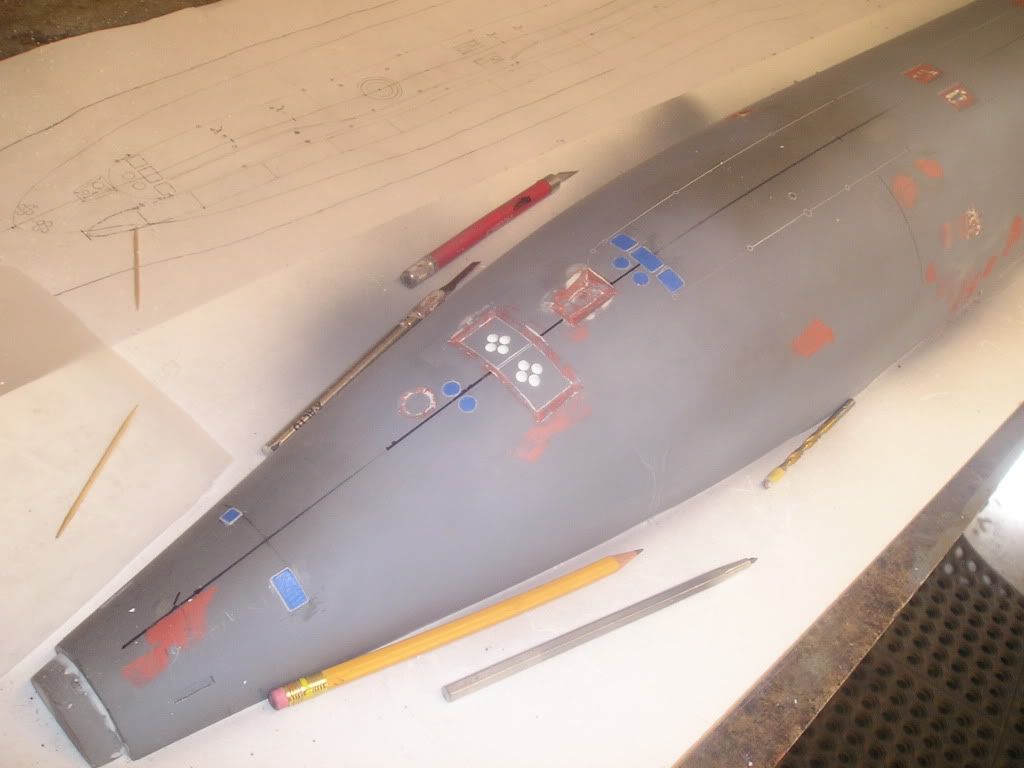

We’re at the biggest, most noticeable detail on the upper half of the boat if you don’t include the sail itself, and that is the fat line towed array fairing.

Here’s some background on this part of the sub. The Seawolf has two (that I know of) towed sonar arrays. First it has a skinny one, which is coiled with a winch and stored within a stern ballast tank. Second is the fat line. This one cannot be coiled and pretty much has to stored lengthwise along the boat. Storing it within the pressure hull is not an option because I assume there is a plausible way to seal this as its entering or exiting the hull. Basically the only solution for the stowage of these bad boys was along the outside of the pressure hull, hence the fairing that we see that runs along one side of attack submarines for the last few decades.

Again, there are many options available at my disposal to undertake this part (eg...skree, external extrusion, foam shaping..bla bla)In a nutshell, I chose to make cardboard profile shapes, glue them directly to the hull and fill between the profile shapes with filler.

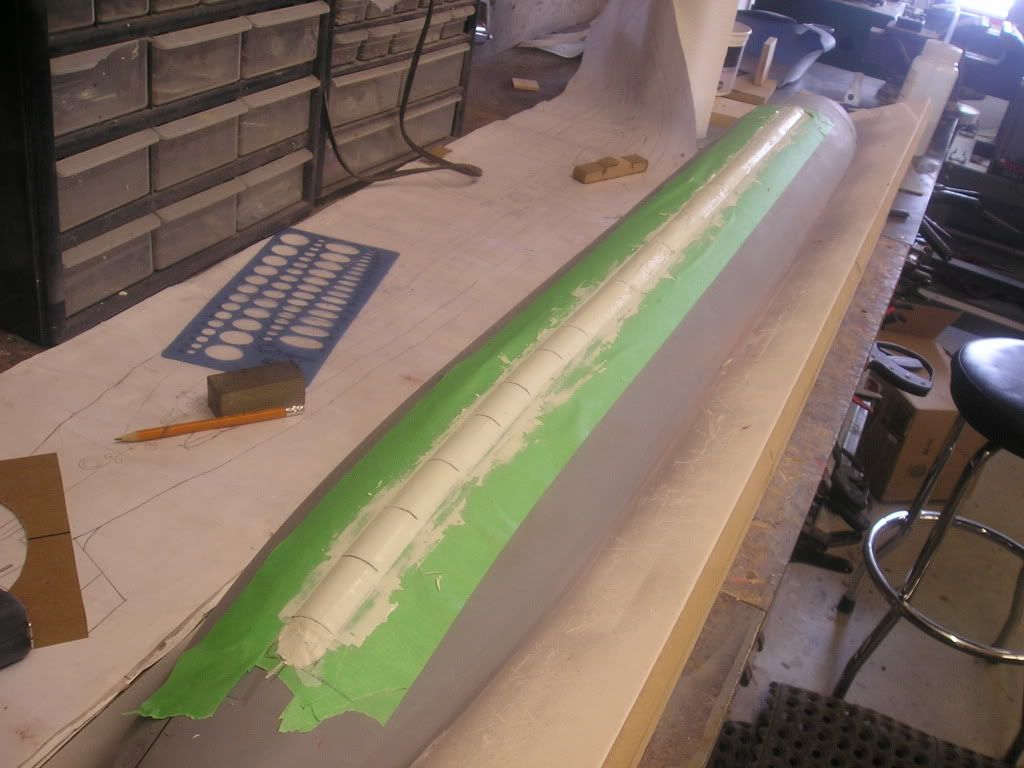

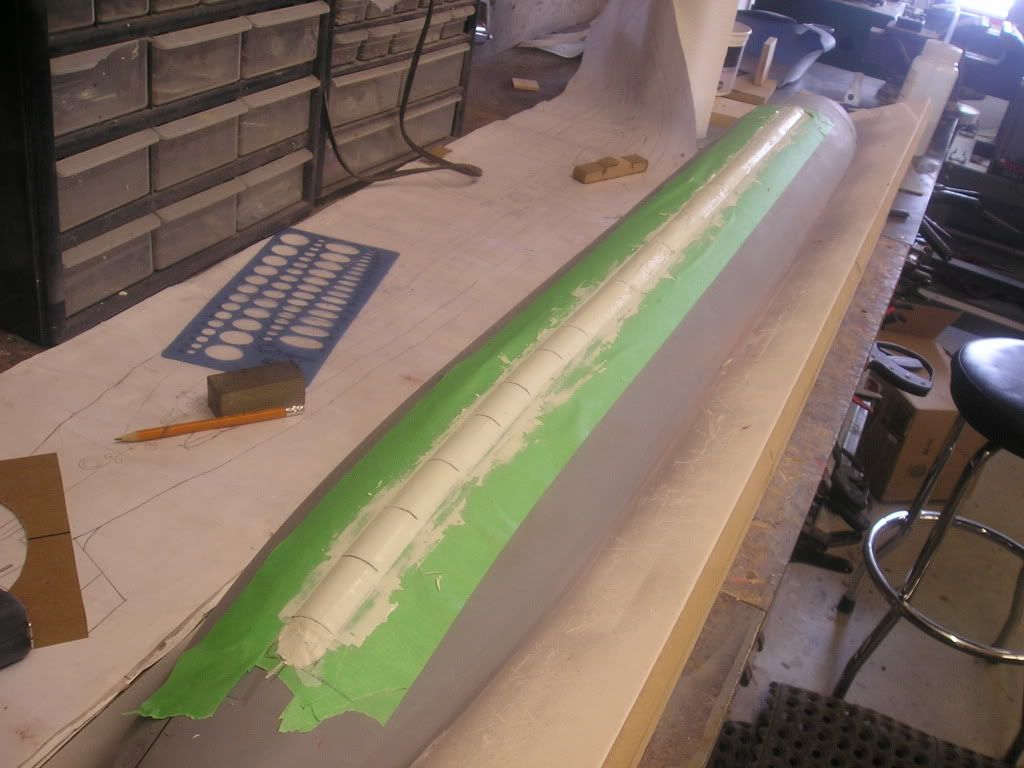

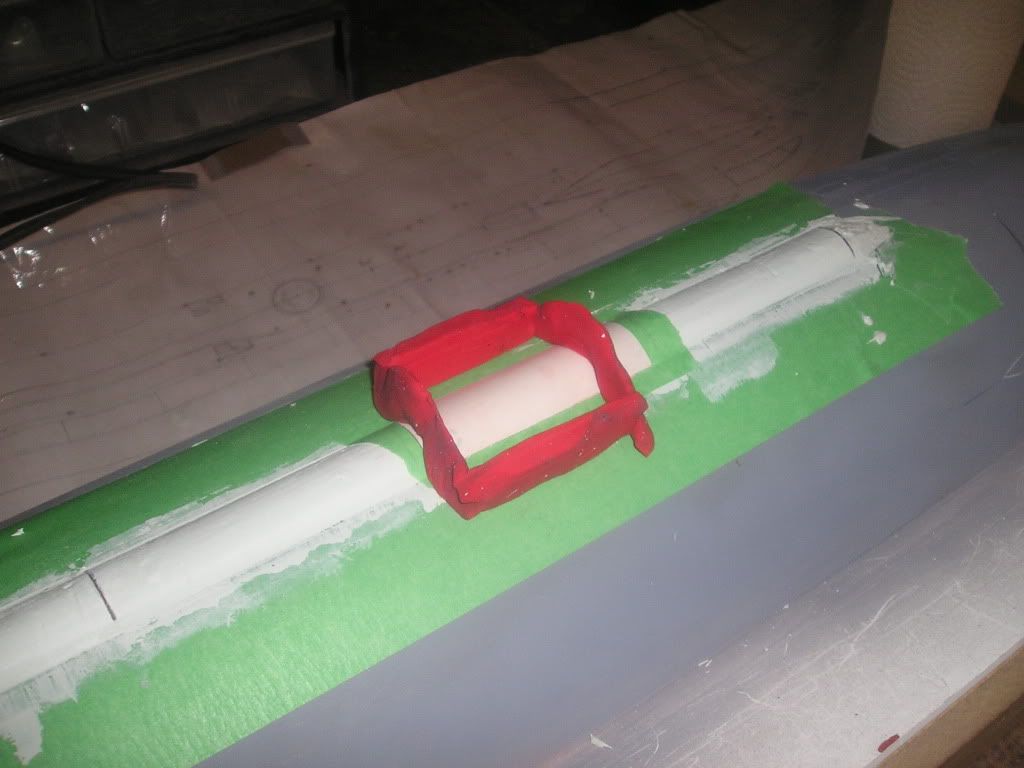

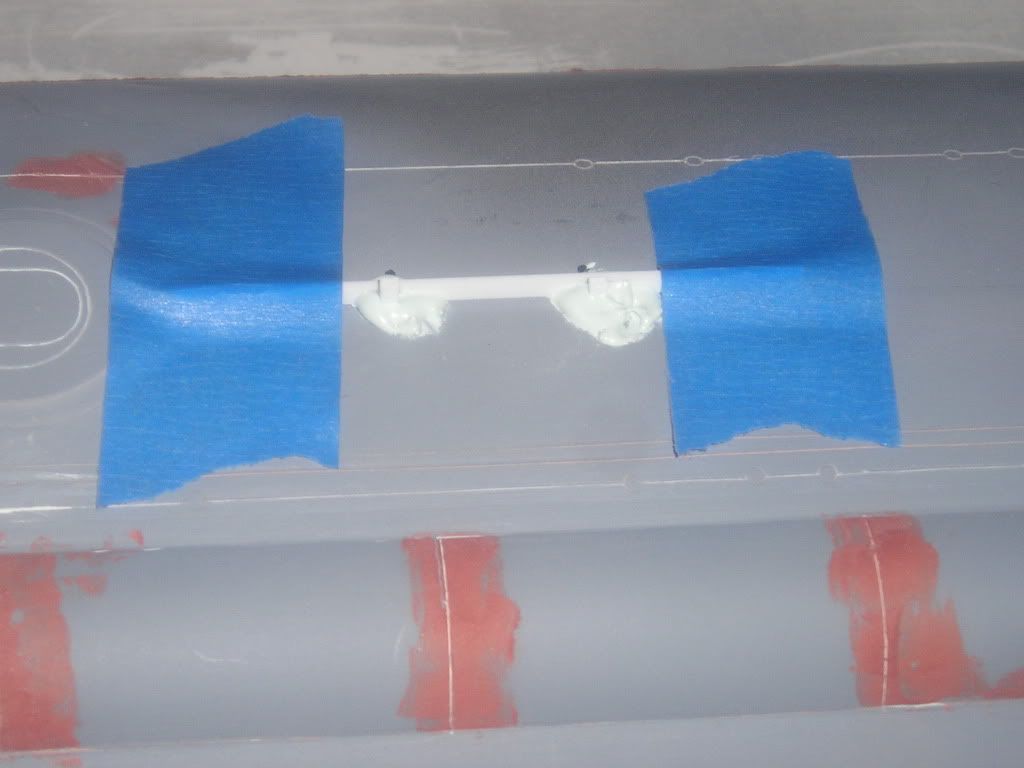

First, my array is marked off with pencil and then tape

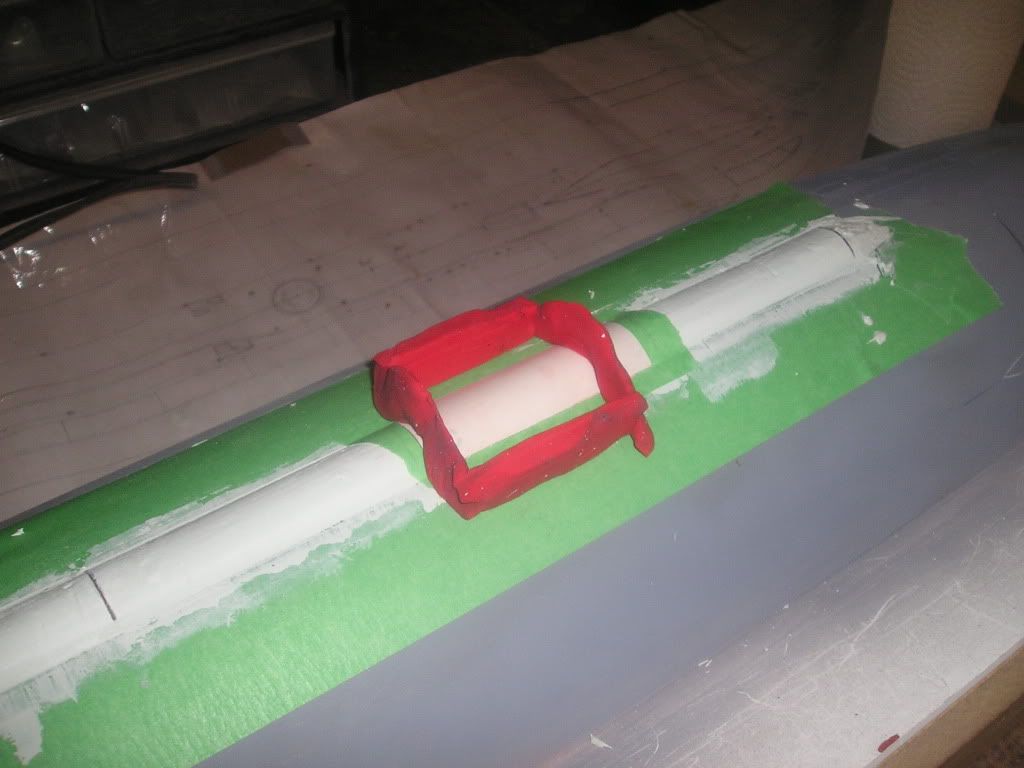

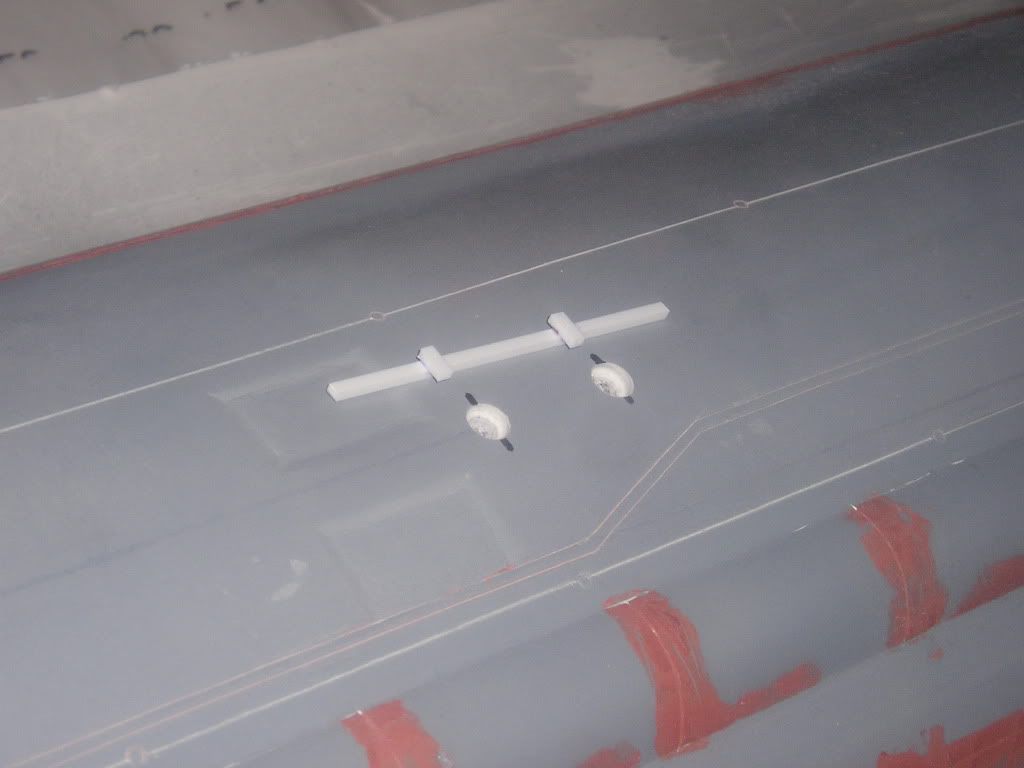

The profile shapes were created on my computer, printed out and then laminated to cereal box card board using super 77 glue

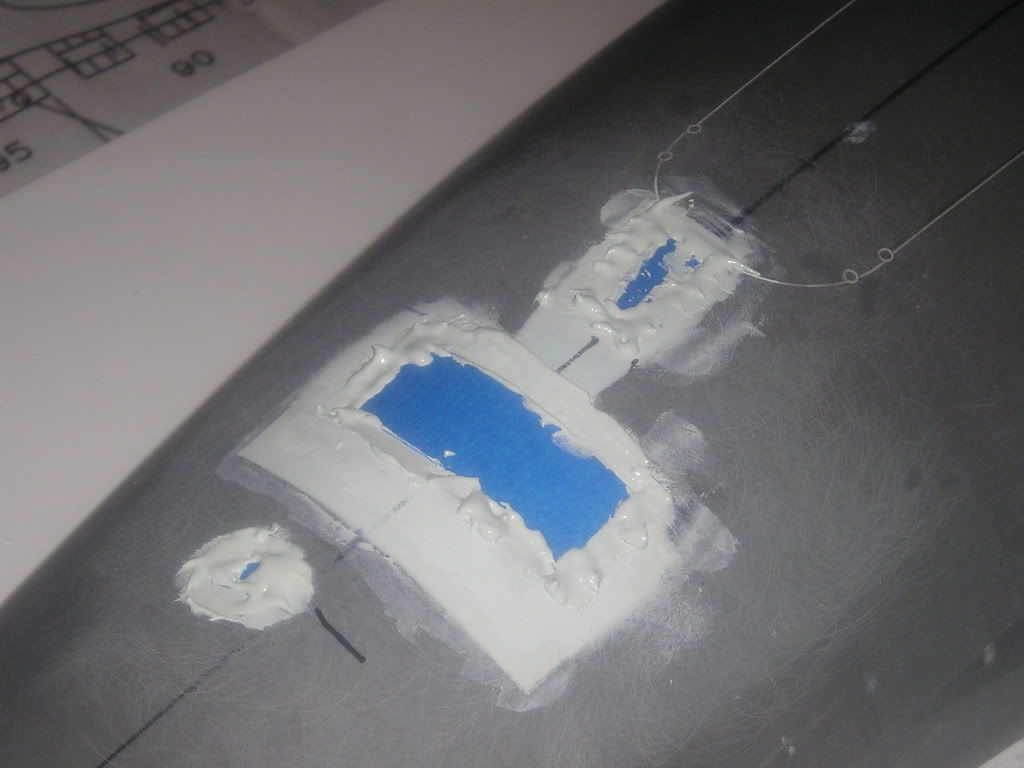

Then CA’d and grouted with baking soda.

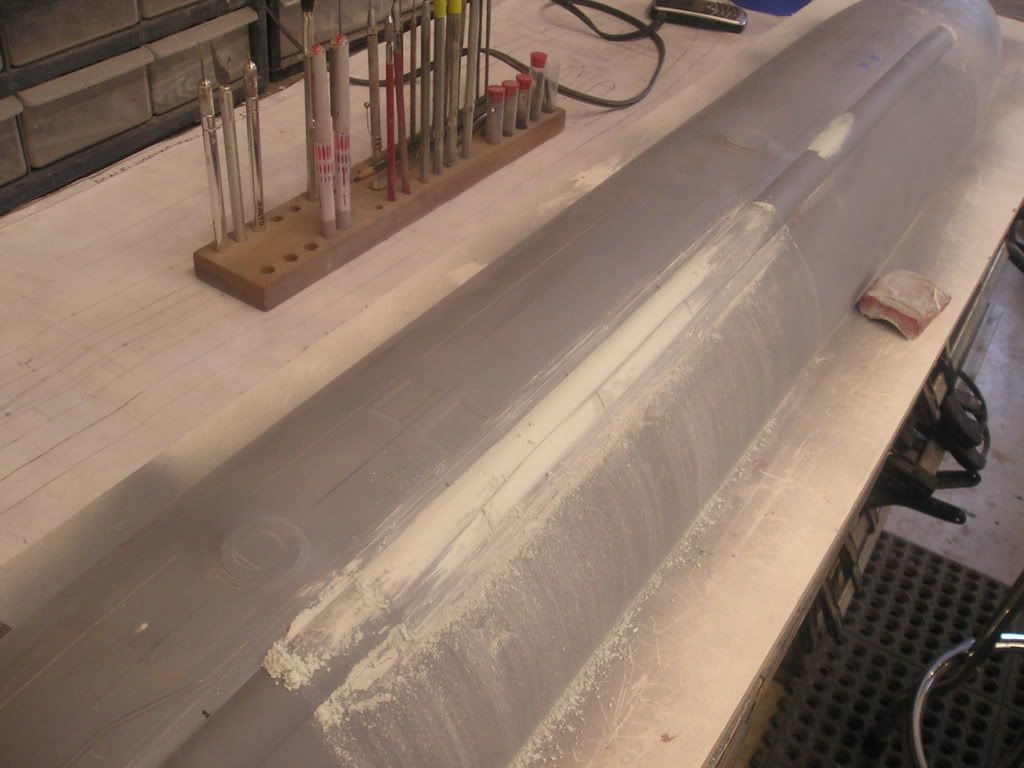

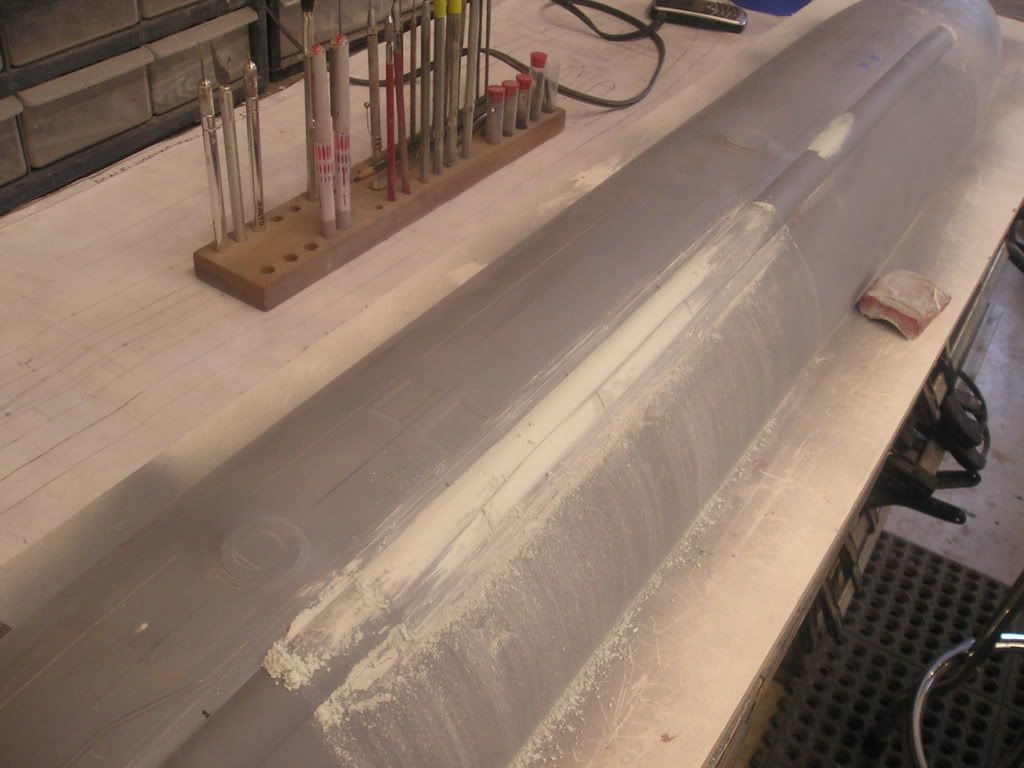

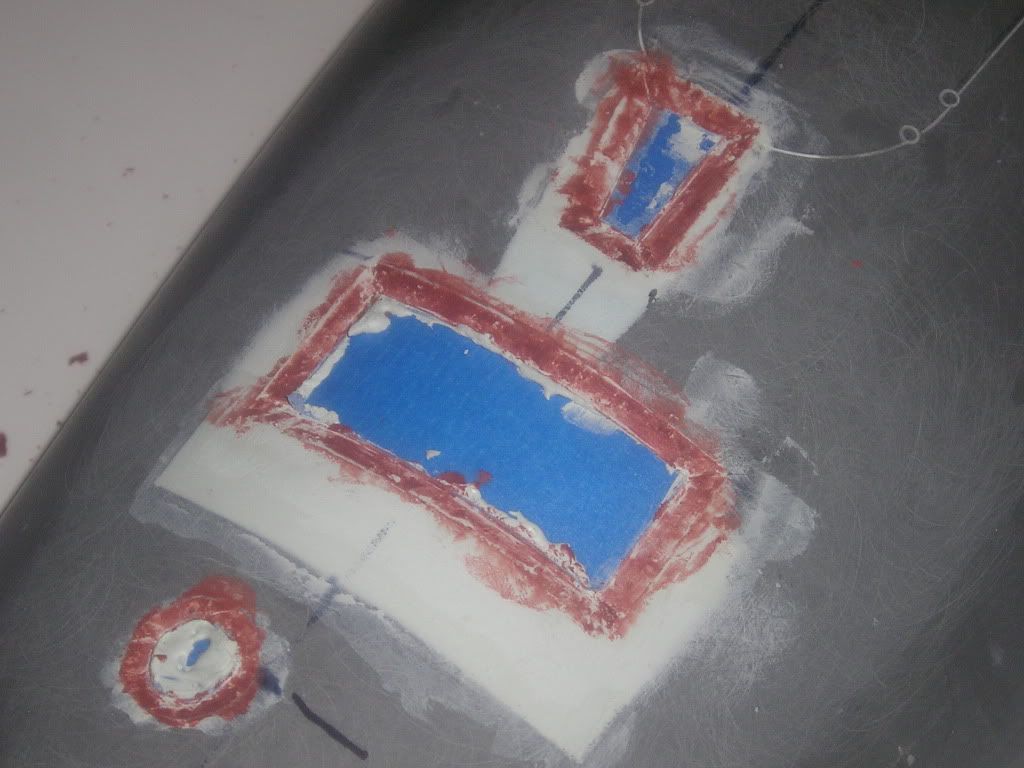

Filled

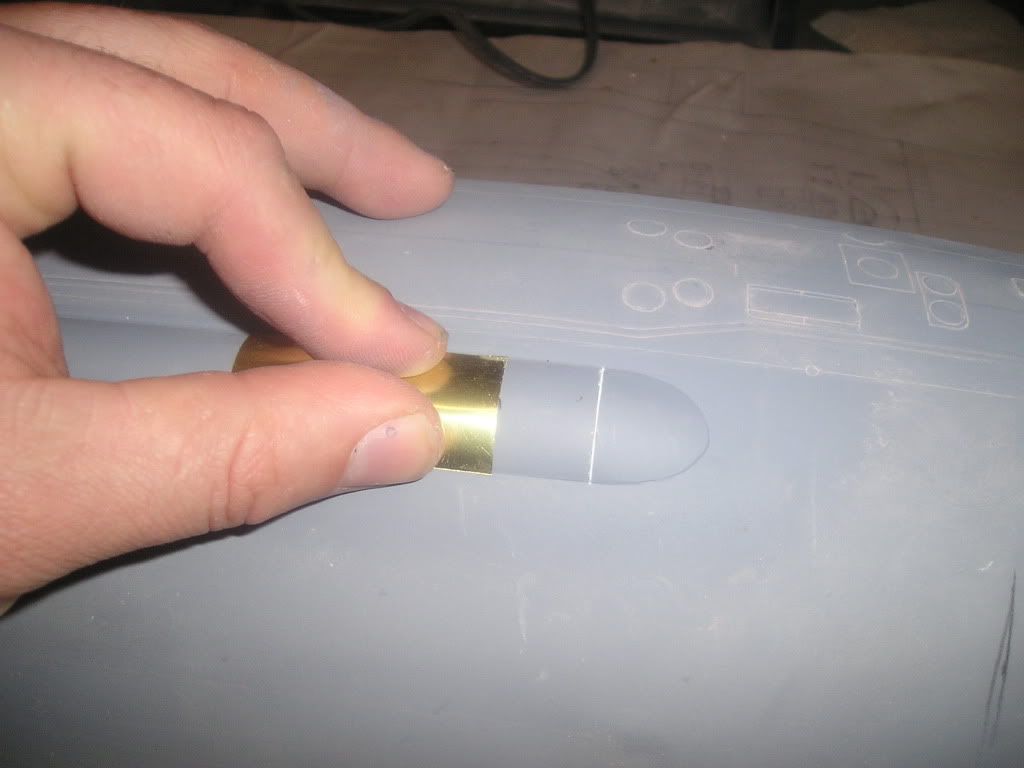

Here’s a little custom shaped block sanding tool made from filler. When the sandpaper on the bottom gets dull I simply pull it off and apply a fresh peice with double sided tape used to adhere. For precision sanding I will add masking tape layers behind the sandpaper to tighten up the radius for a closer shave!

I had a slight droop at one point of the array. To fix, i added filler to the top of the array and applied lots pressure with my custom block on the bottom of the array. This straightened things out nicely!

Here’s some background on this part of the sub. The Seawolf has two (that I know of) towed sonar arrays. First it has a skinny one, which is coiled with a winch and stored within a stern ballast tank. Second is the fat line. This one cannot be coiled and pretty much has to stored lengthwise along the boat. Storing it within the pressure hull is not an option because I assume there is a plausible way to seal this as its entering or exiting the hull. Basically the only solution for the stowage of these bad boys was along the outside of the pressure hull, hence the fairing that we see that runs along one side of attack submarines for the last few decades.

Again, there are many options available at my disposal to undertake this part (eg...skree, external extrusion, foam shaping..bla bla)In a nutshell, I chose to make cardboard profile shapes, glue them directly to the hull and fill between the profile shapes with filler.

First, my array is marked off with pencil and then tape

The profile shapes were created on my computer, printed out and then laminated to cereal box card board using super 77 glue

Then CA’d and grouted with baking soda.

Filled

Here’s a little custom shaped block sanding tool made from filler. When the sandpaper on the bottom gets dull I simply pull it off and apply a fresh peice with double sided tape used to adhere. For precision sanding I will add masking tape layers behind the sandpaper to tighten up the radius for a closer shave!

I had a slight droop at one point of the array. To fix, i added filler to the top of the array and applied lots pressure with my custom block on the bottom of the array. This straightened things out nicely!

Comment