with it leveled off, it was still a little high in the water. Added 1/2 oz. back on the sub near the center of balance.

That was just enough to bring it to the top of the sail. I think that is a good spot.

That worked. It settled nicely.

The video is last, there is a reason.....and I blame Manfred.

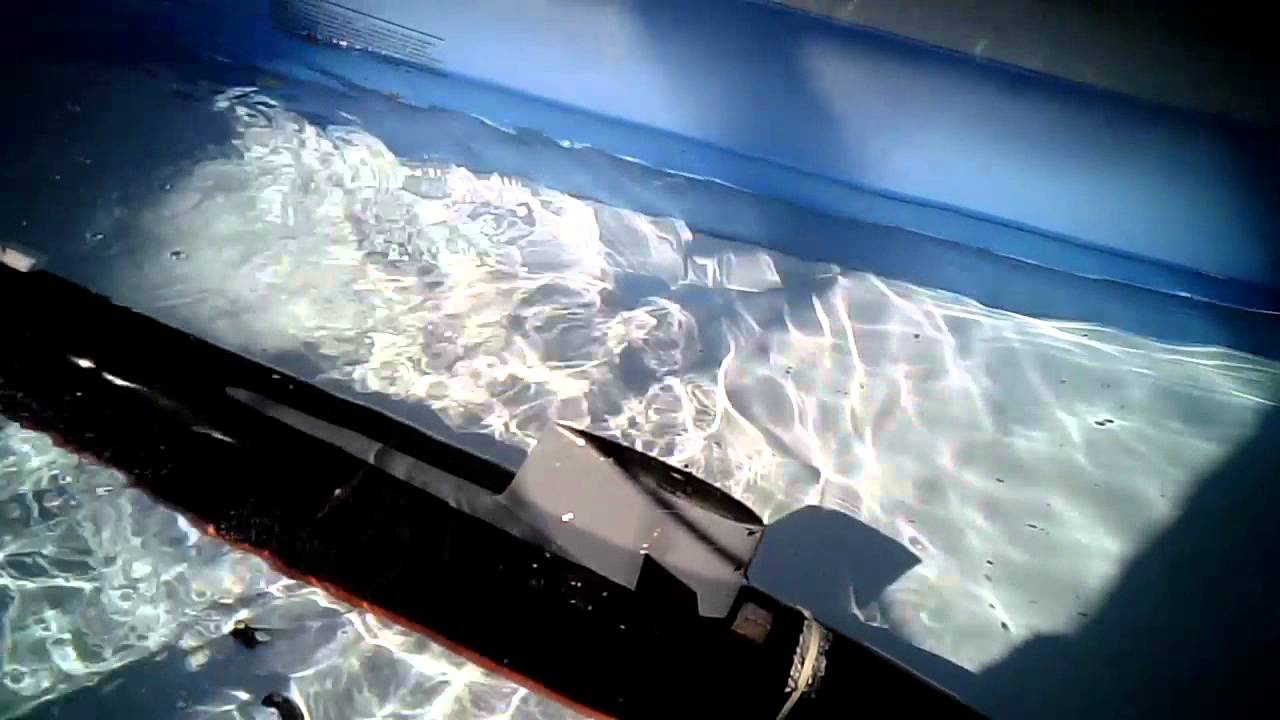

Upon blowing out the ballast tank. Again the rear was very high. (and I bent the prop)

You can see that completely emptying the ballast tank the sub as a whole rises high.

I will need to complete the trimming in the solid walled test tank (tub)

I will get that sound for you Manfred.

Leave a comment: