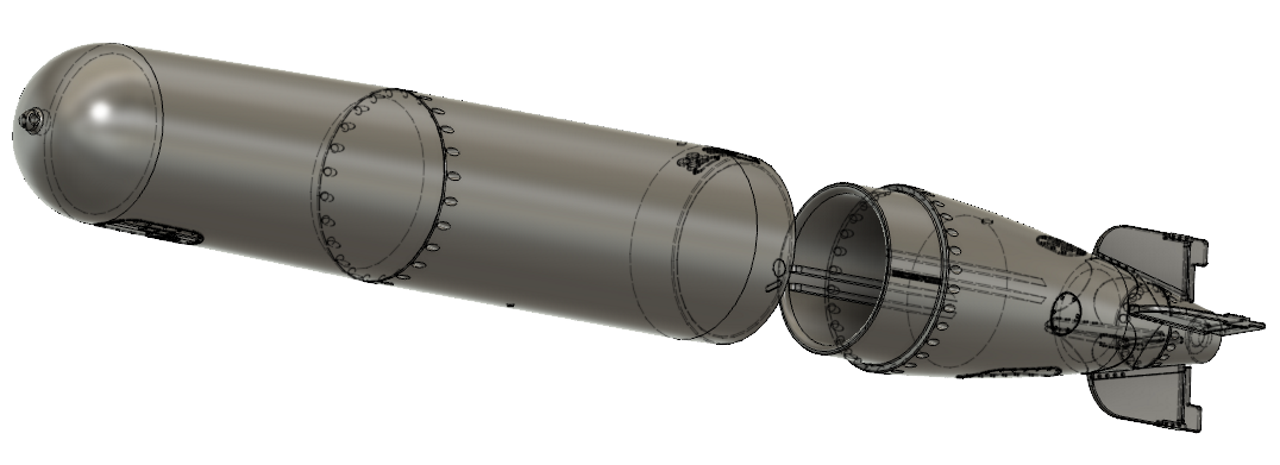

1/20 scale torpedo with counterrotating props

Japanese Class A 1/16

Collapse

X

-

While attending Torpedoman A-school I learned that the counter-rotating propellers on the MK-37 family of torpedoes used a motor whose field winding assembly, as well as the armature, was free to rotate within the motor case. The after propeller was coupled to the armature, and the forward propeller was coupled to the field assembly. Not only does this arrangement eliminate the counter-rotation gear-box, but reduces noise, and assures perfect torque balancing so that net torque presented to the vehicle is a big, fat ZERO! Neat.

I'm thinking of taking a motor, put the entire motor case on a bearing so the motor can rotate. Then it's a simple matter to couple the motor to the outer shaft (forward propeller), and drive the after propeller from the normal motor drive shaft. The motor would sit in the wet (good for one season, at least). Slip rings and brushes would get power to the rotating motor assembly.

If I ever work out how to transfer a stock motor armature-commutator assembly onto a hollow shaft, then I would be able to use two motors in tandem -- The forward motor driving the after screw, the after motor driving the forward screw.

Ah ... the posibilities!

MLeave a comment:

-

OK Manfred, thats impressive. I like the simplicity with the pinion gears of your design. I have been fooling with the motor and mast section of a Venom helo which has counter rotation. Its rarher complex with two motors, but it gave me the idea of a two shaft single motor output, that I already have. only need one gear on each output shaft and a recpricle gear on the inner and outer shaft. Its not that complicated but I like your Idea better. My big question is, what your gear supply source? Also, if water is a problem with the gear tollerance, seal the box and fill with ATF. Small cap, tapped into a fill hole on the top plate. Like a full size transmission, you dont want to overfill. Leave some air space, for relief from expansion of the volume of fluid, due to some small heat that is generated. Viscosity changes but no pressure build up.Last edited by Von Hilde; 03-15-2015, 08:37 AM.Leave a comment:

-

George,

I have no plans, no specs, just builded this freehand, used my experience to get this gearbox running, it's a one off, so no documentation either, by the way, i thought you were working on a Bronco Seehund 1:35?

Manfred.Leave a comment:

-

Hello Manfred

Could you please post plans, specs. for your gearbox? I would like to try to build one, hopefully working like yours. Need it`s sizes as well please.

Thanks

GeorgeLeave a comment:

-

Like you allready know David, i made a "spinning" start.

I'll fill in the story, i was very interested into Gene's magic gearbox, figured out how it worked and made a gearbox of my own, this happened a few days ago, got some very usefull information from David about using it in a wet enviroment.

He explaned about running the gears as sloppy as possible, why?, it's all about fysics, you can't compress water, so a very small tolerance between the gear-teeth will grind you to a halt and mess up your gear.

I decided to use a different approach, and took conical gears, this way you don't need that much parts, there is a catch, when building it up everything has to be in line, if you don't, you're going to loose some teeth.

http://vid276.photobucket.com/albums...psermutlax.mp4

One of the testruns i made last evening, also did a test flooded with water, no difference, running smooth all the way, it's seems to be sloppy, but that's the intension.

Later on the week i can catch up the enlarged drawings, i ordered two, one to cut in pieces, the other one for measurement and building up the master.

Manfred.Leave a comment:

-

Japanese Class A 1/16

Ok Boys and Girls,

I must be barking mad to do this, yes, i take the challence !!!, done some homework and brought the drawing to the copyshop, length will be around 1.37 mtr at scale 1/16.

Want to build her from scratch, and make me some molds, if possible with weldindlines, rivets, etc, the tower will be build from sheet copper.

But first some fun, last few days David and me were mailing around about this sub, he made the remark that we should take this conversation to the Forum, and fool that i'm i did!!!

Have to upload some pics and a vid, be patient.

Manfred.Tags: None

Leave a comment: