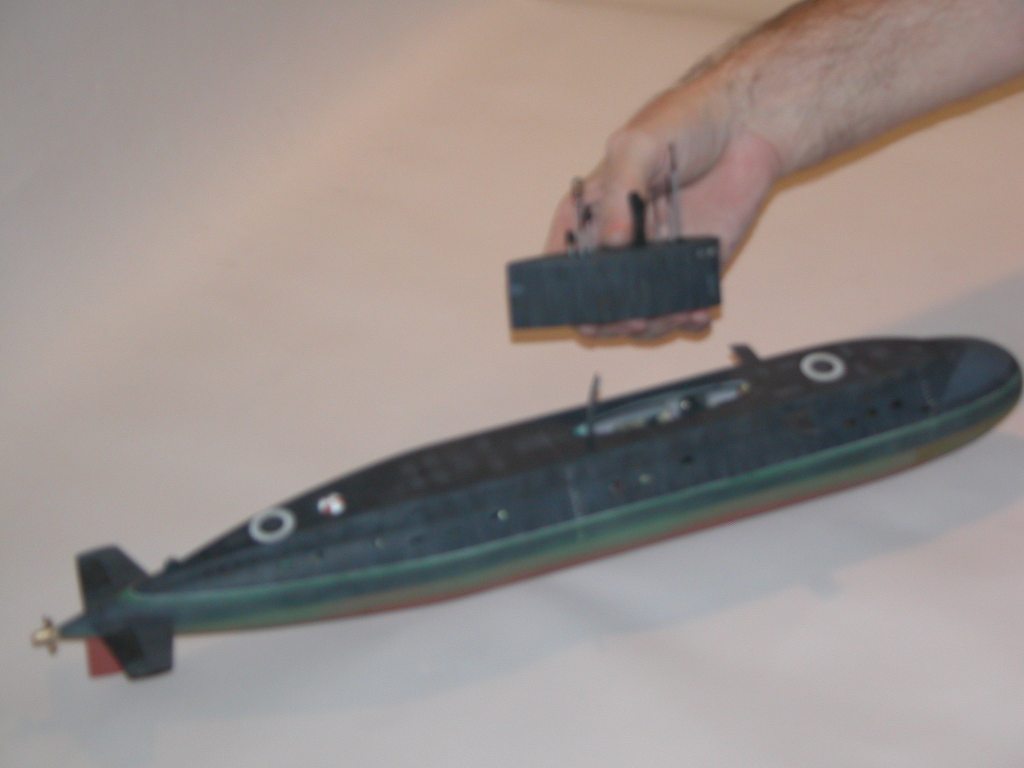

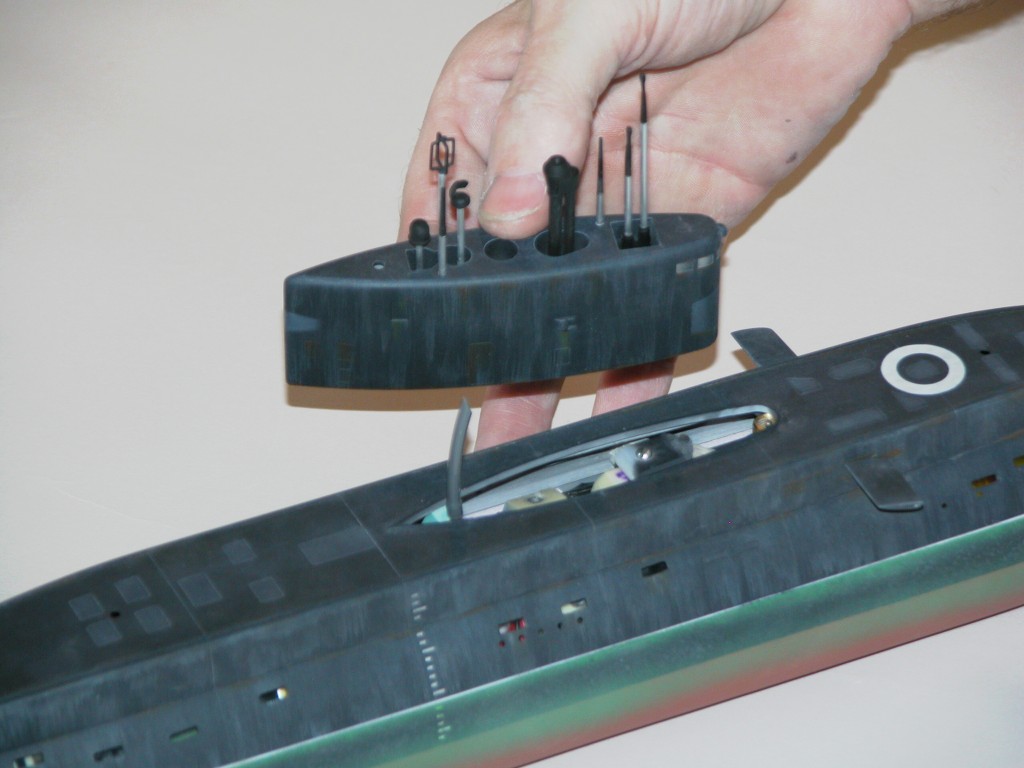

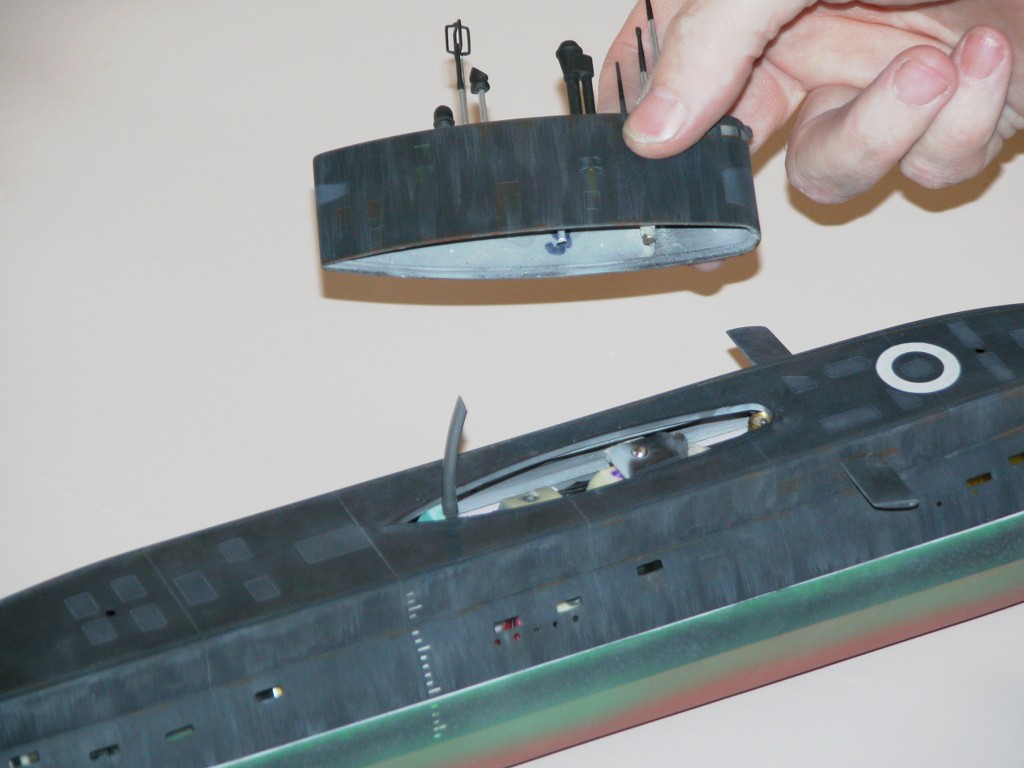

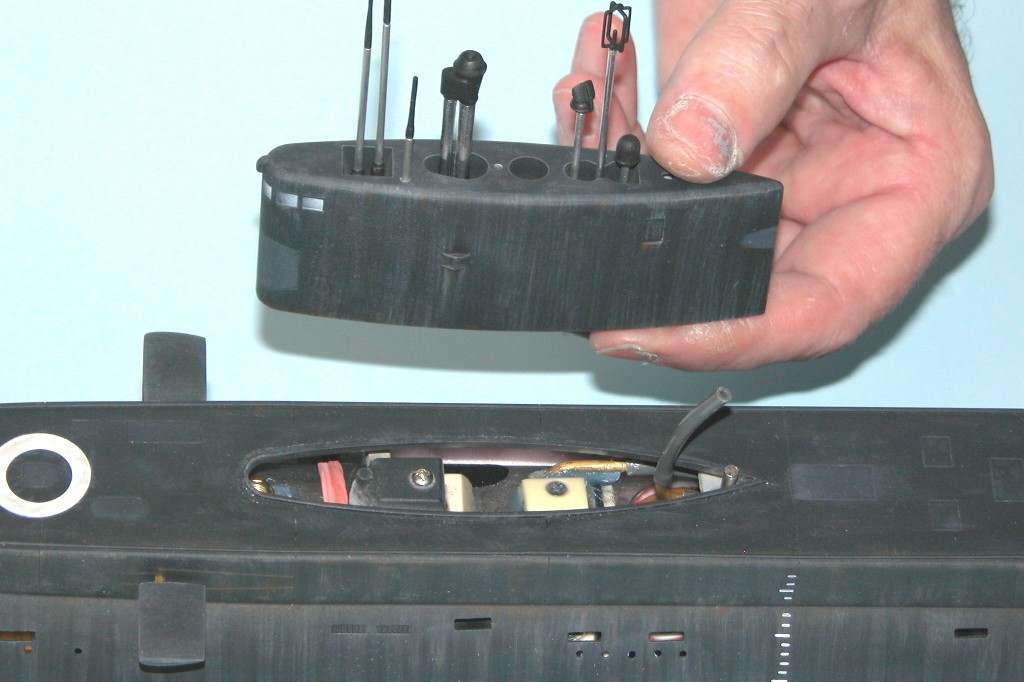

I have removed the Lower hull bow screw guide and inserted a magnet in its place which pulls the upper hull bow nut nicely for a seamless union of the upper and lower hulls.

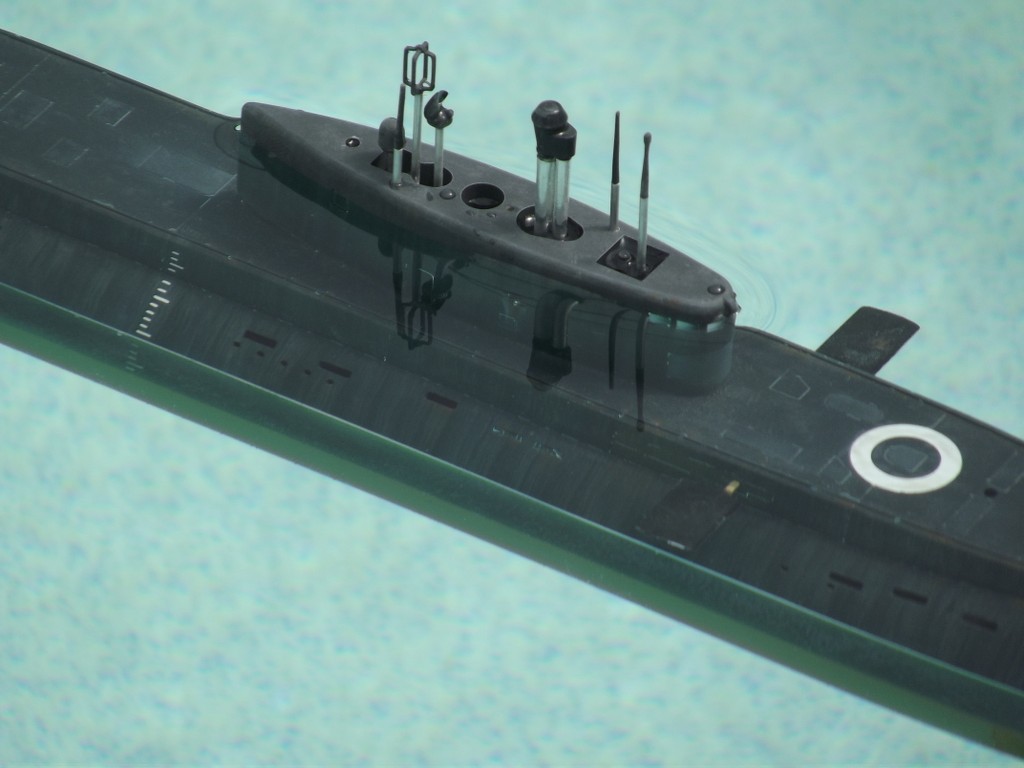

New Trumpeter Kilo 1:144 Build

Collapse

X

-

Biggsgolf, looks like yiu are using round brass rods for the shafts. How did you secure the stock polystyrene control surfaces to their shafts?

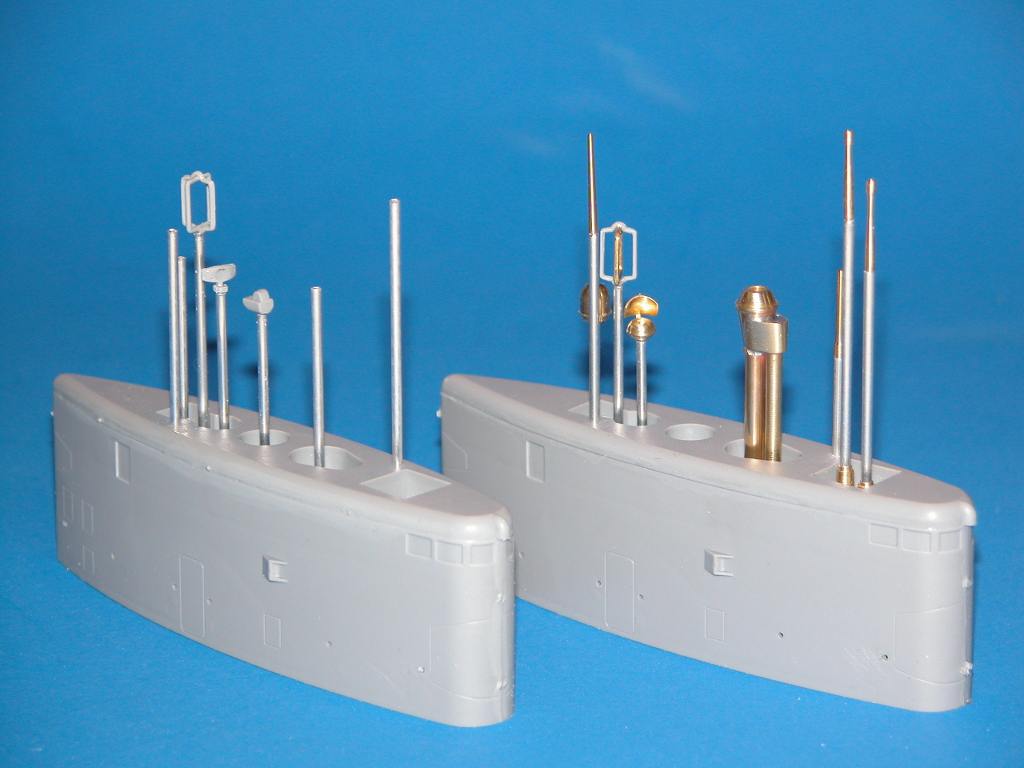

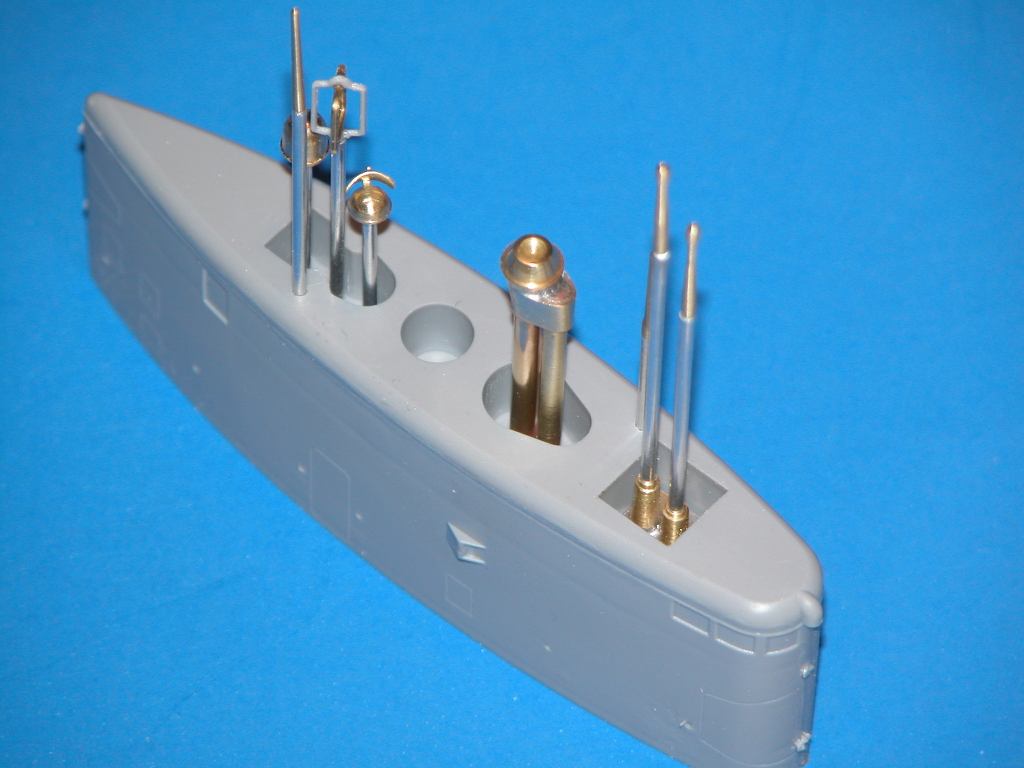

With David's fittings kit he used square brass tubes. These ensured positive attachment of the control surface to the shaft and prevented them from rotating off plane in case the glue failed.Last edited by redboat219; 01-24-2021, 07:45 PM.Make it simple, make strong, make it work!Comment

-

I hand drilled 1.5MM holes into them (servo arms), one for the shaft which runs to the planes and one for the control arm rod. Same for the rudder assembly. I precisely placed and epoxied each to the shafts. Eventually lined up the arms at nuetral for the rudder/planes to be affixed. Hope this is what you were asking.Comment

-

Comment

-

Comment

Comment