Thanks Greenman,

I've no reason to suspect their stuff is not up to scratch, so thanks for the comment, I suppose it's the way a lot of manufaturing is going, in that in can be made for a fraction of the cost in the East somewhere. The price is great, the ony drawback is the cost of shipping to Ireland, but it still puts it way below Engel. More drinking (sorry thinking) will have to be done on this!

Rob

A Skipjack in Ireland

Collapse

X

-

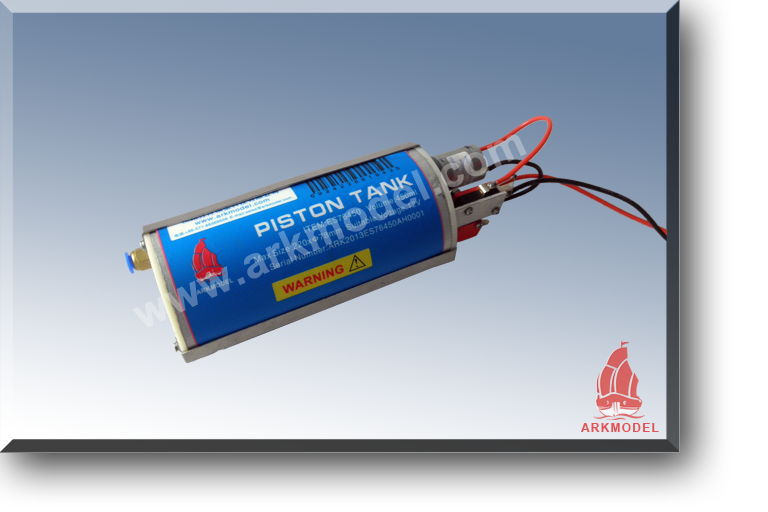

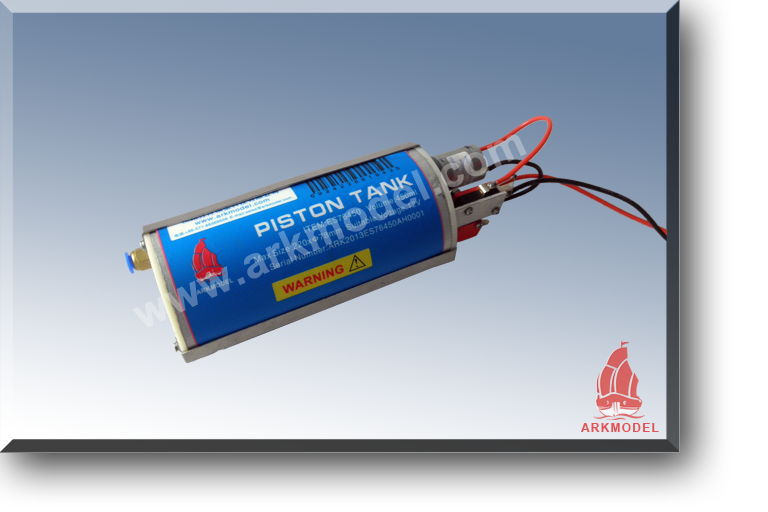

Well I can vouch for the quality of the Arkmodel 1/48 type 7 model but I don't know anything about their other gizmos.I came across Arkmodel from China recently, they've some interesting stuff, including this 450ml piston tank for a staggering 100 dollars!

It's exactly the right dimensions because they have a Skipjack conversion kit, and it's over half the cost of the Engel unit, just never heard of Arkmodel before.

Might go with this if I could get someone to give a recommendation on the quality!

The BoattrainmanLeave a comment:

-

Thanks HardRock,

Just trying to keep this as simple as possible, the nav lights will light when the main switch is activated and go off during the dive (via the switch on the spindle). One less radio channel!

Rob

Leave a comment:

-

I like the idea of using the spindle shaft to turn the lights off.Leave a comment:

-

This odd shaped piece will go over the battery box, it is just two square pieces of 1.5mm styrene. The round holes are to let some air around the battery and the slot in the side and top will take a 'push-to-break' switch for the navigation lights, which be activated by the piston tank spindle.

There is an opening at either end for the piston tank spindle (simulated by the metal rod in the picture).The piece is screwed to the battery box with four M3 self-tapping screws, I use this screw and no other for all mounts etc, inside my models, so if I drop one or lose one I've a large batch. The screws are covered by short lengths of plastic tube to cover the exposed points.

This area will hopefully hold the piston tank controller on top, the receiver (Rx) in front of the piston tank spindle and if there is enough room the pitch controller.

The BoattrainmanLast edited by The Boattrainman; 01-13-2017, 03:47 PM.Leave a comment:

-

I came across Arkmodel from China recently, they've some interesting stuff, including this 450ml piston tank for a staggering 100 dollars!

It's exactly the right dimensions because they have a Skipjack conversion kit, and it's over half the cost of the Engel unit, just never heard of Arkmodel before.

Might go with this if I could get someone to give a recommendation on the quality!

The BoattrainmanLeave a comment:

-

Hi Trout,

Nice to hear from you, apologies for the long break, I'm hoping to have the Skipjack in the pond this summer. To be honest, I'm a shockingly slow builder, between scratch building my own parts and adding extra details my builds are always epics in length. I can't believe my last build took over two years and that was with very few breaks!

As far as speed goes, I think most models I see are over powered for 'scale' operation. I don't want to be too pedantic but workboats trundling along at 50 knots are ridiculous. Even my extremely heavy Ben Ain at over 20Kg has to have the throttle on the TX turned down to 65%.

I also found these on Ebay, they would work as end caps with some work. Two of them for 5 Euro!

They are marketed as furniture leg protectors, they are 90mm in diameter and could be adapted for the 3.5inch/90mm tube, sheer stubbornness has me making my own caps.

I made this small fitting as an extra resting point in the hull for the WTC, there are only two fittings with the Caswell upgrades, now there are three resting points in total

The BoattrainmanLast edited by The Boattrainman; 01-12-2017, 03:33 PM.Leave a comment:

-

Very nice!

I used old Apple laptop cases (white ones) and reclaimed the plastic from them. Made a very tight bond as you did by layering them and making a piston with them. Your tech rack is looking great. regarding David's comment about the speed, I have to be very careful with my Skipjack on it's speed. First, I believe my throttle is adjusted to 50% on the transmitter and hitting full speed even then it is like a rocket underwater. Then with the remaining throttle I probably do not go about 25 - 30% of that. Looking forward to your sub getting finished and running!Leave a comment:

-

Hi David,

Congrats on the handover to Bob in Nautilus Drydocks, I'm a fan of Bob's U-Tube builds, and he seems like a nice guy.

So I've a small addition to the end caps, they now consist of the 90mm outer plate, an 86mm inner plate, an 80mm O Ring plate and an 86mm final plate.

They are bonded together with styrene glue, and the centre hole and a drill bit is used to make sure they are all in line. The 80mm plate will have an O Ring, and I can compress a larger one between the tube rim and the outer plate. Double O Rings, belt and braces!!!

Clamps hold the four layers together while the glue sets.

The rear (motor) end cap is bonded to the tech rack, the centre hole will hold the prop shaft tube and the location means it will lie along the top of the rack in line with the motor.

The tech rack is trial fitted with the 2mm metal stiffening rods inserted in the pre-drilled holes, where the piston will sit the rods are covered in styrene tube.

The Boattrainman

Last edited by The Boattrainman; 01-12-2017, 11:46 AM.Leave a comment:

-

Yeah, this thing gets squirrely if it gets going too fast.Hi Greenman,

Yeah, I'm still mulling the motor over, that MFA unit is my goto motor for scale models, it's powering my 40kg Ben Ain, so I was thinking that a much lighter vessel would fairly whizz along with the same configuration. That said, there is a 2.5 to 1 gearbox with the same motor.

The setup on the tech rack will mean any item can be swopped out, so I might go with the 6.1 gearbox first (as I have one in stock),and swop it out if the model is too slow.

Finally, I'm not a huge fan of models going way over scale speed anyway, I'll report back on this, thoughts much appreciated.

Rob

DavidLeave a comment:

-

The Caswell tube beddings are sanded down at the end points so the 90mm tube can sit neatly in the hull

A spare half circle is used as a template for holes for three metal rods which will pass through the lower part of the rack, stiffening the unit and providing a bed on which the piston tank will sit.

A series of holes have been drilled in the battery tray and motor mount to allow air circulate around both.

The BoattrainmanLeave a comment:

-

The acrylic tube arrived, and I'm really pleased with this, it cost just 30 Euro on Ebay and was flawless and beautifully packaged.

The only issue was that at the end where it was cut was a bit rough, so I sanded it down with my large sanding bar with 240 grit sandpaper, then 400 and 600 grit for a smooth end to take the O Ring.

The tech rack and end caps were trial fitted and are all a good fit.

So just a reminder the tube is 600mm long, 90mm wide (just over the 3.5 inches of the Caswell fittings), and made of 3mm thick acrylic. A small bit of sanding of the Caswell mounts inside the hull will be needed to get the tube to fit snuggly.

The BoattrainmanLast edited by The Boattrainman; 01-10-2017, 03:29 PM.Leave a comment:

-

Hi Greenman,

Yeah, I'm still mulling the motor over, that MFA unit is my goto motor for scale models, it's powering my 40kg Ben Ain, so I was thinking that a much lighter vessel would fairly whizz along with the same configuration. That said, there is a 2.5 to 1 gearbox with the same motor.

The setup on the tech rack will mean any item can be swopped out, so I might go with the 6.1 gearbox first (as I have one in stock),and swop it out if the model is too slow.

Finally, I'm not a huge fan of models going way over scale speed anyway, I'll report back on this, thoughts much appreciated.

Rob

Leave a comment:

-

Just a thought. What is the purpose of a 6:1 gearbox? Considering the size of the prop, a 3:1 would seem to be the more suitable, unless you will be satisfied with "creeping speed" all the time. Just sayin.Leave a comment:

-

Construction of the tech rack continues, another box (L145mm X W52mm X H25mm) is constructed at the bow end to house a 5000mah LIPO battery, this is located low in the rack again for stability, but also because the spindle of the Piston Tank must pass over the battery.

The section over the battery and moving spindle will have the Piston Tank controller and Receiver (Rx) for the servos (away from the drive motor), mounted on a little platform. The battery box is open ended so it can be pulled out of the WTC for charging without having to take the full rack out.

The Boattrainman

Leave a comment:

Leave a comment: