The beginning of a long project.

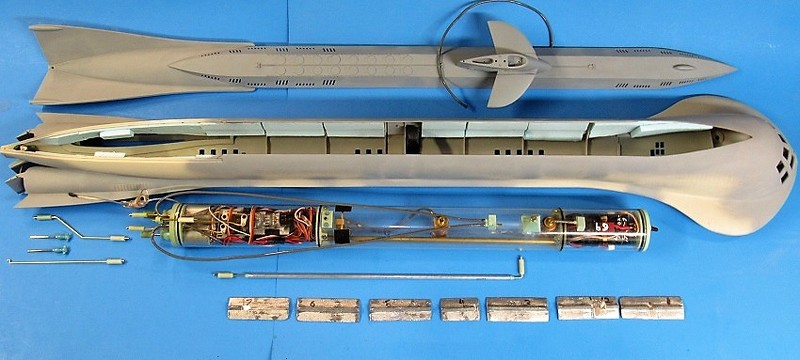

I started this project about a year ago. After acquiring the Arkmodels type VII basic hull kit I started work immediately on developing 1/48 scale torpedoes. After that I put design efforts into developing the launch mechanisms to fit into this particular model’s hull. Then I spent months on developing and testing a custom WTC to fit into this builds hull.

Im now finally switching attention back to the basic hull and beginning that part of the build.

The Arkmodel kit is for the most part great. During the design phase of the torpedo launchers and WTC I was trying to come up with something that dropped right into the originally designed castings. I stuck to this discipline for the most part.

Today finally after a long needed rest from this ongoing project I drew a line in the sand or better yet this

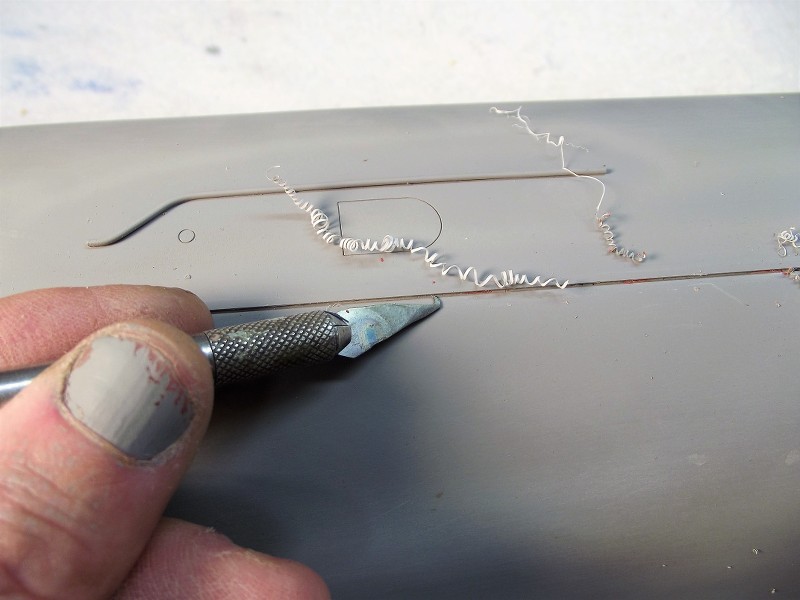

build. Instead of working with the multiple sections this kits hull and deck are produced in (9 sections including port and starboard hull pieces and deck), I decided to join all the pieces and split the hull at the waterline.

WW2 boats have a ton of junk that is easily broken off when messing with the hull and I wanted to reduce the main components to two sections. The below waterline hull with all its junk and the upper deck with all its other junk. blasphemy I know with a kit that is already so sectional. Don’t judge and I won’t judge you.

The dreaded horizontal cut. Pussy’s walk away now as you’re not cut out for this.

Those who are not afraid I will post more shortly.

I started this project about a year ago. After acquiring the Arkmodels type VII basic hull kit I started work immediately on developing 1/48 scale torpedoes. After that I put design efforts into developing the launch mechanisms to fit into this particular model’s hull. Then I spent months on developing and testing a custom WTC to fit into this builds hull.

Im now finally switching attention back to the basic hull and beginning that part of the build.

The Arkmodel kit is for the most part great. During the design phase of the torpedo launchers and WTC I was trying to come up with something that dropped right into the originally designed castings. I stuck to this discipline for the most part.

Today finally after a long needed rest from this ongoing project I drew a line in the sand or better yet this

build. Instead of working with the multiple sections this kits hull and deck are produced in (9 sections including port and starboard hull pieces and deck), I decided to join all the pieces and split the hull at the waterline.

WW2 boats have a ton of junk that is easily broken off when messing with the hull and I wanted to reduce the main components to two sections. The below waterline hull with all its junk and the upper deck with all its other junk. blasphemy I know with a kit that is already so sectional. Don’t judge and I won’t judge you.

The dreaded horizontal cut. Pussy’s walk away now as you’re not cut out for this.

Those who are not afraid I will post more shortly.

Comment