Excellent.

today's work

Collapse

X

-

-

-

-

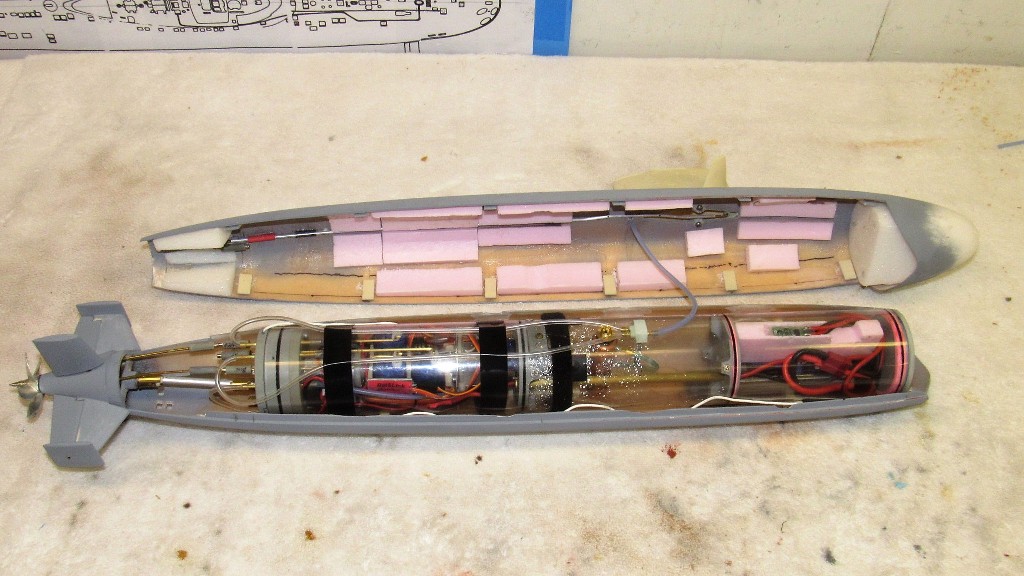

The hull halves matted up; the WTC populated with working devices and certified operational; the entire boat was then taken through the harrowing process of adding fixed ballast weight and buoyant foam to make it stable, maneuverable, and to assume near neutral buoyancy submerged, and to float at the correct waterline when surfaced. Easily said. Not so easy to do!

All that, and more, before its first open-water tests. The open-water test did in fact reveal one last goof that had to be corrected before the model could be sent off to Casey for him to paint and add to his fleet.

Here I'm installing about 1-pound of fixed ballast lead weight low in the hull, well forward, to place the submarines c.g. at its longitudinal center. I have yet to install the buoyant foam in the nose and within the upper hull to counter that weight with an equal amount buoyant force.

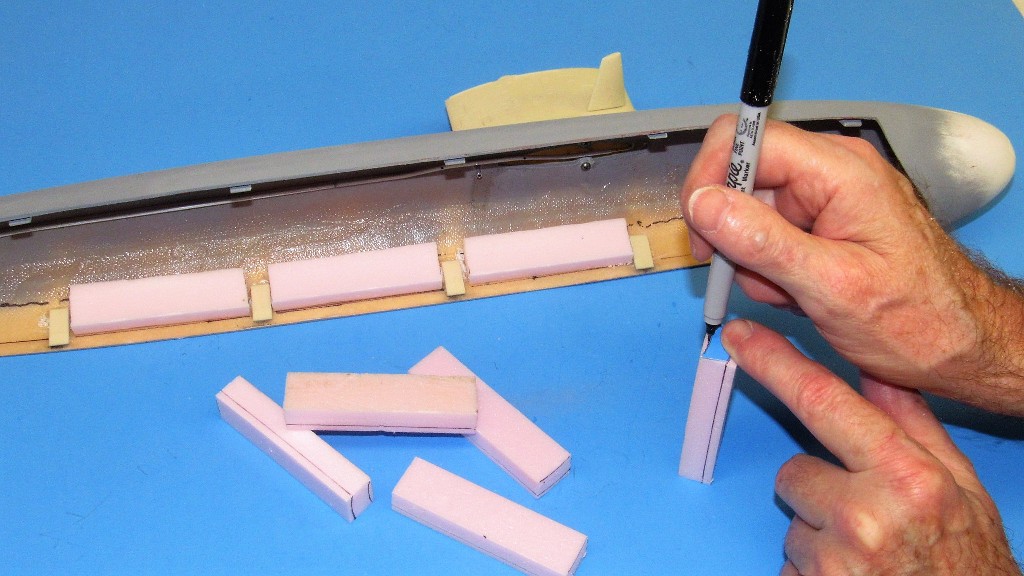

As there was only about a 1/2-inch annular space between the hull and WTC I had to install the initial hunks of buoyant form -- each shaped with convex and concave surfaces -- to fit that tight space. A cardboard template used to mark off those curves to these closed-cell foam blanks.

I knew from experience that I would need a lot of flotation near the bow; these preliminary hunks of foam were installed long before any in-water testing. Only after the in-water tests would I fine-tune the amount and location of the buoyant foam elements within the hull.

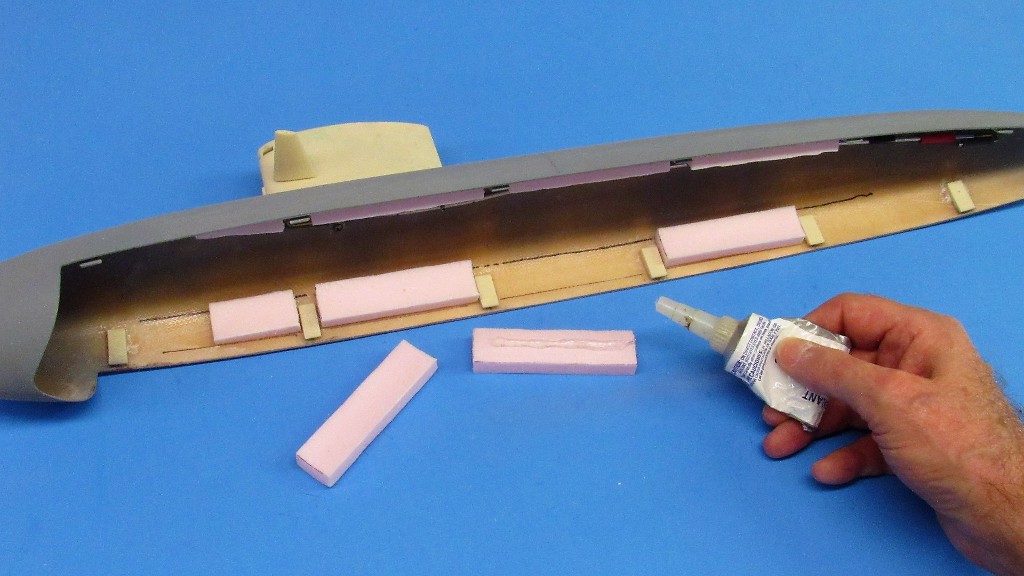

All foam pieces were secured in place with RTV adhesive. Quick and easy to break if, and when, the need comes to remove and/or replace/relocate buoyant foam pieces during the trimming process.

Initial trimming was done in a big trough of water just outside the shop. First, I worked out how much foam, and where it had to be located to get the model to suspend itself totally submerged with the ballast tank full of water, the boat statically stable with no roll and a zero pitch-angle. I then blew the ballast tank dry and noted how high, or low its waterline was, compared to where it should be. Moving foam either above or below the waterline -- a trial-and-error process that can go quick, or not so quick -- until the model submarine sat with the waters surface right at the designed waterline.

Trim for submerged trim first. Trim for surface trim last.

Here's the layout of buoyant foam after achieving correct submerged and surfaced trim.

The submarine was now ready for open-water tests. Here, everything needed to support that activity has been assembled and ready for its ride to the local Jewish Community Center outdoor pool. Show time!

Here's a quick video clip of the JCC pool tests. Things went very well. But, after arrival back at home I found about a spoon-full of water in the WTC's after watertight space. ****! A leak. Gotta fix that...

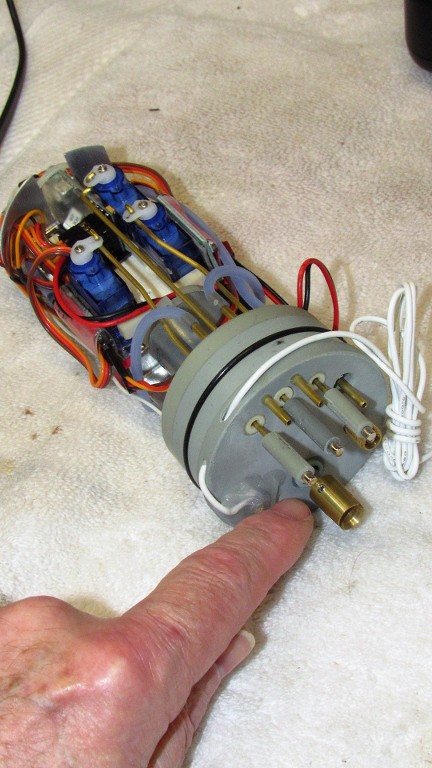

A quick look-see at the dry side of the motor-bulkhead showed some water weeping out from between the motor-bulkhead and its back-plate, which holds the motor in place. Looks like a bad motor shaft seal!

Break out the tools... going to be a late-night fix.

!#@^@&*$)^&(%$^%$^##!

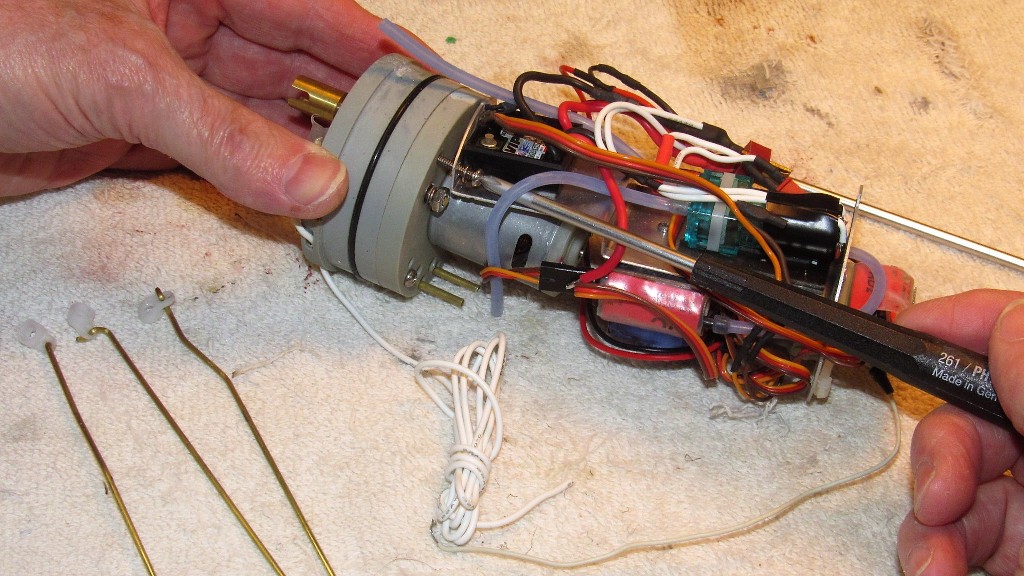

The three servo pushrods were pulled; the aluminum tray and bulkhead with attached devices was unscrewed from the back-plate; the ESC leads to the motor de-soldered; the receiver antenna lead undone from the antenna stud; and the DC and LPB hoses pulled from their nipples. Now I had access to the motor-bulkheads internals.

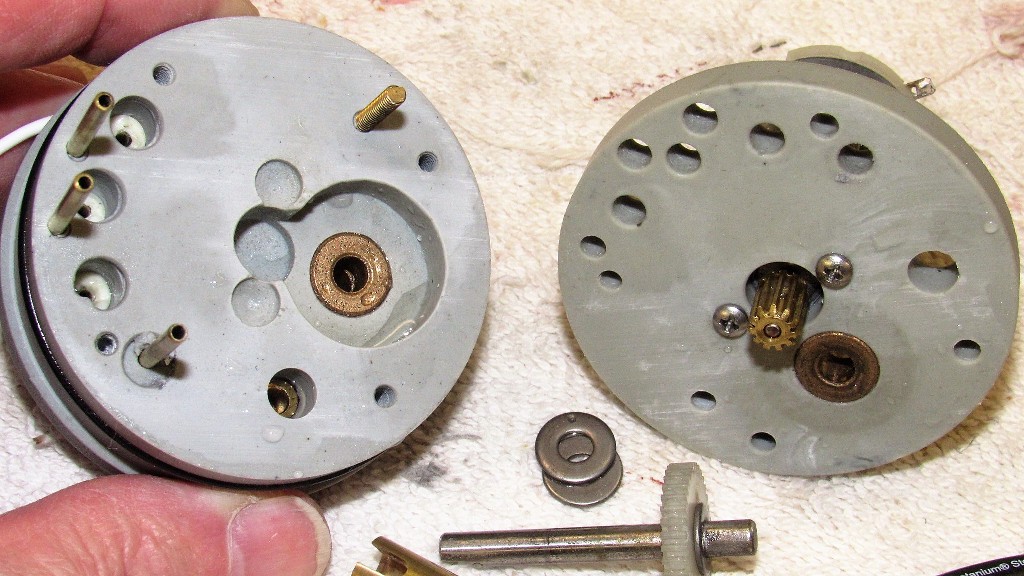

I removed the back-plate and found water still gathered in the well where the motor pinion and motor drive shaft spur gear resided. Yup! Water was getting by the shaft seal. Nuts!

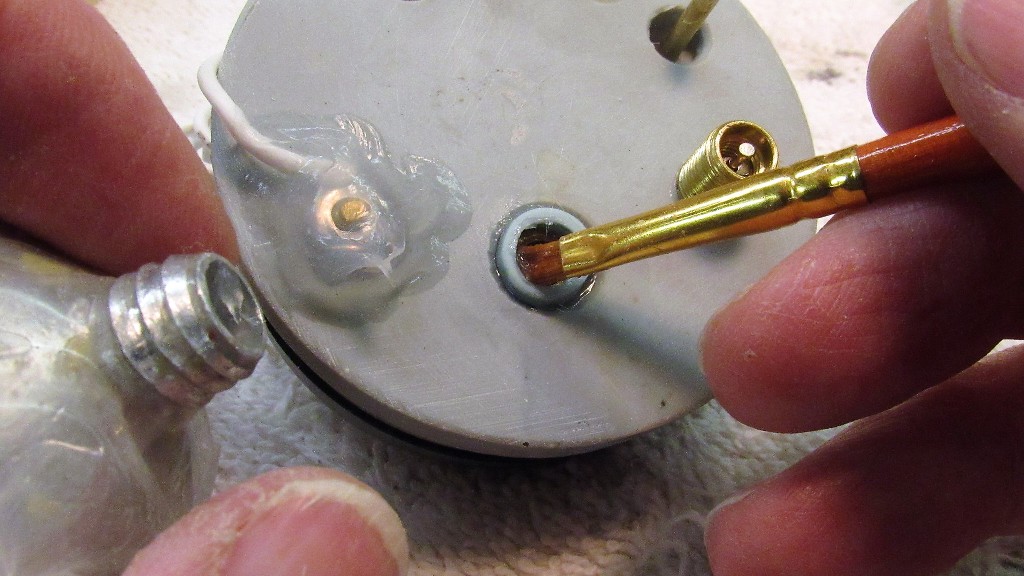

Turns out I failed to properly polish the shaft and a small burr chopped up the inboard lip of the rubber cup-seal. The shaft was turned and polished, and the cup-seal replaced.

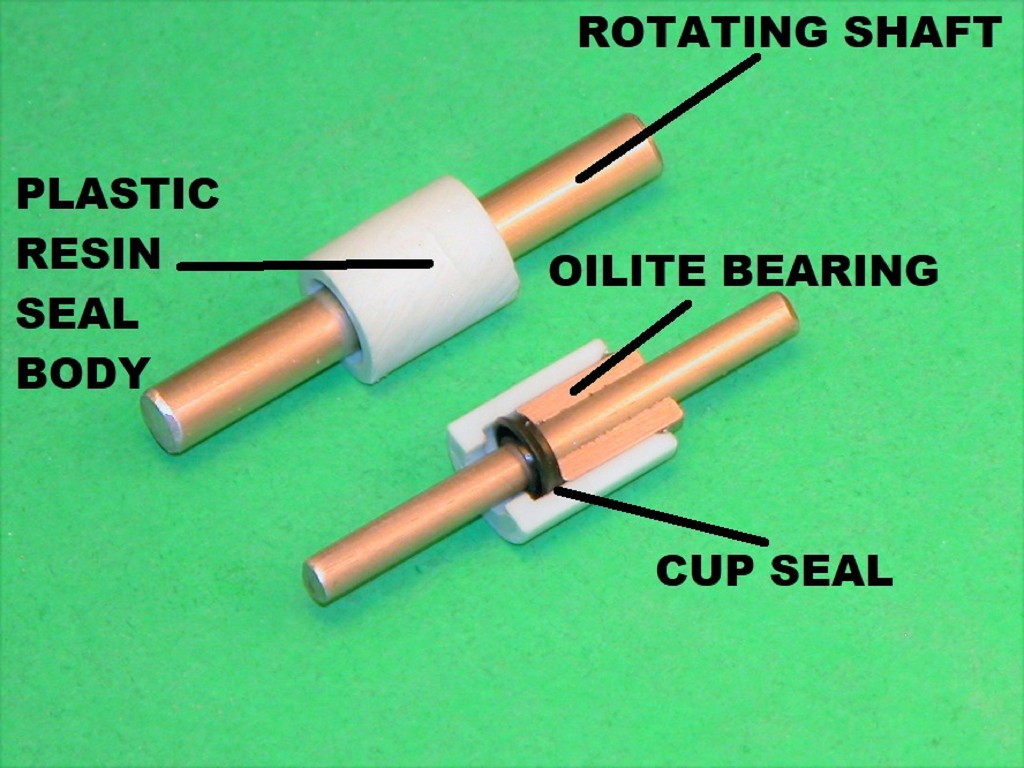

Note that with a cup seal only a very narrow internal and external lip makes contact with the seal body and shaft -- any deformation of the shaft or body, or tear in either of the seals lips will offer a path for water to get by the seal.

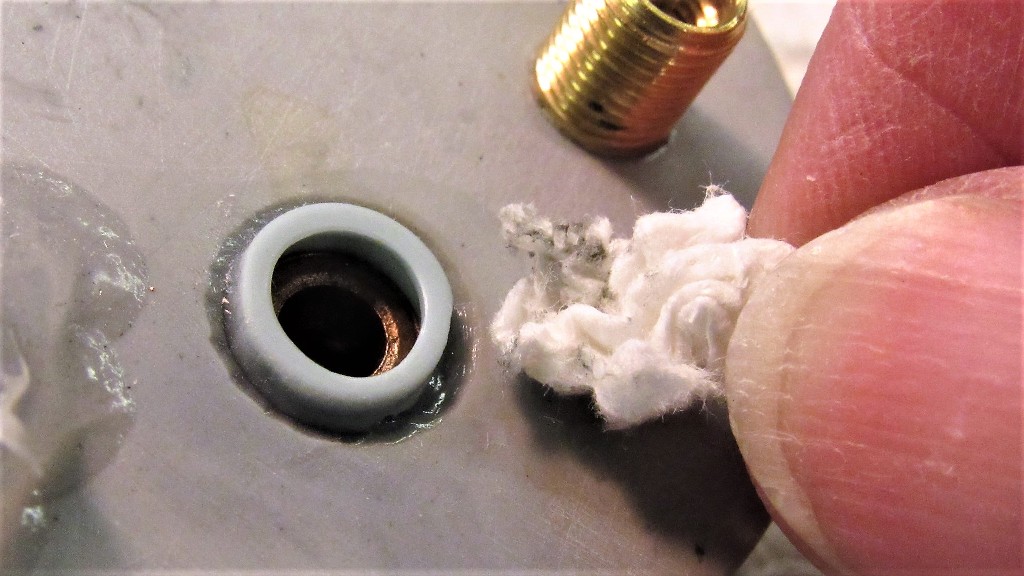

Before installing the new cup-seal I thoroughly cleaned out any gunk from the space where the cup-seal resides.

A liberal amount of silicon grease is packed into that space, and the new cup-seal jammed in place, followed by the motor-shaft, and re-assembly of the entire motor-bulkhead.

The entire WTC was once again leak checked and operated successfully before packing things up for delivery to my boating buddy, Casey.

Whew!... glad that's out of my hair.

Now!... on to Kim's HUNLEY project.

Who is John Galt?Comment

-

Comment

-

Who is John Galt?Comment

-

It's the height of foolishness to have gone to all the work and expense of building an r/c model submarine and to then neglect the need to protect it properly as it is stored and transported between home, pool, lake, cross-country, or even internationally.

Here you see five cardboard boxes. Two containing an r/c model submarine hull and associated parts; two more boxes containing the WTC's for those hulls; and the open box in which I am packing a transmitter and other smaller items that will support operation and maintenance of the models.

All this in preparation to my trip next week to Texas to go play with my former boss, Bob Martin of Nautilus Drydocks fame (in the voice Sheldon Cooper: "it's a trap!").

These items will all go into a much larger outer cardboard box which will convey everything from here to there.

I employ two basic types of storage-transportation boxes for my models: A heavy, large, stout wooden box to protect the completely assembled model during long-term storage and local transportation. And a light-weight cardboard box tailored to tightly fit the model and in turn itself transported within an outer protective box suitable for commercial shipping. Both type boxes illustrated here are custom made to house my little 1/96 SWM BLUEBACK r/c submarine model.

The cardboard box can start life as a store-bought product or it can be cut, bent and glued to shape from a suitably sized slab of 200# cardboard (the weight of this stout cardboard is 200 gram's per square foot and is my preferred type material for this kind of work).

In this example I'm 'telescoping' several 200#, 6" X 6" X 6" boxes to produce a 32" X 6" X 6" box. A hot-glue gun is the ideal tool for sticking cardboard-to-cardboard.

The only reason I employ cardboard as the major box construction material is to minimize the weight and physical dimensions of the package -- these being the two metrics that drive the cost of shipment, be the carrier the United States Postal System (USPS), UPS, FedEx or any other commercial transportation outfit.

Design of the cardboard box is driven by the end-use of the box: is the purpose of the box just to protect the model during transport, to be discarded after arrival. Or, will that box itself be employed for further protection of the model during storage and transportation at the destination?

This particular box is of the disposable variety. The model hull is wrapped in a suitable cushioning packaging material (in this case, bubble-wrap) to suspend it within the cardboard box. As it is my practice to make the sail removable on most of my r/c submarines that feature permits me to greatly reduce the boxes height (and to a lessor degree) and length by housing the sail, and propeller within the models hull. Packaging is provided for and aft between the model and ends of the box.

The objective is to suspend the model within the cardboard box through the use of non-abrasive packaging that has the 'give' to cushion the model against rough handling as it is bounced along from point-A to point-B.

When transporting this is one overriding consideration: Inertia is the enemy!! NEVER package your model for carrier delivery with its WTC in place. ALLWAYS ship the WTC in its own purpose built shipping box when dealing with a (insert air-quotes here) professional shipper.

The other type cardboard box -- this one recently made to get my BLUEBACK from here to Texas, and to be used there for local transport -- is not disposable. This type cardboard box will also be used as I send my stuff back to Virginia. It will see a lot of use!

That requirement demands a more involved and easy to use suspension system between model and box interior -- like that used with my more robust wooden storage-transportation box. This type cardboard box employs soft foam frames, top and bottom, to suspend the assembled model within its cardboard box.

The lid is secured with three Velcro belts, and the upper cushioning frames slide out. The lower half of the frames and back-stops are hot-glued within the box. Getting the hull into and out of the box takes only seconds, not minutes.

Preparing the model for shipping includes transferring the sail and running gear to within the model itself. Also included within the hull are the masts that project from atop the sail; spare fasteners and washers; sail planes, and WTC's snorkel assembly.

Before making up the two hull halves paper sheet packing material is held in place over the bagged items to keep them from rattling around during transport so things don't get lost or start kicking around within the hull as it's outer box is brutally knifed with fork-lifts, dropped from extreme heights, crushed in conveyor-belts, tossed into trucks, slammed into cargo bins, and drop-kicked and used in target practice by bored, over-paid, idiot shipping employees.

The lower frames and back-stops were hot-glued into the box. The upper half of the frames are removable. This feature permits me to install and remove the model from this box with ease.

Protecting my type water tight cylinder (WTC) gets a bit involved because of the delicate pushrods projecting from the motor-bulkhead, aft; and the fragile mission-switch watertight boot-seal at the forward bulkhead. Cardboard cylinders were wrapped around those ends of the WTC, insuring that neither cardboard box or packaging material would make contact with the pushrods or boot no matter how roughly the box is handled during shipment.

The delicate ends of the WTC protected in stiff cardboard cylinders, the unit was bubble-wrapped. Note that the box is over-sized in girth and length to make plenty of room for protective bubble-wrap -- needed to absorb shock-loads encountered during transport.

Plan and execute for the worst. Hope for the best.

To keep the WTC from banging around laterally within the box bubble-wrap occupies the annular space between box interior and WTC. Hunks of balled up bubble-wrap at each end of the WTC absorb longitudinal shock loads as the contents are subject to the not-so-gentle hands of the commercial carrier.

NEVER ship the WTC with batteries installed!

Sending model hulls and WTC's through the various shipping services is one thing. Sending 'dangerous' items -- and in our world, that means high-pressure gas cylinders, spray-cans, pyrotechnics, and Lithium-polymer/ion batteries over a specific capacity -- is another matter entirely. There is a strict protocol to follow. And its our responsibility to follow that protocol to the letter! We don't want that stuff anywhere near a commercial aircraft!

Yes, you can ship these things, but they have to be specifically identified so the shipper (USPS, UPS, FedEx, etc.) will give them 'special' handling -- and that means keeping that box off of airplanes!

The batteries for my BLUEBACK and KILO are just such items and here you see them ready for their trip to the local post office for drop-off. Truck(s) got them from Virginia to Texas in only four days! Not bad.

Who is John Galt?Comment

-

Excellent write up David! I did a little different approach due to the size of my 1/48 Thresher. I used some Sonotubes that slid together giving me double wall protection with wooden end plates. I too removed the sail and interior components for shipment in a separate box and bubble wrapped the hull. I kept the length and girth to 107". According to Bob it arrived safely at his place. It will only take a few minutes to assemble once I arrive on Friday.

Comment

-

Damn! Two great minds, thinking alike... who woulda thunk it?! And so glad you're going to make this shin-dig, Steve.Excellent write up David! I did a little different approach due to the size of my 1/48 Thresher. I used some Sonotubes that slid together giving me double wall protection with wooden end plates. I too removed the sail and interior components for shipment in a separate box and bubble wrapped the hull. I kept the length and girth to 107". According to Bob it arrived safely at his place. It will only take a few minutes to assemble once I arrive on Friday.

I'll be there Wednesday. Plenty of time to rig man-traps between you and the shop door come Friday.

David

Who is John Galt?Comment

-

I am really looking forward to being there and getting to rub elbows with the greats again. It may be a short trip but it is a welcome diversion for me. Never been to Texas before. I must bring tribute.Comment

-

Tribute! Yes!... must bring Tribute! DIET THIS TIME or the deep water God's will be angry.

This is shaping up to be a great start to the r/c model submarine season of regattas, Steve. Can't wait to see that monster boat of yours. You do good work, sir.

DavidWho is John Galt?Comment

Comment