As you said yourself on another thread, there are lots of different ways to arrive at the same goal, I'm just going for ways I've always used and I'm trying to iron out any wrinkles now, rather than have to re-engineer a solution later, probably when the model is painted and more prone to damage.

I've become convinced over time the better the internal build quality, the better the external 'Scale'part of the model as illustrated by the following.

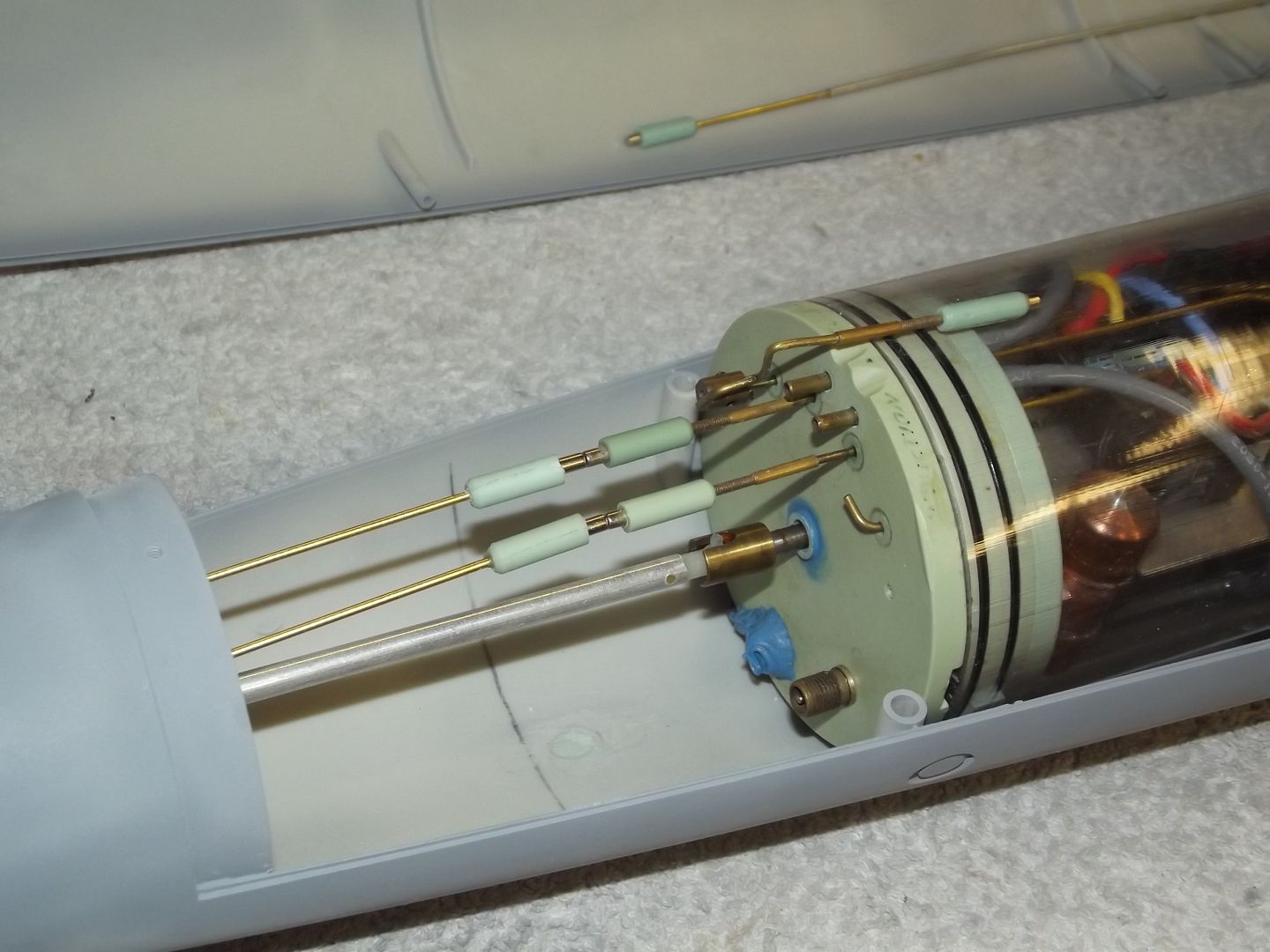

While my Ben Ain is a decent build of a quality kit, it is founded on rock solid internals, everything clearly labelled, all wiring tidy and the electronics in their own enclosures and separately switched if necessary.

I've lost count of the times you see good quality R/C models ruined by poor internals, what passes for 'wiring' in most models looks like a bowl of coloured spaghetti.

Here is the run/off/charge switch hidden under some barrels, with a tiny extra bit of effort it can be made to look professional, including a tiny ON light.

I'll be trying to use some of this learning throughout the Skipjack build, but it's just my thoughts and ideas, no more valid than anyone else.

Rob

Leave a comment: