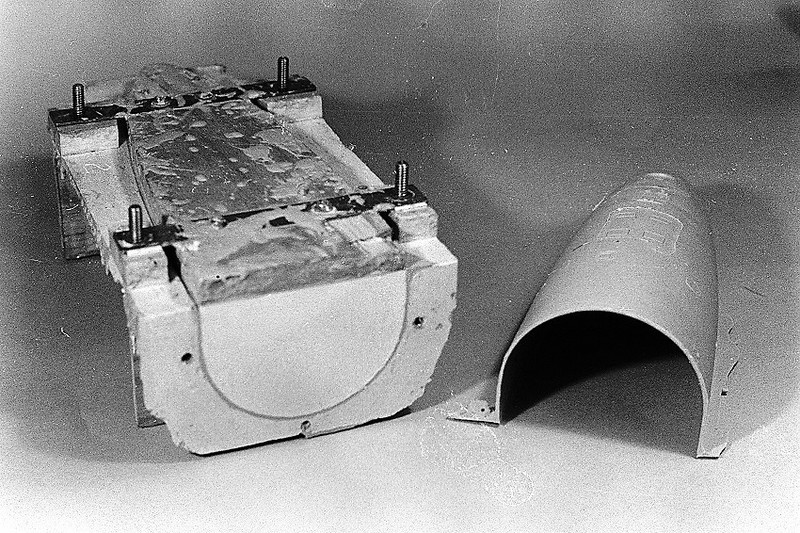

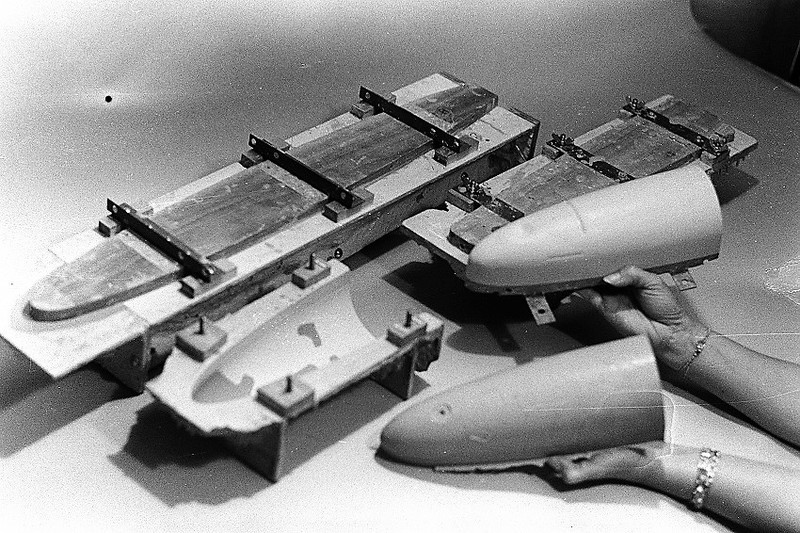

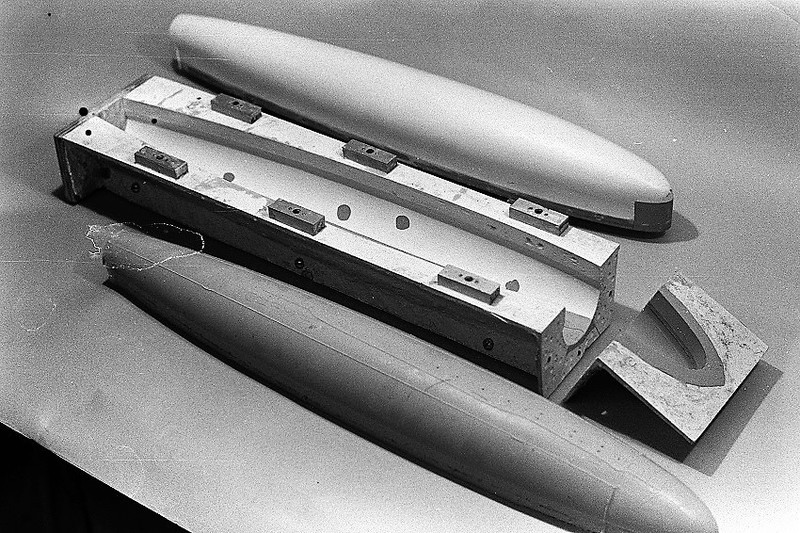

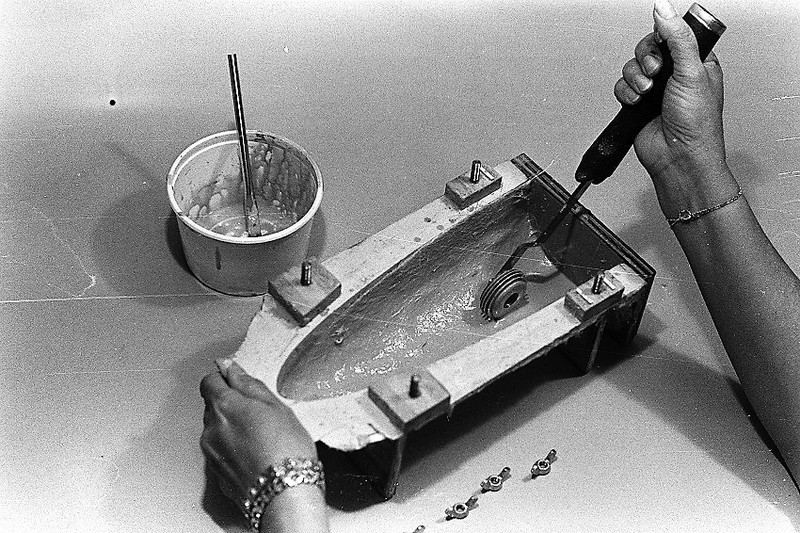

First off, I apologize for the poor quality black-and-white photography here. Ellie and I chronicled this work over 35 years ago when I was doing my own photo lab work to save a few dimes.

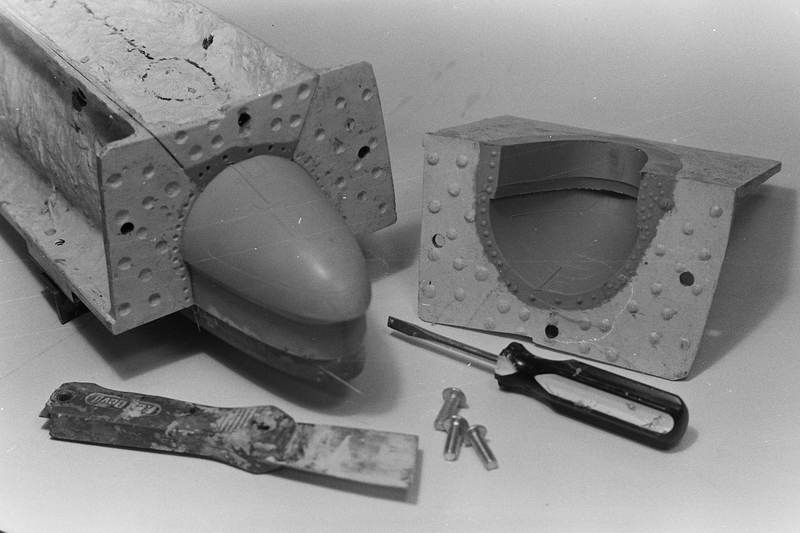

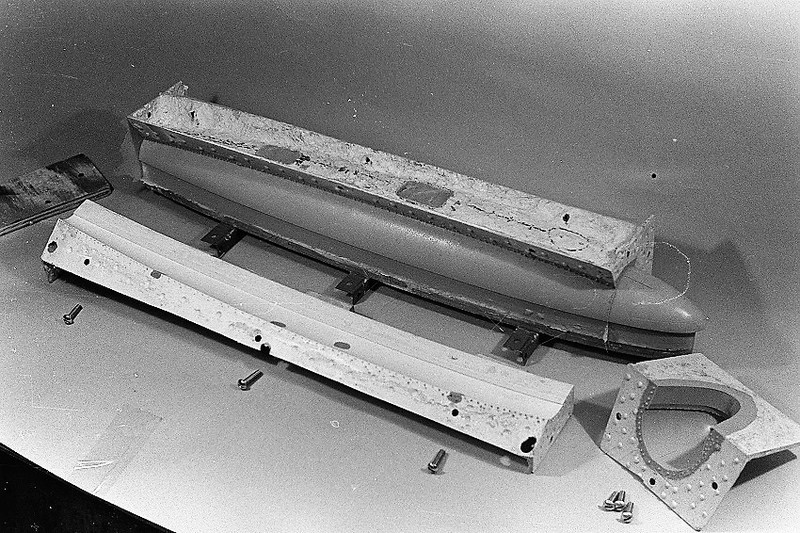

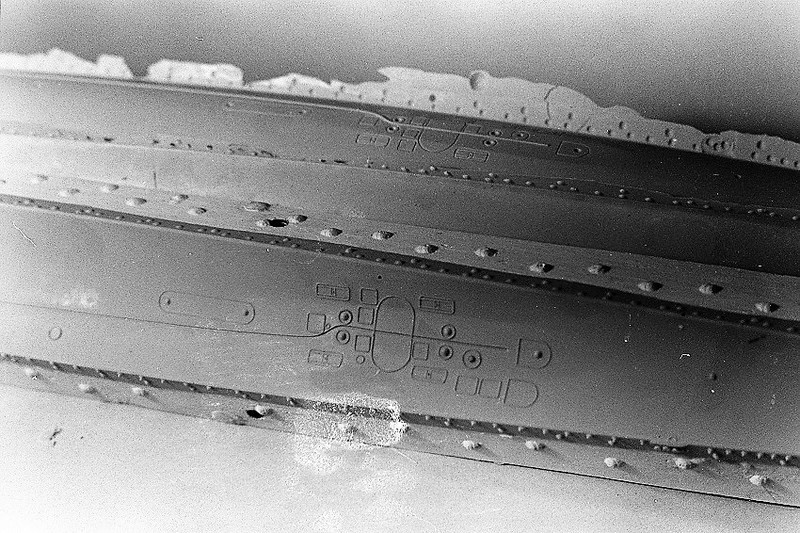

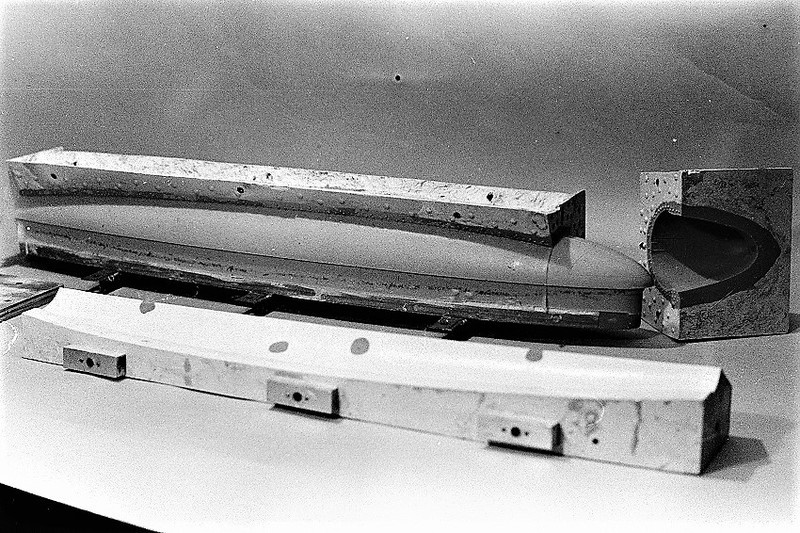

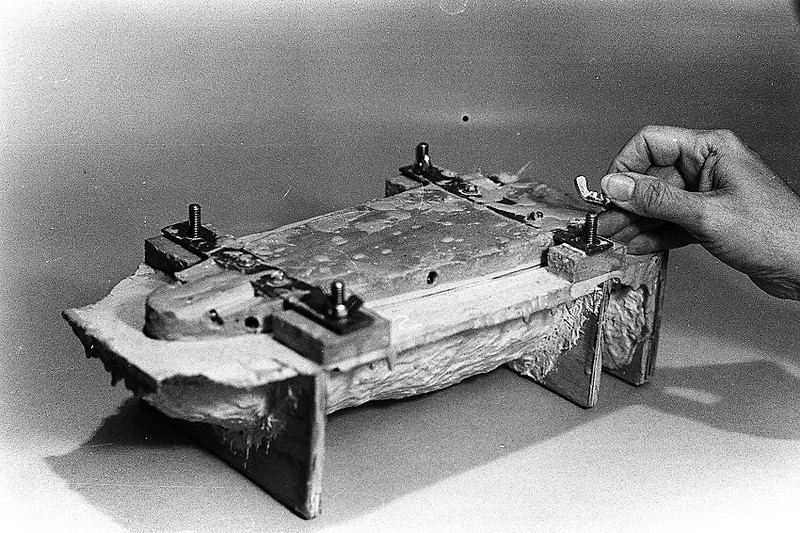

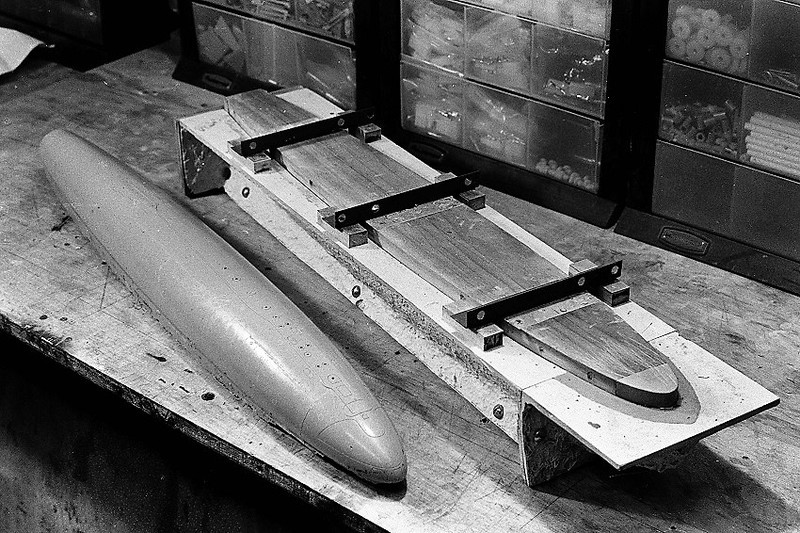

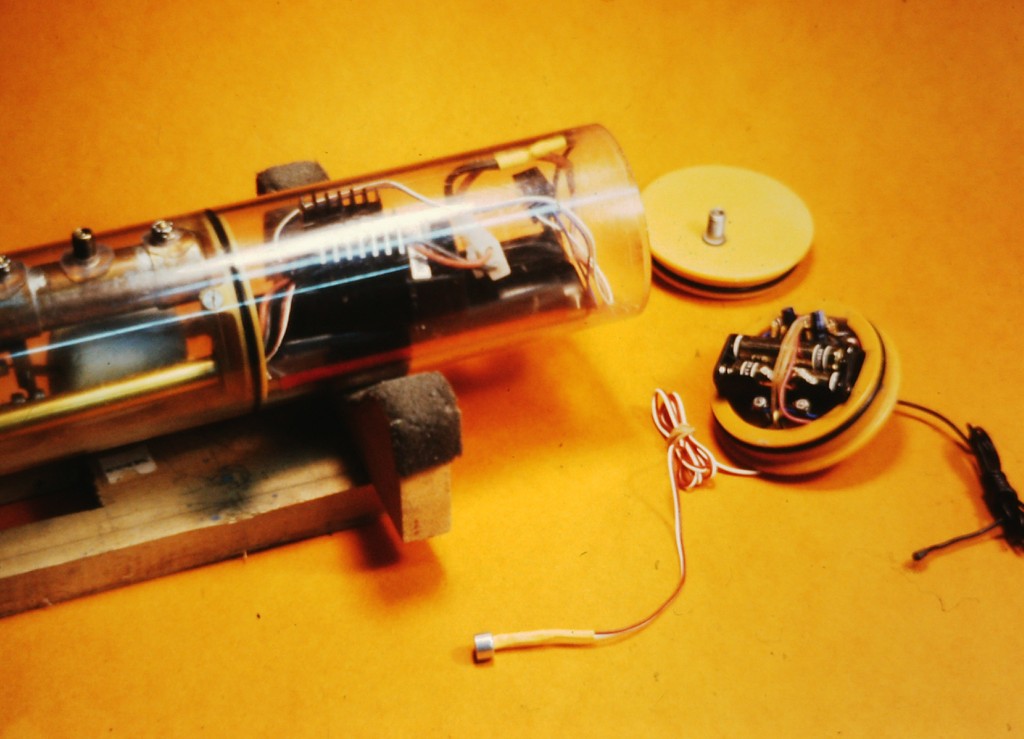

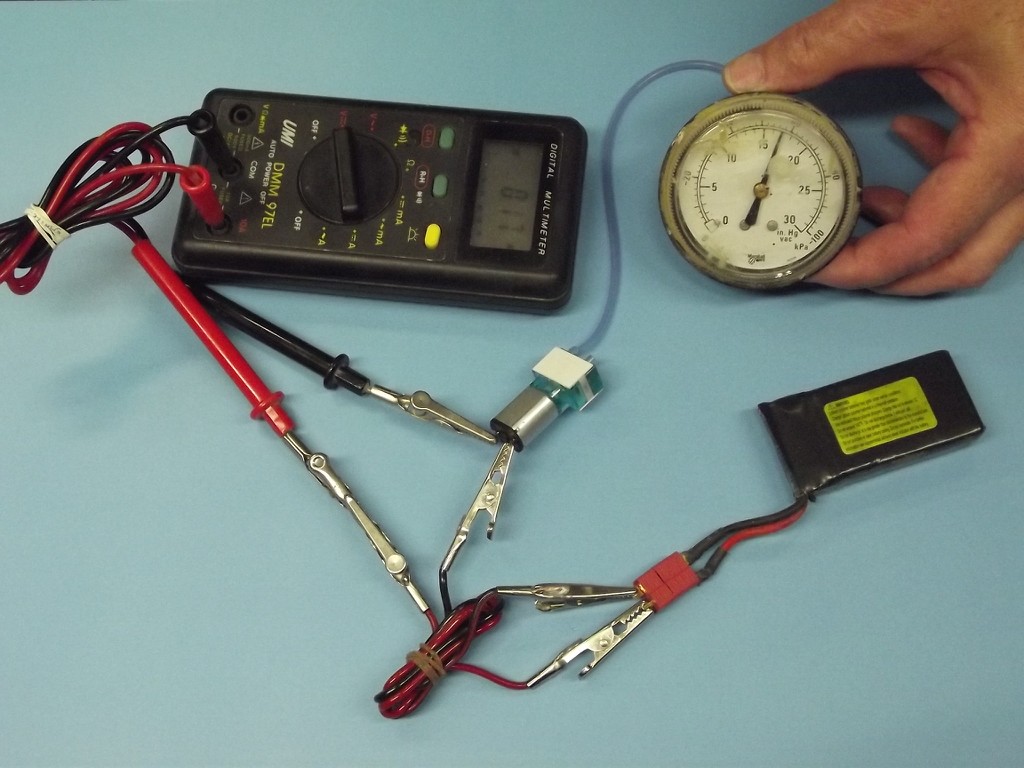

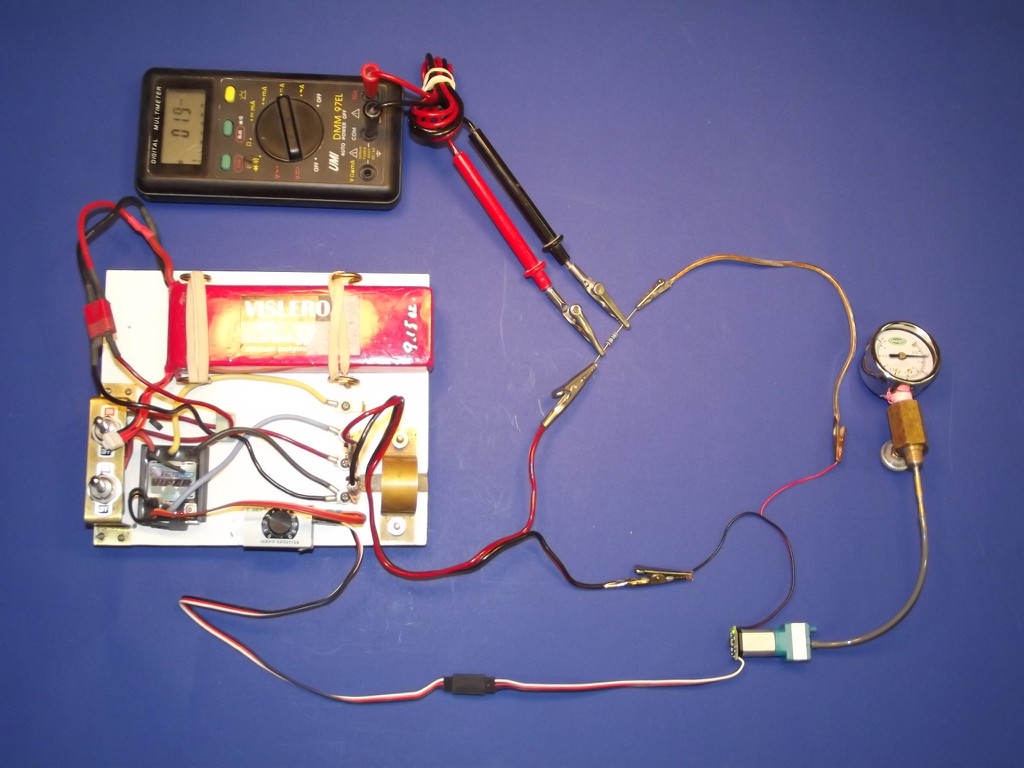

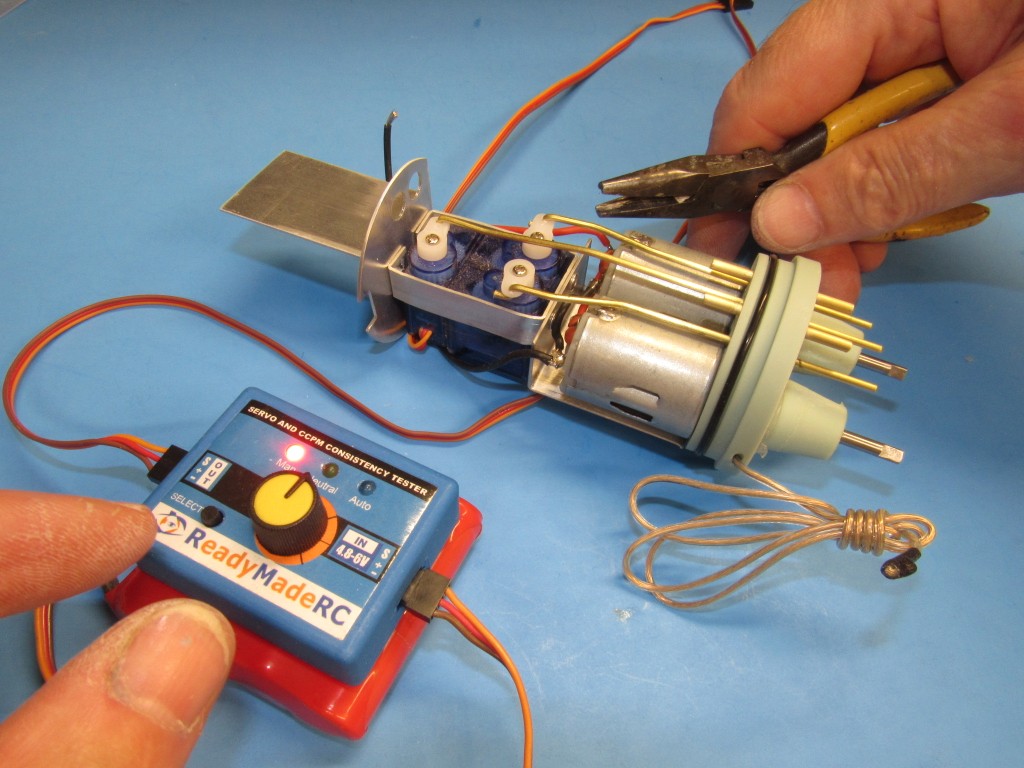

What you see here are three of the eventual five iterations of highbred tooling we produced to manufacture thin walled 1/96 SKIPJACK hull parts for our first commercially available kit. As confusing as some of this may be you will see that our work, very closely, follows your shop-sketches of your proposed tool making methodology: multi-piece tools comprising both hard-shell, and rubber glove surfaces.

Also note that we incorporated a 'displacing plug' to form the inside of the hull pieces as well. This item not only set a specific wall thickness, but also permitted us to only one glass-resin lay-up operation to produce a GRP hull part. Only complication to that was the necessity of pressurizing the entire assembly to two atmospheres during the curing process.

You examine the photos and if any specific questions as to process come to mind address them here and I'll take them on, point by point.

I so enjoy watching you embrace these techniques and processes, David.

Leave a comment: