Watching with interest as usual. Sort of like pressing your nose into the bakery window.

For anyone building this boat, the XXI's and XXIII's had cast steel propellers. http://www.uboatarchive.net/DesignSt...ypeXXI-S44.htm Or, at least, the XXI's did. The XXIII's were next in line and from the same designer. So I think it is a safe bet that they were steel too.

Not of direct and immediate use. But it is an important detail for the finished boat.

- Leelan

Converting the Bronco type XXIII to RC

Collapse

X

-

If the torpedoes are too fat, does that mean we should scrap the styrene torpedo tubes that came with the kit as well? hmmm... I guess if you go with David's weapons rig, it doesn't matter, as the tubes are part of the system... be creative!!!, use what you've got.

Romel,

This week that problem will be solved, right now i'm building at it, be patient.Leave a comment:

-

-

Leave a comment:

-

-

Manfred,

So connection between the stern linkages and SD would be through magnets but how will you secure the SD inside the hull?Leave a comment:

-

I think I had used the word "duplicate" when talking about the Bronco propeller. By that I meant you scratch building a prop master that resembled the Bronco prop. I am aware of your stance and feelings on duplicating the work of others, and that you do not directly use kit parts as master parts. I wasn't suggesting that, though it may have been misunderstood that I was.Don't panic, Sam. More on the launchers later.

I think it was Warpatroller who suggested that I was going to (or have in the past) used kit parts as masters when working up fittings kits.

(and what the hell is that guy over at the SC site talking about, describing the model 'he built' -- an item pooped 3D copy machine!!!???.....)

David

I have to comment about the whole 3D modeling thing. Bronco, as well as most of the injection molded model kit producers, "build" their subject models in 3D on the computer. The Bronco XXIII started life out as a 3D wireframe mesh in a computer. Renderings of it are even shown on the box! Bronco would have also used either a 3D printer or stereo lithography to produce the trial parts, before producing the injection mold tooling for the kit. Some people may be under the impression that "building" wireframe models in the computer is very easy, or can be done with a few mouse clicks and out pops a model. If it was so easy good 3D modelers, who really know what they are doing and are fast, wouldn't be paid $125K to $150K a year salary.

It takes a certain level of skill and time, to create a good wireframe mesh in the computer. It is tedious work and requires meticulous attention to details, to build an accurate 3D model of a complex subject with a high level of detail. Granted that guy's Nuke boat over at SC is an easier subject to model than say a WWII boat.

Some of the software tools actually resemble their real world counterparts, in functionality, such as bandsaws and lathes etc. One can even "sculpt" objects in the computer these days. It is another art form, but in the digital realm.. The real work is in building the wireframe model in the computer. Once it is built, then printing it out afterwards, is the easy part (if you have the money to pay for the rather expensive printing).Leave a comment:

-

Don't panic, Sam. More on the launchers later.

I think it was Warpatroller who suggested that I was going to (or have in the past) used kit parts as masters when working up fittings kits. Let me make something perfectly clear:

To take another man's (or corporations) work and copy it for personal gain -- without their express permission -- is, at the very least, illegal and is, without a doubt, immoral! If you are such a no-talent, mouth-breathing, pretender that you have to copy others work and make it your own, you have no business calling yourself a Model Builder. The only kit parts I have copied into a fittings kit ... EVER ... were the control surfaces of the recent Moebius 1/72 SKIPJACK kit, and that done after securing the permission of the guy who designed that kit for Moebius, as well as getting that companies CEO's permission!

I do not pirate anyone's work. And if I catch anyone doing it, I blow the whistle ... long and loud!

(and what the hell is that guy over at the SC site talking about, describing the model 'he built' -- an item pooped 3D copy machine!!!???.....)

This morning I got to work on the control surface masters (NOT using any kit parts ... I have not had a word with any of the good Bronco folk's about such use). The blanks built up by two laminated pieces of 40 lbs. RenShape. The assembled blanks create a reference plain needed to assure symmetry as I cut, filed and sand the blanks to correct foil section, using the dark perimeter outline as a datum.

And that's a shortcoming of the kit, the hydrofoil shape to the stern planes and bow planes is a bit off. My masters don't suffer that shortcoming. I've elected to go with 1/8" control surface operating shafts for the stern planes and bow planes as they are subject to collisions on this subject. The rudder is well protected, so its operating shaft will be 1/16" (this will make installation of the eventual linkage components within the tight confines of the upper rudder support piece a bit easier).

I also poured a thinned two-part filler into the stern to form the propeller shaft foundation master.

To be continued.

DavidLeave a comment:

-

David-I ran the numbers of the actual G7E torpedo against the one provided in the kit and found the kit torpedo to be too fat and a bit longer than the documents I used -- even more room up there for a practical torpedo, guys.

Man! Manfred's inching ahead of me, I gotta get hot! Working up fittings kit masters today.

David

[ATTACH=CONFIG]19281[/ATTACH]

If the torpedoes are too fat, does that mean we should scrap the styrene torpedo tubes that came with the kit as well? hmmm... I guess if you go with David's weapons rig, it doesn't matter, as the tubes are part of the system...Leave a comment:

-

Relax David,

I shuffed those torps aside, i know my electric one's have the right sizes compared to a 1:35 scale.

I've done even more, but will not show this yet, stacked up the instant pizza's, checked the microwave, got me some tray's of red bull, am i preparing for something?

Manfred.Leave a comment:

-

I ran the numbers of the actual G7E torpedo against the one provided in the kit and found the kit torpedo to be too fat and a bit longer than the documents I used -- even more room up there for a practical torpedo, guys.

Man! Manfred's inching ahead of me, I gotta get hot! Working up fittings kit masters today.

David

Leave a comment:

-

Sam,

The fun bit is, David has taken the waterline cut, i'll try to use the cut that came with the model and slide the SD in, in the mean while avoiding the arrows offcourse, the SAS system is a great improvement compared with the gassystem, less things to worry about (adverticing).

For connecting the torpedotubes mechanically you can read my thread about the 212, works fine for me.

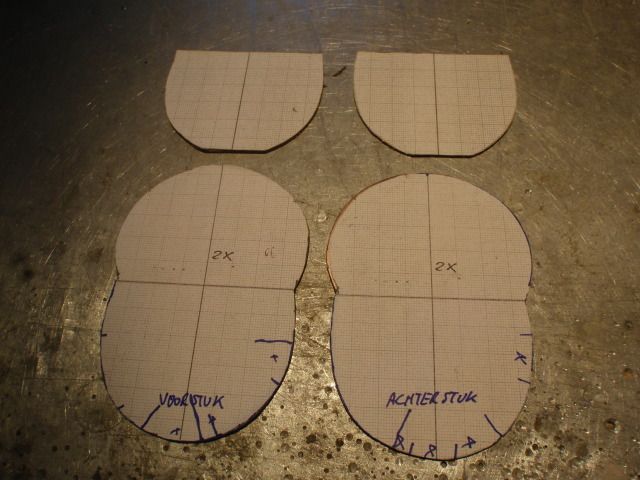

From the minute i had the model, i cutted these, the bigger one's will be inserted at the beginning of the split, the smaller one's will support the SD.

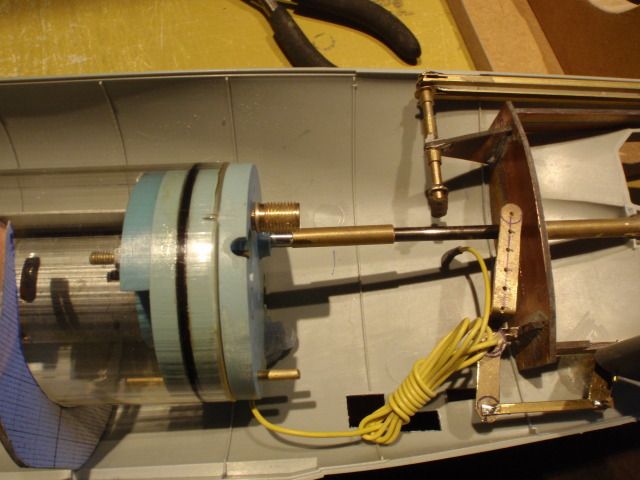

Here you can see one of the bigger pieces inserted into the front part of the XXIII, since i had no SD i just signed of the true center for the shaft.

Today i cutted out those bulkheads and supports, remember this is a standard 2,5" SD, not the shorter one, i'm still able to place my launchtubes inside without space problems.

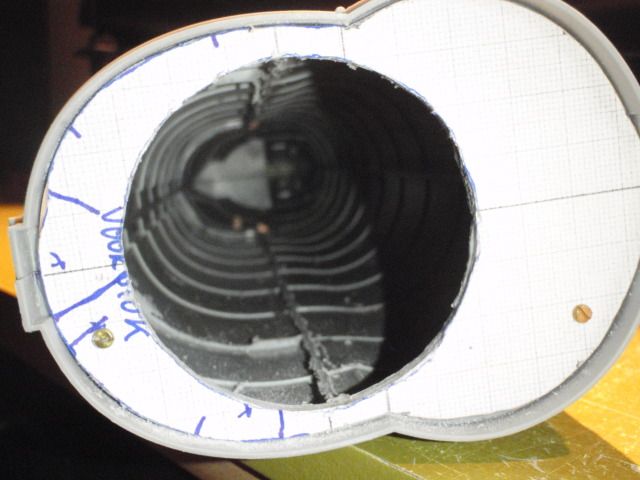

A more close up view of the frontpart, don't know if the launchsystem from David needs more room, for me this will work.

The plan is, just using small machine screws for holding the bigger bulkhead, giving me access inside the hull when removed, the fit is not that tight, so i can slide my SD in/out with no problems.

At the beginning i didn't knew that the shaft of the SD would be off center, solved this by turning this bulkhead upside down, this way the shaft will slide into the copper connector on my propellorshaft in one move.

When all bulkheads and supports are secured i can make my connections in such way that they will "click" on by using the magnectic couplers, the more tricky part will be, to make this happen at the launchtubes.

A peek inside the front gutts, there is plenty of room inside to play with the lead and foam, the bigger bulkhead can be taken off for more access when needed.

Manfred.Leave a comment:

-

Thanks for the links, David. I have downloaded both pdfs and begun reading them. On my OTW Type XXIII, I drove the front planes with a servo, and used the angle keeper on the rear planes. With this boat's size, I wasn't sure if one set of planes would be enough to dive the model. Also, if you recall, that boat used an onboard compressor to control filling and emptying the ballast tank. For this kit, I like the fact that the ballast system leaves enough room to add weapons.Hey, Sam!

Just like old times.

Dropping gas as the means of displacing the air from within the ballast tank I use a small air-pump (with the ability to ingest water without damage), taking a suction from either a snorkel protected induction line or air from within the SD itself to blow ballast water. As the pump is in the after dry space I need to run both the snorkel induction line and discharge line to the ballast tank atop the SD. Hence, the two flexible hoses you see. The forward dry space is for the battery. For more dope on the SAS ballast sub-system, read this: http://support.caswellplating.com/in...--how-it-works

As always (with the exception of the Moebius TV SEAVIEW) bow planes are on independent control loops: the stern plane is tended by the driver or the angle-keeper. The bow/sail planes are tended by the driver or a depth-keeping device -- do not interconnect!

And here's how the torpedo weapon system is employed, either mechanically or pneumatically: http://support.caswellplating.com/in...structions-172

Welcome to the 21st century, pal!

David

The XXIII kit that I ordered from Mike here showed up yesterday, so I have been able to study the hull parts included in the kit, and the details. I'm impressed by the sheer size of the model, and the details look pretty good so far. A couple things already noted elsewhere; schnorkel head is a bit weak, the tubes for the schnorkel could probably be replaced, no horseshoe life ring, the emergency raft hatch at the front of the tower is sparsely detailed. I like that they included some of the trunking under the turtledeck, and some of the other details like the raft and the torpedoes (might be nice for a diorama). I'll be watching this thread carefully as you and Manfred continue to flesh out this conversion process.

Thanks again!Last edited by goshawk823; 03-17-2013, 09:42 AM.Leave a comment:

-

Heh. Just like the real boat.

David- If I may ask.... I'm used to the old WTC3, 3.5, mod2, etc. I'm looking at the photo of the smaller purpose built SD specifically, but I see two extra hoses on both, which I'm assuming are the for the SAS variant? Also, with these systems, how do the forward and rear dive planes interact (front fixed, rear on some angle keeper, front on servo, or vice versa?). Also front area of system is for air? How does one drive a torpedo fire mechanism from this type of system? Sorry, lots of questions; my knowledge is so stale...

Thanks!

Sam

Hey, Sam!

Just like old times.

Dropping gas as the means of displacing the air from within the ballast tank I use a small air-pump (with the ability to ingest water without damage), taking a suction from either a snorkel protected induction line or air from within the SD itself to blow ballast water. As the pump is in the after dry space I need to run both the snorkel induction line and discharge line to the ballast tank atop the SD. Hence, the two flexible hoses you see. The forward dry space is for the battery. For more dope on the SAS ballast sub-system, read this: http://support.caswellplating.com/in...--how-it-works

As always (with the exception of the Moebius TV SEAVIEW) bow planes are on independent control loops: the stern plane is tended by the driver or the angle-keeper. The bow/sail planes are tended by the driver or a depth-keeping device -- do not interconnect!

And here's how the torpedo weapon system is employed, either mechanically or pneumatically: http://support.caswellplating.com/in...structions-172

Welcome to the 21st century, pal!

DavidLeave a comment:

Leave a comment: