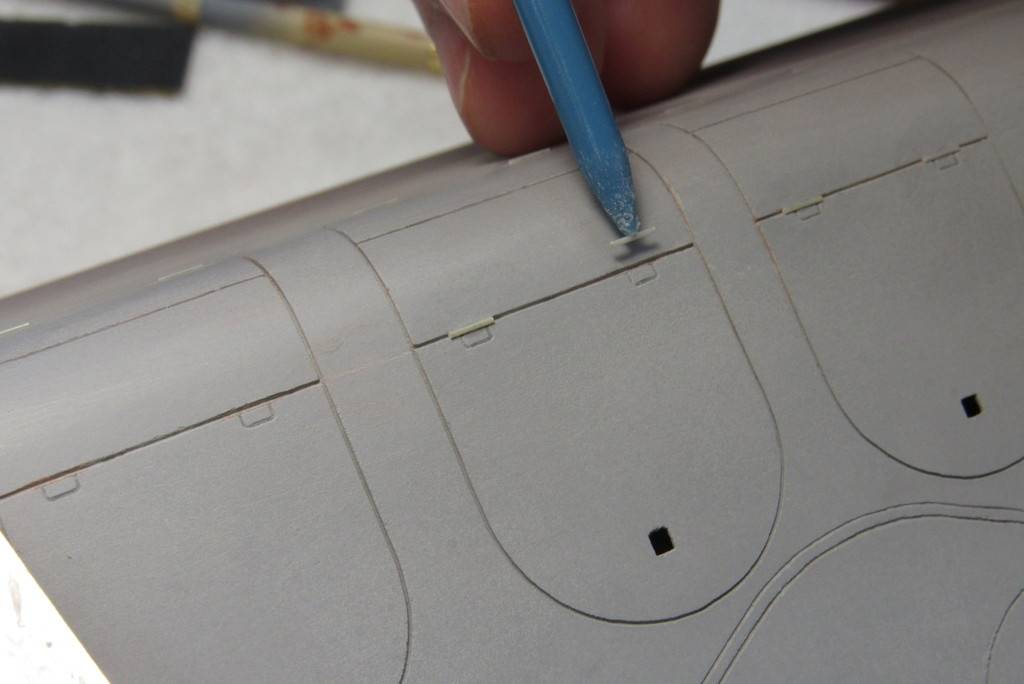

Now that the engraved lines are deep enough to guide the tool there's no need for stencils or straight-edge, just push the tip of the tool into the work and gently guide it along. This pushes any stubborn dust clear of the work. Making things ready for another coat of gray primer which further fills scratches and at the same time renders an easier to examine models surface.

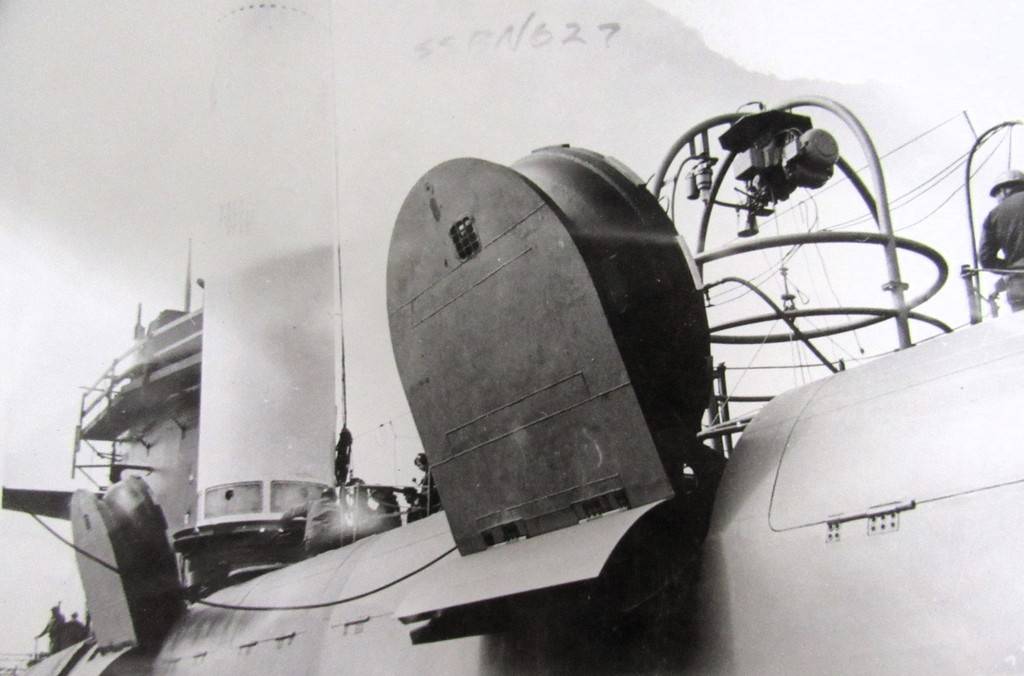

To check for any missed over-strikes, misshapen engravings or other flaws, a coat of primer to fill and identify the problem children.

… and the process repeated until perfection (who am I kidding?!...) is achieved.

Comment