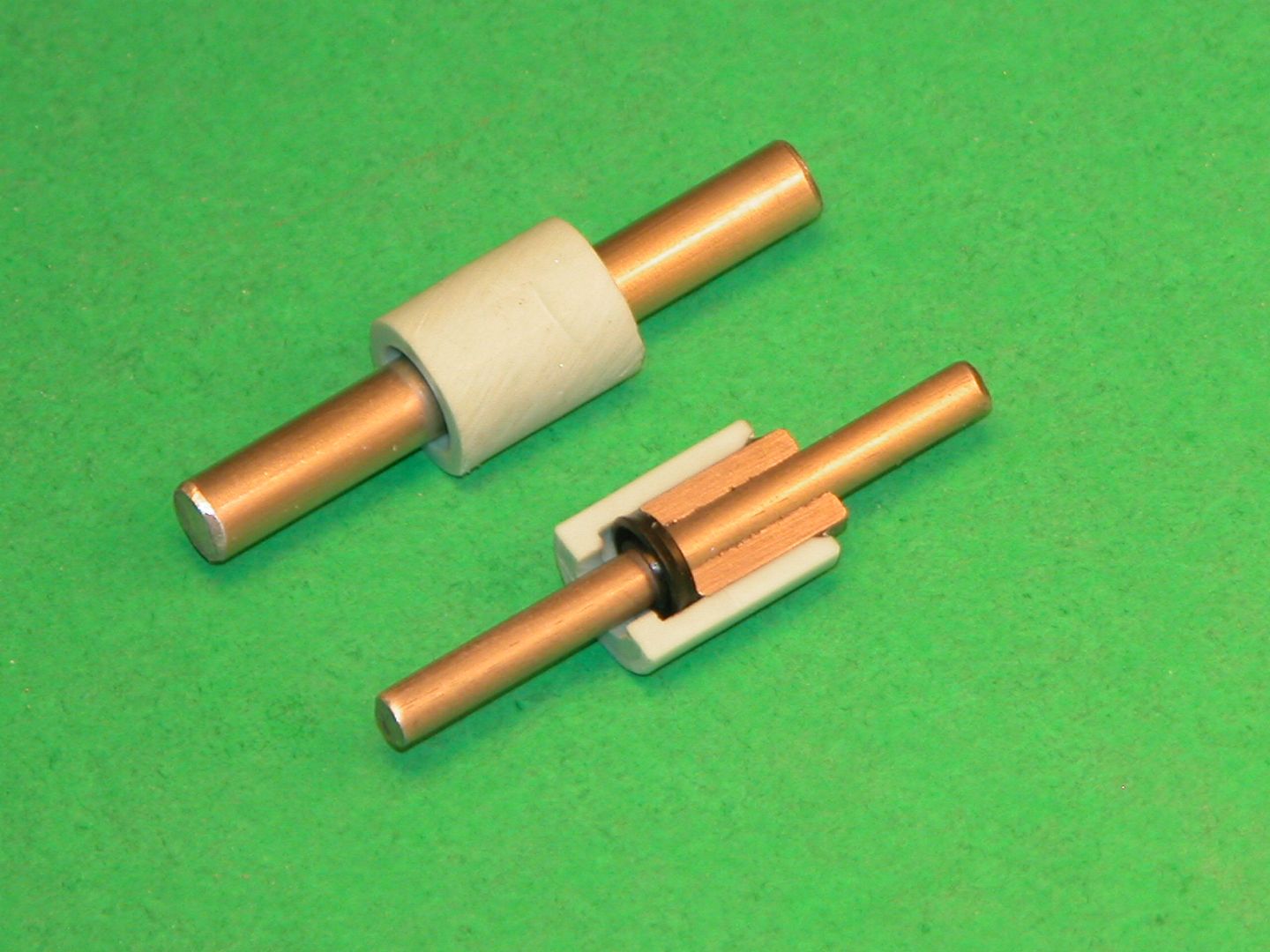

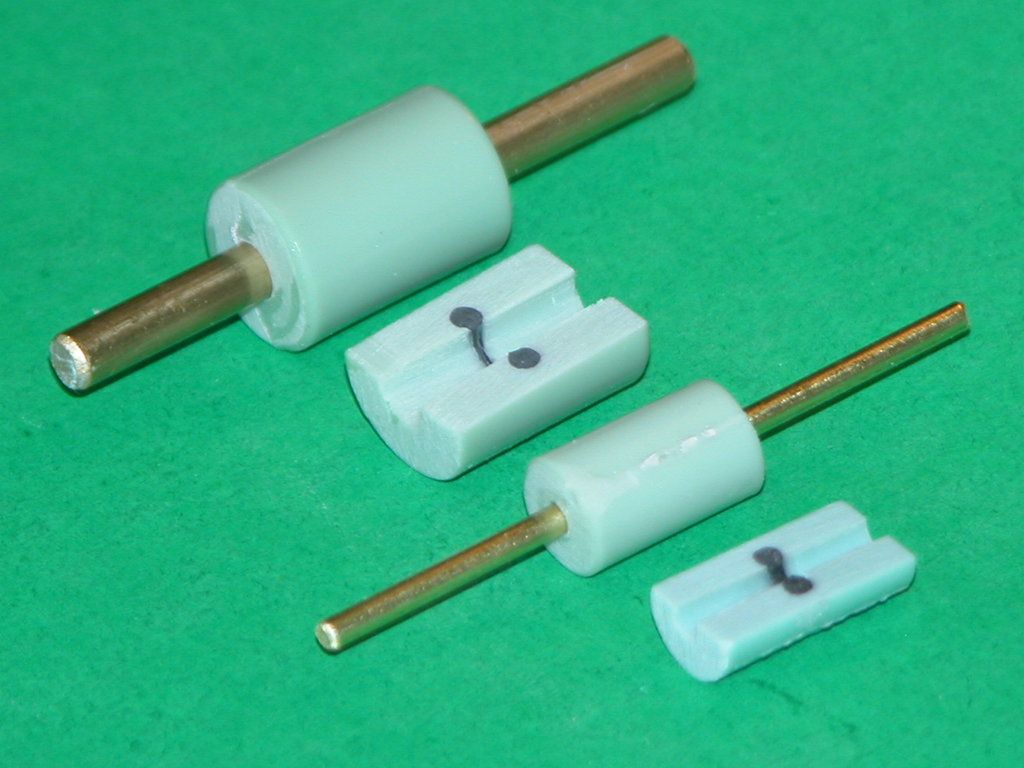

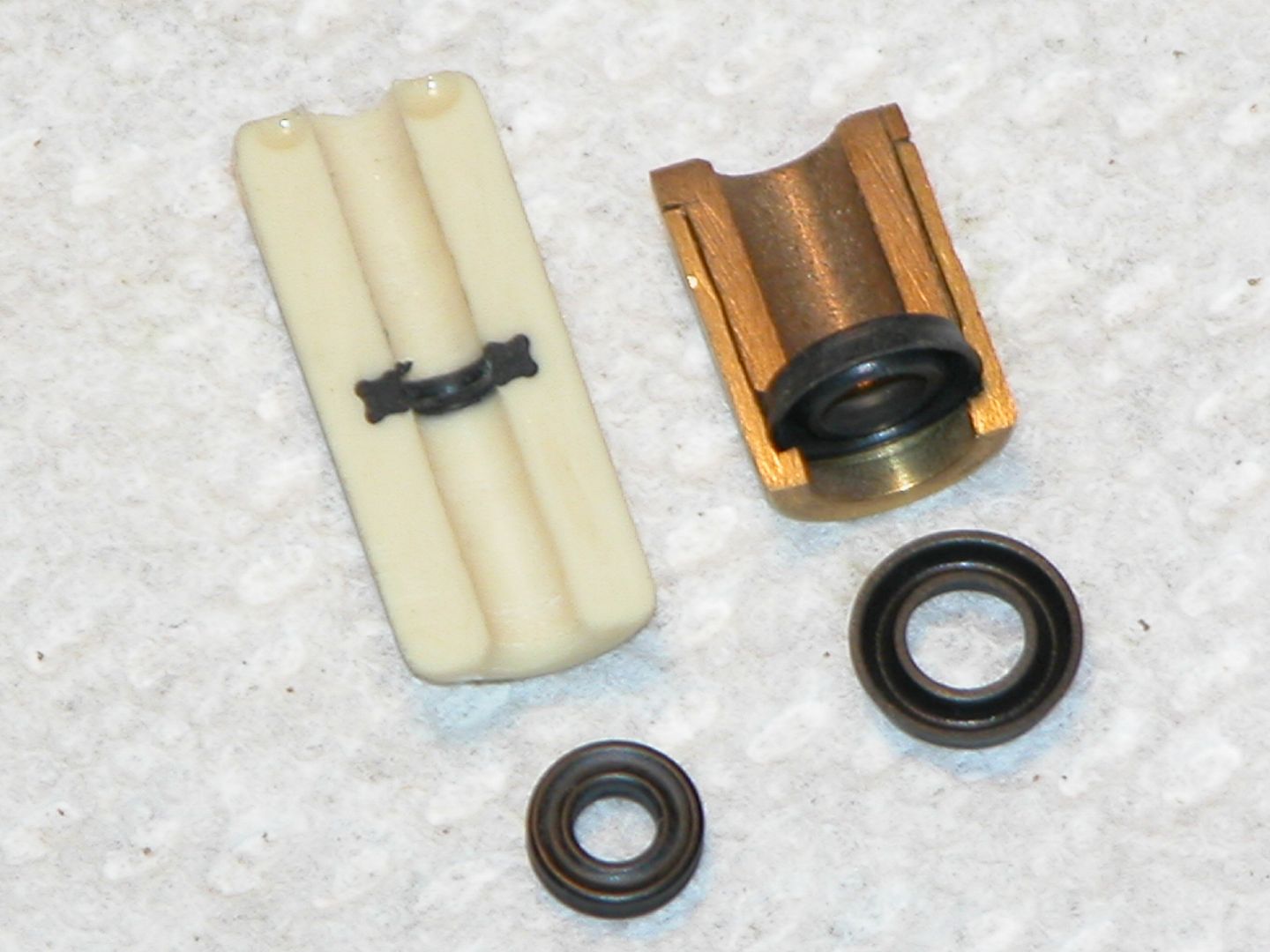

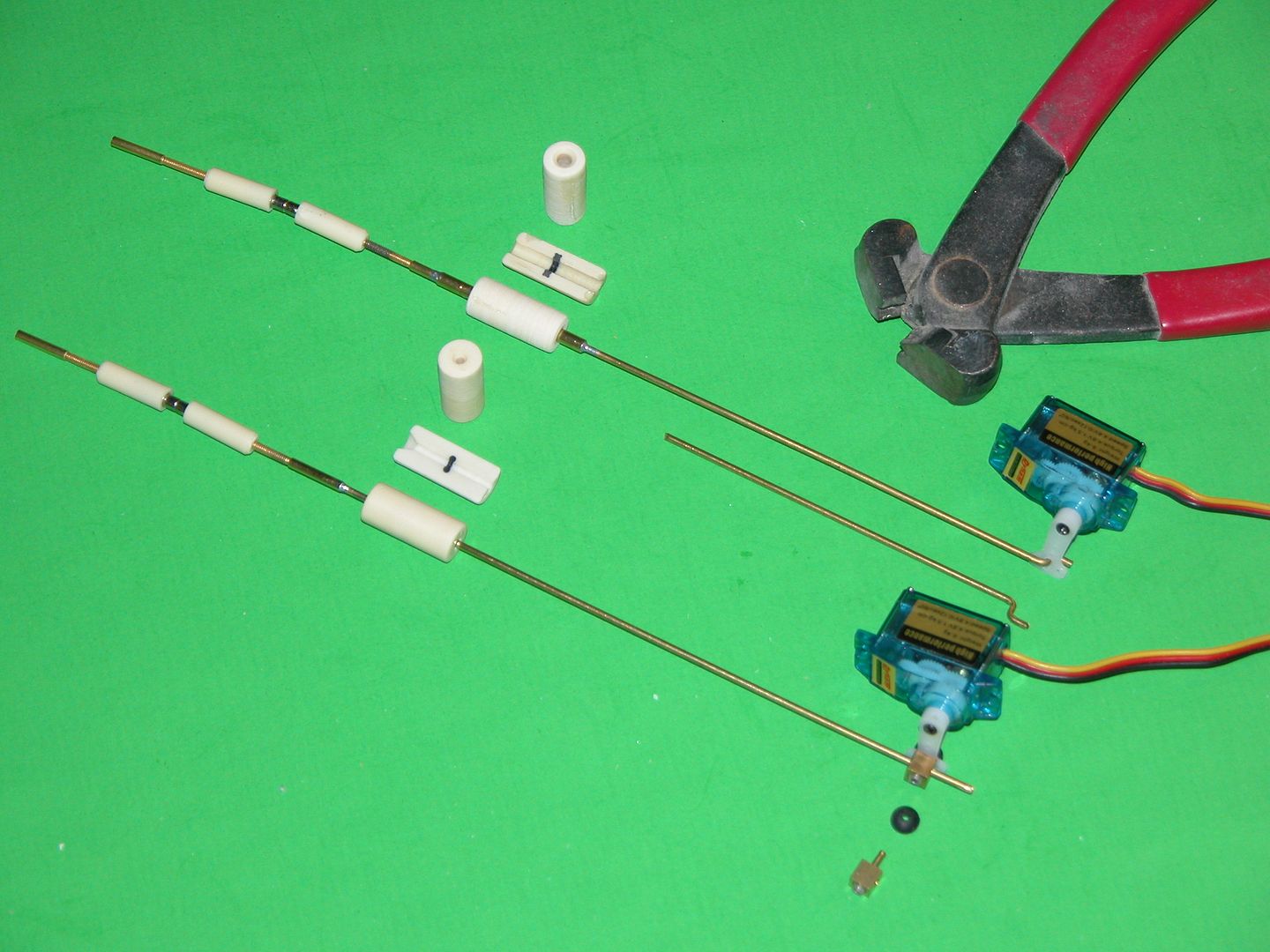

First job was to tighten the inner O ring with a bit of tape.

That sorted out, I the bevelled the edge of the WTC, not an easy job. I decided around a 30 degree bevel, and used a mini sanding drum..........

.....followed by 120 grit sandpaper on a round pole.............

.......and finally 400 grit by hand.

This was a tricky job, as the outer rim must not be damaged or the seal will be lost, the bit to remove is from the inner rim. The mini sanding drum does give a bit of a wavy line, the trick is to keep checking and going back over bumps.

Putting it all back together and giving it a good amount of air down the stuffing tube (as a trumpet player I can get a fair bit of pressure up), the seal at both ends was intact.

Many thanks to Trout for the tape and bevelled edge ideas, the final pressure test will be to get the WTC up to piston tank level of stress.

The Boattrainman

Leave a comment: