Tool time.

Collapse

X

-

-

David,

I initially wanted to private message you on this one however your inbox is full....

I have another question, that I need some direction and pointers to think about in order to fix the problem at hand.

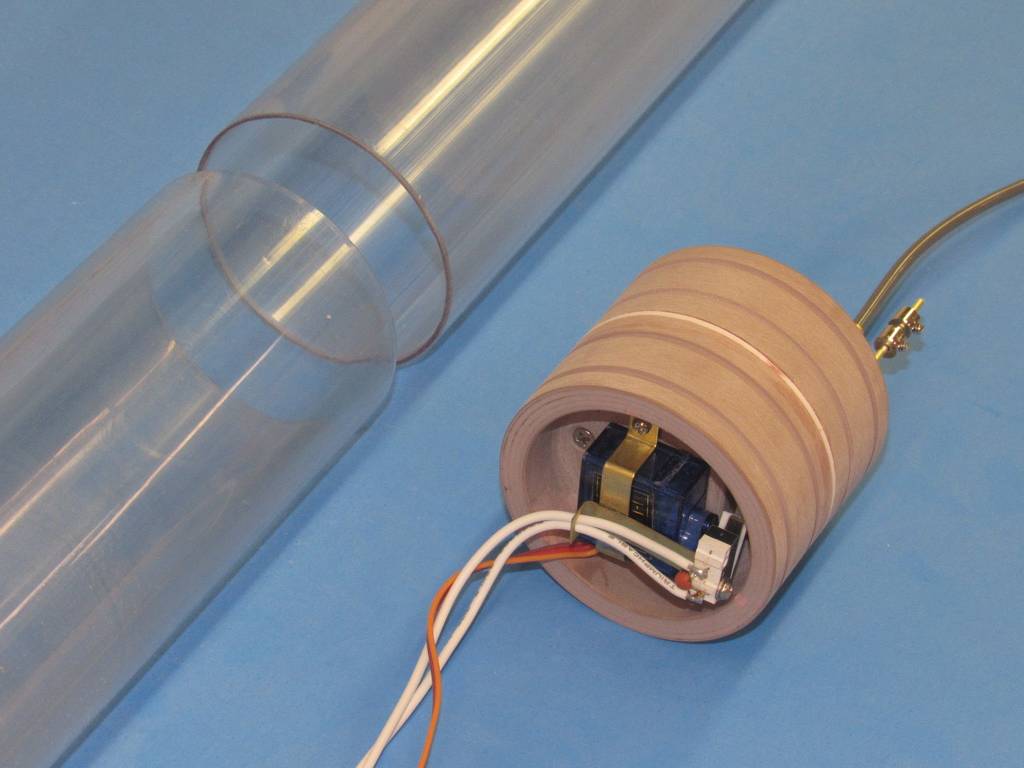

Recently I have been testing some stern cylinder end caps and have to my frustration found that there have been leaks through the inside of the motor. This seems to be something new and yet I can't think of what i have done differently to make this problem materialize. The motors that I use are the RE-380SH type that are common as. I have been testing the rear end cap with what looks like no leaks occurring and then I tilt the assembly and drips come out of the rear slots in the can, shown below.

Now this motor is bolted in with tiny 2.3mm hex bolts in two tiny holes in the front. I silicon over these and the round raised section where the shaft extends at the front is a tight fit into the hole in the end cap as seen in the photo below. The front section of motor is pressed into the end cap to about 10 mm depth. I have always put a bead of silicon about the outer front face of the motor and as i press it back into the housing the silicon pushed backward with it creating a sealing.

So the next photo raises some questions that i have of the front face.

Or is your first and last line of defense the cup seal at the front and you've never had to deal with water so far back? This problem is really annoying me off at the moment.

What is your opinion, views or things for me to think about.

Thanks

David h

Comment

-

It looks like there is a visible dent on the shaft, any dent or spike on the shaft will make the cup seal not waterproof or damage the cup seal. If the shaft is difficult to polish or repair ,you can replace it.

V

Last edited by Sam Victory; 03-17-2022, 09:33 PM.Comment

-

I assume you are currently using the cup seal to keep water away from motor. If so, that is the culprit: water is either getting by the inner lip (which touches the motor shaft) and/or water is getting by the outer lip (which touches the seal body).David,

I initially wanted to private message you on this one however your inbox is full....

I have another question, that I need some direction and pointers to think about in order to fix the problem at hand.

Recently I have been testing some stern cylinder end caps and have to my frustration found that there have been leaks through the inside of the motor. This seems to be something new and yet I can't think of what i have done differently to make this problem materialize. The motors that I use are the RE-380SH type that are common as. I have been testing the rear end cap with what looks like no leaks occurring and then I tilt the assembly and drips come out of the rear slots in the can, shown below.

Now this motor is bolted in with tiny 2.3mm hex bolts in two tiny holes in the front. I silicon over these and the round raised section where the shaft extends at the front is a tight fit into the hole in the end cap as seen in the photo below. The front section of motor is pressed into the end cap to about 10 mm depth. I have always put a bead of silicon about the outer front face of the motor and as i press it back into the housing the silicon pushed backward with it creating a sealing.

So the next photo raises some questions that i have of the front face.

Or is your first and last line of defense the cup seal at the front and you've never had to deal with water so far back? This problem is really annoying me off at the moment.

What is your opinion, views or things for me to think about.

Thanks

David h

The sintered bronze bearing of the motor is only a press-fit to the motor can and is not at all water/pressure tight. And the non-interference fit between motor shaft and sintered bearing bore is also not water/pressure tight. NOT WATERTIGHT!

Bottom line: if that cup seal fails, water flows into the motor and then into your after dry space. If you're not using a proper shaft-seal over the motor shaft (or motor shaft extension which I employ) you are guaranteed to leak massive amounts of water into the motor.

DavidWho is John Galt?Comment

-

What do you think of GWS receivers?

Comment

-

Also a good choice, but since I had no GWS receivers, I cannot tell you whether it could match other transmitters. Maybe for Futaba is OK

VComment

-

Comment

-

Hello David M,

It’s been a while since I posted anything, but I wanted your opinion on something.

I am redesigning my ZB-1 unit. I have over the last couple of days here in the workshop almost finished the patterns. As I have been making the parts out of Renshape, I thought to myself ‘ the unfinished texture of the renshape and also the precise edges created by the lathe and milling machine are going to get covered up by resin and filler and sanding, sanding sanding.’ Knowing my luck if I do that then I will loose some of the preciseness evident. I am thinking about using a minimum of filler and just casting the silicon molds with just the Renshape surface as is. I quite like the texture.

Do you see any problems with this?

Regards

David HComment

-

Assuming you have employed the dense (40 pound-per-cubic-foot) RenShape you can go straight to tool making (providing that attached fillers, putties, and adhesives contain no Sulpher).Hello David M,

It’s been a while since I posted anything, but I wanted your opinion on something.

I am redesigning my ZB-1 unit. I have over the last couple of days here in the workshop almost finished the patterns. As I have been making the parts out of Renshape, I thought to myself ‘ the unfinished texture of the renshape and also the precise edges created by the lathe and milling machine are going to get covered up by resin and filler and sanding, sanding sanding.’ Knowing my luck if I do that then I will loose some of the preciseness evident. I am thinking about using a minimum of filler and just casting the silicon molds with just the Renshape surface as is. I quite like the texture.

Do you see any problems with this?

Regards

David H

Get the work as pristine in the raw as you can and proceed with the tool making -- if you're using Platinum cured RTV rubber, no sweat rendering the tool off the raw RenShape.

Now, if for some unfathomable reason you went with the porous, lightweight RenShape (Idiot!) -- with its awful moon-like surface texture -- you can still pull your nuts out of the fire by simply overcoating the master(s) with a thinned batch of epoxy laminating resin. After curing hard, proceed with your tool making. The epoxy will fill the porous surface and tighten up your tolerances at the same time.

DavidLast edited by He Who Shall Not Be Named; 01-09-2024, 08:54 AM.Who is John Galt?Comment

Comment