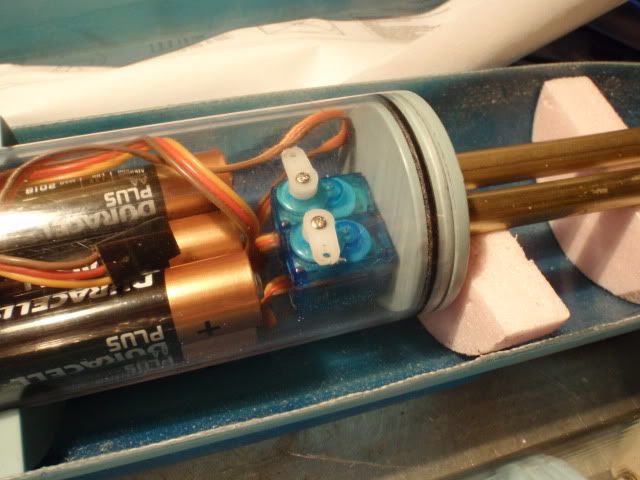

I did a primary test, just to see if it will lock the tube, that worked fine, first i want to have a working SD, this way i can conduct real tests.

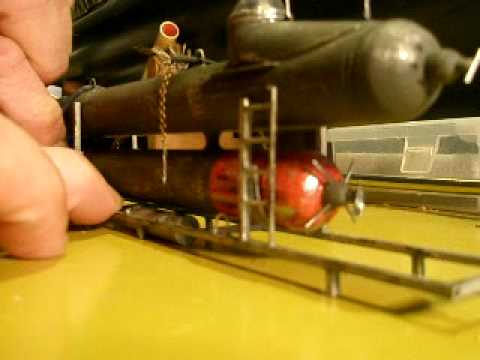

Yeah, it's tight, but i've build smaller, like this Marder.

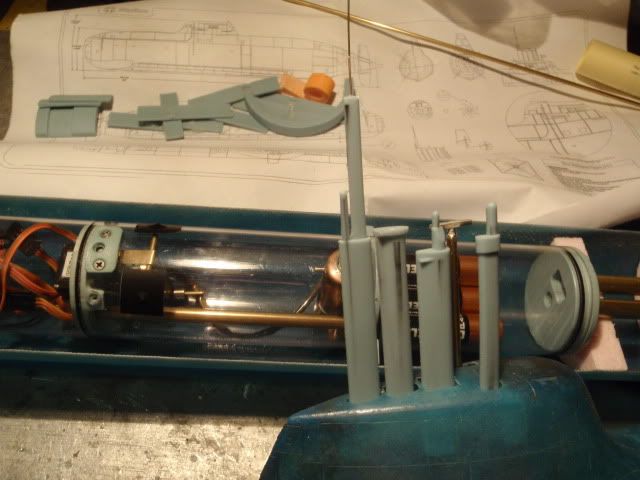

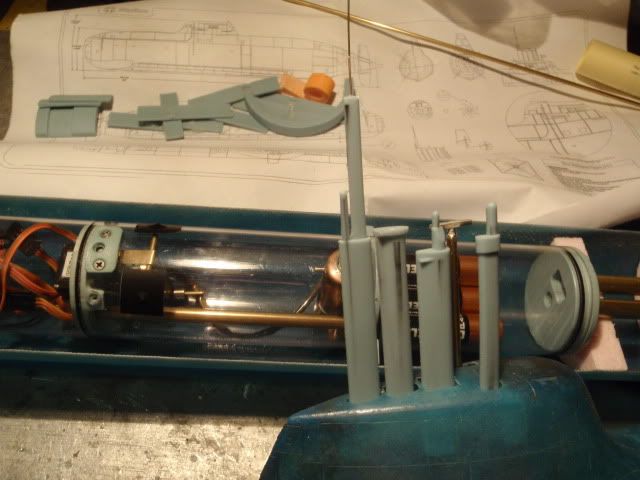

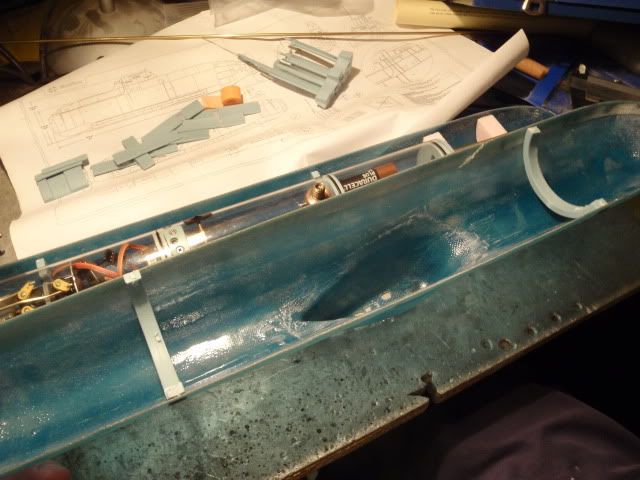

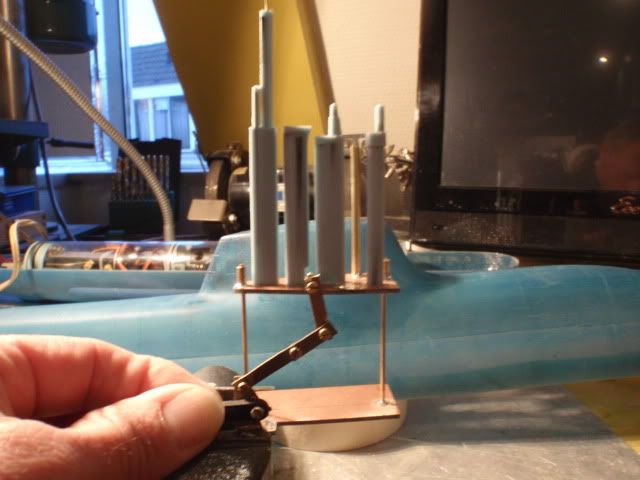

Did some more work on the 212, drilled open the top of the conningtower and builded up the masts, i even went a little bit further with adding some stuff to the SD.

This is how she stands now.

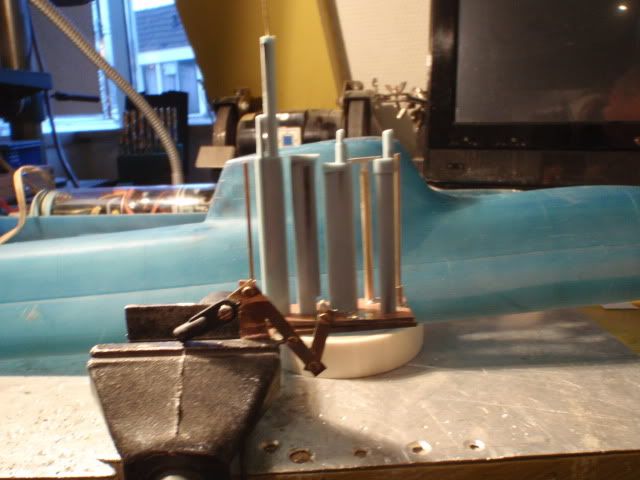

Opened up the conningtower and added the masts, then it struck me, wouldn't it be nice to raise and lower the masts.

It think it would be a nice addition, prepared the masts and the holes for retracting.

There is a dutch guy at our dutch forum who made this possible by using a mechanic lift, got to suck his brains.

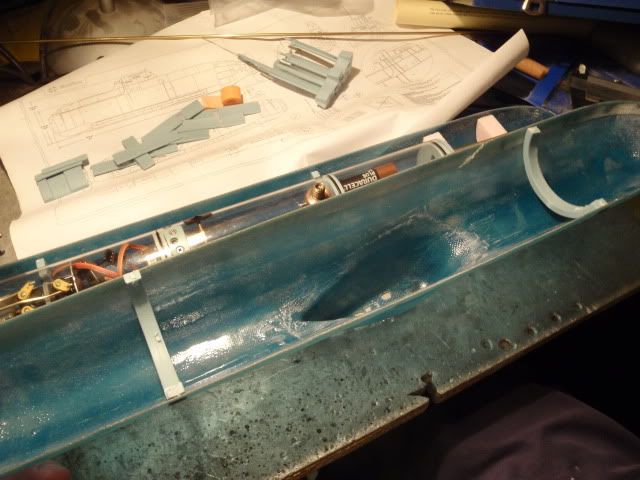

Want to use the surplus parts for the bigger SD to reinforce the upper part, why?, since i want to shoot some torps it's easier to not preform the Z cut, allowing a better access to the moving parts in the front.

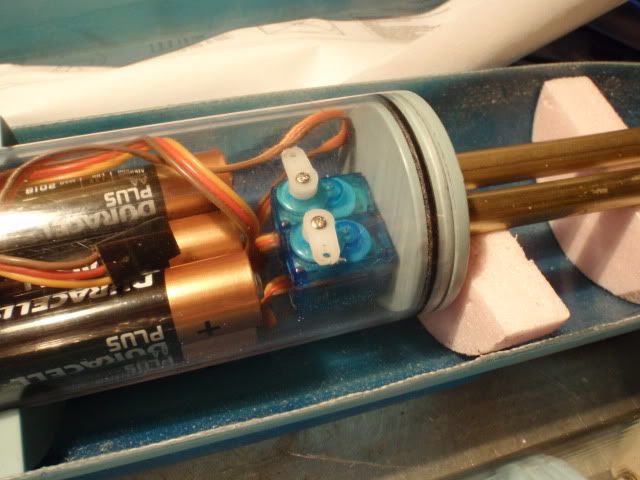

After being inspired by the possibility of moving masts my mind went into overload, grabbed the Kilo SD and cannibilised it for some parts.

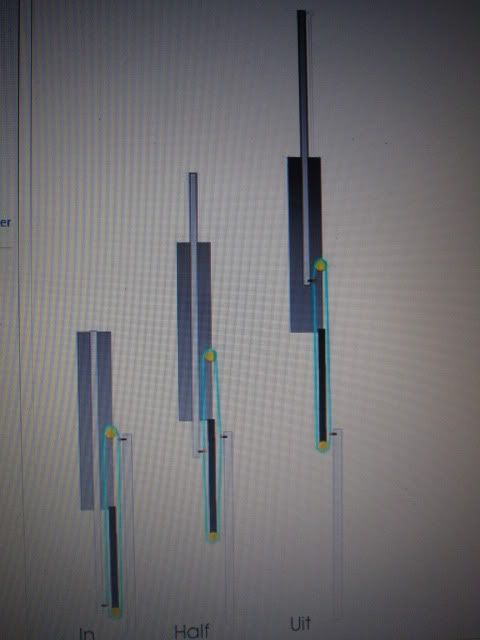

Want to place some servo's in the frontpart allowing me to shoot the tubes separatly, i wonder if i'll manage to jam everthing inside.

I don't know if a SL8 receiver would fit in, i centainly need it with the use of almost every channel.

1 Rudder

2 Divingplanes

3 ESC

4 Pump

5 Tankvalve

6 Peroscopes

7 Tube 1

8 Tube 2

Greetings Manfred.

Yeah, it's tight, but i've build smaller, like this Marder.

Did some more work on the 212, drilled open the top of the conningtower and builded up the masts, i even went a little bit further with adding some stuff to the SD.

This is how she stands now.

Opened up the conningtower and added the masts, then it struck me, wouldn't it be nice to raise and lower the masts.

It think it would be a nice addition, prepared the masts and the holes for retracting.

There is a dutch guy at our dutch forum who made this possible by using a mechanic lift, got to suck his brains.

Want to use the surplus parts for the bigger SD to reinforce the upper part, why?, since i want to shoot some torps it's easier to not preform the Z cut, allowing a better access to the moving parts in the front.

After being inspired by the possibility of moving masts my mind went into overload, grabbed the Kilo SD and cannibilised it for some parts.

Want to place some servo's in the frontpart allowing me to shoot the tubes separatly, i wonder if i'll manage to jam everthing inside.

I don't know if a SL8 receiver would fit in, i centainly need it with the use of almost every channel.

1 Rudder

2 Divingplanes

3 ESC

4 Pump

5 Tankvalve

6 Peroscopes

7 Tube 1

8 Tube 2

Greetings Manfred.

Comment