Like the MK16 Steam Torpedo of old, the RC Gas propelled torpedo's time has come and gone.

The MK148 ADCAP RC Sub torpedo based on the US MK48 ADCAP sub launched ASW/ASuW Heavyweight Torpedo.

The 4-3/4" x 7/16" (19'x21" @ 1:48) weapon is driven by a 3V Coreless drone motor powered by 3V 5F Supercap (22.5 Joules).

This coupled to a modified "Mini Drone" 2-bladed propeller should provide an estimated run length of 50 ft.

The onboard charge and motor activation is provided by a magnetically operated SPDT 280MA Reed switch

RTE (Run to Enable) is calculated at 3ft (starting the surface run after ejection and running submerged during the pre-enable phase).

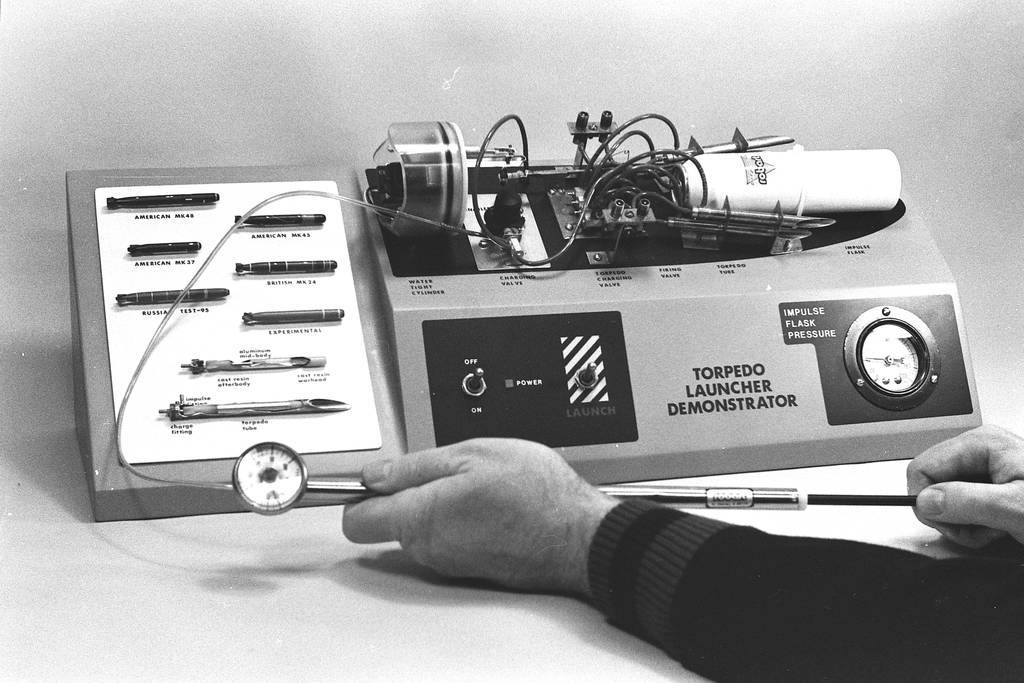

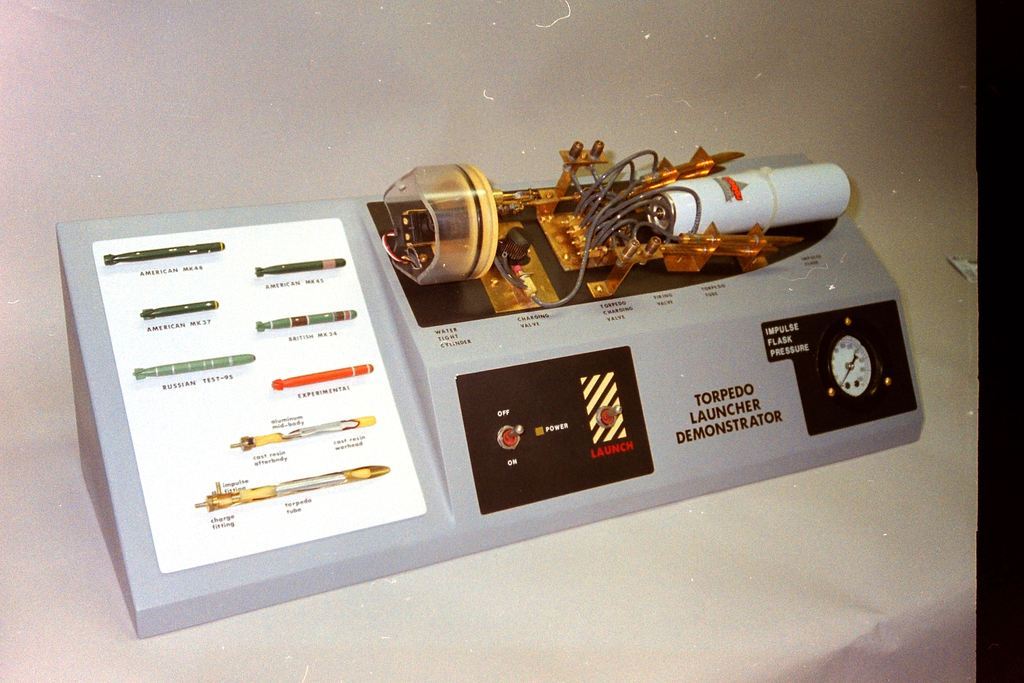

The MK113/RB Fire Control System will consist of the 1/2" standard 1:48 Scale RC Torpedo tube utilizing Impulse water ejection ram powered by an

EPDM - (ETHYLENE PROPYLENE DIENE MONOMER) stored energy subsystem (rubber band) and wet-servo firing mechanism.

Weapon is muzzle loaded into the tube, and the ejection ram "cocked into the firing position.

Charging is done "in tube" via a recessed brass pin on the nose and though an access hole on the torpedo tube to the grounded Aluminum torpedo Body.

The GND pin of the charging mechanism is over-sized and cannot fit into the positive charging location on the weapon nose to prevent an accidental reverse polarity condition.

Parts are on order for the MK113/RB. Detailed specification and plans to be released after final testing IAW the DMerriman-III RC Submarine Freedom of Information Act

This all weather, any depth, weapon system will strike fear into the hearts of all other RC watercraft.

USS SHARK SSN-591 will have the MK113/RB retrofitted by June.

After 25+ years of wanting this, the advent of drone technology that may have hurt us (can you say 2.4Ghz?) also provided me the readily available tech to do this.

Thanks to all of you out there who developed the electric torpedo, and especially Capt. Bob Gaito for his spin on it and inspiring me.

The MK148 ADCAP RC Sub torpedo based on the US MK48 ADCAP sub launched ASW/ASuW Heavyweight Torpedo.

The 4-3/4" x 7/16" (19'x21" @ 1:48) weapon is driven by a 3V Coreless drone motor powered by 3V 5F Supercap (22.5 Joules).

This coupled to a modified "Mini Drone" 2-bladed propeller should provide an estimated run length of 50 ft.

The onboard charge and motor activation is provided by a magnetically operated SPDT 280MA Reed switch

RTE (Run to Enable) is calculated at 3ft (starting the surface run after ejection and running submerged during the pre-enable phase).

The MK113/RB Fire Control System will consist of the 1/2" standard 1:48 Scale RC Torpedo tube utilizing Impulse water ejection ram powered by an

EPDM - (ETHYLENE PROPYLENE DIENE MONOMER) stored energy subsystem (rubber band) and wet-servo firing mechanism.

Weapon is muzzle loaded into the tube, and the ejection ram "cocked into the firing position.

Charging is done "in tube" via a recessed brass pin on the nose and though an access hole on the torpedo tube to the grounded Aluminum torpedo Body.

The GND pin of the charging mechanism is over-sized and cannot fit into the positive charging location on the weapon nose to prevent an accidental reverse polarity condition.

Parts are on order for the MK113/RB. Detailed specification and plans to be released after final testing IAW the DMerriman-III RC Submarine Freedom of Information Act

This all weather, any depth, weapon system will strike fear into the hearts of all other RC watercraft.

USS SHARK SSN-591 will have the MK113/RB retrofitted by June.

After 25+ years of wanting this, the advent of drone technology that may have hurt us (can you say 2.4Ghz?) also provided me the readily available tech to do this.

Thanks to all of you out there who developed the electric torpedo, and especially Capt. Bob Gaito for his spin on it and inspiring me.

Comment