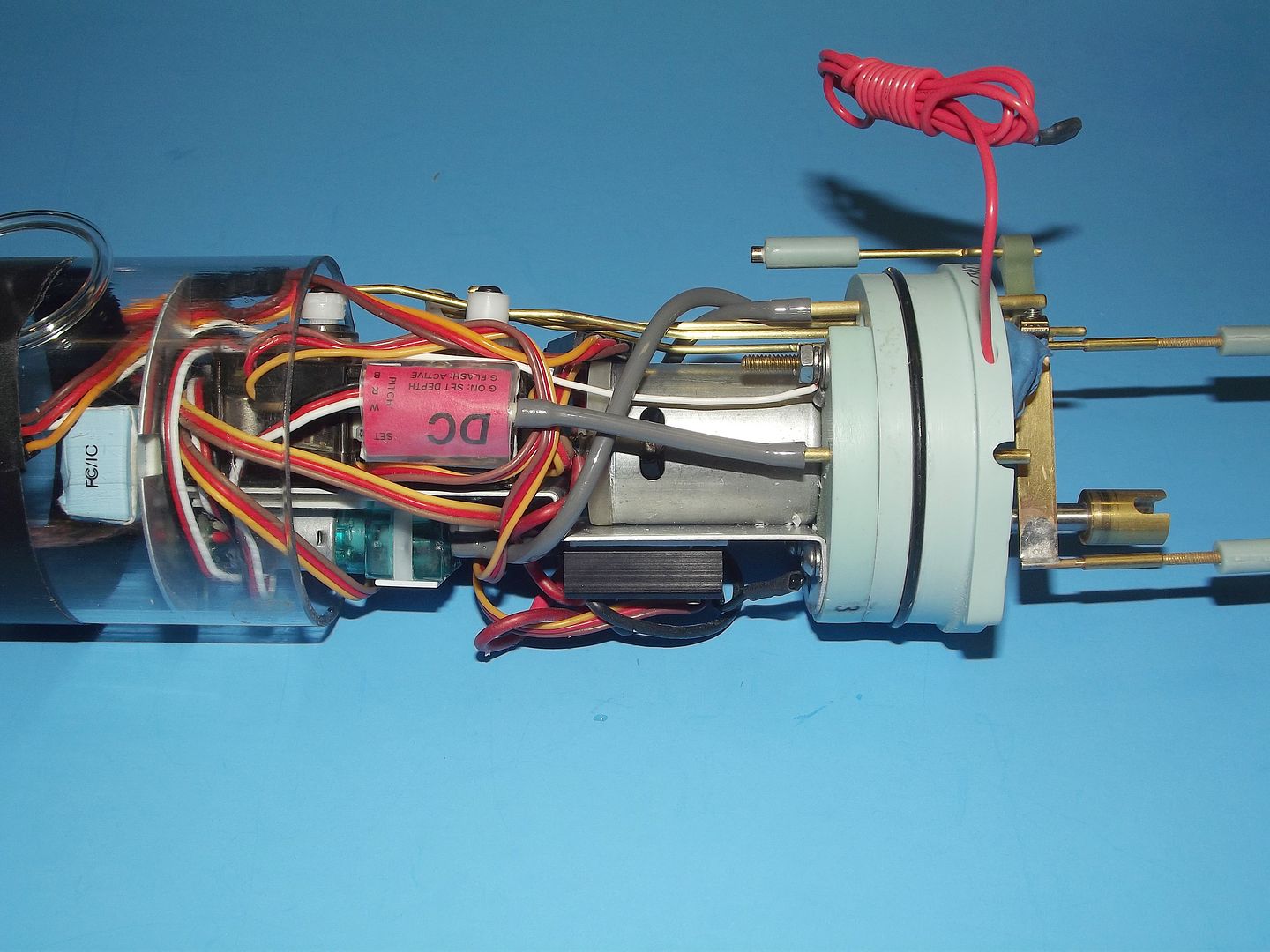

The Piston Tank is fired up to test the spindle fitting which runs through the holes in the styrene box over the battery.

The forward end of the tank sits up to the drive motor housing with the outlet in it's slot.

A single piece of 3.2mm styrene acts as a top bearer, Engel don't recommend you glue anything to the tank in case the glue/epoxy warps the plastic, so the bearer is held in place with double sided tape. The bearer presses against the upper inside of the WTC, and helps keep an air gap around the motor so it doesn't touch the WTC.

.

This 2mm rod inserted in the WTC shows the cooling gap between motor and WTC.

The tank can't move in any direction as it's compressed on all sides inside the WTC.

That's the tank sorted, there's a lot of cleaning up of the styrene to do, but it fitted without any major problems.

The Boattrainman

Leave a comment: