Bronco 1:35 Type XXIII RC Build/ Conversion

Collapse

X

-

Just finish the god-damned thing and move on!!!!!Leave a comment:

-

Oh my Lord, The Greatest, so it should not be brownish. The brown would be dried out sealife in Drydock?Anyway...

You've got a good start with the puke-tan below waterline effort. Now -- at a point about an inch below waterline -- start stippling on toothpaste mask (look it up in past 'today's work' posts). Then, mix up a well darkened batch of clear-coat. Spray this tinted clear on all below-waterline structures, and wait for them to dry. Then, with a wet towel, remove the masking. Dry and repeat till the display stops looking so ghastly.

And don't forget the bow planes, stern planes, and rudder!

Sing my praises!

David

Leave a comment:

-

Anyway...

You've got a good start with the puke-tan below waterline effort. Now -- at a point about an inch below waterline -- start stippling on toothpaste mask (look it up in past 'today's work' posts). Then, mix up a well darkened batch of clear-coat. Spray this tinted clear on all below-waterline structures, and wait for them to dry. Then, with a wet towel, remove the masking. Dry and repeat till the display stops looking so ghastly.

And don't forget the bow planes, stern planes, and rudder!

Sing my praises!

DavidLeave a comment:

-

The brownish discoloration is from the dried out sealife when the boat got drydocked. In the water it's green unless you're making a static display of a boat in drydock.This Type XXII operated in cold waters. Refer to this Post for what a cold water sub looks like:

https://forum.rc-sub.com/forum/silly...cum#post176646Leave a comment:

-

I buy you books, I send you to school, I pay for a tutor, I present pretty pictures, I author endless posts.

And what do you troglodytes do with it all?.... you eat the ****ing Teacher!Leave a comment:

-

David, wtf should I do now, obviously I have no artistic ability..... should I just re paint the lower hull Dark Grey?Leave a comment:

-

-

-

Next task Brass RailsThanks David, will be referencing this post for Handrails

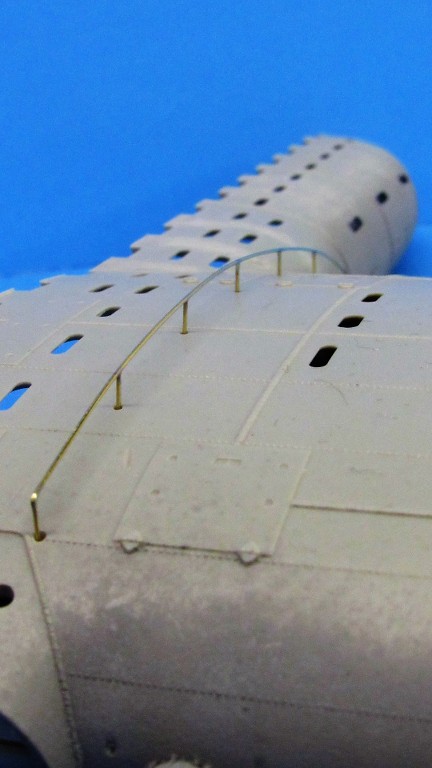

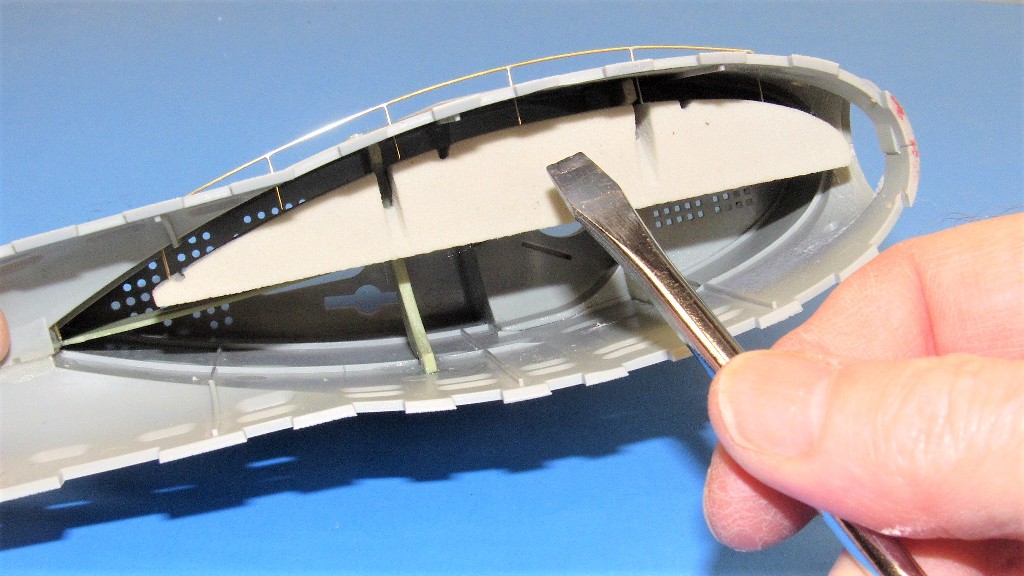

The kit supplied plastic railing that girdle the sides of the sail are just too fragile to be serviceable on a practical r/c submarine. So, I substituted brass wire railings.

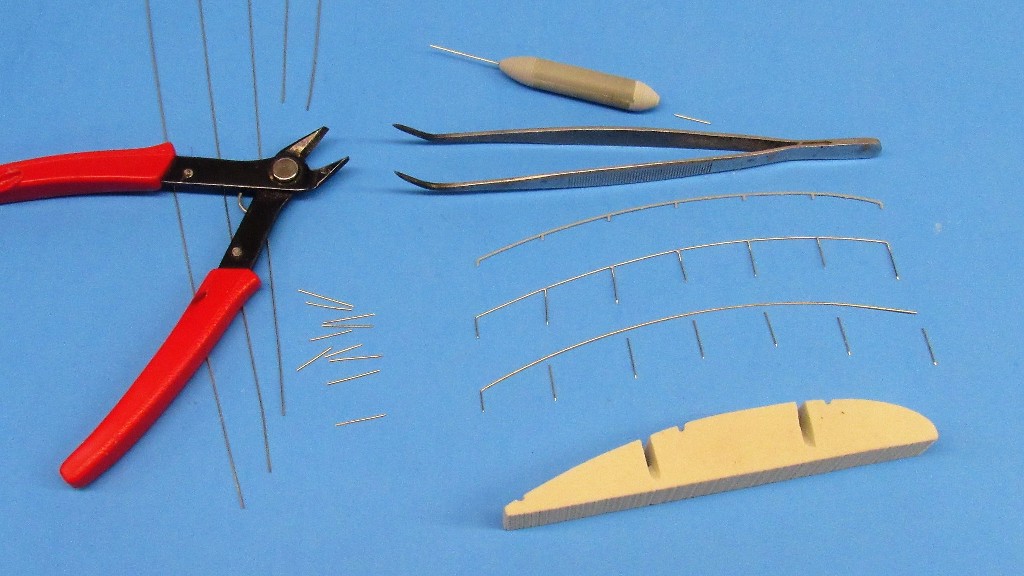

The two brass railing assemblies are formed of .020-inch diameter brass rod. The pins are about .375-inch long, pointed at the inboard end, and ground to a flat at the outboard end.

The RenShape pin-retainer, which temporarily resides within the sail -- and conforms to the curve there -- securely holds the embedded pins in place and also serves as a heat-sink to rapidly dissipate soldering heat away before the easily melted polystyrene plastic of the sail.

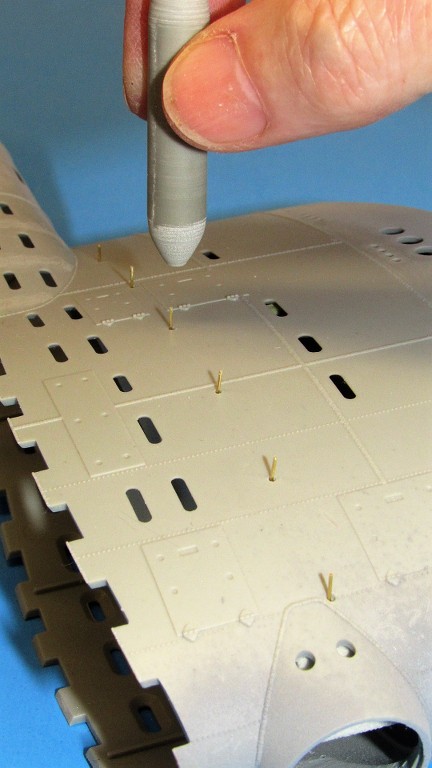

After the pin-retainer is installed within the sail (shown outside so you can see how it would be used) the bore clearing-pin setting tool is used to push a pin through one of the .023-inch holes that have been drilled through the side of the sail.

Pulling the bore clearing-pin setting tool away from the work leaves the pin well embedded into the pin-retainer bearing against the inside of the sail. Use of the tool results in an array of railing pins projecting from the side of the sail, all of the same height.

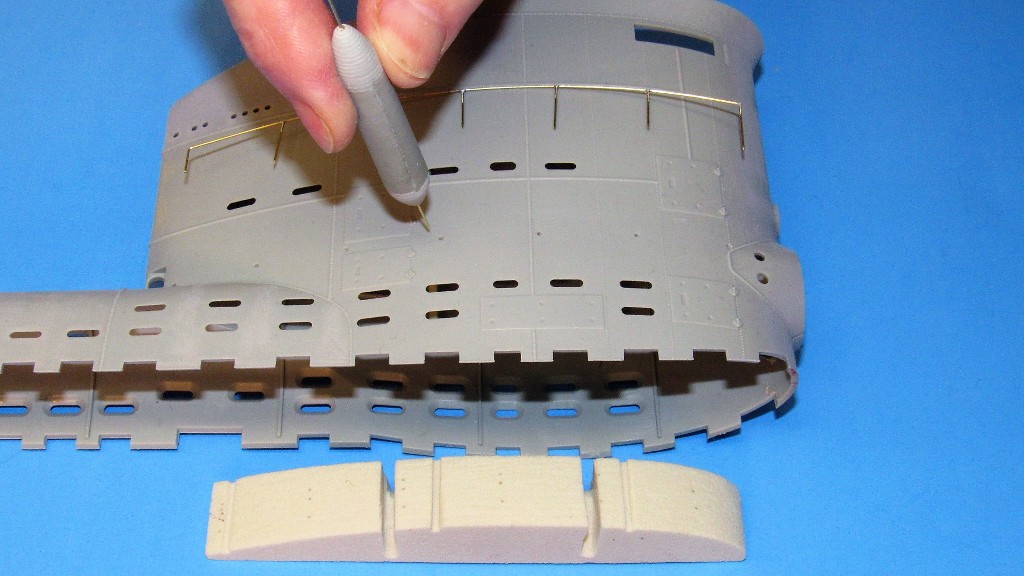

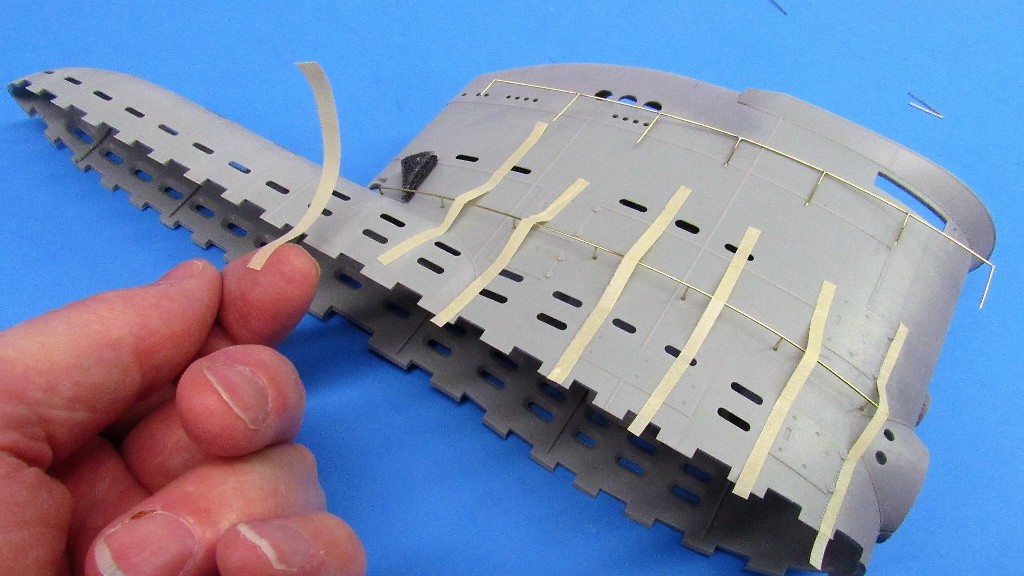

A long length of brass rod becomes the railing proper. Here I'm using thin strips of masking tape to secure the railing over its pins. Note the finished railing assembly laying near the top of the sail. With the aid of the internal pin retainer the sail itself becomes the holding fixture of the parts that, once soldered together, become a railing assembly.

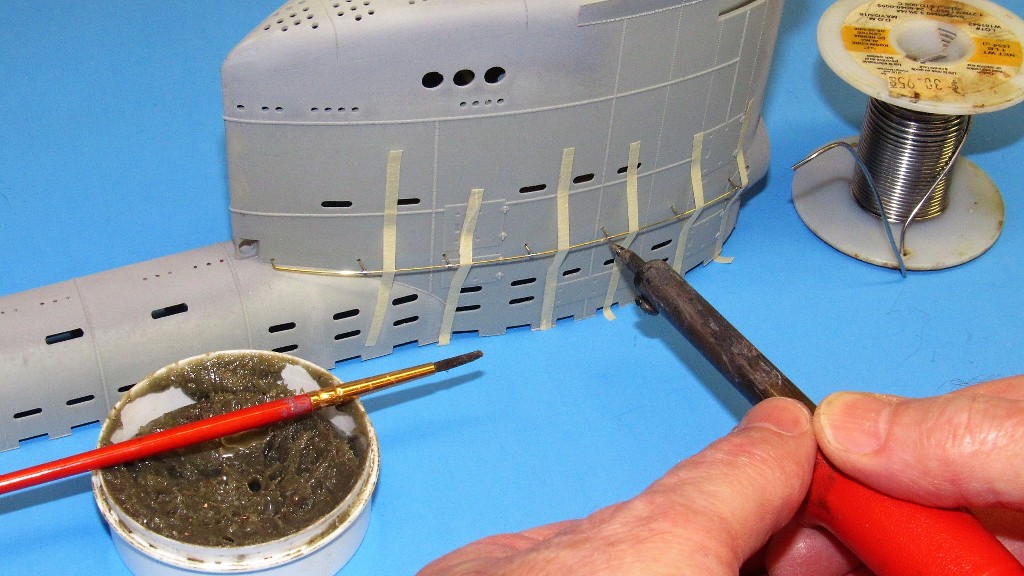

The secret to keeping the heat localized to the joint is a hot soldering iron tip; a tip that is ground small to minimize heat transfer to non-joint structures; and use of the pin-retainer which also acts as a heat-sink.

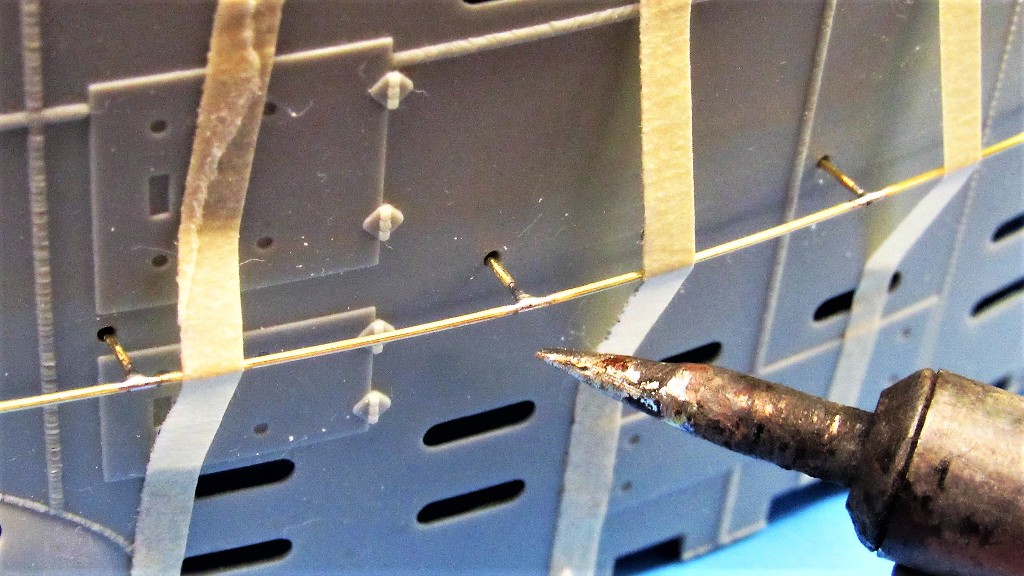

The tip of the iron is applied to the joint with half-second jabs, just long enough to get good solder flow, as evidenced by these small, tight fillets between rail and pin.

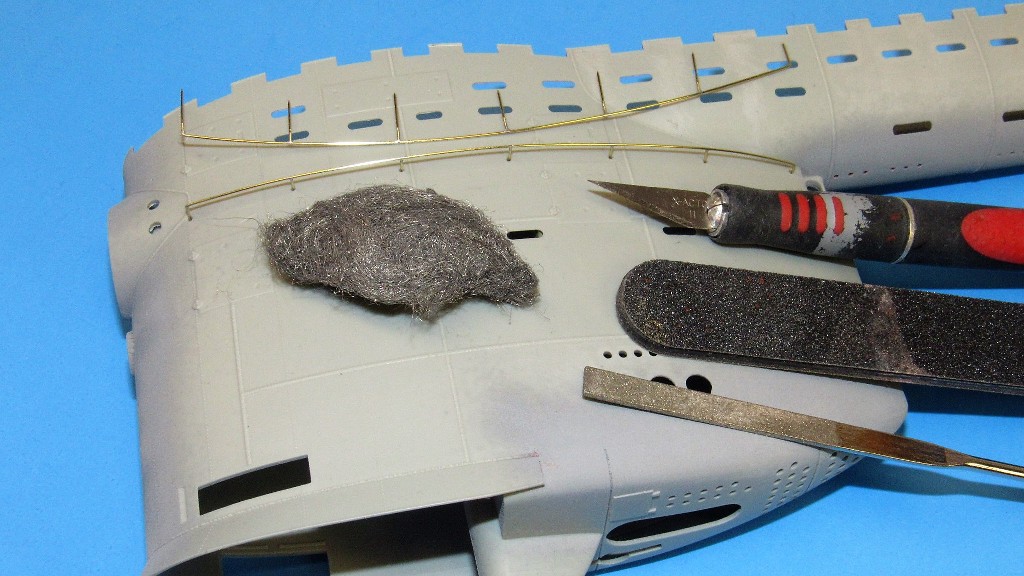

Snipping off the excess railing at the forward-most pin. The raw end here would be worked with file and sanding stick after contouring with very light, carefully applied jabs of the carbide cut-off wheel.

While still in place on the sail the railing assembly has all the solder unions cleaned up by scraping away excessive fillet with a blade; sanding and filing away solder and crystallized flux; and finally abrading away all scratch-marks with a good polishing using #0000 steel-wool.

After all soldering and clean-up work had been done on the railing assembly the RenShape pin-retainer, within the sail, was pried away from the pins and removed.

The pin-retainer is used as a handling fixture if any further work on a railing is required off-sail. Note the three items needed to do the soldering: a 35-Watt soldering iron with custom ground tip; acid paste flux; and 60/40 solder. At the bottom of this shot is the bore clearing-pin setting tool.

Leave a comment:

-

thanks for the adviceWith respect to weathering, my approach always is ..

Primer --> base color --> Filters --> Washes --> dry brushing -> pigments, oils, additional washes (optimal)

Filter: Usually the base coat is very homogeneous and even. In real even new color is never that homogeneous and it becomes less and less homogeneous with age. So you have to introduce subtle color variations. One way to do this is to apply uneven black or white undercoatings (as seen in man of Daves pictures). Another way to do this is to apply a very thinned out, uneven coat of color on top of the base color -> a filter. I take one drop of an acrylic wash (usually Vallejo grey wash) and thin it down with 7-12 drops of water. Then I apply a wet coat with a large brush across the whole surface I want to weather. One van ply with colors (blue, white, green, brown washes...) as base for the filter and one can apply more layers. Usually you shouldn't exceed two.....

Washes: Thinned down acrylics that are thinner than airbrush paints but thicker than filters. You use dark washes that you apply with thin brushes at edges and grooves of the model to accentuate the relief of the surface (e.g. shadows). I also use white washes to apply streaking and stains. There is no limit to layers and one can create quite some depth using different washes and many layers.

Dry brushing: This technique is used to put highlights on raised edges. Take a lighter color than the base color, take a fan brush, dip the tip of it in the color and then dry it with cloth until you think that there can't be any color left. Then brush across the surface and see how the edges start to shine.

Oils I use to apply rust. There are awesome rust effects from Ammo M.I.G.. I all do all the rust on my boats with these oils.

Try it with a small kit, and learn the techniques. No magic involved and you can create nice reuslts quite esaily.Leave a comment:

Leave a comment: