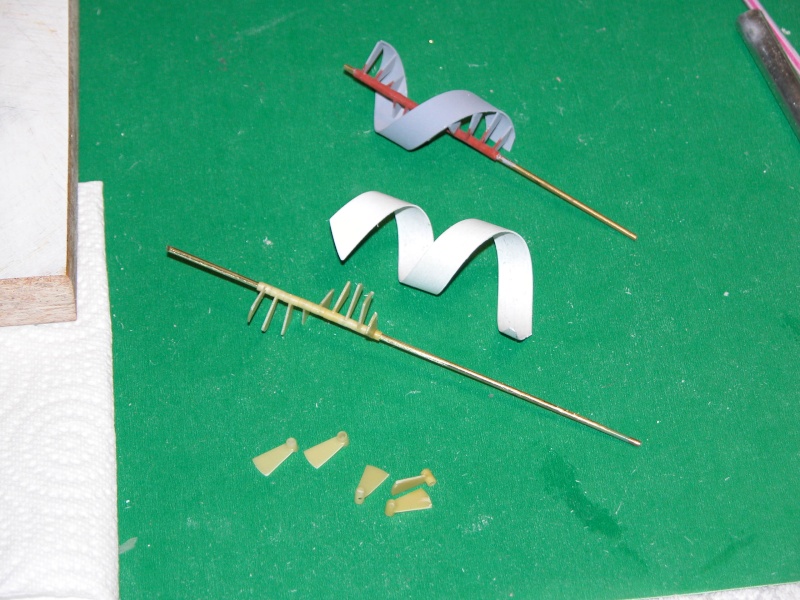

I needed a bunch of ladder-rungs for a spiral staircase. These were best cast using the vacuum assisted method.

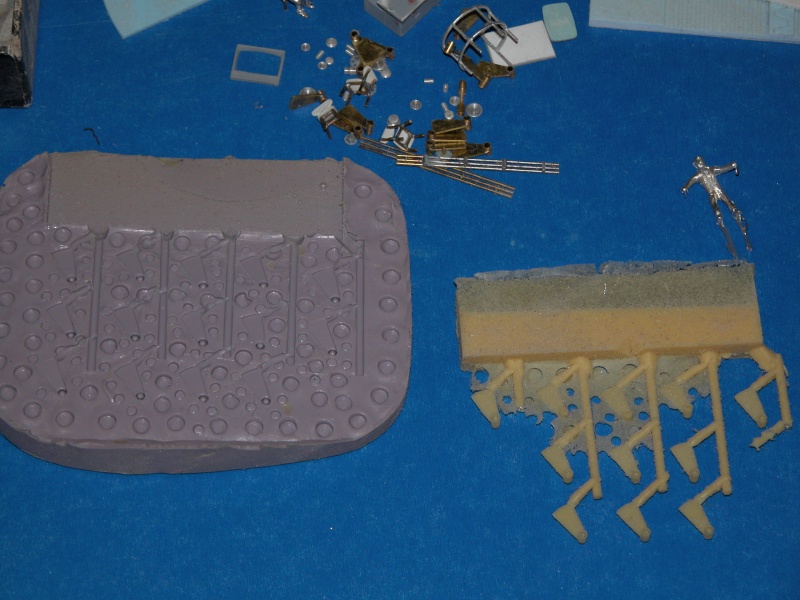

Vacuum assisted resin casting made these girder parts possible with the least amount of hassle and clean-up chores post de-molding.

Making the 1/72 figure masters for the defunct FOXTROT project

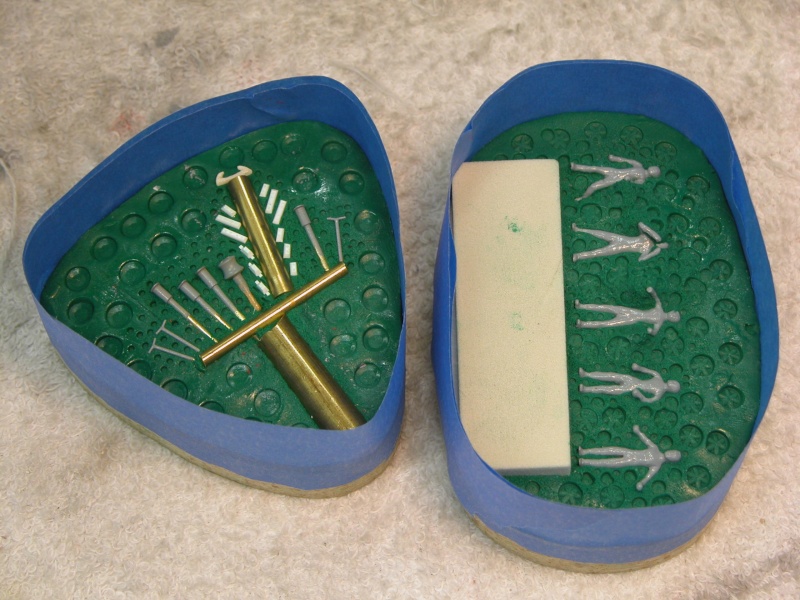

To the right I'm working up another vacuum assisted tool, this one for 1/72 figure blanks.The figure masters embeded in the backing clay along with the block that will give form to the tools resin trough.

To the right is a gravity-pour metal casting tool set of masters under their tall sprue. In metal casting you need at least a five-inch tall sprue to provide the pressure-head needed to insure a complete fill of the tools cavities.

Cast resin 1/72 crew figure blanks posed upon and around the 1/72 FOXTROT sail components.

Comment